Home |Blocks and floors |Overlap on metal beams

Date: January 22, 2018

Comments: 0

To install durable floors in buildings being constructed, builders use proven methods that involve the use of various building materials. An increased margin of safety is provided by profiles made of rolled steel. Floors constructed on their basis on metal beams ensure the reliability of the structures being erected and a long service life. They are superior to structures based on wooden beams in terms of performance and are able to withstand significant loads. Let's look at them in detail.

Structural options for flooring on metal beams

Based on a steel profile, you can make a durable floor using various options:

- The ceiling is monolithic on metal beams. It is formed by pouring concrete into the formwork, and is additionally reinforced with reinforcing mesh. This is a practice-tested option with a range of advantages. The main advantages that attract developers are the increased strength of the seamless surface and the absence of irregularities;

- monolithic prefabricated structure. For its arrangement, blocks of cellular concrete manufactured at industrial enterprises are used. They are laid with their edges on the surface of the steel profile. Thermally insulated formwork is constructed, reinforcement is made and the joint areas are filled with concrete mortar;

- composite structure made of various materials. Standard panels, wooden boards, and slabs can be used. The base elements are installed on load-bearing steel beams. To ensure comfortable operating conditions, it is important to insulate and soundproof the formed surface, as well as seal the gaps between the elements.

Depending on financial capabilities and availability of materials, developers equally use these options.

Particularly stringent requirements are imposed on the quality and strength of floors in a building of any design.

Materials and equipment used

Various types of rolled metal are used as load-bearing beams:

- I-beam number 16 or 20;

- channel up to 20 cm high;

- corner welded into a load-bearing frame.

To form the selected design option, in addition to load-bearing elements, the following materials will be required:

- concrete mixture to form a solid base;

- standard blocks made of cellular concrete for a prefabricated monolithic version;

- planed boards or ready-made concrete panels for a composite structure.

For reinforcement, reinforcing bars are used, the diameter of which corresponds to the results of the calculations performed.

The construction of formwork will require the use of the following building materials:

- wooden panels or moisture-resistant plywood with a thickness of 2 cm or more;

- polyethylene film for waterproofing concrete mass;

- supports made of metal or wood to ensure the stability of the formwork.

For different types of houses, they use both metal and wooden beams, as well as reinforced concrete

You should also prepare the equipment:

- concrete mixer, which speeds up the process of preparing the working mixture;

- a welding machine designed for welding reinforcement cages.

No special tools are required for construction activities. A set of tools available in the arsenal of every home craftsman is used.

Types and properties

Beams are distinguished by size, they are assigned numbers by which you can select the necessary characteristics individually for construction:

- Size “10” is the smallest by standards; it is used as a ceiling and strengthens moving elements in buildings. It can be installed as a guide structure for lifts, provided that they are small.

- “12” - the beam will be slightly larger and, accordingly, withstand more pressure. Most often used as the basis of frames, installed in mechanisms and machines.

- Number “14” is more massive and helps create more loaded floors; it is suitable for installation in reinforced concrete structures, such as are often installed in industrial construction.

- The “16” beam is distinguished by its strength and can already be a full-fledged support; it is installed not only to ensure the stability of gran beams, but also for the movement of workshop vehicles along rail lines.

- Beam “18” can be used specifically in the construction of buildings, creating reliable support. If you need to provide support for large mechanisms or provide stability for wide areas.

- "20" number is already included in the number of large beams; it can be the basis for columns or frames for mechanical engineering.

- “25” is no longer used so often in the construction of houses, but it will sometimes be reliable for any lifting mechanisms, even large cranes.

- “30” number is also used as a basis for lifting, but unlike “25” it is made wider and longer, this provides higher resistance under heavy loads.

Advantages and disadvantages of flooring on metal beams

The design with load-bearing elements made of rolled steel has a number of advantages:

- increased reliability;

- high safety margin;

- long service life;

- increased load-bearing capacity.

By using metal structures made from steel profiles, it is possible to cover spans of increased dimensions by correctly selecting the number of rolled products used.

[testimonial_view id=”19″]

Along with the advantages, there are also weaknesses:

- the complexity of installation work associated with the increased weight of metal structures and the need to transport them using special devices;

- the need to perform complex engineering calculations confirming the load capacity of foundations being constructed based on steel profiles.

Disadvantages also include the metal's susceptibility to corrosion processes, which reduce the strength of structures. However, with the help of special coatings it is possible to reliably protect the metal and ensure the durability of metal structures throughout the entire period of operation of the building.

Metal beam ceilings are very durable and reliable

Basic advantages and disadvantages

Rolled steel I-beam, like any metal product, has its own advantages and disadvantages that you need to know before using it in the construction industry.

I-beam quality control

The main advantages are reliability and high strength characteristics. All this is achieved thanks to the specific cross-section and durable steel. This product evenly distributes all forces acting on it. There is no concentration of forces in one place, therefore the metal does not get tired and its service life is significantly increased. All this allows the use of rolled metal in the construction of large (multi-story) objects with heavy loads.

In addition to these main indicators, the following advantages can be highlighted:

- Relatively light weight. The special cross-sectional shape does not require a large enough amount of metal for production, so the weight of the finished product is light. Weight does not affect the strength characteristics in any way;

- High efficiency. The I-beam has high rigidity, which allows it to be used to strengthen columns and supports without additional reinforcing elements. If conventional reinforcement was used for strengthening, then it would be necessary to spend a lot of money on purchasing the required volume;

- Good resistance to compression and bending loads. This allows the beams to be used in places with increased vibration and other types of vibrations. For example, when constructing bridges for various purposes;

- Easy to weld. Thanks to this, the speed of installation of building structures is significantly increased;

- All characteristics and geometric indicators do not change over time. Rolled metal is so strong that even under the influence of great forces it does not deform, and accordingly all the characteristics are preserved;

- Convenient transportation. The “H” shape allows the I-beam to be placed more compactly in vehicles. This significantly reduces shipping and handling costs.

Need to know

The I-beam also has a number of disadvantages that also need to be known and taken into account:

- Low fire resistance. If a fire occurs in a room or architectural structure, the strength characteristics of the product will significantly decrease, which will not allow it to be used further;

- Subject to corrosion. Low-alloy or carbon steel of several grades is used for production, and it is very susceptible to destruction from corrosion. Therefore, the use of beams of this type in conditions of high humidity is not recommended. If you still have to use it, then it is necessary to additionally treat the surfaces with a special protective agent;

- Cannot be used in the construction of buildings with very large spans. If there are no additional supports, then the main load-bearing capacities will decrease by an order of magnitude;

- Poor resistance to torsional forces.

If you need a metal beam, contact us! We provide all quality certificates, and you can also read reviews from our customers.

All the best!

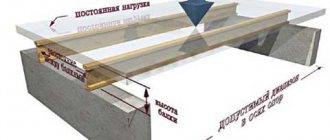

Calculation of floors using metal beams

It is necessary to take a responsible approach to performing calculations when deciding to make a floor or ceiling based on steel profiles.

In this case, it is necessary to take into account a number of factors:

- total weight;

- load capacity;

- area of the formed surface;

- distance between beams;

- span width.

The selection of a suitable number of rolled metal products corresponding to the profile height is carried out taking into account the perceived load.

Load bearing capacity is:

- 0.075 t/m2 – for attic floors;

- 0.150 t/m2 – for the basement base and interfloor foundations.

As the span width increases, the height of the steel beams increases:

- strength over a six-meter span is provided by I-beam No. 20 with a profile height of 200 mm;

- when the distance between the walls is reduced to 4 m, I-beam No. 16 with a height of 160 mm can be used.

Knowing the area of the monolithic surface, it is easy to calculate the need for concrete. To do this, multiply the area by the height of the concrete mass. Having a drawing of the reinforcing lattice, you can calculate the need for steel rods to strengthen the base. All calculations are made on the basis of pre-developed design documentation or a working sketch.

However, they also have a drawback - they are susceptible to corrosion.

Use in construction

The main purpose of metal floors is industrial construction , it differs from civil special requirements. Most often, developers for these buildings already have a ready-made plan, so there will be no problems with sketching the project, but for such an industry the material must have all certifications, because the structures will be used for mass gatherings of people or large factories, which are tested for strength from the outside government agencies.

At the same time, complex metal structures are affordable for really large customers, their price is quite high, and in civil construction aluminum is most often used; although it is not so durable, there is no need to spend money on additional anti-corrosion treatment, and the material can withstand the standard load of a residential building.

Flooring on I-beams - preparatory work

At the preparatory stage, perform the following activities:

- Decide on the material that is supposed to be used to make the ceiling of the room, and also study the sequence of actions.

- Develop a working drawing that provides complete information about the design features of the ceiling and the range of materials used.

- Perform calculations confirming the strength characteristics of the building structure and the safety margin necessary for long-term operation.

- Calculate the need for building materials, estimate the amount of expenses, and prepare tools.

- Mount the I-beams, maintaining an interval between the supporting elements of 1–2 m and check the correct installation using a level.

- Assemble panel collapsible formwork along the lower level of the I-beam using laminated plywood or planed boards, provide a flange 15–20 cm high.

- Anchor wooden beams or steel spacers to ensure the formwork structure remains stationary and must support the mass of concrete.

When installing supports, install one wooden beam for each square meter of area, and metal elements 2 times less often. The use of telescopic racks will significantly facilitate the work of fixing the formwork structure. Having completed the preparatory activities, proceed to the main work.

Correct calculation of flooring on metal beams is very important

Special beam, parameters GOST 19425-74)

| I-beam number | Dimensions | Weight 1m, kg | Meters per ton | |||

| h | b | s | t | |||

| 14C | 140 | 80 | 5,5 | 9,1 | 16,9 | 59,17 |

| 20C | 200 | 100 | 7,0 | 11,4 | 27,9 | 35,84 |

| 20Ca | 200 | 102 | 9,0 | 11,4 | 31,1 | 32,15 |

| 22C | 220 | 110 | 7,5 | 12,3 | 33,1 | 30,21 |

| 27C | 270 | 122 | 8,5 | 13,7 | 42,8 | 23,36 |

| 27Ca | 270 | 124 | 10,5 | 13,7 | 47,0 | 21,28 |

| 36C | 360 | 140 | 14,0 | 15,8 | 71,3 | 14,03 |

| 18M | 180 | 90 | 7,0 | 12,0 | 25,8 | 38,76 |

| 24M | 240 | 110 | 8,2 | 14,0 | 38,3 | 26,11 |

| 30M | 300 | 130 | 9,0 | 15,0 | 50,2 | 19,92 |

| 36M | 360 | 130 | 9,5 | 16,0 | 57,9 | 17,27 |

| 45M | 450 | 150 | 10,5 | 18,0 | 77,6 | 12,89 |

I-beam STO ASChM 20-93.

Standards for I-beams in Russia are determined by both GOST and the standard of the Nizhny Tagil Metallurgical Plant (STO ASChM 20-93). The table below shows exactly the NTMK standards

We install a monolithic ceiling on metal beams

Developers are attracted by the solid structure, made of concrete reinforced with reinforcing lattice.

After installing the metal beams, constructing the formwork and ensuring its stability, carry out work on forming a monolithic reinforced concrete slab according to the following algorithm:

- Check for any gaps in the wooden formwork and, if necessary, seal them.

- Assemble the reinforcement frame using metal rods with a section size of 10–12 mm.

- Place the frame in the formwork, ensuring a constant interval of 4–5 cm to the surface of the future concrete slab.

- Pour the concrete mixture into the formwork and thoroughly compact the concrete mass using a vibrator.

- Do not expose the hardening mortar to loads for 4 weeks and then dismantle the formwork.

Pay attention to the size of the supporting surface around the perimeter of the slab, which should be more than 150 mm.