On any poultry farm or household that works with a large number of birds, the question always arises of how to quickly and easily pluck the birds.

On any poultry farm or household that works with a large number of birds, the question always arises of how to quickly and easily pluck the birds. Of course, if the number does not exceed a dozen birds, it is quite possible to do this manually. But in a large farm you cannot do without a feather removal machine. It makes it possible to pluck birds many times faster, and to do this on an industrial scale.

Advantages and disadvantages of feather removal machines

Like any other, this method has its pros and cons compared to hand plucking. The main advantages are:

- A large number of processed carcasses at a time. In different models of drum machines, in one run you can pluck a couple of dozen quails, 5-6 broiler chickens, one goose or a medium-sized duck.

- Very high performance. If manual cleaning of feathers from a medium-sized bird carcass can take up to half an hour, then in feather photography this, depending on the model, takes from 30 seconds to 1 minute.

- Cleanliness of work. After removal from the car, if successful, the bird looks impeccably smooth - exactly the way we are used to seeing them on store shelves.

Of the minuses, perhaps, we can only note the complete lack of autonomy of such devices, as well as some risk of damage to the bird from strong rotation and the impact of whipping attachments.

Feather removal machines

Assemblers use silicone or rubber fingers of varying hardness. They beat the carcass and pull out the feathers. Before processing, the goose should be scalded - the water temperature should be 60-70 ° C.

The duration of heat treatment is 15-18 seconds. If the recommended temperature is exceeded or the duration of heat treatment is increased, the skin becomes very soft and loses its elasticity. This increases the risk of tear formation during treatment.

There is a possibility of wax hair removal. To do this, the carcasses are immersed in melted paraffin and then in cold water. This treatment is optimal for waterfowl - the presentation will be better than a burn.

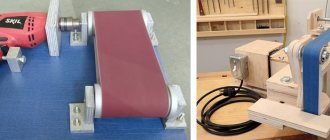

Nozzle

The attachment is the simplest option for a pen case. Visually, it resembles a brush with panicles instead of bristles. The attachment is attached to the drill. The carcass is placed on the table. Install a mesh that partially traps flying feathers and fluff. Treatment is carried out by bringing the tool closer to certain areas and turning the goose while cleaning.

Such a device is not very convenient - fluff and feathers will have to be collected over the entire surface. Fingers damage the skin and cause bruising. It is not always possible to achieve an attractive appearance of a carcass - you need a lot of experience.

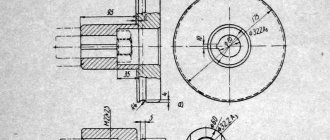

Disc centrifuge machine

The centrifugal disc goose tweezer is used in small farms and households. The rule is simple. Feathers are removed upon contact with movable and stationary beaters.

After the goose is slaughtered, the blood is drained - a small incision is made in the neck so that the head does not come off when rotated in the machine. The bird is scalded or covered with wax.

The machine is turned on. The bottom begins to rotate with the beaters installed. The boiled poultry is placed in the center of the drum, well moistened with water. Close the lid.

If there is no automatic water supply, watering is done manually during operation.

The tamping fingers attached to the sides of the structure remain stationary. The frame is cleaned by a rotating disk, while it is moved by fixed fingers due to centrifugal force - this speeds up the process and increases efficiency. Feathers and liquid are drained through a side drain into a drip tray.

The quality of the picking is average - skin tears, bruises on the carcass, and severed limbs are possible. Due to the use of water, microbial contamination occurs, so the carcass is not suitable for long-term storage. Advantages of this device:

- Good processing speed (on average 10-40 seconds is enough);

- Easy to use.

These machines differ in the number of beaters, capacity and drum size. Fingers of different stiffness ensure effective removal of feathers of different sizes. Their length for large birds should be at least 90-100 mm, and the horizontal/vertical distance between them should be 70-100 mm. The hardness of the material is 48-55 Shore units. The large, raised cut facilitates efficient feather removal.

Travel speed - 200-300 rpm. For safety, there is an emergency stop button. The motor is protected from water. You can pluck several birds at a time, depending on body size. This is convenient for large farms.

The drum can be made of stainless steel or polypropylene. Both materials are hygienic and easy to clean after use. The metal has great strength, which is important because of how the mechanism works. Costs more than polypropylene. This also has its advantages - it weighs less and is cheaper.

What are kicking fingers, and what types are they?

These are the main active elements of feather removal machines, due to which feathers and down are removed from the carcass after scalding. This is a consumable item that you will replace repeatedly as you use the machines. They are usually made of food-grade rubber, which does not peel off and does not leave any discharge on the carcasses even when exposed to high temperatures.

At the same time, it is important to know that the striking fingers are not at all the same, and differ from each other in such parameters as diameter, the presence and shape of notches, and rigidity. All this is very important to take into account before you start plucking, because if you don’t do this, you risk hopelessly damaging the carcass, or simply plucking it poorly. So, there are:

- Nozzles for large birds. They are suitable for ducks, guinea fowl, chickens. Their length reaches 98 mm.

- Nozzles for small birds. Can be used for quails, partridges, chickens. Their length reaches 60 mm, usually a horizontal notch is used.

- Universal. They have a medium level of hardness, horizontal notches, and are suitable for working with any type of poultry.

The general rule is that the shorter the striker, the smaller the bird it is intended for. Most models come with spare attachments suitable for plucking different carcasses. This material can also be ordered online.

Disc plucking machines for geese

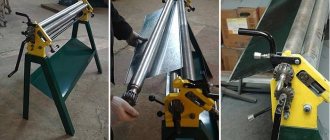

These devices do not have broken pins. The principle of operation is similar to epilators - feathers are torn by movable steel discs, this has no effect on the skin. Two motors available. The first of them moves the disks, the second rotates the fan turbine, which ensures the operation of the blades.

The advantage of this equipment is the good quality of the carcass, without skin tears or bruises. There is no need to steam or wax the goose first. Since no water is used, the shelf life of the meat is increased. Feathers and down remain clean and dry - the material can be sold.

Types of feather removal machines

The choice of a feather removal machine, as a rule, is made between two main types - disk and drum (cyclomatic).

- Drum machines. Most of all, in their design, they resemble washing machines. By the way, ordinary washing machines are sometimes used when they want to make a feather removal machine themselves. Here, unlike disc models, the bird carcass itself moves, and the beating fingers are static and located along the inner radius of the drum. The centrifugal force caused by the rotation causes the carcass to hit the beating fingers, which leave feathers on them. This is a rougher processing method that is more often used in households. Due to strong rotation, quite often the bird is damaged, its skin breaks, and bruises occur.

- Disk machines. They are used for so-called dry plucking - that is, without the use of water. In such devices, the bird itself remains static, and plucking is carried out by disks with beating attachments rotating around the carcass. They have very great advantages over drum ones. Firstly, this is the impeccable preservation of the presentation. Disc feather pickers are very often used for industrial purposes, in large professional poultry farms, where careful cleaning of birds from feathers is needed.

- Homemade portable options. The author's engineering thought sometimes amazes with the simplicity and originality of some solutions. Today on sale you can find special attachments for a drill or screwdriver that can be used for plucking birds. Of course, their performance cannot be compared with professional machines. However, they allow you to clean the birds from feathers much faster than with your own hands. Structurally, they consist of exactly the same punching fingers mounted on a cylinder, made of plastic or rubber. Often the kit comes with additional removable attachments for different types of birds.

How to choose a feather removal machine

First, let's note the key parameters for choosing poultry plucking machines. This will help you evaluate the potential of the models presented in the review and decide what characteristics to look for for your own needs. Here are a number of important factors to consider when choosing:

- Power.

The characteristics vary from 140 to 2200 W. The higher the number, the faster the rotor can rotate under load and not overheat. For professional activities, choose an indicator of 1500 W. - Productivity

. In an hour, one machine can pluck 120 carcasses, and another - 400 of the same size. Your choice depends on the volume of work, but more productive models are more expensive. - Capacity

. There are devices with drum sizes from 200 to 700 mm. The wider it is, the more carcasses it can accommodate at a time, which affects the speed of plucking a large number of birds. The size of the drum also determines what type of birds will fit in it. There are universal models for all types of birds (ducks, geese, turkeys, broilers, partridges, quails) and specialized ones for quails or laying hens only. - Material of the drum and other parts.

Equipment made from food grade stainless steel is stronger and more durable, but is more expensive. Plastic drums also do not rust, but are inferior in durability. But they are lighter, which reduces the load on the motor. - Number of fingertips.

The number varies from 90 to 200 pieces. The more there are, the faster the feathers are plucked. - Dimensions and weight.

If stationary use is intended, then the machine is installed once in a permanent place, after which it is not moved. Heavy weight of 30-80 kg provides good stability and low vibration. When you plan to regularly take the device outside, pluck the bird and return it to its storage location, look for small models weighing 10-15 kg. Although they bounce around a bit when spinning, they won't be difficult to wear.

Tips for choosing

Let's say a few words about how to choose the right feather removal machine and not regret the purchase. Be sure to consider when choosing:

- The volume of the drum, if we are talking about a drum machine. Large-capacity units typically cost significantly more, but can accommodate up to 10-12 chickens, which is very useful in a poultry farm with intensive production. In turn, small devices are perfect for use in personal households.

- The density of the fingertips. The smaller the step between them, the better the cleaning will be.

- Model dimensions. This is of particular importance for private households, in which the car has to be pulled out every time.

- Performance. 100 or 400 cleaned carcasses at a time is a big difference that should definitely be taken into account when choosing.

It is also worth asking the seller about the wear resistance of the pins. They are expressed in the number of birds processed before the attachment has to be replaced. For inexpensive Chinese models it may not exceed hundreds, for high-quality European ones it can reach 1.5 and 2 thousand.

Homemade devices

You can make your own goose plucker. For this you will need:

- plastic barrel;

- frame welded from metal pipes;

- steel plates;

- rotary engine;

- switch for drive;

- disc from a washing machine centrifuge.

Cut the bottom of the drum with thick, strong walls. Separate the centrifuge disk from the walls. At regular intervals, 30 to 35 holes are made in the disk for flails. Secure them with bolts and nuts.

The plate is placed on a metal base with a hole for draining water and secured with screws. Install the frame and secure it. Place the motor on the side and install the drive belt and switch. Then attach the bottomless drum (make sure it is attached as tightly as possible). Drill holes in several rows around the circumference of the drum and install tamping pins. The operation of the device is checked by connecting to the electrical network.

How does the feather picker work?