Choosing rolled metal allows you to make strong and durable sashes with your own hands in a short time. At little expense, the owner receives a gate made of corrugated pipe on a rigid, stable frame. He can choose the material for lining the doors at his discretion.

We recommend that you read other articles:

- Standard garage door sizes

- How to make a garage door

Pros and cons of profile pipe as a material for gates

Gates made from corrugated pipe can be made from rolled steel of various sections - square, round, oval, rectangular. Galvanized, stainless or carbon steel is suitable for manufacturing; after installation, painting with special anti-corrosion primers and paint is recommended.

When choosing a pipe material, it is necessary to take into account the planned loads, for example, a profiled stainless steel pipe is more suitable for a lightweight structure, but galvanized or carbon pipe is used for massive swing and sliding structures.

You can also use the following types of professional pipes for assembly:

- welded hot-rolled pipe is intended for the manufacture of welded structures for which serious loads are not planned;

- welded cold-rolled pipe is used to make the frame of a gate or small sash;

- Seamless pipe is more reliable and of higher quality; it is used for constructing gates.

seamless

hot rolled

cold-rolled

The best option when selecting a material would be a hot-rolled pipe with an affordable cost and excellent performance properties. It is suitable for welding frames and frames of sliding and swing structures, and is used in the installation of automatic opening systems. Such a fence will look stylish and solid, meeting the necessary safety requirements.

Recommendations for choosing material

When planning to install gates from a profile pipe, you need to pay great attention to the selection of materials. Most often this is a corrugated pipe of square or rectangular cross-section; a round pipe is used for support columns.

The size of the profile pipe should not be less than 20x20 mm, but it is best to use a section of 25x25 mm; this option is used when installing jibs and joists. For frame assembly, a cross-section of at least 40 mm is recommended.

The raw materials for the manufacture of corrugated pipes can be the following - galvanized, stainless or carbon steel (can be any brand). At the same time, stainless steel grades are suitable for fastening decorative elements or structures with light loads. For gates with wood or metal cladding, it is recommended to choose galvanized welded corrugated pipes of the following types:

- Hot rolled . Such products are recommended, they are distinguished by an affordable price and excellent performance.

- Cold-rolled pipes provide high quality assembly, reliability and structural strength.

- Seamless corrugated pipes are the best option for making gates, but their cost is much higher than for welded ones. But such material is usually used for the installation of gates and gates of great height and with steel cladding, since such a structure requires a reinforced frame.

Preparing for construction: how to calculate the dimensions of the future structure

When constructing a gate from a profile pipe with or without a wicket, it is necessary to first draw up a drawing that will show the dimensions of the structure, the main parameters and location of the frame, stiffeners, hinges, locks, and cladding attachment points.

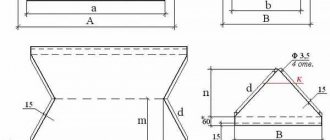

When drawing up a draft diagram of a rectangular gate with cladding made of corrugated board or wooden panel, you can use the following dimensions:

- the standard height of the structure, including the door leaf and the depth of the supports, is 3000 mm;

- the height of the sash will be 2000 mm;

- the supports are deepened by 1000 mm (it is necessary to create a sand-crushed stone cushion and pour concrete, the supports must be leveled using a building level);

- the total width of one canvas can be maximum 3600 mm (this is the optimal value that ensures strength and resistance to wind loads);

- for the manufacture of a rectangular frame, a profile pipe with a rectangular cross-section of 50 mm is used, the same pipe is used for horizontal and vertical logs;

- For diagonal jibs, a profile pipe with a cross-section of up to 25 mm is used.

If you need to perform calculations for automatic gates with a wicket, you can use the following values:

- two rectangular doors with a total width of 4000 mm and a height of 2000 mm (without taking into account the penetration of the supports into the ground);

- to make the frame, a pipe with a cross-section of approximately 40-20 mm will be used;

- the width of the gate should optimally be 900 mm;

- the supports (for swing gates) will be attached to pillars with a diameter of 76 mm and a height of 3000 mm (the pillars must be buried in the ground no less than 1000 mm).

Separately, the drawing indicates the fastening points of hinges, locks, and automatic opening/closing systems.

Pillar concreting technology

Concreting a metal support into a plastic pipe

To properly install the poles, you should choose the best option for fixing them in the ground. It is recommended to take into account the composition of the soil. For sandy and dense soils, supporting elements should be concreted. The racks are screwed into prepared wells or using the driving method.

The concreting procedure takes place in several stages:

- Prepare a hole for the foundation Ø 15-20 cm using a manual or mechanical drill. Make a recess of 0.7-1.5 meters. The exact parameter depends on the composition of the soil and the height of the fence. The higher the fence, the deeper the hole.

- Place the pole in a vertical position - the area around it needs to be concreted. The mixture should be compacted as it is poured.

Their corrugated fences are reliable and affordable structures. The best option for poles is metal products. This is due to its light weight, attractive appearance and the possibility of self-installation.

Tools required for work

For installation you will need the following set of tools:

- inverter welding machine (with power from 220 W);

- level, plumb line (necessary for setting the verticality of the supports);

- screwdriver (necessary for fastening the sheet to the frame, you can additionally use a riveting machine with steel rivets);

- grinder for cutting profile pipes and cleaning welds;

- metal scissors (used for cutting corrugated sheets, for other sheathing materials you can use a saw or jigsaw);

- shovel, hand drill for digging holes for supports.

The installation kit will include the following:

- corrugated sheet or any other material for covering the sash (the dimensions of the sash and gate are calculated in advance, they must take into account the presence of supporting pillars and frame);

- profile pipes (for support pillars square pipes with a cross-section of 80x80 or 60x60 mm are used, for the frame - 40x40 mm, for reinforcing joists - 20x20 mm);

- a set of self-tapping screws (you can additionally use steel rivets if the calculated wind loads are large);

- handles, locks, hinges;

- primer, paint to protect the supports and frame and welds from corrosion.

If cladding in the form of steel sheets, wooden panels or forging elements will be used for the gate, profile pipes must be taken with a large cross-section - up to 100x100 mm, and for the frame - up to 50x50 mm. In this case, the cross-section of the jumpers will be 25x25 mm, this will be enough to assemble a strong, durable structure that is resistant to wind and snow loads.

When assembling the frame using welding you will need:

- welding inverter;

- set of electrodes;

- Bulgarian;

- corner, tape measure and level;

- wheel attachment for grinding welds;

- mask, gloves for protection during work;

- brushes and rollers for surface treatment after welding.

Using the welded fastening method requires certain work skills. It is very important to immediately prepare personal protective equipment in the form of a mask and welding gloves.

Welding frames of sashes

It is better to carry out the process on a flat area - ideally you need a welding table; if you don’t have one, just a flat area or the floor of an empty garage will do. To get an ideal quadrangle frame, we put the pipes together, measure and cut the corners at 45 degrees, compare the diagonals, they should be the same. We “grab” the corners by welding, and again double-check the diagonals and corners. If there are errors, lightly tapping the problem areas with a hammer, correct them and apply seams to the welded joints.

How to weld swing gates yourself

Typically, 2 mm electrodes are used at a current of 50-60 A. The electrode must be kept a couple of mm from the metal and directed towards you with a slight deviation of about 10 degrees vertically. The seam is placed across the joint. Next, the scale is removed and grinding is carried out. Since the gate is metal and therefore heavy, it is necessary to increase the rigidity. To do this, we weld crossbars to the middle parts of the frames, the length is slightly less than the width of the sash, about 40 mm. Steel heads are additionally welded to the lower and upper ends. At the end of the work, the frame is sanded and painted.

Loops

We weld the hinges to the support posts, first once again correlating the locations with the drawing and the gate (we attach the doors to the posts), then onto the gate. The reliability of the doors will depend on the quality of hinge welding.

The final

We put all the parts together, clean them from rust, and treat them with an anti-corrosion compound (you can buy it at any hardware store).

Sheathing

The gates can be sheathed with any materials, most often wood, galvanized iron sheets or corrugated sheets are used. It is carefully laid on the frame and secured with rivets or self-tapping screws in the place where the “wave” deepens. The number of fastening points should not exceed 6 fastenings per 1 square meter. If the hinges are on the side of the sheathing, we cut grooves in the canvas.

Final processing

If wood is used, it must first be treated with an antiseptic against insects and varnished. Corrugated sheeting can be additionally treated with polymer. We carry out priming and painting.

Step-by-step instructions for making a gate from a profile pipe with your own hands

Manufacturing durable gates from a profile pipe requires the following steps:

- You should first take measurements and prepare a drawing indicating the dimensions of the gate;

- materials are purchased, equipment and tools are prepared for the work;

- preparatory work is being carried out, supports are being installed;

- the frame is assembled, which is then sheathed using the selected material;

- installation of hinges, locks and other fittings is carried out, as well as installation of automation, if required.

When calculating the structure, it is necessary to take into account that the optimal length of one leaf should be 3 meters; if the passage opening is larger, then it is better to divide the structure into two leaves, for example, with an opening width of 4 m, the leaves can have dimensions of 2 meters each. In the second case, you can also install one three-meter sash and a gate with a width of about one meter (the minimum width of the gate can be from 75 centimeters). When making calculations, it is also necessary to take into account the space required for installing support pillars.

Calculation of parameters for an already installed fence must be determined as follows:

- the height of gates and gates should be similar to the height of the general fence, but in some situations the height may be reduced by 20-40 cm;

- The width of the gate should be determined by the distance between the two support posts on which the frame is supposed to be generally attached.

Based on the selected dimensions, a drawing is drawn up, after which the number of pipes for the frame, jibs and support pillars is calculated.

Welded construction: how to weld gates correctly

When deciding how to properly weld a gate, you must first draw up an assembly diagram:

- before manufacturing the frame, it is necessary to cut the corrugated pipes into components of the length specified in the drawing;

- Clean the prepared elements from rust, sand the edges;

- carry out preparatory work - holes are dug in predetermined places for installing gate supports;

- the pillars are mounted in prepared holes on a sand and gravel cushion and filled with concrete (you must immediately check the verticality of the supports and install supporting supports while they harden).

Do-it-yourself welded gates and wicket doors are assembled using a common frame, that is, the structure turns out to be one. It is very important to strengthen the corners of the frame in order to give it the necessary rigidity and resistance to snow and wind loads. When assembling, you need to use a construction square and a level, this will make it possible to avoid distortions and inaccuracies.

Welding is carried out for frame elements installed horizontally; it is best to do this in the yard, having first cleared the area. For protection, gloves and a welder’s mask must be used; if there is no experience in carrying out such work at all, it is recommended to order this stage from specialists.

After completing the welding work, the surface of the metal and welds is cleaned of scale. Next, the seams must be treated with a special primer that protects the metal from corrosion and other negative external factors. This will significantly extend the service life of the gate and visually make the structure attractive.

The next step is covering the frame with the selected material, welding hinges to the posts and frame, and installing the rest of the fittings, including automation.

Video: how to cook gates

Threaded version

During assembly, the metal pipe gate frame can be secured using a threaded connection. This option is very simple, you can easily do it yourself:

- frame elements are laid out on a horizontal surface;

- in accordance with the drawn up diagram, the pipe is cut, after which fastening is performed using bolts (for this, a number of technological holes must first be made in the pipe);

- After assembling the main frame, it is necessary to perform decorative cladding, install locks, hinges, a latch, and, if necessary, install automation.

The procedure for calculating fence posts

The number of pillars is determined by the distance between the supports and the length of the section.

Carrying out calculations reduces work time and the cost of materials. If the horizontal girders are not connected clearly, the entire structure loses strength. The number of pillars determines the reliability of the fence, so additional stiffeners should be installed.

The calculation of materials is carried out according to the formula: divide the area of the land by the distance between the posts, including the cross section.

For a rectangular type, a gap of 2-3 meters is taken, for a round diameter - 2-2.5 m. The greater the weight of the structure, the smaller the distance. Fences made of chain-link mesh and corrugated sheets require a length between elements of ~5 meters.

Decorating Tips

When assembling gates from a profile pipe, you can use various auxiliary materials and decorative elements. The most commonly used options are:

- corrugated sheeting with galvanized or polymer coating;

- the use of forged elements for complete finishing or as auxiliary decorative elements;

- wooden cladding (in the form of boards or panels, can be used as combined inserts);

- the use of inserts in the form of a mesh (galvanized or polymer-coated);

- metal sheets;

- finishing using polycarbonate sheets (translucent or opaque, you can choose any color).

Application of profiled sheets

Profiled sheets can be used not only for making fencing, but also for sewing gate leaves. This is an inexpensive and very attractive option; installation is easy to do yourself. For work you can use the following types of corrugated sheets:

- with a galvanized surface (used primarily for industrial areas, warehouses, car parks, and utility areas);

- with one colored side, the second is painted in a simple gray color;

- double-sided painting (various types of polymer paint are used for decorative finishing; its choice is made depending on operating conditions and climatic region).

For installation, the following steps must be observed:

- a frame is assembled from a profile pipe (by welding or bolting);

- the corrugated sheet of the selected type is laid out on a flat horizontal surface, cut (for cutting, only metal scissors are used, a grinder cannot be used);

- a steel profiled sheet is attached to the frame using bolts or steel rivets (the first option is used for large-area sashes; rivets can also be used for additional fixation).

Forging decoration

One of the most attractive finishing options is the use of forging elements. For gates, you can order ready-made decor or make it yourself, but in this case certain experience and equipment are required. Forging can be attached to the frame by welding or bolts, it can be combined with polycarbonate or wooden inserts, and painted in various colors.

forged

Wrought iron gates can become a real work of art; they harmonize with any landscape design, while providing high performance in protecting the site from illegal entry. Such sashes can be blind or visible, it all depends on the chosen design, complexity and other factors.

Wood finishing

One of the most attractive options for cladding is wood. For finishing you can use the following options:

- finishing with planed boards, which are attached to the frame diagonally, vertically or horizontally;

- continuous or double cladding, with alternating boards (provides ventilation of the area, blocking the possibility of viewing);

- plank cladding, which can be made in various styles - classic or antique, using forged hinges and locks.

planed

solid

plank

To fasten wooden sheathing, you can use steel rivets or bolts; this option is one of the most reliable, but requires regular maintenance. The surface of the wood should first be cleaned, wood dust removed, and treated with antiseptics and fire retardants. After the material has dried, the board is covered with a layer of a special primer, painted or impregnated with oils that protect against negative external factors. With proper care, a wooden door will last for many years, delighting you with a stylish appearance and excellent strength characteristics.

Using a Grid

The use of steel mesh is a budget option; the cost of the device is low, but the structural strength is high. For lining, the frame is first assembled, after which the mesh is welded to it. Depending on the requirements for appearance, the gate can be made in the following options:

- a conventional rectangular structure in the form of a frame, which is completely covered with chain-link mesh with galvanization or a polymer colored layer;

- mesh inserts that are combined with solid or through elements;

- decorative mesh insert, which is combined with forging elements.

Metal lining

For gates, you can use various cladding options; the choice of material depends entirely on the operating characteristics and requirements for the appearance of the structure. If there are high requirements for reliability and safety, cladding in the form of steel sheets can be used. The weight of such doors is quite large, which affects the opening method.

Metal lining is usually recommended only for sliding structures, which allows optimizing installation and operating costs - the sliding system makes it easier to open and close the panel, extending the service life of the structure. Metal cladding is not always suitable for swing gates, as it requires the installation of reinforced hinges and locks.

Metal sheets need regular maintenance - steel needs to be protected from corrosion, for which special primers and anti-corrosion primers and metal paints are used.

Polycarbonate sheathing

One of the door finishing options is polycarbonate cladding. Most often, this is a combined design using forged elements, a frame made of profiled pipes and sheathing made of translucent or opaque polycarbonate sheet. To complete the work, the following steps must be observed:

- the finished frame is cleaned, covered with a layer of anti-corrosion primer, and then painted (it is best to use a spray gun and special metal paints for this);

- while the frame is drying, it is necessary to cut the polycarbonate, for which the sheet is carefully laid out on a horizontal surface (the protective film is removed only after installation is completed);

- markings are made on the surface of the sheet using a simple pencil, and the area of the sheet should be sufficient to attach the edge to the profile pipe;

- for fastening, bolts with silicone or rubber gaskets are used, which protect the material from damage;

- After completing the work, the gate leaves are attached to the supports, and the protective film is removed from the front surface of the polycarbonate.

Types of structures

Depending on the manufacturing technology, gates are divided into welded and modular.

Welded entrance structures can be considered the most reliable and least expensive options. In this case, the gate sections are mounted, adjusted and connected directly during installation. Welding work in this case is perhaps the only difficult moment.

Welded construction option

Experts advise that to lighten the load on supports and welds, pipes that act as lags should have a smaller cross-section.

The second option for gates is prefabricated structures. They are assembled from individual parts right on site. No welding work is required for this fence. The fence and fence sections are secured with special clamps.

Modular design option

Various models and design solutions on the market make it possible to build a very decent fence and gate for a summer cottage.