When it comes to car maintenance, nothing is more important than the right tools for the job. Improper use of a tool can lead to a number of problems in the garage, ranging from frustration due to wasted time to more important issues such as driver safety and health. That's why every car enthusiast needs a good 3t rolling jack.

The best jack manufacturers

One of the most essential garage tools is a reliable jack. It is the tool most closely associated with safety and injury from accidents. They start with the purchase of a low-quality device that does not meet the machine's load-carrying capacity requirements. Knowing the design features of the lift will help you avoid most of these mistakes and determine which 3-ton rolling jack is better. Below is a list of favorite brands:

- Nesco Tools.

- Powerzone 3.

- Arcan ALJ3T.

- Inforce TA83003.

- Blackhawk Automotive.

- Biloxxi.

- Powerbuilt.

- Kraft.

- Vettler.

- NOS NSJ0301 3t.

Jack rating - table

| Category | Place | Model | ||

| The best rolling jacks | 8. | Stels 51132 (2.5 t) | Price | Review |

| 7. | Nordberg N32036 (3.5 t) | Price | Review | |

| 6. | Matrix 51040 (3 t) | Price | Review | |

| 5. | VORTEX DMK-2 (2 t) | Price | Review | |

| 4. | BISON T65 43057-2.5-K (2.5 t) | Price | Review | |

| 3. | Sparta 510105 (3 t) | Price | Review | |

| 2. | Stels 51131 (2 t) | Price | Review | |

| 1. | Ombra OHT230 (3 t) | Price | Review | |

| The best bottle jacks | 7. | Sparta Compact 50333 (5 t) | Price | Review |

| 6. | Kraftool Double Ram 43463-6 (6 t) | Price | Review | |

| 5. | Airline AJ-B-04S (4 t) | Price | Review | |

| 4. | Autoprofi DG-08 (8 t) | Price | Review | |

| 3. | Matrix 50752 (3 t) | Price | Review | |

| 2. | BISON T50 43060-10 z01 (10 t) | Price | Review | |

| 1. | BelAvtoKomplekt BAK.00049 (20 t) | Price | Review | |

| The best screw jacks | 5. | Airline AJ-R-02 (2 t) | Price | Review |

| 4. | AVS JA-2000R (2 t) | Price | Review | |

| 3. | BISON Master 43040-2 (2 t) | Price | Review | |

| 2. | ALCA 436200 (2 t) | Price | Review | |

| 1. | Big Red T10152 (1.5 t) | Price | Review | |

| The best rack and pinion jacks | 3. | BISON Hi-jack 43045-3-070 (3 t) | Price | Review |

| 2. | Matrix 505175 (3 t) | Price | Review | |

| 1. | HI-LIFT HL-604 (2.11 t) | Price | Review | |

| The best inflatable jacks | 3. | SOROKIN 3.694 (4 t) | Price | Review |

| 2. | TORIN TOOLS TRA1713 (2.2 t) | Price | Review | |

| 1. | AE&T T08105A (5 t) | Price | Review |

Comparison of three-ton lifts

Compared to bottle jacks, floor jacks have several advantages. One of the biggest strengths is that they tend to be heavier than bottled ones. This is due to the fact that most floor-mounted ones have movable casters that make it easy to maneuver under the car. This means that positioning it is much easier, as you don't have to constantly lift the heavy device while trying to line it up with the car's connector points. Therefore, which jack is better, a rolling jack or a bottle jack, the car enthusiast himself will have to decide.

Another advantage for floor-mounted units is that they have a low profile, allowing them to be placed under low-clearance vehicles. There are what are called low profile or racing jacks, which are extremely low and can fit under cars with lowered suspensions.

The disadvantages of floor lifts are that they have a larger support area than a hydraulic bottle lift of similar power. This means that if the driver is working in a confined space, he will have to maneuver difficultly on the floor to be able to operate the handle.

Another problem is that dolly lifts have a small height range. If the vehicle is extremely tall (like a truck), they may not have the maximum position to lift the vehicle to the required height.

What parameters to look for when choosing a rolling jack

Load capacity . The main selection criterion, because the jack simply will not lift a load that is beyond its capabilities. For use with a passenger car, a screw jack with a lifting capacity of 2-2.5 tons is sufficient. If the tool is intended to be used in a car repair shop, then it is better to choose a hydraulic device with a lifting capacity of 8-9 tons. In any case, if you want the jack to serve you faithfully for many years, you need to choose a tool whose load capacity exceeds the usually lifted weight by at least 300-500 kilograms. Working to the limit will quickly damage the jack. Lifting height . If the jack is not able to lift the load to the required height, then there is not much point in it. Therefore, you should always choose a tool with a small margin for this indicator. As a rule, 40-60 centimeters is more than enough for domestic use. Typically, the most impressive results on this point are shown by rack and pinion jacks. Pickup height . This parameter, in turn, determines how low the load can be located, which the jack is able to pick up for lifting. If the car's ground clearance is less than the lifting height, then the jack will not be able to work with such a car. Based on this indicator, it is advisable to select a tool with a margin of 5-10 cm, otherwise it will be inconvenient to use the device.

Safety when lifting cars

Obviously, the most important thing when using a floor unit or doing any work on a vehicle is the personal safety of the driver. Below is a list of some safety principles and tips for using a jack:

- Never trust homemade lifting devices when lifting a car. Always use only factory-made car jacks from well-known, time-tested brands.

- Before starting lifting work, carefully study the manufacturer’s operating instructions. As soon as you start lifting the car with a jack, you need to secure it using special devices: you cannot rely only on the hydraulic components of the mechanism.

- Before starting repairs, you should rock the car a little to make sure the installation is secure.

- Always lift the vehicle on a level surface. Placement at an angle due to an uneven floor creates a risk of tipping over.

- Raise and lower the machine slowly.

- Use the permitted lifting points and lifting key on the vehicle specified by the vehicle manufacturer in the technical documentation.

Types of car jacks

A situation that any car enthusiast has encountered is changing wheels. This is often done, for example, when it is necessary to change seasonal tires. But besides this, there are more problematic situations with a punctured tire or broken brake pads. At such moments, further driving is impossible, and most often the owner of the car changes the tire. To do this, you must have a car jack with you, which can be used to lift high masses to a certain height.

Rules for choosing lifting mechanisms

You need to be very careful when purchasing a floor lift. Important aspects that the buyer should pay attention to when purchasing:

- Choose a jack that is only tied to a specific type of car.

- The most important factor here is ground clearance. Ground clearance is determined by how high off the ground the jack contacts the vehicle when lifted. Vehicles with low ground clearance are easier to lift using conventional hydraulic floor jacks. They can be used in low profile versions for sports and racing cars. They are also a favorite for most sedans, SUVs, vans, coupes and trucks.

- All floor jacks are designed for a certain maximum load capacity. You need to make sure that the maximum power on the jack exceeds the lifting weight of the machine and possible load and will allow you to use it for a long time. Typically this rating is provided in tons, with 2-ton and 3-ton units being the most common. Most compact and economical mid-range cars can be safely lifted with a 2-ton lifter. For luxury full-size cars, vans, minibuses and mini-trucks, three-ton units are suitable.

- Build quality. A well-built jack has mostly metal parts, while a cheap one has a lot of plastic components. In addition, the quality of the finish is often an indicator of the strength of the material. If the metal has a polished surface with beautifully painted areas, it means the manufacturer is openly displaying reliable parts of the devices, but when the paint is carelessly applied with visible overspray, the manufacturer may be trying to hide poor quality metal underneath. High quality devices are heavy weight and operate very smoothly.

What you shouldn't forget

It is important to remember that for a passenger car, an amateur rolling unit is sufficient, which is characterized by reduced weight and dimensions, which helps with transportation. It makes no sense for the average motorist to overpay for a more powerful model. It is also worth paying attention to the manufacturer; it is not uncommon for domestic manufacturers to make a device better than foreign ones.

Some design parameters of the car, namely the presence of a special recess for the blade, should be considered before purchasing the mechanism. If the bottom of the car is flat, you can purchase any rolling unit. In cases where the mechanism is used in a garage with different types of cars, it is necessary to purchase a universal spatula or a set of them.

There are various tests of rolling jacks, which describe the technical characteristics in detail. When purchasing a product, you need to pay attention to the availability of a guarantee; a high-quality rolling mechanism can last a long time without failing in any conditions.

Reviews of the best brands

This is a list of the best lifts that have won the sympathy of buyers. There are some traditional devices here, as well as some interesting new options. Rolling jacks for passenger cars and reviews of their work will help car enthusiasts make a choice for the safe maintenance of their car.

There are two common materials used to make jacks: aluminum and steel. The advantage of aluminum is that it is significantly lighter (travels well) and steel is significantly cheaper.

Arcan ALJ2T

Absolutely superb high quality aluminum construction which makes it strong yet lightweight, weighing just 22kg. The low profile design allows for easy access under vehicles with a minimum ground clearance of 90mm. It lifts loads to a maximum height of 490 mm. Easily lowers in seconds due to the quick-release two-piece handle. It allows for few pressures when pumping, so very little force is required to lift the car.

The mechanism has two fixed casters at the front and two swivel ones at the rear, which make it very maneuverable even in tight spaces.

It has a rubber pad on the saddle that serves to protect the vehicle by preventing contact with the metal parts of the jack. Arcan uses just 12 pushes to achieve maximum lift height, reducing the time it takes to lift a 3t vehicle. The price of the model is 200 dollars.

Inforce ta83003c

This device is made in China . Along with the well-known yellow design, this highly cost-effective lift features a release mechanism for precise load control, as well as increased stability thanks to side plates. The strong, lifting arm is reinforced by a wide, stable base, making the hydraulic hand mechanism incredibly easy to use. The one-piece handle adds the ability to lift a truck or SUV.

This lifting device has impressive features such as a minimum height of 130mm, a lift height of 470mm and a chassis length of 680mm.

Along with its precise control, durable wheels and casters, and stand, this product also comes with an excellent two-year warranty. If you need a reliable lift for your truck, Jeep Wrangler, or SUV, this is a great option at a budget price. Price: $80.

Hydraulic lift

These lifting mechanisms have the following advantages: compact and convenient design; excellent stability of the car when raised; quick and easy climb .

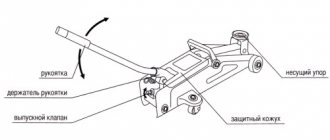

The operating oil pressure in a hydraulic car jack can be done using an electric compressor or manually using a pump handle. According to the design, they are distinguished between rolling and vertical bottle jacks .

Rolling jacks contain wheels and, due to their fast operation and mobility, are widely used in auto repair shops and service stations. Rolling jacks are effective where they are used quite actively. The main advantages of hydraulic lifts include:

- High efficiency value.

- Good load capacity with small dimensions of the device.

- High force transfer coefficient.

- Smooth movement of the lifting mechanism.

The disadvantages of a hydraulic lifting mechanism are:

- Expensive repairs and short service life.

- Needs constant maintenance.

- Low lifting height.

Pneumatic jacks

This design is an inflatable cushion that is inflated with exhaust gases or compressed air.

It has excellent stability due to its large support area. To lift a machine, a pneumatic device requires a supply of gas or air under high pressure. Car exhaust pipes or gas cylinders are used for this.

Under the pressure of the connected air, the chamber quickly expands and lifts the car. In this case, the driver makes almost no special effort to directly lift the car. Unlike other types, a pneumatic jack provides the lowest labor costs for lifting work. The ascent speed is also quite high.

This jack is widely used in construction, at service stations, and has also found application for evacuating cars stuck in a swamp or mud. Its advantages include:

- ease of installation;

- adaptability to any condition and surface of the roadway or soil;

- excellent load capacity;

- minimum manual effort;

- possibility of installation anywhere under the bottom, regardless of its damage;

- quite a high rise.

Disadvantages when using pneumatic jacks include:

- Availability of a separate compressor for pumping compressed air.

- When positioning the camera, it is necessary to exclude the presence of cutting and sharp objects that could damage it.

- During injection of exhaust gases, a caustic residue accumulates inside the chamber.

How to choose a jack

You should choose a device depending on the purposes for which you intend to use it. In order to understand this, you need to consider several very important factors that will help you make a choice. These criteria include:

Load capacity

One of the decisive factors that any car owner should consider when purchasing. But it is important to remember that it is not necessary to carry with you all the time a huge thing that can lift several tens of tons. Of course, you need to think about reserves, but if your car weighs about 1.5 tons, up to 2 tons will be enough in any conditions. Do not forget that the more mass you have to deal with, the more reliable the jack should be. Even when a normal wheel installation is carried out, if the mechanism breaks down, this can be disastrous both for the machine and for human health.

Lifting height

The maximum lift height refers to the height from the support point to the bottom of the vehicle. Usually this parameter is not lower than 30 centimeters, and on average ranges from 350 to 500 mm. This is enough to carry out a full installation, or to get an overview of the rest of the machine. There are also rack and pinion jacks, which are popularly called hi-jacks. The maximum lifting height of these devices sometimes reaches more than a meter. But it makes no sense to have such equipment with you, and is completely used in fairly rare cases. For example, when a car is driving off-road and gets stuck in the mud, such equipment can save the situation.

Pickup height

When it comes to pick-up height, you need to pay special attention to this. Essentially, this parameter means the height from the ground to the bottom of the car, and the point from which the rise begins. Before choosing a jack, find out the ground clearance of your car. On average, jacks with a height of 60 and 250 mm are excellent for working with the machine. Remember that when purchasing equipment, you need to find out its working progress in advance. This is the distance the device rises from the pick-up point. If you add the pick-up height and the working stroke, you get the maximum lift height. This is how these parameters are designated in the instructions.

type of drive

There are several types of drives, these are:

Mechanical drive –

This method involves lifting a load while applying physical force to the handle. Force is applied in 2 types - pressure or rotation. The main advantage of jacks with this system is quick and easy use, for example, changing a wheel.

Hydraulic drive

– as with a mechanical drive, lifting requires physical strength, but you don’t need to exert much effort. This can be explained by the fact that there is a working fluid inside the mechanism, which creates pressure and automatically pushes out the applied load.

Pneumatic drive –

These are jacks that work by filling them with compressed air. Such equipment is not often found and is used in the field. The main advantage of this method is lifting a heavy load without any effort.