Despite the proliferation of power tools, hand tools are still necessary and have their uses. The advantages are obvious - no electricity or batteries are required for operation, hand tools are usually compact and lightweight. Such tools include a rasp. The construction portal Firststroy.ru will tell you what a rasp is, how to work with it, its types and recommendations for choosing a tool.

Wood rasp

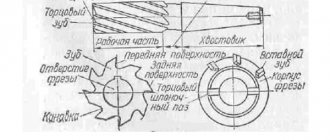

Despite advances in science and technology, wood is considered one of the most common materials today. Its processing can be carried out using a variety of tools, including a rasp. When considering what a rasp is, we note the following points:

- The most common design has a flat working part with a blunt nose. It is used to remove material from flat and other surfaces.

- The notch is made in large form. This ensures the formation of large chips, which are quite easy to remove from the surface. There is a special groove in front of each tooth, which simplifies the process of removing chips.

- The tool is divided into the main working part and handles. In some cases, the handle can be removed; a variety of materials are used in manufacturing.

In general, we can say that the rasp file is designed for rough work. After its application, finishing and other similar operations are also required. The degree of roughness of the treated surface is very high.

What is a file and why is it needed?

Structurally, a file is a very simple tool. It is a steel plate on which a notch is applied. The notch can have different depths and profiles, which determines the scope of application of the tool. During operation, it is held by a handle made of wood or various composite materials. A tool intended for rough (grinding) work may have two handles and externally resemble a familiar plane.

The purpose of the file is to remove a thin layer of wood, thereby leveling the surface of the workpiece and giving it the required shape. In principle, a grinding machine does all this, but it is extremely problematic to do delicate work with it.

Types of rasps

There are quite a large number of different types of such instruments. Classification is carried out according to various criteria, the most important being the type of working part:

- Flat rasps are much more common than other options and are usually included in standard sets. A similar working surface can be used for finishing flat surfaces; the tip can be tapered or straight.

- There is also a semicircular rasp. In most cases, a tool with a similar surface is used for processing semicircular workpieces. The degree of rounding of the main part of the product may vary significantly.

- To work with products that have an unusual shape, versions with a triangular or other complex cross-section are often used. The special shape allows material to be removed from corners and other complex geometries.

There is a roughing rasp with a different working surface, which is made using structural or tool steel. The type of alloy used largely determines the performance characteristics of the product.

What should a set of rasps consist of?

It is worth considering that for high-quality work, a whole set of rasps is required. The classic set is represented by a combination of the following options:

- Flat.

- Round.

- Semicircular.

Classification is also carried out according to the type of notches applied into two classes, only if both are available it is possible to carry out work with high accuracy. The semicircular rasp of the second number has more notches on the surface, which ensures higher efficiency in use.

Most often, a metal rod is made using steel grade U7, in some cases U8 and U10. By increasing the hardness and sharpness of the cutting edge, the degree of engagement with the surface being processed significantly increases at the time of processing.

Only two types of tools are produced abroad: regular and grooved. The teeth of such designs, as a rule, have standard sizes.

Subtleties of work

Finding out what a rasp is used for and learning how to work with it, you should gradually learn specialized subtleties that allow you to achieve much better results.

- Having already completed work on the part, it is necessary to ease the pressure on the rasp so that the work turns out softer and more delicate. The fact is that the pressure force affects the depth of the recesses left by the tool on the surface.

- When working with wood, wood dust always remains on the tool. It needs to be brushed off. It is also recommended to fan the surface being treated as often as possible. This way it will be much clearer how the work is going, what needs to be faked or corrected, where you can use the rasp one more time.

- If you have to work on a thin or too small area, it is better to take not an ordinary rasp, which is useless here, but a miniature corrugated one. With its help you can easily reach the most difficult places.

Brief characteristics of rasps

As previously noted, each type of rasp is characterized by its own specific properties. The most common version is a flat version, designed for processing concave surfaces. The key features are the following:

- The purpose is for rough processing of wood or various non-ferrous metals.

- Modern versions are equipped with comfortable handles, which are available in two materials. Often a special hole is created for hanging.

- The main working part is made of tool steel, the composition of which eliminates the possibility of severe wear.

The semicircular rasp is very common. It is also often equipped with an ergonomic two-component handle. This ensures the most comfortable conditions for convenient work. This shape of the working part makes it possible to process various round holes and remove unevenness in hard materials. Such tools are often used to perform almost all plumbing jobs.

The semicircular shape allows processing not only concave surfaces, but also flat ones.

The created handle is covered with a special coating, which eliminates the possibility of hands slipping. The working part is represented by a combination of a semicircular and flat surface.

A rasp cut is represented by a cutting edge that removes a layer of material from the surface. Do not forget that depending on the intensity of use, it can quickly wear out.

Types of files

The industry offers various types of this tool, most of which are universal and can be used with equal success for fine processing of wood and metal. The tools are classified according to the type of cutting part:

- with a single notch;

- with double cross notch;

- for wood with an arc notch;

- with rasp notch;

- stamped file.

Separately, it is worth noting a tool designed for delicate work with miniature parts. A wood file is the same file, but smaller in size, which makes it indispensable for making small crafts from wood and other soft materials. For the same purposes, a type of needle file is used - riffles. Their working part is curved, which significantly facilitates the production of small parts of complex shapes.

All files, regardless of their purpose, are classified according to the cross-section of the working part. The most popular tool is the following profile:

- flat (rectangular);

- square and round section;

- triangular;

- semicircular;

- rhombic.

The shape of the tool, size, depth and type of notch are selected depending on the type of work performed. The rougher the processing, the larger the notch should be and the larger its pitch. From this we can conclude that a home workshop should have not just one file, but a whole set of similar tools with different characteristics.

Areas of use

The product in question has become very widespread. In some cases, the rasp is used as an attachment, in others as a separate tool. The feature is as follows:

- Rough wood processing.

- Processing of metals of varying hardness.

As a rule, the product in question is found in locksmith shops and garages. Such a tool allows for preliminary surface treatment, removal of serious irregularities and various defects.

How to use a rasp correctly?

Only with proper use can you extend its service life and eliminate the possibility of serious defects. The small file in question can be used taking into account the recommendations below:

- In order to increase the convenience of work, the workpiece is secured in a vice or using a clamp.

- At the time of work, the elbows are located on the jaws of the vice, hold the handle with your right hand, and hold the end slightly with your left. Due to this distribution of effort, the efficiency of the work performed increases.

- To remove the required layer of material, you need to carry the product along the entire length of the working part. If certain unevenness is being leveled, a short stroke is performed.

- In most cases, a flat version of the tool is used. If the surface layer of wood is being removed, it is recommended to move the rasp diagonally relative to the grain. It is worth considering that after completing this stage, serious marks appear on the surface, which are removed during subsequent finishing.

- At the first stage, you need to press hard on the tool, as this significantly increases productivity. At the end of the procedure, it is recommended to reduce the pressure force, due to which a higher quality surface can be obtained.

In many ways, the principle of use of the product depends on the specific task at hand. Only after gaining the required experience can you obtain a high-quality surface by carrying out the appropriate processing.

Features of using the tool

Working with a file does not require special knowledge and skills, however, do not forget about attentiveness and caution. If you move incorrectly, you can ruin the workpiece; if you hesitate, you can get hurt. To make work convenient and safe, the workpiece must be clamped in a vice or secured with several clamps on a workbench.

With your right hand, take a file or rasp by the handle, and place your left hand on the edge of the work surface. They make reciprocating movements from themselves - towards themselves. In this case, the left hand presses lightly on the instrument. A good result is obtained by moving not perpendicular to the grain of the wood, but slightly at an angle.

The quality of work is constantly monitored; for this it is necessary to periodically sweep away the chips with a long-haired brush. Towards the completion of the work, the pressure on the tool is reduced. At the same time, you don’t need to try to get an ideal surface right away; most likely, in order to completely remove roughness, you will have to work with sandpaper.

Knowing how to use a file is a useful skill in all respects. This is not difficult to learn, you just need a little practice. Diligence and hard work will help you master this simple instrument, which will certainly come in handy more than once in life. It is only worth noting that you need to choose a quality tool, otherwise simple work can turn into real hard labor.

Tool care tips

Only with proper care of the tool can you significantly extend its service life. Among the features of care, we note the following:

- At the time of work, there is a possibility that the recesses and notches will become clogged with material. This is manifested by the fact that when performing movements, the proper layer of material is no longer removed from the surface, and the instrument begins to move without significant effort. Cleaning can be done by lightly hitting the surface. You need to be careful when doing this, as too much force can cause damage to the tool.

- If the notches become clogged with chips, it is possible to clean them using a standard brush.

- Before using the rasp directly, it is prohibited to place it on metal surfaces. Such long-term operation causes rapid wear of the cutting edge.

- Contact of the tool with various lubricants is not allowed. Even a small amount of such a substance can cause a significant reduction in the performance of the product.

Upon completion of work, you should check the condition of the tool. The appearance of minor defects indicates that the tool will have to be replaced in the near future, as it will lose its basic performance characteristics.

Handle sizes and shapes

The correct size and shape of the handles are important for convenience, high productivity and safety when working with a file. The length of the handle should be approximately 1.5 times longer than the shank. The file shank enters the handle to a depth of 2/3 to 3/4 of its length.

When placing the handle on the file shank, a distance of 10–20 mm is left between the shoulders of the heel and the ends of the handle, which is necessary in order to seat the file into the handle for a more durable fastening.

Handles for files are made from hard wood: birch, maple, beech, ash. The surface of the handles is made smooth and smoothly polished. To prevent the handle from splitting when the file settles and during operation, a steel ring is put on its end. The hole for the file shank is drilled or burned.

When inserting a file, its shank is inserted into the hole of the handle and with the right hand, with vertical strokes, hit the head of the handle on the workbench (Fig. 5, a) or, inserting the shank into the hole of the handle, lightly hit the head of the handle with a hammer (Fig. 5, b). To remove the file, take the handle in your left hand and apply two or three weak blows with a hammer to the upper edge of the ring (Fig. 5, c).

Rice. 5. Attaching and removing the file handle

The main differences between a rasp and a file

A rasp is a type of file. Features are as follows:

- The rasp is intended for rough processing; after its use, finishing files (with finer notches).

- Due to the large cutting edge, productivity is significantly increased. In other words, this tool takes much less time to remove material.

- If you pay attention to how the notches are located, the differences are almost immediately evident. In the case of a rough instrument, they look like large cells arranged in a checkerboard pattern.

- The product in question is designed to transmit high force. That is why the main part is more massive and is made using a thicker layer of material.

The file is characterized by the fact that it allows you to obtain a better quality surface in comparison with the case of using a rasp.

In most cases, the technological map provides for a combination of several similar tools, thereby increasing the productivity and quality of the resulting product. That is why the set is often represented by a combination of several types of products, which can have different shapes.

What is a rasp and where is it used?

In this article, the RMNT website will talk about such a popular hand tool as a rasp. Let's look at its features and scope of application, differences from a regular file, types, and also give advice on caring for this tool.

A rasp is a cutting tool that has not one blade, but many. The working part, in fact, is one sheet, but it has a large number of large and sharp notches and teeth. A rasp is a type of file. However, unlike this tool, the rasp has large teeth on the working blade, arranged in a checkerboard pattern.

The areas of application of the rasp and file also differ. The first is used exclusively for rough, rough processing. A simple file will not cope with this; its small notches will very quickly become clogged with debris and the tool will stop working.

The rasp does an excellent job if rough processing is needed:

- Wood of different species.

- Metal.

- Plastics.

- Rubbers.

- Skin.

- Soft rocks.

Important! There is a special type of rasp for working with sheets of drywall. It is also called a gypsum plaster planer; it is used to align the edges of cut sheets and strips, helping to slightly equalize their size.

The rasp works best for leveling the ends, edges, and holes of various products. In this case, the entire working surface is used, along its entire length. When working, the master’s hand should be protected by a reliable handle.

Accordingly, depending on the material that needs to be processed, rasps are divided into tools for metal, wood, and drywall. As the portal Rmnt.ru has already written, with the help of a special rasp you can make interesting garden figures from broken aerated concrete. This type of tool is called a sculpting tool and is designed for working with soft stones.

Important! There are such specialized types of rasps as shoe rasps, manicure rasps, pedicure rasps, rotary rasps, dental rasps, and so on. Of course, most of them will not find use in a home workshop, but shoe rasps are convenient for working with soft materials - leather and rubber.

According to their shape, rasps are divided into:

- Flat. With a sharp or blunt end. Used for working on concave surfaces and processing ends.

- Round and semicircular. Used for processing flat and uneven surfaces. Round rasps are convenient for processing holes; they are used for working on metal.

In addition, rasps differ in the number of triangular teeth per square centimeter:

- Large ones. There are from 8 to 12 teeth per centimeter of canvas.

- Average - from 12 to 20.

- And small ones - from 18 to 22 teeth.

The largest rasps are used for the roughest work; small ones can be used to process surfaces almost like a file.

Since rasps are different, for working with different materials, surfaces, for the roughest roughing and subsequent processing, it is best to purchase this tool as a set. One or two removable handles and several attachments that can be easily changed depending on the work being performed. Such sets, a set of three or four tools, cost around 500–1000 rubles. Popular rasps from manufacturers Intertool, Mastertool, Topex, Stanley.

Rasps made of carbon or alloy steel serve for a long time. According to advertisements on the Internet, you can still find for sale products made in the USSR.

When working with a rasp, it is important to fix the workpiece, apply serious efforts at the first stage in order to increase productivity, remove the top layer of wood diagonally relative to the grain, and also use a short stroke to correct a specific unevenness.

It is easy to care for the rasp - chips and other debris are removed from the surface with a regular or metal brush; while working, you can simply lightly tap the tool on a hard surface so that all excess falls off. The rasp should not be allowed to come into contact with lubricant or be wet as this will impair its performance.