Chrome paint. Application Features

A special chrome effect paint is used to paint the car. Before the procedure, the car must be thoroughly cleaned and prepared, as before regular painting. The painting process has some differences from applying conventional paintwork.

In auto repair shops, chrome paint for cars is applied in several stages:

- A thin layer of black paint is applied to the surface of the part or body. The surface is carefully prepared before this.

- After the paint has dried, it is polished.

- The surface is degreased and, in order for the next applied layer to lay more evenly, it is heated with hot air.

- Then special chrome car paint is applied using a sprayer. It contains microparticles of aluminum.

- After this layer has dried, the surface of the body is carefully polished and the desired texture is created using tools.

In some workshops, chrome paint for cars is applied using a different method:

- The surface is covered with a layer of primer, which is highly adhesive and creates glare, therefore it is considered a good base.

- Paint is sprayed over the primer, which gives the surface a reflective mirror effect. To prevent dull spots from appearing on the body, the master uses a distiller.

- At the final stage, the chrome paint is coated with a special protective layer that contains colored pigments. They create the effect of silvering or gilding and have a high percentage of reflective effect (94%).

Stylistics

Every detail is important in creating an authentic interior. Provence and shabby chic are an extravaganza of warm shades against the background of opaque floor surfaces, furniture and door panels. White door handles fully correspond to the chosen concept.

The industrial loft, born on the outskirts of abandoned workshops and factories, requires the primacy of metal. Heavy canvases are equipped with massive dark handles: antique silver and antique bronze. Any manifestations of black are also appropriate.

The canons of the classics are not subject to time. Brass and bronze handles on the rosette will come in handy, just like a hundred years ago. Neoclassical is less conservative and allows you to choose between nickel, brass and bronze colors.

Art Deco is a manifestation of luxury in every detail. Brass and gold door handles with all kinds of decor will emphasize the aesthetics of the space.

Scandinavian style and japadi have a similar philosophy - nothing extra in the name of light. Door handles are selected to the point of mimicry with the surrounding environment, with the exception of chrome fittings, which can act as full-fledged room decor.

Minimalism is the new religion of small apartments for big money. The door handles are smooth white brushed metal, with nickel and 925 silver being the best candidates.

Italian style is synonymous with luxury and beauty, combining the principles of strict antiquity and carefree country. The aesthetics of the interior are determined by solid wood furniture, expensive textiles and natural finishing materials. At the same time, in an exclusive setting there is no pretentiousness. The choice of door handles is not limited to strict limits; the main condition is the shades of expensive metals: antique bronze, French gold and patinated silver. The shine is restrained, as if muffled by the salty sea wind and hot sun.

Painting a car matte color in a car service center

To paint a car with matte paint, it is advisable to contact specialists who have enough experience in this type of work. Matting the car coating takes place in several stages:

- Cleaning the car paintwork from dust and dirt;

- Masking windows, mirrors, wheels and headlights using protective film;

- Removing body parts that do not require painting (if not the entire car is supposed to be matted);

- Removing all paint on the body down to the primer layer;

- Leveling the surface of the body to perfect condition, eliminating all possible scratches and chips;

- Consecutive application of several layers of matte auto enamel;

- Application of matting varnish (if additional matting additives are required);

- Assembling the car after the coating has completely dried.

Painting a car with matte paint requires extreme care, since inaccuracies in application on such a coating are immediately noticeable.

When agreeing with the craftsmen about painting a car in a matte color, you should clarify the level of matting of the coating. It is determined by the numerical value of the reflectivity of the paint and should be no more than 30 for a slight muted color and no more than 10 for complete matte.

Colorful question

The number of shades of door handles created by designers is not inferior to the palette generated by nature. Cold chrome, matte nickel, imitation of noble gold, silver or bronze impress with their laconic shine. Tightly colored models are the trend of the day, where white and black are eternal antagonists.

The decor on the handle is also strikingly varied. Carving, blackening, curls, rhinestones and other decorations determine the aesthetics of the door leaf. The generous variety of accessories sometimes makes it difficult to make the right choice. Purchasing a doorknob for a specific home with its unique color and style can be a challenge.

Nickel plating

The application of nickel to metal products and other conductive materials by the galvanic method is carried out for various purposes. Nickel plating can be carried out for:

- creating a protective layer that resists metal corrosion;

- as a primary treatment, to create a sublayer on which another layer of metal will be applied;

- to increase the aesthetic features of products.

Nickel plating is rightfully considered the most economical way of finishing components of various devices and interior elements. Nickel coating:

- parts of production and laboratory equipment. In this case, nickel coating solves the problem of increasing the protective properties of the surface layer, aimed at improving the ability to withstand the effects of an aggressive environment. This coating is especially relevant for chemical production;

- parts of vehicles - cars and bicycles. Coated with nickel, they acquire a rather attractive appearance and receive reliable protection against rust. This type of coating is used both in car production and during auto tuning;

- interior elements of residential premises and household items. Nickel coating of plumbing fixtures and metal parts of shelves, hangers and fasteners increases the decorative functions and the ability of the material not to be exposed to the harmful effects of moisture and temperature changes.

In addition, nickel plating, or applying a layer of nickel to the surface being treated, is used to create measuring instruments and various parts that are designed for operation under conditions of minimal mechanical loads.

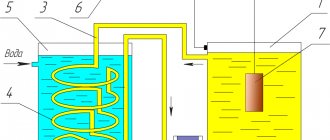

Nowadays, electroplating with nickel is becoming the most popular method of final processing of metal and alloy products that fully meets today's requirements. The use of galvanic equipment will give reliable results at minimal cost. In addition, galvanic nickel plating is the most cost-effective and fastest method of applying nickel, the use of which allows you to obtain high-quality products in the shortest possible time.

Nickel itself is a malleable, silver-white metal that can be easily processed in various ways. Nickel-containing electrolytes are used to process products using the galvanic method. It is typical that for galvanic coating carried out for the purpose of protection against corrosion, pre-treatment is often carried out - copper plating, or the material is coated with nickel in several layers.

The result of electroplating with nickel are parts whose surface is covered with a uniform layer of nickel and have increased protective and decorative properties.

What is the difference between brushed nickel and chrome?

Brushed nickel and chrome are materials that we can use to make fittings and equipment in our homes. The key difference between brushed nickel and chrome is that brushed nickel produces a matte finish while chrome produces a shiny finish. Moreover, brushed nickel can range from golden to almost white in hue, while chrome typically has a bluish tint. Brushed nickel is best for traditional homes, while chrome is best for modern homes and farmhouses. Additionally, brushed nickel fittings are suitable for remodeling on a budget, while chrome fittings are suitable for remodeling on a budget.

The differences between brushed nickel and chrome are summarized below in tabular form.

Composition of metallized paints

When creating metallic paints, it must be taken into account that metallic pigments interact best with non-polar solvents that have high surface tension.

In this case, it is undesirable to use low molecular weight alcohols. At one stage in the production of metallic paint, a lubricant based on a concentrated fatty acid is added to the pigment to impart hydrophobic and oleophobic properties to the metal surface. But low molecular weight alcohols destroy the protective film formed on the metal surface. Isopropyl acetate provides a satisfactory result, which is a good solvent for typical binders used in metallized paints and leaves behind less residue, which is especially important for confectionery and tobacco packaging. Isopropyl acetate is a highly volatile solvent and can also be used in small quantities in offset metallized inks.

The use of esters instead of toluene affects the wetting ability of the solvent. One of the important advantages of toluene was the ability to perfectly wet the cylinder at the point of contact with the squeegee blade during printing, improve the sliding and quality of the squeegee, which had a positive effect on the quality of the finished product.

With ethereal solvents, the degree of wetting has decreased, and this must be compensated somehow. In the absence of aromatic hydrocarbons, the most effective way to increase wetting power is to use plasticizers, low-volatility substances that improve the plastic properties of resins and can simultaneously act as wetting agents in metallized paint formulations.

Composition and characteristics

Chrome paint is available in several varieties, each of which helps create a high-quality effect on the surface. Dyes of black and other colors are available either in jars or in spray form. Standard cylinders are used; they are most suitable for doing independent work.

The metal powder in an aerosol, which is part of any such material, is highly reflective. Among the important characteristics that chrome paint has are high strength and heat-resistant protection.

The main filler of such compositions is tiny particles with a metal base. Alkyd or nitrocellulose base varnishes are added to the product. They are needed to form reliable connections when applied.

A mirror-like, reflective surface is provided not only through the use of powder. This is facilitated by the original properties of the composition, which allow the material to be distributed evenly over the surface.

What is Chrome?

Chrome is a metal that is used primarily in the automotive industry, as well as in the production of fittings and hardware. This material is known for its resistance to rust and corrosion. It also has a relatively low price. However, the main disadvantage of chromium metal is the need to regularly clean its surface. This is because the surface of chrome plated metal can pick up water stains and fingerprints.

Figure 02: Chrome faucet

Chrome usually gives a modern or industrial look and is shiny, sometimes showing bluish tones. It can also complement cool colors. This type of metal is suitable for rooms with a cool color scheme, modern or industrial farmhouses, white bathrooms, and when we are remodeling on a budget.

Coating options

There are several types of coatings, depending on the ingredients used:

The classic version of painting chrome on metal is the most common. These are compositions with a white mirror shine. They are similar in appearance to polishing silver. Additional dyes are not used in this case. The chrome effect is ensured without them.

The gold version of chrome plating is also quite common on the market. The paint contains yellow metal particles, which makes it possible to obtain a noble shade. The mirror gold metallic effect appears when the composition dries completely.

Black chrome has a very original effect created by the surface itself. There are special spray paints designed not only for car wheels, but also for plastic and various products made from it. The photo below shows the decorative effect itself.

Any chrome paint forms a mirror-like glossy surface when it dries. It looks like liquid silver. Matte chrome is the option that differs most from previous varieties. This popular spray painting solution is used to decorate the interior.

It is necessary to slightly change the composition of the paint to achieve an unusual effect on the surface. Otherwise, painting under chrome will not achieve the desired result.

In the video: spray paint with bosny chrome effect.

How to choose the color of a door handle

When buying a door handle, you should follow the principle of harmony: cold shades are combined with cold ones, and warm shades are combined with warm ones. Mixing opposites looks unattractive and creates visual discomfort. In order not to suffer a color fiasco, it is necessary to take into account the color scheme of the door leaf, walls, floor, baseboards, as well as the design of the home.

Door leaf

Tree rings and curls on the surface of the canvas are a unique natural decoration, the relief of which is emphasized by delicate tonal transitions. To avoid overload in this context, preference should be given to ascetic matte fittings. Handles in chrome color are appropriate if the wood grain is weakly expressed.

The beauty of walnut is emphasized by polished brass; silver is the best solution for noble bog oak. Maple and cherry woods with pink or red reflections go well with gold and bronze, including aged ones. Nickel handles are suitable for pearl gray alder. Enameled models allow you to play on contrasts; a white canvas in combination with a black door handle sets the dynamics of the space. A universal option for all other opaque colors is chrome.

Walls

The color scheme of vertical surfaces determines not only the temperament of the home, but also the shade of the door handle. The latter should be 2-3 tones lighter or darker than the color of the walls. The light palette looks harmonious with matte or antique bronze, as well as French gold.

Nickel and silver balance out the dark colors.

Floor

The colors of the flooring and door together form a harmonious ensemble. As with walls, when choosing a handle, you need to be guided by the richness of the shades. The fittings should be a little lighter or darker. Light doors and light floors are organically combined with polished and matte brass, dark ones are an excellent background for all shades of gold and nickel.

Skirting

The classic solution is a plinth matched to match the trim and door. The interior door handle, which correlates with the shade of the canvas, by default matches the color of the baseboards. If the starting point when choosing a baseboard was the shade of the floor, then it should also be the main thing when buying door fittings. In any case, the color of the baseboard is a secondary factor.

Interior

In an apartment where several generations live at the same time, the furnishings are subordinated to personal convenience, and not to a specific style. Handles should be neutral in color. Matte silver or soft gold would be appropriate. In other cases, you should rely on the design of the premises.

How is dyeing done?

An important stage is preparatory work with the surface. This is especially true for glossy products rather than matte ones. Even small defects can be noticeable on smooth materials; this will only harm the effect of chrome. The room must be completely free of dust during processing. Only after the necessary conditions have been met can you proceed to subsequent processing.

Liquid acrylic compositions (liquid chrome) have their own positive qualities. They are heat-resistant, able to withstand any chemical exposure, moisture in any quantity. Unlike powder compositions, liquid acrylic materials can be applied to parts of parts, creating multi-colored chrome-effect paint designs.

The workflow itself is described as follows:

- The part is first primed and then coated with a layer of black dye

- The color may be different, it does not play an important role.

- Polishing is carried out after the initial layer has dried.

- Using an aerosol can, we apply paint with a chrome effect; there may be several layers.

- Each chrome layer must dry thoroughly before applying the next one.

- The final stage is varnish treatment.

Powder paint Bosny belongs to another type of composition

The elements that are included in its composition provide a chrome effect and increased coating durability. This option is ideal for disks

Powder paint Bosny belongs to another type of composition. The elements that are included in its composition provide a chrome effect and increased durability of the coating. This option is ideal for disks.

The painting process is not particularly problematic and can be easily done in a garage. There will be four stages in total: thorough cleaning of parts, primer coating, drying, and application of powder paint.

Printing pigments

For different printing methods, pigment is used from the same metal raw material, but with particles of different sizes. For offset and letterpress printing, flakes with a thickness of about 0.1 microns and a diameter of 3.5 microns are needed. And for gravure and flexographic printing, polished particles with the same thickness have a diameter of 8 to 9 microns. It would seem that the easiest way to increase shine is to use a pigment with enlarged particles. But for good covering properties in the paint, it is necessary to maintain a sufficiently high pigment content, and an increase in the size of metal particles leads to a weakening of the action of binders and settling, precipitation of bronze or aluminum pigments.

The shelf life of finished paint is sharply reduced. In gravure printing, the presence of particles larger than 10 microns in ink leads to the formation of absorption and other defects on the print - mainly due to unwanted accumulation of ink behind the squeegee. Such layers of paint “pop out” from under the knife from time to time, significantly worsening the quality of the finished product. It follows that in metallic printing inks particles of arbitrary sizes cannot be used, and when combining, a certain balance must be maintained.

Dry metal powder is transformed into ink suitable for printing processes thanks to the binders that envelop and carry each pigment particle. The powder is slightly moistened beforehand to facilitate subsequent mixing. Naturally, the composition of binders for inks intended for different printing methods is different. The composition of firnis (prepared binders) for offset inks includes solid resins (modified rosin and/or hydrocarbon resin), plant-based alkyd resin, mineral oil thinner, vegetable oils, structure formers. Ink binders used in gravure printing include cellulose derivatives (nitrocellulose, ethylcellulose, cellulose acetate butyrate and cellulose acetopropynate), polyamide resins, vinyl copolymers and other resins.

Summary – Nickel vs Chromium

We mostly use the terms "brushed nickel" and "chrome" when talking about hardware and fittings in our homes. The key difference between brushed nickel and chrome is that brushed nickel produces a matte finish while chrome produces a shiny finish. Additionally, brushed nickel is best for traditional homes, while chrome is best for modern homes and farmhouses.

Link:

1. “Five reasons to choose brushed nickel for your kitchen.” Native Trails, December 29, 2022, available here.

Nickel properties

Density and mass

Nickel belongs to a number of heavy metals. Its density is twice that of titanium metal, but is equal in numerical value to the density of copper.

The numerical value of the specific density of nickel is 8902 kg/m3. Atomic mass of nickel: 58.6934 a. e.m. (g/mol).

Mechanical characteristics

Nickel has good malleability and ductility. Thanks to these characteristics, it can be easily rolled. It is quite easy to make thin sheets and small pipes from it.

At temperatures from 0 to 631 K, nickel becomes ferromagnetic. This process occurs due to the special structure of the outer shells of the nickel atom.

The following mechanical characteristics of nickel are known:

- Increased strength.

- Tensile strength equal to 450 MPa.

- Highly plastic material.

- Corrosion resistance.

- High melting point.

- High catalytic ability.

The mechanical characteristics of the described metal depend on the presence of impurities. The most dangerous and harmful are sulfur, lead, bismuth, zinc and antimony. If nickel is saturated with gases, its mechanical properties will become worse.

Thermal and electrical conductivity

- Nickel metal has the following thermal conductivity: 90.1 W/(m K) (at a temperature of 25°C).

- The electrical conductivity of nickel is 11,500,000 Sim/m.

Corrosion resistance

Corrosion resistance refers to the ability of a metal to resist destruction when exposed to an aggressive environment. Nickel is a material with high corrosion resistance.

Nickel will not rust in the following environments:

- Ambient atmosphere. Nickel has good resistance to high temperatures. If nickel is exposed to an industrial atmosphere, it is always covered with a thin film, which leads to tarnishing of the nickel.

- Alkalies in hot and cold form, as well as their molten states.

- Organic acids.

- Inorganic acids.

In addition, nickel does not rust in hot alcohols and fatty acids. Due to this, this metal is widely used in the food industry.

The chemical industry also widely uses nickel. This is due to the corrosion resistance of nickel to high temperatures and high concentrations of solutions.

Nickel alloys have increased corrosion resistance. Especially compounds of this metal with iron, molybdenum, chromium and copper.

Nickel is susceptible to corrosion under the following environmental conditions:

- Sea water.

- Alkaline solutions of hypochlorites.

- Sulfur or any medium containing sulfur.

- Solutions of oxidizing salts.

- Ammonia hydrate and ammonia water.

Nickel toxicity is discussed below.

Temperatures

The following thermodynamic properties of nickel are known:

- Nickel melting point: 1726 K or 2647 °F or 1453 °C.

- Nickel boiling point: 3005 K or 4949 °F or 2732 °C.

- Casting temperature: 1500-1575 °C.

- Annealing temperature: 750 – 900 °C.

Toxicity and environmental friendliness

In large quantities, nickel has a toxic effect on the body. If we are talking about taking it with food, then an increased content of this element will certainly pose a health threat.

A frequently encountered negative consequence from an excess of nickel is allergies. Also, when exposed to this metal (in large quantities) on the body, stomach and intestinal disorders occur, and the content of red blood cells necessarily increases. Nickel can cause chronic bronchitis, kidney stress and lung dysfunction. An excess of nickel provokes lung cancer.

If drinking water contains 250 parts of nickel per million parts of water, then this level can cause blood disease and kidney problems. However, this is quite rare.

Nickel is found in tobacco smoke. Inhalation of this nickel-containing smoke or dust leads to bronchitis and impaired lung function. It is possible to obtain this substance under hazardous production conditions or in environmentally unfavorable areas.

Nickel toxicity is only a danger if it enters the human body in large quantities. If nickel is used in industry and construction, then it is not dangerous.

Other characteristics

Nickel also has the following characteristics:

- The electrical resistivity of nickel is 68.8 nom m.

- Chemically, nickel is similar to iron, cobalt, cuprum and some noble metals.

- Nickel reacts with oxygen at a temperature of 500 C.

- If nickel becomes finely dispersed, it can spontaneously ignite.

- Nickel does not react with nitrogen even at very high temperatures.

- Nickel dissolves more slowly than iron in acids.

And how much does this beauty cost?

To get a flawlessly matte car color, you will have to fork out some money, and for some, even dip into your piggy bank. Elegant matte finish is not a cheap pleasure.

Thus, the price of wrapping a car with vinyl film ranges from 25 to 80 thousand rubles, depending on the class of car, and carbon fiber will cost one and a half times more. Add to this the cost of the material (on average 500 rubles per roll of vinyl or 5000 per roll of carbon film) - and the amount adds up to quite a decent amount.

A high-quality matte varnish for a car will cost about 5 thousand rubles for a two-liter jar, and you will need at least three of them. The cost of work in this case starts from 20 thousand for a budget car and varies upward for more prestigious cars.

Painting in a matte color will also require significant costs. For work, it is better to buy a set of materials, which, in addition to paint, includes base paint and a solvent for it, matting varnish with a solvent and a hardener. The cost of such a kit is approximately 30 thousand rubles.

The price for painting work can fluctuate around 40 thousand rubles for domestic cars and even exceed a hundred thousand for prestigious foreign cars and SUVs. So those who want to tone down the gloss of their car’s original paintwork need to invest heavily.

Some enthusiasts may wish to matte their car themselves. On the Internet you can find many instructions on how to cover a car with vinyl yourself or how to paint a car with matte enamel on your own.

It should be noted right away that this is a bad practice: inexperience and non-compliance with paint or film application technologies will be very noticeable in the quality of the result. If the matte film bubbles, you can still remove it, and you will only regret the money spent.

But nothing can be done about uneven body color and drips, as well as dust getting into the enamel after applying matte paint. It is not for nothing that it is applied under conditions of complete sterility, strictly observing all algorithms.

Owners of matte cars are no strangers to the admiration and questions of others. Discreet, discreet luxury in the absence of gloss demonstrates the impeccable taste of the car owner. The only condition is high-quality execution of your own ideas.

A little about door handles and their quality and why externally identical handles cost differently.

A little about door handles and their quality and why externally identical handles cost differently.

Very often, seeing pens that look identical in appearance, even in the same store, people are surprised that they cost differently. The most common explanation from the seller is that one is heavy and the other is light, one is powdered aluminum and the other is cast brass, or one is Chinese and the other is Italian (or also Chinese, but branded). In fact, this is such a simplified explanation that, due to its simplicity, it does not correspond to reality.

Perhaps it’s worth starting with weight.

The main materials for door handles are:

ZAM alloy (Zinc, Aluminum, Copper. English name - ZAMAK, zinc-based alloy, which usually includes 95% zinc and 5% aluminum, copper and other components)

Aluminum - various alloys and composites based on aluminum, silicon, etc. – we will call it for short – aluminum.

Brass – An alloy of zinc (50%) and copper (50%) or other proportions and components depending on the purpose, but for handles it is not particularly important.

So, how much does the cost of the material affect the price of the pen:

TsAM alloy, at the time of writing, costs approximately $3 per kilogram and 3 door handles can be made from a kilogram, which means the price of the material in one handle is $1

Aluminum – costs $2 and almost 8 handles can be cast from 1 kilogram of aluminum. The price of metal in one pen is 25 cents.

Brass costs $4.5 and one kilogram produces 2.5 handles, which means the price of brass for one handle is $1.8. (brass is here just to understand the situation, we will consider in detail TsAM and Aluminum, as the most popular)

This means that the difference between a heavy handle and a light one in production is much less than on the price tag. Heavy handles made of TsAM alloy cost $1, and light ones cost $0.25, the difference is only 75 cents, and on the price tag the difference is at least $5, but usually $10-15 - where does it come from? It's all about the coverage...

Coatings of door handles made from TsAM:

The fact is that the TsAM alloy consists of zinc, and zinc is a very active metal, convenient for casting, pressing and machining, but ugly in appearance, and coatings are poorly applied to it. If you open any catalog of pens, you will see how the manufacturer boasts about the number of layers of coating, here we will look at them:

1. “The first layer is a layer of copper, which provides reliable adhesion to the remaining layers.” - This is a very thin layer of copper cyanide.

The fact is that this is the only way to cover a TsAM handle with anything. Other coatings do not stick.

The process of coating a pen with copper cyanide is extremely expensive, complex and harmful, therefore, the galvanizer’s task is to apply as thin a layer of such copper as possible, and the essence of the process is to soak the pen for a few seconds in a bath of electrolyte. Then they will work with the handle as if it were made of copper, but if there are even tiny places on the handle that are not covered with copper, the entire coating will peel off during use within 1-2 years indoors, and one winter outdoors.

Therefore, high-quality pens have a thicker first layer of copper - accordingly, they are more expensive, because copper plating from cyanide electrolytes is very expensive, and the thicker the layer, the more expensive the product, and the thinner the layer, the more uncovered areas.

2. “The second layer of copper – evens out unevenness” - after a thin layer of copper cyanide is applied to the handle, the manufacturer builds up a thicker layer of copper from a cheap electrolyte. After casting, the handle is all porous, uneven and ugly. To level it, the handle can be machined, but this is expensive, or you can simply cover it with a thick layer of copper; the copper levels the handle after casting.

3. “A layer of nickel – evens out even the smallest irregularities” – the leveling copper turns out matte, and in order not to polish it by hand, the matte ground is simply covered with nickel; nickel makes the surface smooth and shiny.

4. “A layer of chrome makes the surface hard and durable” - yes, that’s right, after this the handle is ready for the final decorative coating. Only here it is worth saying that some manufacturers use cheaper decorative nickel instead of chrome. It is at this step that the so-called COPPER-NICKEL-CHROME coating, or the cheaper analogue COPPER-NICKEL-NICKEL DECORATIVE, ends. The quality of this coating determines how long the handle will not peel, scratch or peel.

To find out what quality the coating has, the pen is placed in an incubator with salt fog, and the time is measured after how many hours the coating on the pen begins to deteriorate. After this, the coating can be assigned a class. As a rule, cheap pens can spend 48 hours in salt fog, mid-range pens - 72 hours, and premium pens - 200-250 hours. The difference in the cost of coating for a 48 hour pen versus a 72 hour pen is approximately $2-3. A pen with a premium coating is 200 hours more expensive than an economy one (48 hours) by $5-7.

5. “Tinting layer” - a decorative layer that determines the appearance of the handle; it can be copper, bronze, gold, nickel, chrome, etc. Can be applied galvanically or vacuum sprayed. May be matte or shiny. The cost of the handle and its resistance to abrasion depend on its thickness.

6. “One or two layers of varnish” - needed so that the pen out of the box would shine and has almost no effect on the durability of the coating.

7. “Laser logo” – everything is clear here

Coverings for door handles made of Aluminum:

The easiest and cheapest way to reliably coat aluminum is to anodize it (aluminum itself takes on a beautiful appearance in an electrolyte under the influence of current), but the colors of anodized aluminum differ from traditional galvanic coatings, and it cannot be passed off as a brass handle or a ZAM handle. Therefore, aluminum is coated in galvanic baths.

The situation with aluminum is simpler than with DsAM. Aluminum can be coated in the same way as ZAM, but without the cyanide electrolyte. Therefore, coatings are cheaper, and the manufacturer himself, when producing aluminum handles, tries to make them as cheap as possible and saves on coating. Therefore, at best, aluminum handles will spend 48 hours in salt fog, but usually even less.

If we talk about aluminum handles, their service life is short, usually no more than 3-5 years, therefore the coating on them is weak and, as a rule, they are sold in catalogs, where people do not have the opportunity to hold a high-quality one in their hands and compare it with a light one with a pen.

In addition to the material from which the handle is made, it is important to evaluate the quality of the coating. Therefore, if you see 2 outwardly identical handles, both are heavy, but one costs $15 and the other $25, this does not mean that you are being deceived, perhaps one is covered better.

Characteristics of metallic paint

Metallic paint is characterized by two main parameters:

- metallicbrilliance

- sparkle (sparkle-effect).

The first describes the level of reflection, in other words, the higher the proportion of reflected light relative to scattered or absorbed light, the greater the shine of the metallic effect. In practice, the more perfect the surface of the metallized pigment (no defects), the higher the area-to-perimeter ratio of an individual pigment (ideally a round disk), and the narrower the particle size distribution, the higher the brilliance. Very fine pigments with an irregular shape and a wide size distribution produce a simply gray color that bears little resemblance to metallic silver. Sparking occurs when reflections from individual particles of metallized pigment can be seen.

The ideal shape, size distribution and orientation of the metallic in the paint film also play an important role.

When using only aluminum metallized pigment in metallic paint, the result is metallic silver. To give any color to the paint, for example blue metallic, green metallic or gray metallic, highly dispersed tinting pigment pastes are introduced into the paint.

In the same way, when painting, you can get a gold or bronze metallic, respectively. The direct use of copper, bronze or brass pigments is limited due to their poor light fastness and weather resistance.

Binders for pigments

In total, at least a thousand types of binder components are used in the production of paints. It is clear that the number of possible combinations is infinite. That is why so many series of paints have been developed, different in their properties, although initially there were only two pigments for metallized paints. The composition changes, the proportions of components change, the properties of the product change. Naturally, first of all, when creating a paint composition, the printing method is taken into account. Thus, inks for letterpress and offset printing must be much more viscous than inks for gravure and flexographic printing. And here the choice of solvent and determination of its proportion becomes crucial.

Matte car color advantages and disadvantages

Matting a car is not yet very popular, but its advantages are difficult to deny. Why is the matte color of the car gaining more and more fans?

It's mysterious and stylish - the lack of glossy shine gives the car's color an inexplicable depth. It's unusual and attracts attention. A matte car catches the eye, arousing interest not only in the car itself, but also in its owner. It's expensive and sophisticated. The unobtrusive color saturation gives the car a solid and luxurious appearance. This favorably emphasizes the lines of the body. The matte color without the usual play of polishing forces you to focus on the shapes of the wings, hood, roof, giving the already flawless lines real perfection. It's practical in its own way. Car gloss requires intense daily polishing, which is not necessary if the car's color is matte.

However, it is still difficult to call matting a car an ideal solution: all its advantages are only one side of the coin. This method of changing the appearance of a car also has its disadvantages:

There is no need to polish a matte car, but you will still have to constantly take care of it: such a coating quickly collects dust and sand, which are extremely noticeable against a lackluster background. Even the smallest damage to the matte finish of a car is clearly visible and difficult to repair; If the car is painted with matte paint, it is very difficult to re-match the color even for experienced craftsmen, especially if there is no sample; Matte color is not suitable for any car: it perfectly focuses attention on the magnificent shapes of cars above the average price segment, Executive and Luxury class cars, high-quality SUVs and sports cars. Budget cars and domestic “classics”, made in a matte color, will look ridiculous and rough... If the shortcomings do not deter you, and the desire to become the owner of a car of a rare color only grows stronger, you can try to make your dream come true

But before that, you should learn more about matting a car.

If the shortcomings do not deter you, and the desire to become the owner of a car of a rare color only grows stronger, you can try to make your dream come true. But before that, you should learn more about car matting.

Metal coating

Chemical coating of some metals with others is captivating due to the simplicity of the technological process. Indeed, if, for example, it is necessary to chemically nickel-plate any steel part, it is enough to have suitable enamel cookware, a heating source (gas stove, primus stove, etc.) and relatively scarce chemicals. An hour or two - and the part is covered with a shiny layer of nickel.

Note that only with the help of chemical nickel plating can parts with complex profiles and internal cavities (pipes, etc.) be reliably nickel-plated. True, chemical nickel plating (and some other similar processes) is not without its drawbacks. The main one is that the adhesion of the nickel film to the base metal is not very strong. However, this drawback can be eliminated; for this, the so-called low-temperature diffusion method is used. It allows you to significantly increase the adhesion of the nickel film to the base metal. This method is applicable to all chemical coatings of some metals with others.

The chemical nickel plating process is based on the reduction of nickel from aqueous solutions of its salts using sodium hypophosphite and some other chemicals.

Water-soluble metallic paints

Changes in the technology of manufacturing and using metallized paints were caused by increased demands from customers and legislators. We had to look for new paint formulations based on solvents and at the same time develop metallized water-based paints.

In narrow-web flexographic printing, water-soluble metallized inks are already widely used today, since this sector traditionally works with water-based inks and has adopted its own standards.

Strictly speaking, water is also a solvent, only inorganic, and is very difficult to volatile: the evaporation number of water is 90, that is, it evaporates 90 times slower than ether.

In addition, water has a stronger surface tension than other solvents. But artificial resins, which are used as a binder, do not dissolve in water!

To make them water-soluble, resins are emulsified in water like a dispersion or neutralized with ammonia or organic amines (saponification). It is clear that water-soluble inks dry more slowly than regular inks, and this process can be accelerated by increasing the temperature, additional ventilation, reducing the printing speed and reducing the stack height. When intaglio printing, the etching depth of the impression cylinder must also be reduced.

In addition, they are more difficult to wash off. Because of their chemical composition, water-soluble paints and varnishes adhere well. Therefore, the rollers and cylinders must move until the work is completed, and after running the print run, all parts of the machine in contact with the paint must be immediately washed with water or a mixture of water and ethanol. Dried paint can be removed using a mixture of water, ethanol, ammonia or amine and any cleaning agent. Ethyl acetate will also work well to clean dry cylinders. Paints containing water should never be left in the cold.

Unlike ground gold paints or offset bronze paints, which are fixed as a result of oxidative polymerization, paints with a binder composition similar to dispersion varnishes do not have a characteristic odor and are suitable for printing on food and cigarette packaging.

In terms of the quality of the metallic sheen and the degree of gloss, prints obtained using these inks, which can be applied through a modified varnish tower of an offset printing machine, are far superior to the results achieved today with offset printing. These paints are supplied in both one-component and two-component forms.

You can introduce colorful tints yourself using a special series of concentrated colorful pastes.

The advantages become obvious when comparing this method with bronzing. Gold priming and bronzing require additional work steps and space for intermediate storage of prints between operations. In addition, this process is labor-intensive and harmful due to the formation of dust from the metal pigment.

What is brushed nickel

Brushed nickel is a nickel finish that is achieved by wire brushing the metal to give it a textured appearance. We can use this process to create a warm tone and interesting interplay of light and shadow on a brushed nickel metal surface. This type of metal finish is primarily used in door handles, house numbers, kitchen faucets, bathroom fixtures, cabinet hardware, and lighting fixtures.

More importantly, brushed nickel produces a matte finish without varnish. It is less expensive compared to other types of fastening materials such as satin nickel and chrome.

Figure 01: Brushed Nickel Faucet

We can define the appearance of brushed nickel as antique or handmade, and its shade ranges from golden to almost white. Additionally, it can complement earthy tones, warm tones, stone and tiles. In addition, this metal surface hides water stains and dirt well. It is best suited for warm-toned rooms, traditional homes that require a low-budget remodeling process, and kitchens with stone, granite, or slate countertops.

How to paint a car chrome yourself

Unfortunately, most chrome plating methods used in modern auto repair shops cannot be used at home. But chrome coating of plastic and body parts can be done in your garage if you know some painting secrets.

The room in which the procedure will be carried out must be thoroughly cleaned of dirt and accumulated dust. You will also need to prepare a spray bottle and an airbrush, which will be needed in the process. To understand what effect you can really achieve, before starting the procedure, you can experiment a little on old car parts. The entire procedure for chrome plating a car includes several stages:

- The prepared part is coated with black paint.

- Only after it has completely dried, the surface must be thoroughly polished. Outwardly it should resemble glass.

- The surface is degreased with alcohol and then warmed up well with a hairdryer.

- Then chrome is sprayed (you must remember that there should be more air in the tool than paint). After complete drying, the surface is polished again.

You will need to apply several layers of chrome, after thoroughly drying each one. Then the part will need to be dried (the better the drying, the stronger the mirror effect will appear).

Painting wheels in chrome

Today you won’t surprise anyone with chrome wheels, although a few years ago painting wheels chrome was a great way to make your car stand out from the crowd of others. Chrome plating of disks is the application of a special coating to them, which creates a mirror effect.

chrome painting of wheels

Such tuning allows you not only to decorate your vehicle, but also reliably protects the wheels from various damages, environmental influences and corrosive processes.

Chrome rim painting is especially suitable for car enthusiasts who prefer to drive at high speeds, since strong pressure, load on the rims and temperature changes provoke premature wear and breakage.

How to paint wheels chrome with your own hands?

Before coating, the disc must be prepared (sanded and polished the surface), then degreased so that the adhesion of chrome and the disc is as strong as possible. All disk mounting holes must be closed to prevent chromium from getting into them.

For painting, you can purchase a special aerosol can and carry out the procedure at home. But this does not guarantee the appearance of a mirror shine on the discs, and the effect will last until the first wash.

All methods of painting wheels in chrome are not considered to be of high quality, since the desired result can only be achieved by painting with chrome itself.

Therefore, it is better to entrust this procedure to professionals who will provide high-quality diffuse or galvanic chrome coating of the disks.

Doors and handles: win-win color duets

To be sure to avoid mistakes when buying door handles, you should take design tips into account. Experts have compiled a concise color matching guide. Handles with a wood pattern are suitable for handles in French gold, matte bronze and polished brass.

Shades of brown, ranging from beige to coffee, look aesthetically pleasing with warm-spectrum fittings.

Gray and black colors love a cool shine.

Painted doors have a special eclecticism. If the canvas is one-color, then the handles should be bought to match or vice versa - bright, contrasting. The rich palette looks attractive with handles in black, white, bronze and silver.

Designer door models with patina and imitation abrasions are combined with PVD gold and matte nickel.