Metal welded I-beams have been used for the construction of structures and floors for a long time. But until this time in Russia its use was strictly limited to the sphere of industrial construction, i.e. when truly grandiose structures are erected, which should not care about anything.

And only in recent years have such types of I-beams begun to appear that can actually be used in the construction of new houses of an ordinary residential building. Are you thinking about just such an overlap? Then we will help you learn all the features of its manufacture!

About the new technology of private housing construction

Today, the production of welded I-beams has been launched throughout the country, and is in demand even in private housing construction. And all this is due to new design and architectural solutions! Their modern volumetric planning projects require special quality load-bearing frames and reliable ceilings, which will be most effective for large spans - from 7 meters.

You've probably noticed how country cottage houses and similar buildings differ in their appearance from the original Russian hut. Now imagine how different their architecture and construction principles are! That is why steel I-beams today have become actively used to cover spans from 4 to 18 m, and both carbon and low-alloy steel are used for their production, which guarantees the required qualities and strength.

For the manufacture of such beams there is even a GOST and the necessary certificates. Tangential stresses are taken up by solid walls, and compressive and tensile stresses are evenly distributed along the length. To make it more clear to you, the role of such a vertical wall is essentially the same as that of a zigzag lattice in a metal truss. Although at first glance such beams do not look too strong or monolithic:

Areas of use

Applications for welded I-beams in construction include:

- load-bearing structures, columns, braces;

- covering both small rooms and large spans;

- technological equipment supports;

- corner crane consoles;

- external structures: bridges, balconies.

The product is used in all sectors of construction: industrial and private, apartment buildings and public buildings.

What is a welded I-beam?

According to their type of section, I-beams today are usually divided into rolled or composite, which are also called welded. A welded I-beam is a special type of shaped rolled metal in the form of an inclined or horizontal beam. Today it is made from carbon and low-alloy steel, always of high quality.

Let's list the main advantages of welded I-beams:

- Cover large spans with significant loads.

- Ideally redistribute horizontal and vertical loads.

- They work well in bending due to the rigidity of the beam profile.

- They do not burn and do not lose their load-bearing capacity when heated even at fairly high temperatures.

- Resistant to biological influences.

- Excellent for the construction of prefabricated building structures.

- They allow a significant reduction in the weight of the entire structure compared to hot roots.

- They are also manufactured with a completely asymmetrical cross-section.

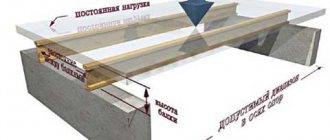

That is why such welded beams are used today in the construction of residential buildings, industrial complexes, and even bridges and tunnels. It would seem that such a beam would be too heavy for private house construction, but in fact, the use of steel I-beams can ultimately reduce the total weight of load-bearing structures. But remember that in relation to the ceiling made of welded steel I-beams, there are strict requirements:

Defects that may occur during welding

Defects in the weld and heat-affected zone can occur due to violations of welding technology, non-compliance with rules, negligence in work, and so on. Most often, defects are associated with cross-section of steel, that is, changes in its structure under the influence of high temperatures. Somewhere, grains of a different steel phase are formed, which have different physical properties. Defects may reduce strength and rigidity, as well as corrosion resistance. Because of this, the operation of such a product is impossible. During the manufacturing process, all I-beams are checked for such defects. Advantages of using welded beams During the construction of buildings and structures, a large number of metal structures are used, including welded I-beams. Compared to rolled metal I-beams, welded I-beams have a large number of advantages:

- Rolled metal beams have a size limitation, while a welded beam has no such restrictions;

- High quality of the resulting product;

- No harmful production waste;

- Metal structures produced by welding are made from various grades of steel. For example, in places where stress is minimal, carbon steel can be used, and in places that will subsequently be subject to high loads, on the contrary, high-strength alloy steel can be used. Thanks to this technology, the price can be reduced when the rolling mill produces only one grade of steel;

- There is also the possibility of obtaining a welded beam of variable cross-section, thanks to which any architectural ideas can be realized;

- Also, due to the harmonious and correct selection of the cross-section, the weight can be reduced by approximately 10%;

- Beams can be made to order to a predetermined length.

Advantages of the welded beam production method

Today, metal I-beams for the construction industry are manufactured in two main ways: hot-rolling and welding. A welded I-beam has great advantages over a rolled one. It also has better strength characteristics, while its weight is lower by as much as 30%. And all thanks to the fact that the calculation of a welded I-beam involves a competent combination of different grades of steel. This is why a welded beam in industrial production is cheaper than a hot-rolled one.

Also, welding itself as a method is good in that with its help, metal beams can be made of a wide variety of sizes, even up to 4 meters or more in height, but all this is impossible to do with hot-rolled beams. In addition, only with this method is it possible to produce a beam with different widths along the entire length.

Why create beams with variable sections, you ask? The fact is that such beams are much more economical than shelves with a constant profile. After all, even a person who is far from construction understands that in different places of the beam after its installation it will have to be subject to different stresses: in some places it is almost not loaded, and in others it is subject to wear and tear. In such “important” places they make it thicker, and where possible they rationally save on material.

In addition, if we are talking specifically about a welded beam, then a variety of steel grades are used for its manufacture. This technique allows you to reduce metal consumption. Almost the entire beam is made of ordinary steel, the most stressed part is made of high-strength steel, and the least stressed part is made of low-carbon steel. Thanks to all this, the cost of the beam is reduced by 5%, which is quite noticeable.

General information

A welded beam is a type of beam structures that are made by welding individual metal blanks. The main material for the production of this type of spare parts is steel, which may contain small amounts of manganese, chromium, vanadium, titanium or lead. They are usually made in the form of I-beam structures resembling the letter “H”. The design itself looks like this:

- In the middle of the part there is a long flat jumper part with a constant width. To obtain tapering I-beams, metal bridges of variable width can be used when the width of one edge is less than the width of the other edge. Such spare parts are used for mounting suspended structures or fastenings.

- On the sides, two parts are welded perpendicularly to the jumper, which act as a kind of “walls”. The walls have a constant width, although sometimes tapering walls can be used if it is necessary to create a ceiling.

- For marking, a “stamp” can be applied, which will reflect basic information about the spare part. Key information - metal grade, spare part type, part category, production date, information about the manufacturer.

Calculation and production of welded I-beam

High-quality welding of I-beams for floors will require a lot of attention and responsibility from you. You will need to calculate all the upcoming loads on the structure in general and on the joints of the beams themselves.

Just designing and planning I-metal welded beams takes a lot of time. Therefore, we recommend that you focus on the dimensions and purposes of finished products from manufacturers.

The modern market offers a fairly large variety of sizes of finished I-beams with their own designations and types. The dimensions of the beam are determined by the number, which indicates the distance between the outer edges parallel to each other.

For example, the marking K denotes columns and beams that must withstand enormous loads. Keep in mind that there is also a certain type of beams that are not used for floors, but only for creating heavy equipment and machinery. Such beams have their own manufacturing standards and properties.

Wide-flange designs are suitable for lighter loads. And the strength of such beams will directly depend on the length, the formula of the transverse profile, the use of raw materials and manufacturing methods, i.e. metal rolling technologies. Here is a standard welded beam for private housing construction:

Here are the parameters of welded steel I-beams for the manufacture of such beams:

How to weld a beam yourself?

If you already have some experience working with this material and you want to make welded beams for building your house yourself, you will need an alloy steel sheet as a base. The hot-rolled method of manufacturing at home is quite complicated, so welding is really better for you. This is a responsible task, so if you have the opportunity, it is more rational to immediately invite an experienced welder.

After the individual elements are ready, assemble the structure using the selected welding method. First you will need to install a vertical wall and secure the stiffeners and press everything down with clamps. The finished beam must be protected with a special coating so that it does not corrode in an aggressive environment.

How to avoid deformation?

If you make mistakes during the manufacturing process, you may encounter such unpleasant deformations of the beam, which in the future will significantly complicate the installation process:

Let us explain in more detail. Your main task when making welded beams is to then join the parts so that the seam does not work in tension.

You also take into account this important fact that the welding itself puts some stress in the beam, and this is not always noticeable to the eye. Therefore, it is advisable not to immediately weld the next part to it. Just push the seam back slightly and the beam will be level.

Comparisons: in order to avoid any deformation of the beam, especially for arranging an interfloor floor, it is subjected to special processing in the factory:

If you undertake making such a beam yourself, the following steps will help you figure it out:

Possibilities

In addition to the advantages, the use of welded steel beams will allow each buyer to:

- Increase the width of the building span, as they are longer;

- Order different parameters and sizes, there are a huge number of GOST standards for I-beams, so that every customer can find suitable parameters;

- The architecture of the structure, as mentioned above, can be completely diverse.

Thus, the welded beam has a huge number of advantages, which is why it is widely used in all areas of construction. The use of welded beams has helped people improve the quality of structures of buildings and various structures, increase their safety, and therefore safety for people.

Fastening units for welded I-beams

So, now let's understand the support nodes of metal I-beams. Their support on a steel column (support) can be rigid or hinged, that is, movable.

The connection of finished welded beams to each other during the installation process can be done in two ways:

- The first of which is that the I-beams are first welded to a special plate, and welding is carried out along the contour of the profile using fillet welds. The advantage of this particular method is that it is not necessary to separate the edges of the beams.

- The second method is to use overlays that are mounted symmetrically to the longitudinal axis, cut and welded with oblique seams. Thanks to this, it is possible to avoid problems with applying a weld along the entire side of the overlay. This welding method is suitable for structures with little future load, i.e. just for the construction of a private residential building.

- Welded beams can also be connected using a bolted connection - this is a detachable method, which is necessary to ensure that there is no residual stress in the structure, and the floor structure itself is resistant to shock and vibration loads. And also when it is not possible to invite professional welders.

Here is an interesting video comparing both types of beam connections:

As you already understand, in most cases, a metal welded beam is connected by welding, less often with bolts and even less often with rivets. All this directly affects the cost of installing such beams.

As for rivets, working with them is the most labor-intensive, although sometimes, unfortunately, you cannot do without such elements. For example, if the beam will be constantly subject to vibration (such equipment will be used), then it cannot be connected too rigidly to the structure.

If you are going to connect the entire metal structure with bolts, then:

- You will need normal and high precision fasteners. Only in places where there will be a shear load, bolts of normal or rough accuracy should not be used.

- You will need to make gaps in the beam in advance (or order something similar at the factory) so that the outer diameter of the hole itself is only 2-3 mm larger than the outer diameter of the bolt. This design will be resistant to deformation, and assembly is generally simpler.

- Precision bolt connections are well suited for hard-to-reach areas where riveted connections are not possible. But here the diameter of the holes needs to be increased by 0.3 mm so that the fasteners can easily withstand the upcoming load.

So, let’s now consider such an important stage as welding the main beam with the secondary one. Do everything step by step:

- Step 1. At the top of the main beam, make a triangular cutout of the exact size.

- Step 2. Weld the trim to the bottom of the main beam.

- Step 3. Make cuts in the bottom of the auxiliary beam that will be equal to half the width of the bottom of the main beam.

- Step 4. Now the top of the secondary beam needs to be formed into a triangular shape, the same as the top of the main beam was cut.

- Step 5. Next, we carry out installation: first the main beam, then the secondary one, and all this using the method of using an overlay.

- Step 6. And finally, the last stage is the installation of the junction of the upper parts and walls, where the overlay is also welded to the lower parts of the beams.

You can also fasten metal I-beams to each other using the bolt connection method. This method is necessary when from time to time you have to install or dismantle a specific unit. The advantage of such a connection is that there will be no residual stress in the structure. Which in itself is good, because then the ceiling will be more resistant to shock loads, and, in addition, you will not need to invite a professional welder to create the unit.

Rigid node: for static loads

Those. the beam can rest on top, directly on the center of the column profile, or the beam can be attached to the side. Then only a compressive load arises in the column, but the action of all forces occurs, so it has to be made stronger and more reliable, and this is an overconsumption of metal.

Sometimes it is also necessary to lay two beams across a span, then they are connected to each other using bolts and plates are installed between the two ribs. It is important to remember that metals are subject to thermal expansion due to temperature changes, and therefore you need to leave a small distance for their unnoticeable movement.

To transmit transverse pressure force, the rib of the beam is placed so that during installation it is directly above the column flange. In this case, the beam is connected to the column using a special overhead plate, and preferably immediately on both sides. But in such a way as not to create too tight a knot.

Here is a good example of how welded beams are combined on two spans so as not to create point stress on the intermediate floor wall:

To create a rigid beam connection, you will need a bolted or welded connection:

Hinge joint: for dynamic loads

Now about the hinged support of the welded beam. It is created using a support rib on the support table, where the entire load will be transferred. You will need to make the table itself from sheet steel.

Weld a table on three sides of the beam and make its width 2-3 cm larger than the rib of the beam. So the supporting edge should lie completely on the supporting table.

Submit your application

| № | Profile | I-beam height, mm | Shelf width, mm | Shelf thickness, mm | Wall thickness, mm | Weight 1 piece 12 m, t | Price according to st3, st09g2s rub/t with VAT |

| 1 | 80B1 | 791 | 280 | 18 | 14 | 1,952 | Submit your application |

| 2 | 80B2 | 799 | 280 | 22 | 14 | 2,166 | Submit your application |

| 3 | 90B1 | 895 | 300 | 20 | 16 | 2,425 | Submit your application |

| 4 | 90B2 | 909 | 310 | 22 | 16 | 5,598 | Submit your application |

| 5 | 100B1 | 999 | 320 | 22 | 16 | 2,776 | Submit your application |

| 6 | 100B2 | 1010 | 325 | 25 | 18 | 3,172 | Submit your application |

| 7 | 100B3 | 1015 | 320 | 30 | 18 | 3,440 | Submit your application |

| 8 | 100B4 | 1019 | 330 | 32 | 20 | 3,802 | Submit your application |

| 9 | 50Ш3 | 494 | 295 | 22 | 16 | 1,909 | Submit your application |

| 10 | 50Ш4 | 500 | 300 | 25 | 16 | 2,104 | Submit your application |

| 11 | 60Ш1 | 591 | 300 | 18 | 12 | 1,654 | Submit your application |

| 12 | 60Ш2 | 594 | 300 | 22 | 16 | 2,081 | Submit your application |

| 13 | 60Ш3 | 600 | 305 | 25 | 18 | 2,381 | Submit your application |

| 14 | 60Ш4 | 605 | 300 | 30 | 20 | 2,735 | Submit your application |

| 15 | 70Ш1 | 694 | 305 | 22 | 12 | 2,008 | Submit your application |

| 16 | 70Ш2 | 695 | 305 | 25 | 14 | 2,229 | Submit your application |

| 17 | 70Ш3 | 711 | 305 | 28 | 18 | 2,731 | Submit your application |

| 18 | 70Ш4 | 714 | 305 | 32 | 22 | 3,198 | Submit your application |

| 19 | 70Ш5 | 727 | 305 | 36 | 25 | 3,626 | Submit your application |

| 20 | 80Ш1 | 781 | 300 | 18 | 14 | 2,009 | Submit your application |

| 21 | 80Ш2 | 794 | 320 | 22 | 14 | 2,328 | Submit your application |

| 22 | 90Ш1 | 880 | 295 | 20 | 16 | 2,389 | Submit your application |

| 23 | 90Ш2 | 890 | 305 | 25 | 14 | 2,556 | Submit your application |

| 24 | 100Ш1 | 989 | 325 | 22 | 16 | 2,783 | Submit your application |

| 25 | 100Ш2 | 1005 | 325 | 25 | 18 | 3,162 | Submit your application |

| 26 | 100Ш3 | 1014 | 310 | 32 | 18 | 3,492 | Submit your application |

| 27 | 100Ш4 | 1012 | 310 | 36 | 20 | 3,889 | Submit your application |

| 28 | 35K1 | 342 | 350 | 16 | 10 | 1,352 | Submit your application |

| 29 | 35K2 | 355 | 350 | 20 | 12 | 1,684 | Submit your application |

| 30 | 40K1 | 395 | 390 | 20 | 10 | 1,812 | Submit your application |

| 31 | 40K2 | 404 | 400 | 22 | 12 | 2,074 | Submit your application |

| 32 | 40K3 | 410 | 400 | 25 | 16 | 2,438 | Submit your application |

| 33 | 40K4 | 415 | 400 | 30 | 18 | 2,875 | Submit your application |

| 34 | 40K5 | 432 | 405 | 36 | 22 | 3,509 | Submit your application |

Additional functions of an I-beam in private housing construction

The floor itself does not necessarily have to consist only of metal I-beams. Often they are used only in the most intense places, and wooden I-beams are installed between the metal parts.

Why is that? The fact is that welding requires highly qualified workers. Further, in ordinary literature and Internet sites there is not that variety of components and ready-made design diagrams for installing such a ceiling; a competent engineer is really required here, and even we only give recommendations. In addition, metal is not cheap. And the quality of welding is very important. It must work for a long time, even under conditions of corrosion or changing loads.

Therefore, this option not only has the right to life, but is also quite practical:

And finally, a metal I-beam often serves as an additional functional element, which has value in any household:

Possible defects

During welding of an I-beam, due to non-compliance with the technology, crystallization of the steel occurs due to high temperature. Due to phase discrepancies, internal stresses arise in the metal. Strength and rigidity decrease, and the risk of corrosion increases.

When welding steel sheets, other defects are possible:

- violation of the shape of the seam; deviation from the shape of the outer surfaces or the geometry of the joint;

- burns, when the melt flows out of the bath, holes form in the seam;

- undercuts – grooves along the joint boundary;

- cracks forming in places where the seam breaks;

- slag or tungsten inclusions in the diffusion layer; at high welding speeds, refractory oxides are formed.

Metal products with defects are unreliable; they will not withstand heavy bending or torsion loads. They are discarded and boiled again if possible.