The technology for constructing buildings on a metal frame came from industrial and commercial construction. Metal has higher thermal conductivity.

For this reason, the construction of houses on a metal frame has spread with the advent of thermal profiles and insulation. Today, metal structures are a competitor to wooden ones.

Metal frame of a residential building

Use of metal frames

Not only private houses on a metal frame are built using light steel thin-walled structures.

The construction of buildings with wide spans without additional supports makes it possible to use this technology in the construction of garages, hangars, production workshops, warehouse complexes, shopping pavilions, sports facilities, agricultural buildings for keeping poultry, small and large livestock. Economical prefabricated buildings are characterized by high strength, low weight and mobility. Recently, practical and convenient stairs on a metal frame have been installed in residential buildings and administrative buildings. Covered with plasterboard, wood or metal-plastic, they have no restrictions when choosing a shape and configuration.

Having experience in construction work, pouring the foundation and assembling a house from a metal frame with your own hands will not be difficult. And the external decoration and decoration of the rooms of a self-built home will bring great pleasure.

The welded frame of a metal building is a durable and strong internal skeleton of the structure. The advantages of such metal frame structures are lightness, strength, relative simplicity, high production and installation rates, mobility and independence from the access road to the installation site, and ease of integration into any space. The metal frame of the building is perfectly compatible with the simplest block and pile foundations, and is also easy to complete, configure and rebuild. The material of the metal frame of the building is profile pipe; angle and channel are less commonly used.

The metal frame of the building includes a lower frame, an upper frame and racks between them. In a metal frame it is very easy to provide doors, openings, windows and metal sheathing for the roof and floor. A frame building made of metal can be sheathed with corrugated sheets, wood, or sandwich panels. The metal frame is very easy and convenient to sheathe and insulate.

Metal frame for a building

Advantages of metal frame buildings:

- Buildings erected using metal frame technology are characterized by low cost (if compared with buildings constructed using traditional technology). The cost of the structure mainly depends on the materials used. The cheapest ones today are houses with wooden frames. The cost of houses with a frame made of profile pipes is much higher, and their price is directly proportional to the cross-section of the pipe. After all, for example, bending a profile pipe is a rather labor-intensive operation and is not cheap.

- High speed of construction of metal frame buildings. Using a profile for the frame as the main material can reduce the construction time of a building several times.

- The absence of so-called “wet” processes in the technology of constructing residential buildings using a frame (except for laying the foundation). This allows installation of frame buildings at any time of the year and regardless of weather conditions.

- Making metal structures with your own hands ensures the absence of any shrinkage - not only during construction, but also during operation of the structure.

The most suitable types of foundations

Before you start building a frame-panel house with your own hands, you need to decide on the type of foundation. Due to the lightness of such buildings, there is no need to construct a massive foundation, but in any case it must be reliable.

Construction of a columnar foundation with your own hands for a small frame house

The most economical is the base in the form of free-standing pillars with shallow depth. A small amount of material is required for its construction. The supports can be made either from ready-made blocks or using concrete. They should all be on the same level.

Example of a columnar base made of concrete blocks

The use of ready-made blocks greatly simplifies the construction process, which is why this option is the most popular. During construction, corner supports are first installed using a building level. To do this, holes are dug into which sand is poured for leveling. Then the intermediate posts are dug in.

Formwork for the production of free-standing supports from concrete mixture

If necessary, supports are made of concrete. With this option, holes are dug at the locations of the racks, formwork is made around each load-bearing point and the building composition is poured.

The process of constructing a strip base with shallow depth

A fairly rational solution is to install a strip foundation. You can avoid deep deepening, since frame buildings do not heavily load the soil. Typically, for such structures, a network of trenches is dug under load-bearing walls with a depth of 20 to 60 cm.

Scheme of a tape-type base with a slight recess

The construction process can be divided into the following stages:

- Carrying out excavation work related to excavation of soil around the perimeter of the building, as well as under load-bearing partitions.

- Installation of a sand cushion at the bottom of dug trenches.

- Construction of formwork to create the basement part of the foundation.

- Manufacturing and installation of a metal frame from reinforcement to increase the strength properties of the base.

- Pouring concrete composition inside the formwork.

Strip foundation for medium-sized buildings

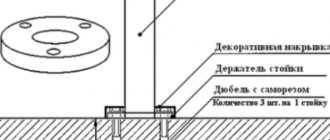

Foundation construction using metal piles

In this situation, metal rods with a special plate act as supports. Most often they are simply screwed into the ground to a certain level. Their underground part is usually buried at least 150 cm. The use of piles is especially important in relatively weak soil.

Type of mounted piles

What is a metal frame house made of?

The main element of LSTK is a thin-walled galvanized profile

, solid or perforated.

When properly calculated, a frame made of thin metal profiles becomes a reliable supporting structure. The galvanized profile does not oxidize, does not deform, or rot

.

The floor of any floor can withstand a load of up to 1000 kg. This indicator is comparable to the load-bearing capacity of a reinforced concrete slab. Layers of insulation dampen sound waves and vibration.

Some profiles are perforated to reduce heat transfer and avoid “cold bridges”

, do not allow the heat to escape. The thickness of the profile offered by the market ranges from 0.75-3 mm.

The frame made of profiles is insulated, the outside is laid with two layers of gypsum fiber, after which the outer cladding is attached.

The outside of metal frame buildings is finished with:

- siding, metal or vinyl;

- OSB, DSP boards, followed by finishing with plaster;

- metal profiled sheet;

- brickwork.

A vapor barrier film is laid on the side of the room and covered with interior finishing material. An air gap is left between the film and the fence

.

As a rule, gypsum plasterboard sheets are used for the inner surface of the wall, finishing with plasterboard sheets as desired.

For insulation, only non-flammable materials are used - mineral wool, extruded polystyrene foam

.

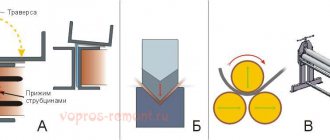

Wall and frame elements are assembled on mechanized assembly tables and delivered to the construction site in large-sized parts or individual posts, adjusted to the millimeter.

The thickness of the walls depends on the climatic region, varies between 150-300 mm

, the number of storeys is limited to six.

Types of steel profiles

For the manufacture of elements of lightweight thin-walled steel structures, durable structural steel is used. The product itself is made using the cold stamping method. To protect against corrosion, a zinc coating is applied to the metal sheet.

Metal structures are also made from hot-dip galvanized sheets. They are used less frequently due to their high cost, but are much more durable in use.

To produce the profile, a sheet of steel from 0.7 to 2 mm is taken. The choice of thickness is influenced by the required load-bearing capacity of the structural element.

The following types of profiles are used:

- guides,

- rack-mounted,

- hats

Types and types of profiles for building a house frameSource nastroike.com

Special beams are also used to cover the floor and shelf. The rafter system of the building consists of the same elements. All elements of the metal frame structure are connected using bolts, rivets, and self-tapping screws. In some cases, resistance welding is used.

Frame assembly

Parts manufactured at the factory with extreme precision are marked in accordance with the “skeleton” assembly diagram. The construction of a house from a metal frame is facilitated by the fact that each element and hole strictly corresponds to the approved project. To assemble a durable building frame, you don’t need any special skills or complex tools: you don’t need to measure, cut, or adjust anything.

Low-rise private metal-frame houses are usually assembled by a team of 3-5 people. Transverse frames are assembled using bolted connections from vertical posts and horizontal crossbars, which are installed on the foundation. The design strength of the structure is given by ties and braces attached to the frames. Then the wall and roof purlins, frames for doors and windows are installed. The assembled supporting frame is filled with insulation and lined.

The cost of 1 m2 in a multi-storey metal frame building is reduced by approximately 20-30%, and the speed of construction of a residential building is 3 times faster. The construction of houses made of metal frames with high heat-saving indicators makes it possible to use economical LGST technology in the cold regions of the Far North.

What is a metal profile building?

Metal profiles (LSTC) for frame prefabricated houses were once used in Russia more for industrial, utility, and technical buildings.

It was rarely seen in private housing construction, since the cost of heating a home exceeded normal amounts - the metal has high thermal conductivity. But with the development of technology and closer acquaintance with this type of frames, the situation has changed noticeably.

The principle of a house on steel enclosing structures is standard: the structure is assembled on a load-bearing hollow frame made of profiles fastened together . A solid, strong, stable structure is formed, onto which the main wall materials with layers of insulation and waterproofing are attached.

LSTK began to be used in Canada starting in the 1950s. Over time, special thermal profiles were invented. The combination of these technologies and effective insulation materials completely solved the problem of heat retention and some other disadvantages.

Housing made of steel profiles is extremely common in the USA and Japan due to low labor costs and the absence of the need for complex equipment and special equipment.

Construction of a metal frame for the construction of a garage

When creating metal structures using your own hands, you need to take into account that this structure must be very rigid, durable and stable. The material for the frame can be a large section corner. It is better to fasten the frame elements by welding, but you can also use a nut-and-bolt connection by drilling holes for fasteners with a hammer drill.

The assembly of the metal frame must be carried out on the construction site. First, the lower frame is mounted, which is attached at the corners to the pins protruding from the foundation - this ensures its immobility. Then corner posts are installed, connected at the top by ceiling purlins.

Vertical posts are installed along the back and side walls of the metal structure made by hand, which will ensure the rigidity of the structure and will serve as lathing for installing wall cladding. There should be a distance between the racks equal to the width of the sheathing sheet, or be slightly less by 3-5 cm if installation with overlap is provided.

The cost of building a turnkey house from light steel thin-walled structures includes a budget for the frame, a set of finishing and other materials, as well as a fee for installation work. This technology is characterized by short implementation times, as well as a favorable price for finished projects.

A residential building using LSTK technology is built according to the following principle:

- Design.

- Laying the foundation.

- Assembly and installation of wall panels.

- Assembly and installation of roof trusses.

- Roofing.

- Arrangement of communications.

- Interior and exterior finishing works.

At the design stage, the main attention is paid to calculating the rigidity and strength of the supporting frame. The foundation for a lightweight LSTC building can be absolutely anything.

Wall panels and roof trusses are assembled from ready-made perforated profiles manufactured in production from galvanized steel. To cover the roof, traditional materials are used - corrugated sheets, metal tiles, etc.

The basis of the wall pie is insulation. From the outside it is covered with wind protection and facade cladding, from the inside - with a vapor barrier, plasterboard and finishing.

Advantages and disadvantages

Any private house based on a metal frame has the following undeniable advantages:

- the total weight of the mounted structures is much less than that of a brick or log building of the same area and volume. A lower load allows for a cheaper foundation;

- the house is actually manufactured in a factory where metal elements are cut to the required length. At the site you just need to assemble it according to the instructions. Two to four people can handle this;

- speed of construction. In a few weeks, you can not only assemble the frame, but also form a wall pie, cover the roof and sheathe the outside of the walls.

Construction using LSTK frame technology has one significant drawback - this is the requirement for private developers to strictly comply with all construction algorithms.

Also, metal frames need a large number of stiffeners to withstand the same wind loads.

The wall metal profile fully meets the requirements of SNiP from a safety point of view. However, many believe that houses with an entirely wooden frame are more environmentally friendly, although a noticeable difference is observed only in sound insulation, since metal is more permeable to all kinds of vibrations.

Simple foundation of a frame house

Metal frame houses

Metal frame construction has been used in construction before. This construction method was used in the construction of industrial buildings: workshops, farms, greenhouses, warehouses and hangars.

After modernization of technology, frames made of profile pipes are used for the construction of public and commercial buildings (cafes, shops, gas stations), cottages and low-rise residential buildings. Technologies are used in the reconstruction and repair of buildings - the construction of wings and attics, the addition of floors.

Advantages of frame construction

The whole world uses metal frame technology in construction. In the USA, Western Europe and Japan, 70% of residential buildings were built using this method. The technology has enough advantages to make it your choice when planning to build your own home.

Minimum labor costs are the main advantage of metal frame construction

- The first advantage of building a frame house from a profile pipe with your own hands is its low cost. Traditional technologies are more expensive. The price of the structure will directly depend on the materials you are going to use. The cost of the frame depends on the cross-section of the pipes, and the cross-section is selected depending on the scale of the construction. For example, if you need to assemble a staircase frame from a profile pipe (section 60x40 mm), the material will be cheaper than for the frame of a house, where the cross-section is much larger. Also, one-story houses are built from smaller diameter pipes than two-story houses.

- The next plus is speed. The use of profile pipes as a frame will reduce the construction time of the building several times.

- Frame technology does not provide for “wet” processes, so weather conditions do not affect construction. The exception is laying the foundation. But often the base is assembled without a foundation. For example, if you are building the frame of a greenhouse or temporary shed from a profile pipe.

- There is no shrinkage in buildings constructed using frame technology. During construction and operation, the building does not change its shape and does not crack. This is another plus.

The main advantage is lower labor costs compared to traditional technologies. To build a house, you only need a couple of helpers and a month's vacation. During this time, you will have time to complete the main stages of construction and leave the interior work until your next vacation. A garage frame made from a profile pipe can be built with your own hands in a week.

Disadvantages of metal frame houses

When starting construction, weigh the pros and cons of frame buildings. The technology has many advantages, but there are also disadvantages. The main disadvantage is the complex design. Calculating the load on a profile pipe in frame nodes is not as simple as it seems at first glance. If you can't do this yourself, contact a professional. It will help calculate the permissible load per meter of pipe. When choosing the cross-section and thickness of a pipe, use the online profile pipe calculator.

Another disadvantage is the cost. Compared to wooden beams, metal material is more expensive. When purchasing pipes, people are faced with the problem of choosing: buy cheaper and save money, or choose a thicker pipe and ensure durability for many years. Here everyone judges based on their budget, but it’s better not to save money. Especially if this is a house, and not a frame for a garage made of a profile pipe.

It is difficult to insulate such houses - this is also a minus. Problems with thermal insulation arise because the metal frame allows cold to enter the building. In such rooms the air quickly cools down, even despite intense heating. Therefore, the building must be insulated efficiently: inside and out. This means you will have to spend extra money.

The metal frame facilitates the entry of cold into the building

diverse possibilities of modular houses

Metal modules are most often chosen for areas with aggressive climates. Wind gusts and precipitation cannot be compensated by the standard construction of an ordinary house. A base made of strong and durable metal protects the interior of the house from possible negative factors, creating a feeling of privacy and security.

In order not to lose touch with the natural environment, the architects made an attractive maneuver by using continuous glazing of the front façade on the north side. The back side is lined with wooden boards. The color scheme of the finishing materials looks harmonious, because the wooden beams have an unnatural greenish tint. Thus, the exterior merges with the landscape, masquerading as the beauty of the surrounding area.

In conditions of strict modulation, the owners of such a shelter do not have many layout options. The corner section houses the bedroom and bathroom, while the central section is reserved for a small kitchen and living room. Thanks to the compact distribution of living space and choice of furniture, residents can move freely around the room.

An additional advantage is the presence of a balcony with wooden flooring. The minimalist design style is maintained inside and outside the building. The black and brown color scheme of the interior smoothly transitions into the exterior in the form of metal railings and natural wood texture. The straight lines of the structure become an allegory to the natural environment, complementing its curved forms and constant intertwining of plants, trees, and hills.

The fact remains indisputable that a metal modular house is a modern, practical, rational solution for organizing living space. Designers are only increasing the popularity of such housing by presenting different interpretations of interior and exterior design.

| Architects | Bruno Zaitter arquiteto |

| Photo | Sergio Mendonça Jr. |

The procedure for assembling an iron frame, features

Rolled waterproofing in two layers is laid on the mastic over the finished foundation. Installation of a LSTC frame house occurs in the following sequence:

- laying the lower binding profile;

- installation of wall studs, from the corner, controlling the verticality of the elements;

- installation of intermediate racks;

- overlapping fastening of the upper guide profiles;

- construction of a rafter system;

- laying electrical wiring and utility networks;

- installation of facing materials with parallel insulation.

The strapping profile is attached to the foundation with anchors, the remaining joints are connected with self-tapping screws.

Special requirements are imposed on the electrical safety of the building.

. Wiring and disassembly points are carried out in strict accordance with the project. The rules for making connections, the grounding circuit, the power of automatic fuses and their number are strictly observed.

Important! The roof circuit must be grounded and a lightning rod installed

optimal location and linear configuration of metal frame construction

The facility is located away from the noise of the city and highways. The nearest neighbors and the country road are hundreds of meters away - the windows offer views of natural landscapes in any direction. The architects chose to make the metal frame house as open as possible, without hiding the landscapes behind the fence. In one direction there is a panorama of the lake, in the other - of the garden.

At the same time, the site is localized from views from nearby areas with the help of green spaces - trees, shrubs. And modern security systems make it protected even in open conditions.

The linear configuration provides direct access to the local area from any room in the building. There is a close connection between the external and internal space, a smooth transition between them.

Construction cost

MANUFACTURE AND INSTALLATION OF METAL STRUCTURES

- Manufacturing of metal structures from RUB 50,000/t

- Manufacturing of a metal building frame from RUB 2,100/m2

- Installation of the building frame from RUB 12,500/ton

CONSTRUCTION OF RAPIDLY CONSTRUCTED BUILDINGS ON TURNKEY

Manufacturing, delivery and installation of a complete building set including foundation work from RUB 6,700/m2

MONOLITHIC WORKS

- Floor slab (Concrete class B20 / Reinforcement 40kg/m3) 10,000 rub./m3

- Walls (Concrete class B25 / Reinforcement 80kg/m3) 17,000 rub./m3

- Columns (Concrete class B25 / Reinforcement 120 kg/m3) 20,000 rub./m 3

- Floor slabs (Concrete class B25 / Reinforcement 120 kg/m3) 17,000 rub./m 3

CONSTRUCTION OF RESIDENTIAL HOUSES AND COMMERCIAL BUILDINGS FROM FOAM BLOCKS ON A TURNKEY basis

Turnkey construction of residential buildings and commercial buildings with foam blocks starting from RUB 20,000/m2

DESIGN AND SURVEY

- Draft design from 600 rub./m2

- Design documentation for construction from 700 rub./m2

- Project documentation for reconstruction from 600 rub./m2

- Inspection of building structures with a conclusion from 900 rubles/m2

RECONSTRUCTION

- Comprehensive reconstruction from

12,500 rub./m2 - Facade work from 700 rub./m2

- Redevelopment of premises from 3500 rub./m2

NETWORK ENGINEERING

- Water supply and sewerage 850 rub./m2

- Heating 850 RUR/m2

- Ventilation 850 rub./m2

- Electricity supply 850 rub./m2

- Low-current networks (SCS) 550 rub./m 2

GENERAL CONTRACTING

The cost of services under a general contract is from 3% to 9%

For more detailed information, depending on the chosen project and the scope of work, please contact the managers or directly visit our company.

Cost of welding works of metal structures

The cost of welding work on metal structures depends on the weight of the product in tons. The cost of welded metal structures includes not only the depreciation coefficient of the equipment, but also the types of welding used, including argon welding, electric and gas welding.

Prices for installation of metal structures

We have mastered high-quality production and installation of metal structures in Moscow at prices that the customer can study on our website or call our specialists at the specified telephone number.

Prices for building metal structures

It is efficient and profitable to manufacture structures at MK Monteco, because all calculations are carried out by us on the basis of the design, and they are technologically justified. If you have any questions, please contact the company’s specialists and clarify the cost and prices depending on the characteristics of your specific project.

Cost of structures made of metal structures

The cost of structures made of structures, including premises, shops, car service stations made of metal structures, frame pavilions, workshops and warehouses made of metal structures, as well as prices for these and other objects, are formed taking into account a number of basic and additional factors.

Price for a metal structure frame

We have mastered high-quality construction of framed objects. The cost of the metal structure frame is lower due to the accuracy of the calculation. If the customer needs to find out more detailed information, our company offers to call and get advice from specialists.

Metal galvanizing

provides services for hot and cold galvanizing (galvanizing) of metal and metal structures at a competitive cost and price in Moscow. We also carry out hot and cold galvanizing of metal, which can be purchased from us to order.

Making and erecting a frame with your own hands

Independent construction of a frame from a profile is possible if you have assistants, welding skills and financial resources. Major work can be completed during a month's vacation.

The whole process is divided into the following stages.

- Determining the concept of the future home, calculating the required amount of materials.

- Project development.

- Purchase of materials and tools.

- Creating a foundation.

- Installation of the frame.

- Installation of floors and roofs.

- Finishing and insulation works.

Development of a metal frame house project

Typical projects based on LSTC technology have been standardized; all that remains is to choose the best option with the required climatic characteristics.

An individual house project is carried out by the manufacturer

. The first stage will be the creation of technical specifications for the project. The technical specifications determine the desired size of the building in the axes, number of storeys, layout features, main and finishing materials of the building.

In places where wall-mounted furniture and hanging cabinets are attached, reinforcement of the wall rigidity with additional profiles is provided in advance.

On average, calculation of a private house project takes 2-5 working days

. Miscalculations, errors, disproportionality, inconsistency of parts must be eliminated in a factory manner. Sometimes on forums the characteristic clicking sound of the frame when heated is discussed.

note

Profile cracking in the sun is possible only due to errors in installation, trimming of the profile, or installation of additional holes.

Properly mounted, unmodified profiles do not produce sounds.

LSTK technology

As in a classic wooden frame, in a house made of LSTK, a prefabricated post-and-beam frame is used as the basis of the enclosing structures. Frame elements are prefabricated from galvanized rolled steel, first class galvanizing (275 g/m²), 1-2 mm thick. To reduce thermal conductivity and increase thermal resistance, manufacturers produce galvanized thermal profiles - with a minimum cross-section and through slot perforation.

The use of a thermal profile helps reduce thermal conductivity, but does not eliminate the need for insulation and insulation of the frame. If we are talking about a seasonal dacha, you can get by with a regular profile without perforation.

tdkFORUMHOUSE Member

A metal frame for living not only in summer, but also in winter, always needs to be “wrapped” and it doesn’t matter whether it has marketing “perforations” or is solid. I have a country house, so “the economy should be economical”!

A house kit for a private house is manufactured according to a standard or individual design; it can be ordered either externally or from the manufacturing company. A more labor-intensive, but less expensive option is to develop a project yourself for the LSTK profile; fortunately, there are enough special programs and calculators for calculating the load-bearing capacity.

Zhenya_83 FORUMHOUSE Member

I’ve been living in a house made of LSTK for six months now – the flight is amazing! The house is 15x27 m, one floor, height at the ridge 7 m, ceilings more than 3.5 m. I did the project myself. I hired people for assembly, but was present at the construction site every day and controlled everything.

Assembly order

All material comes from the factory packaged in bundles. Each part is marked, the same marking is present on the working drawings. The frame of the LSTK house is assembled like a constructor: everything is already ready, even the holes for the hardware are stamped. Put the parts in place, align the grooves and install the fasteners. A metal frame house is assembled in exactly the same way as from wooden blocks. If we outline the stages briefly, step by step everything looks like this:

- The lower frame is fixed to the finished foundation.

- Corner posts are positioned and secured.

- Intermediate posts, jibs and spacers are installed between them.

- The top trim is installed.

- Floor beams are installed and secured. If there is a second floor, its frame is assembled.

- The ceiling is being installed.

The frame of the steel house is ready. All that remains is insulation and finishing work. One note: no matter how much you want to save money, the sheathing should also be assembled from metal. Identical expansion coefficients are precisely what contributes to the high strength of such structures. This cannot be achieved when connecting metal and wood: the fastenings gradually weaken. This is especially critical in regions with increased seismic activity. But even in calmer regions there is little joy in the rattling finish.

Can you build it yourself?

If we are talking about assembling parts that came from the factory into one design, then it’s easy, but with help. All the work consists of finding the required part and installing it in the place indicated in the drawings. It’s difficult at first, but then you get the hang of it.

If by “building a metal frame house with your own hands” you mean welding it from a profile pipe, then this is an ambiguous matter. If you are planning to build a small country house, then there are no questions: the frame can be installed according to the same principle as a wooden one, and for a one-story building, 80 * 80 mm pipes are enough for the corner posts, and smaller ones can be used for intermediate ones. But the installation step is still dictated by the insulation: the clearance distance should be 58-59 cm (slightly less than the standard width of mineral wool).

Assembled skeleton of a house from a special galvanized profile

The only thing you need to remember: when using a profile pipe, there will definitely be cold bridges. Then the insulation itself will need to be done in several layers, blocking heat leaks, which will solve the problem. One layer is traditionally placed in the spacer between the posts. The cross-section of the profile pipe is far from 200-250 mm, which is necessary for insulating a house in the Moscow region (under mineral wool). Therefore, a transverse sheathing is installed under the missing layers (on one or both sides - decide for yourself). It turns out that the insulation is laid vertically between the racks, and horizontally along the sheathing. There are significantly fewer cold bridges.

On the room side, the insulation is covered with a vapor barrier membrane (it should not allow moisture to enter the insulation). From the street side, a windproof, vapor-permeable membrane with waterproofing properties is fixed to it. It performs three functions at once:

- protects from the wind,

- prevents condensation or sediment from accidentally getting into the insulation,

- removes steam from the insulation, which still penetrates there from the room (despite the vapor barrier).

Only with such a cake and the presence of a ventilation gap between the outer membrane and the finishing materials can you be sure that the insulation will not get wet. Only in order for the ventilation gap to work, ventilation holes are also needed at the bottom of the wall and a leak-proof exit under the roof from above: the air flow between the exterior finish of the metal-frame house and the windproof membrane must pass without encountering obstacles.

For inspiration, here’s a video of the process of welding a country house from a profile metal pipe. For those who know how to weld metal, making a metal frame house from a pipe with their own hands is not difficult.

Read about what else you can quickly build a house from here.

Peculiarities

Metal frame structures, originally used for the construction of warehouses and retail facilities, are now being used in private housing construction. The basis of a frame house made of metal profiles is made of light but durable structures made of galvanized steel. The thickness of the profiles is calculated individually for each section of the object and depends on the loads experienced. Steel profiles provide the structure with the necessary strength, zinc coating acts as anti-corrosion protection, guaranteeing the durability of the structure. In order to increase reliability, the profiles are supplemented with special stiffeners.

Profiles can have a cross-section in the form of various Latin letters (C, S and Z). Each of them is used on a particular construction site. For example, the base is laid out using C and U profiles connected with self-tapping screws. The pitch of the frame is determined by the width of the insulation and cladding panels used. On average, it is 60-100 cm. The profiles are perforated, which solves the problem of ventilation and increases the thermal insulation characteristics of the object.

They are assembled according to the principle of a children's construction set; the construction process itself does not involve the use of special equipment (except perhaps to create a foundation). Having minimal construction skills, you can assemble a house with your own hands with a small number of helpers (2-3 people). Due to the insignificant thickness of the walls of a frame house (on average 25-30 cm), it is possible to obtain a larger usable area than when using standard technologies (houses made of timber, brick, blocks).

At first glance, it seems that metal frame houses look unattractive and monotonous. However, this is absolutely not true, because due to the lightness of the structure and the ability to give it different configurations, it is possible to create objects of unusual shape. The structural features allow the use of most modern hanging materials for finishing external walls, which can be changed if necessary. If desired, the facade of a metal frame house can imitate stone and wooden surfaces, brickwork.

Cladding can be carried out immediately after the construction of the object, since the frame based on the metal profile does not shrink. The advantage is the high speed of work. Typically, a house for a small family can be built in 2-4 months. In this case, most of the time will be spent preparing the foundation and waiting until the poured concrete gains the necessary strength. There is a misconception among ordinary people about the instability of frame houses. However, this design can withstand significant wind loads and can even withstand seismic activity (its resistance is up to 9 points on the Richter scale).

Another “myth” about frame houses is related to its ability to attract electricity. From this point of view, frame objects are completely safe - all metal elements are grounded. In addition, the external and internal steel parts are treated with dielectrics. One of the disadvantages is the high thermal conductivity of the material. Therefore, it is impossible to do without high-quality insulation and protection of the metal from moisture vapor.

The use of ecowool or mineral wool insulation, as well as the installation of warm cladding panels, allows optimizing the thermal efficiency of a frame house and preventing the formation of cold bridges. Frame houses based on metal profiles cannot boast of durability. Their service life is 30-50 years. Although it is true that the repair of such structures is quite simple and does not require large investments.

The metal profile itself is characterized by fire resistance. However, the material is sheathed inside and outside with a variety of synthetic insulation, vapor barriers, and finishing materials. This can significantly reduce the fire safety of a frame house. The cost of building a frame house is much lower than the price of building a brick, wooden or even block analogue.

This is due to the smaller volume of required material, the possibility of using a lightweight foundation, and the lack of involvement of special equipment and professional builders. A frame house can be made according to an individual or standard design. Of course, the first option will be more expensive, but it will allow you to create exclusive housing that meets all the requirements of its owner.

Materials for mounting profile frames

In order to produce a strong and durable structure, we first study the metal frame assembly elements offered on the modern market. They consist of various types of profiles and fasteners.

Table of elements required for assembly and installation of a metal frame:

| Name | Definition | Comments |

| UD profile | guide | serves to determine the plane of the structure |

| CD profile | load-bearing, holds the weight of the manufactured structure | plasterboard sheets are attached to it |

| Connector-CD | straight | used to increase the length of the product |

| Connector-CD | cross-shaped (“crab”) | necessary to increase the strength of the product |

| Connector-CD | two-level | Connects the upper and lower load-bearing levels |

| bracket | U-shaped | attaches the CD profile to the wall |

| Teks | diameter 3.5mm and length 9.5mm | metal self-tapping screw (connects profiles to each other) |

| Self-tapping screw for metal | length 25 mm and diameter 3.5 mm | they are used to fasten drywall |

| Dowels | diameter 6 mm | connect the frame to the wall |

Notes:

Fastening materials for frame assembly

Required materials and tools

All types of metal profiles (also abbreviated LSTK) for house frames are made from structural steel using cold stamps. Each sheet is coated with a protective zinc coating to prevent corrosion. The thickness of the coating varies from 18 to 40 microns. The thicker the coating, the more expensive the profile, but also the higher its durability. The most expensive profiles are coated using hot-dip galvanizing.

The thickness of the sheet from which the profile is made is also different. The thinnest is 0.7 mm, the thickest is 2 mm. The thicker the steel, the higher the load-bearing capacity of the LSTK. However, as thickness increases, weight and cost also increase. Therefore, the thickness of the metal and the type of profile are calculated by specialists based on the loads that the frame will bear.

Today, light steel products come to the market from dozens of sources: foreign and domestic, small factories and large steel mills. It is difficult to recommend a specific manufacturer here. It is worth looking at the quality of the metal (no traces of rust, chipped coating, etc.)

There are several types of profiles:

They are also divided into subtypes depending on specific tasks:

It is impossible to determine which profile to install on each site without special knowledge. That is why it is better to entrust the drafting of a frame house to a specialist.

The set of tools may differ slightly, depending on which manufacturer the LSTK was ordered from. But almost always the profile kit is supplied with a screwdriver assembly in mind: everything is numbered, laid out in the appropriate order, and equipped with the appropriate fasteners.

Construction of a house on a frame made of profile pipes

Construction of a metal frame house

Despite their apparent simplicity, houses on a metal frame made of profile pipes have a rather complex design.

Its main elements are:

The foundation is lighter than in traditional construction, but still required.

- Interior decoration

. For interior decoration, the best option is to use tongue-and-groove boards 40-60 mm wide made of softwood. The board must be treated with antiseptics and antipyretics (substances that reduce the flammability of wood). - A board laid on top of joists from the same profile pipe is used as a subfloor

. Any profile covering can be laid on top of the subfloor. - Insulation

. A good option here would be to use extruded polystyrene foam 60-100 mm thick. The frame racks themselves, made from a profile pipe, can be additionally thermally insulated with strips of foam insulation. - Exterior finishing

. Here you can use facade plaster or siding, and if finances allow, then natural wood. - Roof made of profile pipe

. It can be manufactured both as a separate structure and as a frame element. The calculation of a profile pipe for the manufacture of roof rafters is made taking into account the planned roofing material: the lighter the roof, and the greater its angle, the thinner the pipe can be used.

Sequence of operations when building a house

Work on the construction of a frame house is carried out in the following sequence:

We start, as you would expect, with the foundation. For a house on a metal frame made of profile pipes, both a permanent concrete frame foundation and a non-permanent one (on platforms or screw piles) are suitable. A frame house on a non-permanent foundation is, in principle, transportable - so it can even be transported!

- After the foundation is laid, you can begin installing the frame

. If you use a factory-made frame for your home, then the task is greatly simplified: the assembly of finished frames, as a rule, is carried out without the use of welding, using screw connections. - If you decide to make the frame yourself, then you will have a much more difficult time. When installing such a frame, it is necessary not only to control the relative position of its elements, but also to carefully check the quality of their connections, because welded joints are the “Achilles heel” of the frame.

- The frame is mounted “from the bottom up”, with the main vertical elements

(racks and columns) first installed, which are then connected by horizontal elements made of thinner pipes, and reinforced with braces. - Lastly, the roofing part of the frame is installed

- at this stage, part of the team can begin insulation and finishing. - When the frame is mounted, you can begin interior decoration.

Many experts in the field of architecture are confident that metal frame technologies are the future. This means that it is quite possible that the skills that will allow you to independently build a house or garage from a profile pipe will be useful to you – both for yourself personally and as an additional profession!

Metal frame

A frame house made of metal profiles is a more reliable and durable structure. Such buildings will have a high level of sound and thermal insulation. It is worth noting that metal products have replaced wood, which has a number of disadvantages, including susceptibility to precipitation and rotting processes. In our article, we will look in more detail at the features of a metal profile and how to make it yourself.