Most home craftsmen always have a tool at hand that helps them cut a piece of metal of the required size, sand the surface, or even sharpen a kitchen knife. This is an angle grinder. Its disk rotates at high speed, which ensures efficient performance of work. But not every operation requires maximum speed. Then a grinder with speed control will come in handy, which will ensure quality and safety.

Tool types

Typically, devices used at home are characterized by small sizes and increased requirements for working conditions. Their technical capabilities do not go beyond household operations. As a rule, after 15-20 minutes the technician’s hands will feel an increase in the heating of the device body. This means that you need to take a break from work. Intensive work every day is beyond the capabilities of such an angle grinder.

For industrial use, you need a high-performance, reliable angle grinder with soft start and speed control, with a moisture- and dust-proof housing for manipulation in adverse environments. Typically, such devices are difficult to break , so it is perfect for daily full-time work. When performing operations with such a device, you do not choose the type of material, even if it requires delicate processing. All you have to do is reduce the rotation speed of the disk and any tool will do the job.

Such units can also be used at home, for example, during the construction of suburban housing or major renovations. He will show himself only from the best side.

Which grinder to choose

When buying an angle grinder, you need to look at the following parameters:

- rotational speed;

- availability of additional functions;

- power;

- disk sizes that fit the device.

An indispensable device in everyday life is a grinding machine. It is compact in size and very easy to work with. It will only take 15 minutes for a person who has never worked with an angle grinder to fully master the principle of working with it.

If you need to buy a household grinder, then you should take into account the fact that it is not intended for daily and long-term use. The technical performance of such devices is much lower than that of a professional device, which can be used for a very long time without overheating. Professional angle grinders are also equipped with special brass inserts, as well as a metal body.

This is necessary in order to use the grinder in extreme conditions, such as:

- excavation;

- pipeline laying.

For such work, it is necessary to purchase a tool that will be maximally protected from moisture and dust. That is why in no case should you use ordinary household grinders in such work, since they will very soon fail.

Main characteristics

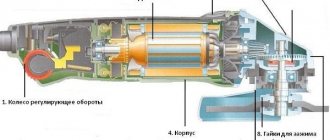

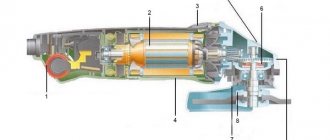

The grinder itself is simple both in design and in working with it. However, like any tool, it must be used effectively and safely. In order to combine these qualities, it is necessary to understand the technical features of the device.

Engine power

Most angle grinders with a speed controller have an electric motor power ranging from 500 to 1500 watts.

There are, of course, samples with parameters that go beyond this framework, but these are the ones that are popular. The average power model of 700-800 W will cope well with most cutting materials. The grinding operation will require a more powerful tool, because with such work the contact area with the surface being processed is larger. If the engine cannot cope, shutdowns and, as a result, overheating of the tool are inevitable. Therefore, for insurance purposes, you need to choose a more powerful device. Then you won’t have to carefully choose the scope of its application.

Protective automation

Safety has become the main condition for working with power tools. Any rotating machine, be it a drill with speed control or a grinder, has a whole range of protective systems that protect people from injury. The most popular automatic types of health protection are:

- The soft start device ensures smooth operation initially after the start button is turned on. Limits starting currents, which extends the life of the electric heart of the angle grinder.

- If the tool disk jams or bites, an emergency stop using a safety clutch will help to avoid injury.

- During operation, if the tool is skewed, it may break out of your hands. The emergency disc brake will stop rotation in 3 seconds.

- The worst enemy of windings after a short circuit is abrasive dust that gets inside during grinding or cutting. To prevent it from getting inside the electrical circuit, the coils are impregnated with special compounds.

- For comfortable operation in conditions of intensive use of the device, the case has heat dissipation slots.

- If the grinder's circles are ground unevenly, beating and trembling of the tool occurs. To smooth out these consequences, there is an automatic balancing system.

- When heated above 160 degrees, the rotation speed slows down, reaching 200, and stops completely. This is how automatic overload protection works.

Selection criteria 125 usm

The main parameters are the speed of rotation of the circle, the power of the electric motor, decent ergonomics, the presence of basic and additional functions and devices. The price of the car crowns all the possibilities.

Affordable price

A low price is not an indicator of low quality, as the ratings of grinders say. For a fairly low cost, you can choose an angle grinder model that will have:

- good equipment;

- rotation speed controller;

- spindle locking device;

- Possibility of mounting an additional handle and a protective shield in different positions.

It all depends on the required characteristics and planned working conditions.

A review of proposals shows a wide range of “price – quality – parameters” relationships. Less expensive brands are Zubr, Hammer or Military, and Makita even has a slightly higher price, but the quality will be excellent.

Power

The power and speed of rotation of the wheel are directly related, so you should not set the diameter of the wheel larger than specified. It is for it (most often - from 125 to 230 mm) that the structure is drawn up and manufacturing materials are selected.

The specific speed required for a specific task or material is the basis for selecting power. For most tasks, an angle grinder with a power in the range of 0.5-3.0 kW will be sufficient.

The type of circle is important here. If abrasive wheels are used for cutting, not very much power is needed. For grinding wheels with a larger contact patch or larger diameter, increased power is required.

Speed

The rotation speed of the working body, measured in revolutions per minute, is the main parameter for selecting an angle grinder. The ability to regulate speed makes the device universal - it becomes possible to grind, cut, sharpen and even polish with one tool.

The typical speed gradation depending on the operations performed is as follows:

- up to 3000 – surface grinding;

- 3 – 4 thousand – work with wood;

- 4 – 5 thousand – work with metal, without cutting;

- 5 – 7 thousand – cutting stone and concrete;

- 7 – 10 thousand – metal cutting.

Adjusting the disk rotation speed

The quality of the work performed is often determined by the set speed of the tool, if the design allows it. Thick, hard materials are easier to cut at maximum speed. An aluminum billet, on the contrary, will melt when heated. Therefore, there are operating modes that require the use of an angle grinder with speed control:

- Reduced speed is required for stone work. Each variety has its own.

- Sanding and finishing at high speeds can damage the product.

- When changing a wheel from one size to another, speed adjustments are required.

- Diamond-coated discs and bits are used at low speeds to avoid breakage due to overheating.

If the device is used exclusively for cutting operations, a speed controller is not necessary, but as a tool for universal use, it is simply necessary.

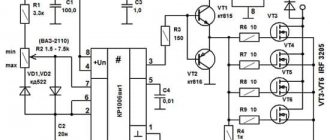

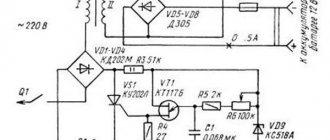

Speed controller circuit

To install this system, variable resistance alone is not enough. If you simply lower the voltage in the circuit, the power and speed of the device will decrease. Having dropped to minimum values, such voltage will not turn the angle grinder shaft. Therefore, it is necessary to develop a complete scheme.

The most modern regulators are manufactured using integrated circuits. The electrical circuit of the simplest tool includes a motor and a start button. These are reliable components that often outlive the device itself. Therefore, you should not be afraid of including electronic components in the form of a tuning module and a soft start system.

The wide distribution of products with such devices in the mass sector is hampered by the high price. However, very often they make homemade devices or purchase a ready-made product.

Popular models

All well-known world manufacturers produce a huge number of angle grinding tools. There are simpler models, for not the most demanding client, and there are also highly effective specialized modifications. There are several Bulgarian women who deserve special attention:

- Metabo WEV 10-125 Quick. The device with the highest possible speed performs its duties efficiently even when the voltage drops. This is achieved by adjusting the electronics, which includes a speed controller and a soft starter. Has a protective coupling. The long cord makes this model a versatile and convenient tool.

- The Japanese company Makita is known for the memorable appearance of grinders, electric drills, screwdrivers, as well as high quality. This is confirmed by the Makita GA5030 model, which has proprietary reliability, noise protection, speed control, soft start and locking the start button. All this is placed in a compact case.

- The Bosch GWS 12-125 CIE angle grinder turned out to be the best option for a professional tool. Its entire design is aimed at uninterrupted and safe operation. Several speeds, a power of 1200 watts, a protective shutdown system when biting - all this is created for comfortable work with the tool.

An angle grinder with a speed controller can perform many different operations in skillful hands. You just need to know when to increase the rotation speed and when to turn on low speed. Which tool is more suitable is up to each owner to decide for himself.

Originally posted 2018-04-06 09:07:39.

The best manufacturers

Both foreign and domestic manufacturers are engaged in the production of angle grinders. The Germans have achieved very great results in this industry. This is Bosch.

Japanese units are also in great demand; they are produced by Hitachi and Makita . These companies mainly produce models that can be used professionally. Grinders from these manufacturers have adjustable speeds and high power, which exceeds 1200 W. It is also very convenient that there are different diameters of disks that can be installed on the machine. Angle grinders make it possible to perform various types of complex work.

If you use special diamond blades, you can even cut stone or concrete, as well as walls for laying wire. The presence of a side handle is very convenient, because it will provide complete control over the powerful tool during all work.

Bosch GWS 850 CE

Grinders from Bosch have variable speed control and a power of 850 W. Such machines are ideal for grinding natural and artificial stones if you use a diamond disc. This type of grinder is very popular among electronic tools. Typically, Bosch equipment is purchased by professional stone engravers, who daily face the need to polish marble or granite. This grinder is quite light in weight, and therefore can be controlled very easily. Anyone can hold it in one hand.

The Bosch grinder will have a one-year warranty, and in the event of a breakdown, you can easily exchange it for a working model.

The machines are equipped with special 6 positions, thanks to which you can adjust the rotation speed. Speed range - from 2800 to 11000 rpm.

The quality of polishing will depend on the speed of rotation of the nozzle. The lower the speed, the higher the quality of work. This requirement must be remembered, since working with granite, marble or glass parts must be done very carefully. To process marble surfaces, experts recommend a speed of 2800 rpm. Wooden surfaces can be treated with a special nozzle, which allows you to develop high speed.

The kit includes a special wrench, a handle and several fastening washers that will hold the discs and attachments.

Nozzles

The quality of work will directly depend on the selected nozzle. If you have to work with marble and granite, then experienced engravers will choose diamond flexible disks. For wood, a flap sanding wheel is suitable. To polish metal products, it is better to use circles consisting of felt or felt, which can be attached to a special attachment using Velcro. Felt tips can also be used for polishing glass. But in this case, you also need to purchase diamond paste, which will greatly simplify the work. If the surface is painted or varnished, it is best to use sheep wool attachments.

Makita GA5030

This is an excellent model of a household grinder. It also has adjustable speed. The price is approximately 2500 rubles. The Makita device has a very small weight, which will not exceed 2 kilograms, and therefore this machine has many advantages compared to other similar models that have a much larger weight.

The manufacturer guarantees very high build quality of all units. A grinder with adjustable speed makes it possible to engage in different types of work:

- sharp;

- grinding;

- polishing

There are numerous reviews about this device, which indicate that all users are very satisfied with the purchase of such a device. The grinder has very low vibration, and the additional handle makes operation much easier.

Makita has a lot of advantages, but the owner should not forget that this is still a household grinder, which means you should not work with this equipment for a long time. You need to take breaks periodically to prevent the Makita from overheating.

Makita 9565CV

This Makita model also has variable speed and provides speeds from 2800 to 11000 rpm. You need to buy a disk with a diameter of 125 mm. Power consumption - 3400 W. The grinder is a professional tool, the design of which will contain the following components:

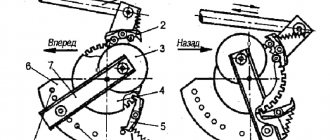

- Adjustable speed, which makes it possible to optimize the operating mode. The spindle will receive a certain rotation speed, which is necessary for a specific task: cutting, stripping or grinding.

- Lock the power button. This is a very good feature that ensures safety during operation, especially in cases where the light turns off or the plug is accidentally pulled out of the socket. With the help of a secondary start fuse, the owner will always be protected from accidentally turning on the angle grinder, and therefore eliminates the possibility of injury.

- Double insulation.

- Stabilization of speed. This function lightens the load on the disk, and therefore the process of working with massive and labor-intensive parts will be much easier.

- Two-position side handle. Thanks to this component, the owner will be able to properly hold the power tool during operation.

The Makita unit is protected from critical overloads at the moment of switching on, and has a soft start, which protects the system and numerous parts from strong voltage surges. You can pick up speed very smoothly.

Selecting the right disk size

Special discs are made for grinding machines, which have a diameter from 115 to 230 mm. The working part will always protrude beyond the body of the machine. The attachments will wear out over time during use. Those discs that have a diameter of 115 mm wear out very quickly and are suitable for cutting products with a thickness of less than 3 centimeters. And this diameter will also be unsuitable for working in hard-to-reach places. For such operations, it is better to choose a disk with a diameter of 180 or 230 mm.

Metabo WEV 10−125 Quick

This is another piece of equipment that has a speed controller. The optimal disk size is 125 mm. This is the best model of this power. It is distinguished by a very wide adjustment of the spindle speed and a constant number of revolutions under the influence of alternating loads. This was achieved thanks to built-in electronics that will protect the engine from overload. The grinder is equipped with an automatic safety clutch, as well as an angular brush, which will turn on if the voltage disappears.

The device also has an overheat indicator, an automatic clutch and a long power cable. This angle machine has no drawbacks, judging by user reviews, and therefore is successfully used for various jobs.

Hitachi G13SS

This is a Japanese model of the device, which is characterized by average performance. But this grinder is very comfortable, ergonomic and relatively inexpensive. It can be used in car repair shops or at construction sites. This power tool is made specifically for cutting metal and grinding any surfaces. The grinder is light in weight and has a narrow grip, so it can be held with one hand in any position. The power tool is intended for professional use. Users note its convenience. The only disadvantage is the low power of the device.

The model has an ergonomic shape, it has an attached handle, and therefore can be moved to any side. The carbon brushes are also very easy to replace. These are the main advantages that many people have already appreciated.