On any poultry farm or household that works with a large number of birds, the question always arises of how to quickly and easily pluck the birds.

On any poultry farm or household that works with a large number of birds, the question always arises of how to quickly and easily pluck the birds. Of course, if the number does not exceed a dozen birds, it is quite possible to do this manually. But in a large farm you cannot do without a feather removal machine. It makes it possible to pluck birds many times faster, and to do this on an industrial scale.

Advantages and disadvantages of feather removal machines

Like any other, this method has its pros and cons compared to hand plucking. The main advantages are:

- A large number of processed carcasses at a time. In different models of drum machines, in one run you can pluck a couple of dozen quails, 5-6 broiler chickens, one goose or a medium-sized duck.

- Very high performance. If manual cleaning of feathers from a medium-sized bird carcass can take up to half an hour, then in feather photography this, depending on the model, takes from 30 seconds to 1 minute.

- Cleanliness of work. After removal from the car, if successful, the bird looks impeccably smooth - exactly the way we are used to seeing them on store shelves.

Of the minuses, perhaps, we can only note the complete lack of autonomy of such devices, as well as some risk of damage to the bird from strong rotation and the impact of whipping attachments.

Manufacturing options

Screwdriver attachment

The simplest option. It is not recommended to make fingers for the machine yourself. The reason is low cost.

Step-by-step production of a tool such as a pinching machine:

- Creating a blank in the form of a tin can. A tin can will not work (due to the thin and easily crumpled tin). A pipe made of light-melting metal is suitable for the workpiece.

- Fixing the bottom on one side (using screws).

- Drilling a hole in the center.

- Secure in the center of the stud (using nuts). The size of the pin should match the drill attachment.

- Drilling a hole for the hammer fingers (in the cylinder of the future machine).

- Inserting rubber bands into the hole made.

- Using a carcass plucking machine.

From the washing machine

The ideal option is an old washing machine. Characteristics: fixed cylindrical container, drive located at the bottom, presence of an oil seal. The main principle of the new design is to use the maximum properties of the existing factory machine.

Step by step steps:

- Making holes for the pen fingers.

- Installation of a round plate made of hard metal above the bottom. You can use the bottom of an unnecessary pan. Attaching this base to the axis.

- Drilling a hole in the bottom to install the pins. The part of the installation that rotates must be smaller in diameter than the main tank. The required difference is 5 cm. Exceeding the difference leads to the birds’ limbs getting into the gap.

- Closing the rotation axis from water entering the electric motor.

- Processing of a test carcass in the created design.

It is best to move the engine located under the washing tub outside the entire structure. This will eliminate the possibility of water entering completely. The resulting unit is capable of processing poultry of various sizes. It is important to remember that the washing machine used must initially be in working condition.

From a plastic barrel

The process of creating a bird picker with your own hands from a plastic barrel:

- Finding a plastic barrel. Dimensions: height – 1 meter, width – 70 cm. The barrel must be durable so as not to bend or break from impacts from carcasses.

- Making a hole at the bottom. The goal is to install rubber strikers.

- Making a frame for the main parts of the machine. Required materials: wooden boards, metal corners. The metal frame is more reliable.

- Placing the drum in a pre-made frame.

- Adding another layer to the first bottom layer. The purpose of the second layer is to secure the rotating installation.

- Connecting an electric motor (power – 1.5 kW). It is necessary to make a stand for the motor (the purpose is to protect one of the main parts of the machine). The motor must be installed away from the rotating drum.

Making a feather removal machine with your own hands saves money. The created design is not inferior in its properties to analogues manufactured in special production.

What are kicking fingers, and what types are they?

These are the main active elements of feather removal machines, due to which feathers and down are removed from the carcass after scalding. This is a consumable item that you will replace repeatedly as you use the machines. They are usually made of food-grade rubber, which does not peel off and does not leave any discharge on the carcasses even when exposed to high temperatures.

At the same time, it is important to know that the striking fingers are not at all the same, and differ from each other in such parameters as diameter, the presence and shape of notches, and rigidity. All this is very important to take into account before you start plucking, because if you don’t do this, you risk hopelessly damaging the carcass, or simply plucking it poorly. So, there are:

- Nozzles for large birds. They are suitable for ducks, guinea fowl, chickens. Their length reaches 98 mm.

- Nozzles for small birds. Can be used for quails, partridges, chickens. Their length reaches 60 mm, usually a horizontal notch is used.

- Universal. They have a medium level of hardness, horizontal notches, and are suitable for working with any type of poultry.

The general rule is that the shorter the striker, the smaller the bird it is intended for. Most models come with spare attachments suitable for plucking different carcasses. This material can also be ordered online.

Principle of operation

External design description:

- presence of large capacity;

- a lot of rubber beaters on the bottom and walls of the tank (beaters are strong and elastic pins equipped with threads at the ends).

Operating principle of the device:

- Pouring boiling water over dead birds.

- Throwing carcasses into the tank.

- Turn on the engine and start rotating the container with carcasses.

- Impact of the product on the beaters (birds are thrown throughout the entire space).

- Feather removal process (duration: 2-3 minutes). It is necessary to periodically water the product (for faster and more thorough feather removal). In addition, water washes away unnecessary feather residues and protects carcasses from various damages.

- Removing cleaned birds from a homemade device.

- Removing the remaining small feathers by hand (as a rule, there are not many feathers left after the feather removal machine).

Types of feather removal machines

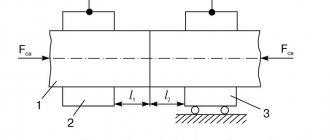

The choice of a feather removal machine, as a rule, is made between two main types - disk and drum (cyclomatic).

- Drum machines. Most of all, in their design, they resemble washing machines. By the way, ordinary washing machines are sometimes used when they want to make a feather removal machine themselves. Here, unlike disc models, the bird carcass itself moves, and the beating fingers are static and located along the inner radius of the drum. The centrifugal force caused by the rotation causes the carcass to hit the beating fingers, which leave feathers on them. This is a rougher processing method that is more often used in households. Due to strong rotation, quite often the bird is damaged, its skin breaks, and bruises occur.

- Disk machines. They are used for so-called dry plucking - that is, without the use of water. In such devices, the bird itself remains static, and plucking is carried out by disks with beating attachments rotating around the carcass. They have very great advantages over drum ones. Firstly, this is the impeccable preservation of the presentation. Disc feather pickers are very often used for industrial purposes, in large professional poultry farms, where careful cleaning of birds from feathers is needed.

- Homemade portable options. The author's engineering thought sometimes amazes with the simplicity and originality of some solutions. Today on sale you can find special attachments for a drill or screwdriver that can be used for plucking birds. Of course, their performance cannot be compared with professional machines. However, they allow you to clean the birds from feathers much faster than with your own hands. Structurally, they consist of exactly the same punching fingers mounted on a cylinder, made of plastic or rubber. Often the kit comes with additional removable attachments for different types of birds.

conclusions

The choice of car should reflect your preferences and goals, each of them has its own advantages and disadvantages. It is impossible to say unequivocally which of them is better or worse, if speed and ease of use are important to you, then it is better to choose feather picking machines, but if you require versatility and a higher level of quality, with low productivity, choose feather plucking machines.

Our organization offers a wide range of any feather-picking and feather-plucking machines; if you cannot make a choice, you can consult with our specialists either directly on this page or on the page of the product you are interested in.

Tips for choosing

Let's say a few words about how to choose the right feather removal machine and not regret the purchase. Be sure to consider when choosing:

- The volume of the drum, if we are talking about a drum machine. Large-capacity units typically cost significantly more, but can accommodate up to 10-12 chickens, which is very useful in a poultry farm with intensive production. In turn, small devices are perfect for use in personal households.

- The density of the fingertips. The smaller the step between them, the better the cleaning will be.

- Model dimensions. This is of particular importance for private households, in which the car has to be pulled out every time.

- Performance. 100 or 400 cleaned carcasses at a time is a big difference that should definitely be taken into account when choosing.

It is also worth asking the seller about the wear resistance of the pins. They are expressed in the number of birds processed before the attachment has to be replaced. For inexpensive Chinese models it may not exceed hundreds, for high-quality European ones it can reach 1.5 and 2 thousand.

Advantages of a homemade car

Advantages of a device created at home:

- Performance similar to commercial equivalents.

- No need to create a drawing.

- Simple and clear assembly algorithm.

- Low cost of construction. The reason is the use of unnecessary parts from old devices. The only part required to be purchased is the hammer-type fingers (they have a low cost).

- No need for special training. To assemble the device, a minimum set of skills is required.

- Processing a large number of carcasses (40 units in 1 hour).

- No need to participate in the process (the bird does not need to be held with your hands).

- Preserving the integrity of the poultry's limbs and skin.

- Uniform processing on all sides.

- The feathers do not fly away, but come out from below through a pre-created hole.

- Easy replacement of fingertips (if necessary). This part is secured with bolts that can be easily unscrewed.

- The ability to regulate the rotation speed of the centrifuge (by increasing or decreasing engine power).

The only minor drawback is the unsightly appearance (can be corrected by painting the structure).