Brass pipes are hollow-shaped products made from an alloy of copper and zinc. They are used in instrument and mechanical engineering, construction, housing and communal services and other areas of industry.

Brass pipes are supplied in coils or sections of irregular length. Diameter – from 4 to 200 millimeters, other sizes – upon request.

You can buy rolled metal wholesale or retail by filling out the application form.

Pros and cons of brass products

Since brass pipe is resistant to mechanical stress, it is often used in the installation of water mains in a private home. Products made of brass are not exposed to temperature changes, so there are no restrictions on their use in regions with frequently changing climates.

Important! Brass products of any shape and volume are durable. Subject to compliance with operating rules, they last up to 50 years.

Disadvantages include the susceptibility to cracking of parts that are manufactured using cold pressure techniques.

This technology can leave microscopic cracks inside. They are invisible during visual inspection, but during long-term operation foreign substances can penetrate into the cracks. This significantly reduces the performance of the product.

However, this can be avoided. Products made with low-temperature annealing are of higher quality.

LTs40S, LS59, L63T

Slow deep heating of the metal followed by gradual cooling eliminates the occurrence of microcracks. The same is observed when using the casting technique.

What is brass rod

It can have a rectangular, hexagonal or square cross-section. Manufacturing method: drawing or pressing.

There are many areas where rods are used:

- in shipbuilding;

- aviation technology;

- mechanical engineering;

- in instrument making;

- shipbuilding.

They are also used to make nuts, screws and some types of fittings. The technical conditions for the production of brass rods (also called brass circles) are stated in GOST 24301-93 (previously GOST 24301-80 was relevant).

This is interesting: Soldering with brass: how and with what to solder brass correctly

Application area

Nowadays, in the non-ferrous metal industry, brass pipe is very popular. This product is used in several industrial areas:

- mechanical engineering;

- instrument making;

- automotive industry;

- aircraft manufacturing;

- shipbuilding;

- construction industry;

- heat and electricity;

- Department of Housing and Utilities.

The disadvantages and advantages of pipe rolling are associated with production technology, as well as with the correct operation of these products. The mechanical strength of our products allows us to install systems of any complexity. Rolled brass is used in the construction of the following engineering systems:

- heating (sectional radiators);

- water supply;

- hot water supply (boilers);

- decorative (furniture fittings).

By contacting “Tsvetnoy Metalloprokat”, you can order any quantity of the goods presented. We organize deliveries directly from our warehouse in St. Petersburg, so orders are completed in a short time. Call now!

Regulations

You can familiarize yourself with the GOST requirements for brass pipes by downloading the document in pdf format from the link below.

GOST 494-90 Brass pipes. Specifications Download

The pipe, the material of manufacture is brass, can be produced in several ways - pressing, cold rolling, broaching. All brass pipes with a round cross-section profile, produced using such technologies, must meet the requirements specified by GOST 494 from the year 1990. This regulatory document stipulates that the dimensions and weight parameters of pipes manufactured using different technologies may differ. Thus, GOST regulates the following parameters of round brass pipes:

- outer diameter of cold-rolled and drawn products – 3–100 mm, extruded – 21–195;

- wall thickness of cold-rolled and drawn pipes is 0.5–10 mm, extruded pipes – 1.5–42.5;

- the theoretical weight of one linear meter of products obtained by cold rolling and broaching is 0.0334–20.282 kg, pressed – 0.781–173.

Weight of brass pipes (P - increased manufacturing accuracy; N - normal manufacturing accuracy)

Extruded pipes, which are made from brass alloys, are not divided into different categories based on the degree of accuracy. At the same time, a brass pipe produced using cold-rolled technology or the broaching method can be of normal or increased accuracy.

Regardless of the production technology, brass pipe can be produced in three lengths: measured, unmeasured (1–6 meters), multiple of measured. Brass products produced using broaching technology, the wall thickness of which does not exceed 1.5 mm (thin-walled), and the outer diameter of 10 mm, can have a length of 10 meters, and are sold to consumers in coils whose weight does not exceed 150 kg.

Thick-walled brass pipes are used in water heaters, air conditioners and refrigerators, as well as oil separators

Is it worth making a plumbing system from brass?

The quality of the water supply system of a country house depends on the material used. Preference is given to classic metal pipes. The use of metal-plastic or metal-propylene products in the bathroom and in the general heating system has also become widespread.

Brass pipes are used if there is a need to reduce the overall weight of the system, since they have a low specific gravity.

Classification by shape and wall thickness

The two basic types of products (thick-walled and thin-walled) differ in their properties. Thick-walled pipes are manufactured without connecting seams. Accordingly, they have an increased strength coefficient. They are used for pumping gases or liquid substances under high pressure.

In pipelines that are installed in residential or social buildings, such products are not relevant. It is designed for extreme loads, which are practically not provided for in domestic conditions.

Thin-walled pipes are most often used in everyday life.

Manufacturing method: pressing and cold rolling. Their technical characteristics are somewhat reduced, but, nevertheless, they are quite durable products. Products with a thin wall are used in boiler systems and for the installation of pipelines for various purposes.

In addition, profile pipes are used to solve various production problems.

It can have several types of sections:

- round;

- square;

- rectangular.

What sections are there?

Types of brass pipes

Experts divide them according to their mechanical and physical properties.

| Sign | View |

| Mode of production | drawn or cold rolled (LS59-1, LZhMts59-1, L63); pressed or hot-deformed (L63, L68). |

| Section shape | round; complex; multifaceted; profile. |

| Round pipes are most often used | |

| Material condition | L63m - soft; L63ptv - semi-solid; L63tv - solid (T); L63Thu. |

| Precision manufacturing | high; increased (P); normal. |

| Wall thickness | thick-walled; thin-walled. |

Classification by type of alloys and areas of application:

- L63 and L68. Required in mechanical engineering, shipbuilding, instrument making. In addition, they are used to make pressure gauge tubes and sectional radiators.

- L96. Required for the manufacture of radiator and plumbing systems. The waveguide is made from the same alloy .

- L68 (thin-walled). Required in the production of heat exchangers, climate control devices and refrigerators.

- LMsh68-0, 05, LO70-1, LOMsh70-1-0, 05, LAMsh77-2-0, 05, and also L68. Required for the manufacture of parts and assemblies of heat exchangers.

- LS59-1. Required for the manufacture of threaded couplings, nipples, fittings (for plumbing equipment). In addition, this type is used in many engineering structures.

The scope of use is determined by highly specialized properties.

The product range is extensive, it includes pipes not only for general use, but also:

- waveguide;

- capillary;

- highly specialized;

- for heat exchange devices.

Brass pipes are needed in various areas of the national economy for pumping liquid substances. Their advantage is wear-resistant properties and resistance to aggressive external factors.

This is interesting: Do-it-yourself patination (blackening, aging) of copper, brass and bronze

Pipe L63

The brass pipe from grade L63 has a double (simple) structure. Composition: 63% Cu 37% Zn. Due to the fact that the structure of the material is single-phase, it is characterized by excellent ductility, good strength and corrosion resistance. The inclusion of zinc in the composition made it easier to process mechanically, as well as reduce the price of the product. Products made from L63 alloy are susceptible to: processing under pressure in a cold state, soldering, welding. Brass tubes L63 are: soft, semi-hard, hard, based on the pressure required during cold deformation. The annealing method is used for products to increase wear resistance. Rolled products are mainly used for the production of various semi-finished products, cryo technology, wires deposited on carbon steel and gas welding of copper-zinc alloys. These pipes, in a cold state, can be deformed by methods: drawing, rolling, deep drawing, embossing. The L63 pipe is also suitable for soldering, welding, and lends itself well to polishing.

Brass pipes. Specifications

| Designation: | GOST 494-90 |

| Status: | active |

| Type: | GOST |

| Russian name: | Brass pipes. Specifications |

| English name: | Brass tubes. Specifications |

| Date of text update: | 06.04.2015 |

| Description update date: | 01.06.2019 |

| Publication date: | 01.05.2002 |

| Effective date: | 01.01.1992 |

| Last modified date: | 12.09.2018 |

| Reissue: | reissue |

| Area and conditions of application: | This standard applies to brass round drawn, cold-rolled and pressed pipes for general purposes. |

| Instead: | GOST 494-76 |

| Substitute: | GOST 494-2014 |

| List of changes: | No. 0 from (reg.) “Restored on the territory of the Russian Federation” |

| Is located in: | All-Russian Classifier of Standards → Hydraulic and pneumatic systems and components for general purpose → Pipelines and their components → Non-ferrous metal pipes Classifier of state standards → Metals and metal products → Metal pipes and tubular products → Pipes made of non-ferrous metals and alloys All-Russian Product Classifier → Rolled non-ferrous metals → Rolled heavy medium-melting metals → Rolled brass |

| Application #0: | Change to GOST 494-90. Restored on the territory of the Russian Federation |

Appendix to GOST

Change to GOST 494-90. Restored on the territory of the Russian Federation

| Designation: | Change to GOST 494-90. Restored on the territory of the Russian Federation |

| Effective date: | 01.03.2016 |

The text of the amendment is integrated into the text or description of the standard.

About brass couplings and adapters

Once upon a time, the pipeline system was a monolithic pipe. One end of it went to the water source, and the other - directly to the taps. This structure was very strong. But it did not involve restoration work.

Today's plumbing technology has come a long way. Modern pipelines can be upgraded or repaired as needed. This is ensured by couplings that simplify installation work and allow you to change the system configuration. For this, convenient fasteners , brass adapters and couplings are used.

Couplings

Pipeline parts for any purpose are connected by couplings. They can be different in size and shape. But at the same time, their main task is to ensure a hermetically sealed connection between the elements of one system. Crimp couplings allow for the dismantling or reconstruction of pipelines if necessary.

The process of connecting pipes occurs by screwing.

Reinforced couplings and adapters

Experts distinguish between transitional ( crimp ) and straight couplings. To connect pipes of the same size (diameter), straight couplings are used. Adapters are required for the hermetically sealed connection of pipeline parts that have different diameters.

Advantages of brass couplings:

- light weight;

- high strength;

- ease of installation;

- low electrical conductivity;

- immunity to temperature changes.

For ease of use, the outer side of the couplings is equipped with technological protrusions. This makes it possible to use a wrench.

Adapters

In modern plumbing, several types of adapters are used:

- flanged;

- welded;

- bell-shaped;

- coupling;

- threaded

Their task is to connect products of different diameters and even those made of dissimilar materials. With their help, insertion is carried out in the right place.

Types of pipe adapters:

- For connecting pipes of different diameters. In essence, this is a regular coupling with different diameters at the outlets. It is used when laying pipelines. It is not recommended to use any homemade connection devices to avoid breaks.

- For joining products made of different materials. They are used when it is impossible to weld fragments of one system.

Brass adapter Rehau MX 20-Rp 3/4 inch

The advantages of brass adapters are especially felt when it becomes necessary to repair a fragment of a dilapidated pipeline consisting of metal pipes. When installing external branches of the system, an adapter that connects elements made of different materials helps. The fragment is cut out and a new insert is made in the same place. 5061 Far is often used in the installation of heating systems .

This compact and very robust part (5061 Far) is used in systems:

- drainage;

- sewer;

- heating

With the help of small adapters, insertion into any section of the highway is carried out.

Connection with threaded fittings

In order for the plumbing or heating system to function smoothly, proper installation is important. To implement it, it is necessary to use polypropylene and brass fittings. They are needed to connect pipes of different sizes within the same engineering project.

In addition, fittings and clamps provide connection between the water supply system and water-consuming points.

Combination and brass fittings are threaded. This means that the pipeline in which they were used is detachable.

Modern plumbing systems can be repaired for upgrades or renovations in any area. After dismantling, fittings or clamps are reused without loss of performance.

To ensure an ideal connection, specialists usually use high-quality seals:

- FUM tape;

- sanitary linen;

- plumbing thread.

The market offers fittings without special coating (yellow) or galvanized. They have a white metallic tint.

A special category includes fittings with external threads for pipe extension: squeegees. Most often, elongated brass leads with a length of 100 or 200 mm are used. But in normal practice, short runs (barrels) can also be used.

Pentacles for pumping station

It is important that adapters, clamps or fittings are used from reputable manufacturers. The use of polyethylene analogues is not recommended: they are inferior in strength and reliability.

Only branded fittings and plugs ensure the tightest, tightest connections and eliminate the possibility of an emergency. Therefore, reviews about them are the most favorable.

Reviews of STR brass tee LS-59 1/2 vvn

About the product manufacturing process

Technical conditions for the production of brass pipes are stated in GOST 21646-2003. In particular, GOST 2003 prohibits the presence of dents and burrs on the surface of the product. If any defect can be eliminated by lightly impacting the outer shell, then it is considered acceptable.

In production conditions, pipes of different diameters, gears and other important products are made from brass. It can be used to make objects with complex geometric shapes. This is explained by the fact that the material is malleable to processing.

Depending on the production task, brass is processed:

- pressure;

- casting;

- sharp;

- by pulling;

- soldering;

- stamping.

Part of the technological process is rolling .

The malleability of brass to processing is so great that in production conditions it is not always heated: the metal can be worked with cold.

There are three methods for making brass pipes:

- pressing – hot method;

- deformation – cold method.

- horizontal casting.

Finished products are divided into thin-walled and thick-walled.

The most practical are thick-walled pipes. They do not have a welded seam, so they are designed for use in particularly difficult conditions. Thick-walled products are used in the industrial sector.

Thin-walled brass products are made by pressing or rolling without the use of heat.

Brass pipe L63

Properties and technical specifications

With all the variety of these products, their common quality is ease of maintenance and installation. Any systems using brass pipes are laid quite quickly. If necessary, they are easily replaced.

The technical characteristics of brass pipes are stated in GOST 21646-2003. It also stipulates the technical conditions for the production of these products.

In particular, GOST prohibits the presence of dents and burrs on the surface of the product. If any defect can be eliminated by lightly affecting the outer shell, then it is considered acceptable.

Check GOST 21646-2003

Characteristics of brass products. Table No. 2

Other important qualities of brass products:

- resistance to external influences;

- high corrosion resistance;

- anti-friction qualities;

- durability.

Experts define finished pipes as cast or deformable. The quality of the product depends on the presence of zinc.

Pressure

According to GOST 21646, brass products are subject to strict requirements for tightness. They are considered to be of high quality if during testing they withstand a pressure of 4.9 MPa (50 kgf/cm2) for 10 seconds.

At the customer's request, the pressure during testing can be increased. In addition, at the request of the customer, each product corresponding to the following dimensions can be subjected to hydraulic testing: 16x1, 19x1, 20x1, 20x2 or 22x4, 24x1, 25x2, 25x3, 32x2, 40x2, 50x3.

Diameters

Diameters vary from 3 to 195 mm.

The most popular dimensions: 5, 7, 8, 10, 14, 16, 22, 32, 38, 40, 53, 60, 93, 110, 120 mm. In this case, the accuracy of the parameters can be normal, increased or high.

To solve a wide range of problems, pipe sizes are suitable: f36x3, 10x1, 12x3, 16x2, 20x20x2, 30x30, 32x1, 40x60, 40x40, 48x2, 50x2, 58x25, l48x1, 19x1, 20x20, 16x1, 19x1, 2 0x1, 20x2 , 22x4, 24x1, 25x2, 25x3, 32x2, 40x2, 50x3, 5x1, 8x1. 8 x 2 x 4000.

Compound

According to GOST 494-90 standards, an alloy of copper and zinc is used in the production of brass pipes. To alloy copper, nickel, aluminum and some other components are added. Alloying additives improve the performance of the product.

Important! If the zinc content exceeds the threshold of 45%, then the product loses its ductility. In industry, brass that exceeds the permissible limit for the presence of zinc is not recommended for use by experts.

Products differ in chemical composition and phase state. According to this criterion, products are divided into foundry and deformable.

Hot deformed

Characteristic

A lot of technical documentation is responsible for meeting production standards when creating the products in question, among which there is also GOST 11383-75. In accordance with it, the following advantages take place:

Advantages

- No susceptibility to corrosive processes. With constant contact with liquid, this is an incredibly important quality, especially when transporting drinking water, because if rust settles in it, it is very harmful to the human body.

Brass plumbing will deliver drinking water without any impurities

- Ecological cleanliness. Full compliance with all necessary sanitary standards.

- Affordable price. Compared to copper, which has similar qualities, brass is much cheaper.

- High strength. Polypropylene products are left far behind, and the increase in the amount of zinc in the structure of the brass connection makes it possible to leave copper products far behind in this regard.

- Chemical inertness. Allows use for working with aggressive substances.

- Relatively low specific gravity. They do not require reinforced fastening systems. The brass structure will not put a significant load on the foundation of the building

- Easy DIY processing. Cutting, flaring, bending pipes or other necessary transformations are carried out easily due to the elasticity of the material.

- Wide range of sizes and section shapes. You can find products with diameters from 4 to 160 mm.

- Simple installation instructions. Brass pipes can be connected using soldering, welding, threading or sewer pipe fittings.

Advice: if you have doubts about your own abilities, it is recommended to invite a specialist to carry out soldering. Because poor-quality sealing can subsequently result in much greater costs for repairing the system than paying for the services of a professional to install it.

- Attractive appearance. Brass is very similar in appearance to copper, which has always been considered a decoration for any home.

- Many areas of application:

- mechanical engineering;

- Department of Housing and Utilities;

- instrument making;

- electric power industry;

- construction;

- furniture manufacture.

Varieties

Brass pipes are distinguished by many indicators. By using them correctly, you can always select or order the product you need.

So let's look at the possible types and classifications.

- Production method , corresponding brands and possible sizes:

| Name according to manufacturing method | Possible brands | Section size, mm | Wall width, mm | Symbol |

| Drawn and cold rolled | L63, L68 | 3-100 | 0,5-10 | D |

| Pressed | L60, L63, LS59 1, LZhMts59 1 1 | 21-195 | 1,-42,5 | G |

Pressed brass pipes

- The length can be of the following types:

| Name | Options | Designation |

| Unmeasured | From 1 to 6 m, while a batch may contain a product whose length is less than 100 cm but more than 50 cm | ND |

| Measured or multiple of measured |

| KD |

| In the bays | At least 10 m | BT |

- The cross-sectional shape is most often round, sometimes profile, less often multifaceted or complex.

Examples of square sections

- For drawn and cold-rolled products, the condition of the material is also established, which is indicated by the following letters:

- M – soft;

- L – soft with increased plasticity;

- H – quarter-solid;

- P – semi-solid;

- And – semi-solid with increased plasticity.

- Depending on the wall thickness, there are thick-walled and thin-walled brass pipes.

- Manufacturing accuracy:

- N – normal;

- P – increased;

- B – high.

- Conditions may be specified:

- T – increased accuracy in curvature;

- K – high accuracy in curvature;

- A – antimagnetic pipes.

Tip: when choosing a suitable sample, pay due attention to the markings. The letters and numbers it contains will give you a complete idea of the technical characteristics of the product.

Pipe L68

The product is made from brass brand L68 and has a double (simple) structure. Composition: 68% Cu 32% Zn. Due to the fact that such a material is single-phase in structure, it is characterized by high ductility, good strength, and corrosion resistance. The inclusion of zinc makes the machining process easier and also reduces the cost of production. The product is well processed using cold pressure and is easy to solder and weld. L68 pipes are: soft, semi-hard, hard. The type is selected depending on the pressure required during cold forming. The annealing method is used to improve wear resistance. Mainly used for the production of various semi-finished products, ammunition, and cryogenic equipment.

Popular brands and manufacturers (Table)

Brass products are extremely in demand due to their unique combination of mechanical and technological characteristics.

Important!

The composition of brasses subject to pressure treatment is regulated by GOST 15527-70. The composition of foundry brasses is determined by GOST 17711-80.

To mark simple brasses, the letter “L” is used. The numbers following it indicate the amount of zinc. For example: L90 or L 68. More complex designations are used to mark multi-component brasses. For example: LMts58-2 or LS59-1.

Markings and properties of brass are presented in table No. 3

The most famous manufacturers of brass products:

| Company `s logo | Name | Since what year on the market |

| Unipump | since 2000 | |

| Valtec | since 2002 | |

| Zilmet | since 1970 | |

| Becool | since 2004 | |

| Karcher | since 1935 | |

| Mpstar | since 2005 | |

| ART-Metal | since 2006 | |

| Leroy | since 1923 | |

| Alfa Laval (Alfa Laval) | since 1883 | |

| Funke | since 1973 | |

| ONDA | since 1998 | |

| Ridan | since 1998 | |

| Rehau | since 1948 | |

| Uponor | since 1918 |

Pipe LS59-1

The LS59-1 grade pipe consists of multi-component lead brass. Composition: about 59% copper, 40% zinc, 1% lead. The structure is two-phase; a distinctive feature is that the rolled products have high strength and wear resistance. The inclusion of zinc makes the machining process easier and also reduces the cost of production. The material can be easily processed by pressure when hot and is easy to cut. Brass tube LS59-1 comes in: soft, semi-hard, hard. The type is selected based on the pressure required during hot deformation. Hot annealing improves resistance to friction and imparts anti-corrosion properties. This type of rolled product, grade LS59-1, is used to produce gears, semi-finished products, hardware, gears, and bushings.

Questions and answers (FAQ)

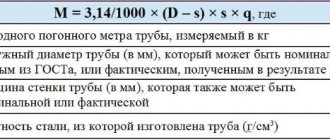

How much does a brass pipe weigh?

Weight can be calculated from the table

How much does a brass pipe cost?

Where are brass pipes used?

The scope of application of the products is varied. It is used in instrument making, mechanical engineering, and shipbuilding. It is necessary when installing pipelines for industrial and domestic purposes.

How to solder brass pipes?

For soldering, a flux with potassium fluoroborate or borax is required. In addition, you need to stock up on high-quality solder. The peculiarity of the technique is that only the connecting layer melts. The ends remain intact. The connection is very strong.

Why did the brass valve on the copper pipe turn dark?

This happens because oxides have formed on the surface.

How to clean brass pipes?

To clean brass, use products containing oxalic, nitric or formic acid. Acetone also works well for this. The most effective folk remedy is a solution of salt (1 tablespoon) and vinegar (1 tablespoon) in two liters of water. The solution is brought to a boil and a hot compress is applied to the pipes.

How to connect a HDPE pipe with a brass fitting?

Fittings are required at main branch lines. They also connect fragments of different sizes. To make the connection you will need a crimping tool.

You can clearly see how to connect HDPE pipes with brass fittings in the video:

How to bend a brass pipe?

The product is first filled with molten rosin. The bending radius depends on the wall thickness and diameter. According to pre-made markings, bending is performed using pipe bending equipment. At the end of the operation, the rosin is melted out of the pipe.

How to make a handrail from a brass pipe?

Brass is very easy to work with. The required radius is given to the brass wall handrails using rollers. At the same time, we must remember that it may be impossible to bring a long pipe that spans the entire wall into the room. Therefore, brass handrails are made according to the design principle. Connections are made using glue or welding.

How to wind a 12 mm brass tube onto a 50 mm pipe with a spiral?

- Seal the tube on one side with a plug.

- Pour sand inside. You can use baking soda.

- It is necessary to monitor the density of the sand inside. This will prevent flattening during winding.

- A product with a larger diameter is clamped in a vice.

- The tube is then wound in a spiral around a larger diameter pipe.

- Upon completion, remove the plug and pour out the sand.

Bending and soldering of brass pipes

To give the desired shape, the products are bent. Connections are made by soldering.

- Before the process, fill the cavity of the product with soda.

- After completion, if you can’t knock out the soda, use a syringe and a thin PVC tube

Bending

This process is performed only using the cold method. Before work begins, the products are filled with molten rosin. This will prevent wrinkles at the fold points.

The main thing in this operation is to choose the right radius. It, in turn, depends on the diameter and wall thickness of the pipe. Marking is done with a marker.

Bending is performed using special equipment:

- pipe benders;

- special plates with stops;

- pipe bending machines (the most effective method guaranteeing impeccable quality).

Upon completion of the process, it is necessary to melt the rosin from the inside.

Attention! Rosin is melted from the ends of the product for safety reasons. If you start heating from the middle, then there is a high risk of rupture.

Bending - advice from technologists

- The pipes are pre-annealed at a temperature of 700 degrees Celsius and cooled in water.

- During the operation, shrinking of the inner side is performed simultaneously with stretching of the outer side (the procedure should be performed smoothly without jerking).

- If deformations form on the surface, they must be corrected immediately with a hammer.

- You can avoid folds in the following way: initially bend intensively, exceeding the standards specified in the template. Then bend it to the desired parameters. The wrinkles will disappear.

Soldering

The soldering method guarantees a high-quality and hermetically sealed permanent connection. Connections with a large contact area are selected for it.

First of all, you will need flux. In common practice, rosin-alcohol fluxes are used. However, they do not remove the oxide film from the metal surface. Therefore, the correct choice would be a flux with potassium fluoroborate or borax.

If the pipe contains a large amount of copper, the solder may contain copper-phosphorus or silver components.

Although similar to welding, this method is still significantly different.

Important! The essence of this method is that only the connecting material (solder) melts, while the surface of the pipes is preserved in its original state.

Hard solder (eg copper L-CuP6) is also used on an industrial scale. The melting point of hard solders reaches 1200 degrees. In this case, the result can be of high quality, and the strength of the connection is maximum.

The gap size when hard soldering should be less than 0.5 mm. An acetylene-oxygen flame is used to heat the edges. Fluxed ends must be heated to a temperature of 700/800 degrees Celsius. Then the solder is quickly introduced. The process is considered complete when the soldering area has cooled.

The most important parameters according to GOST

When choosing a brass pipe, you should pay special attention to those parameters that are regulated by the provisions of the regulatory document. Thus, according to GOST, cold-rolled and drawn pipe products (both thick-walled and thin-walled) can correspond in terms of their hardness to one of three categories: soft, quarter-hard, semi-hard. A round brass pipe, if it is produced in a semi-solid version, must undergo a procedure during the manufacturing process such as the removal of internal tensile stresses.

The provisions of the regulatory document also set out the requirements for the surface condition of such profile products. Thus, in accordance with GOST, a round brass pipe should not have significant burrs, holes, or cracks on the surface. If the size of the defects, which also include dents, burrs and depressions, are insignificant and can be easily corrected by stripping, then their presence on the surface of the pipes is allowed.

Symbols for brass pipes

The regulatory document also allows the following defects on the surface of profile pipe products made of brass:

- redness;

- ringiness;

- traces of editing and tarnish;

- seam marks – for products produced by rolling and drawing methods from welded blanks.

GOST also stipulates such a parameter of brass pipe rolling as the cutting angle, which can be:

- up to 7 mm – for thick-walled pipes whose outer diameter exceeds 0.17 m;

- up to 5 mm – for pipes with an outer diameter from 0.1 to 0.17 m;

- up to 4 mm – for products with an outer diameter from 0.05 to 0.1 m;

- up to 3 mm – for pipes with a diameter of 0.02–0.05 m;

- up to 2 mm – for pipes whose diameter does not exceed 0.02 m.

Brass pipe L68 is a common type of non-ferrous metal, costing much less than similar copper products

For pressed brass pipes with an outer diameter of up to 12 mm, manufactured in quarter-solid and semi-solid versions, GOST specifies a parameter such as the degree of curvature per meter of length, expressed in mm. Thus, the following dimensions are specified:

- pressed pipes with an outer diameter exceeding 160 mm - 15 mm;

- pressed products of other diameters – 5 mm;

- pipes with an outer diameter of at least 13 mm, produced using cold rolling and drawing technology - 5 mm.

For cold-rolled and drawn brass pipes, which have a small outer diameter and are sold to consumers in coils, this parameter is not standardized.

There are also the following mechanical parameters for brass pipes:

- the value of relative elongation - for pipes made of brass grades LS59-1 and LS60 - 20%; for products made of brass brand L63 – 25–40%; LzhMts59-1-1 – 28%; Lc68 – 35–40%;

- the value of temporary resistance is 270–430 MPa.

Thick-walled brass pipe dimensions - Metalworker's Handbook

Brass pipe can be used for various purposes: from the construction of pipelines for domestic and industrial purposes to the manufacture of frame structures, since the material is resistant to corrosion and other aggressive environments, durable and easy to install.

Pipes made of brass

Brass thick-walled bronze pipe: GOST 1208 90

thick-walled bronze pipe

Bronze pipe, due to its advantages in storage and service life, is very popular among buyers: bronze pipes are not susceptible to corrosion, are very reliable and flexible, are not attracted to magnets, and the most important advantage is that they retain heat for a long time and conduct it well.

Such a pipe can be made from bronze alloys of various types, which are capable of deformation in cold and hot states. The pipe production operation most often occurs in the intervals of some long cycle in the field of technology. Once received, they go through the process of stamping or pipe cutting, it all depends on what kind of product we need to make.

Based on cross-section models across the pipe, they are classified into several types.

The most popular will be:

- Circle shape;

- Oval shape;

- Flat oval shape.

What is bronze alloy pipe made of?

During the production of such a pipe, the bronze alloy must consist of two or more components. In this case, you can use metals of different types, but there are exceptions - these are alloys of zinc and nickel. By adding any other metal, the quality and strength of the bronze alloy improves.

The material is divided into several types depending on its composition:

- Made of aluminum (see Aluminum pipes);

- Made of tin;

- From beryllium and so on.

Bronze, which is based on aluminum, should contain it from 5% to 10% (see corrugated aluminum pipe). Compared to tin-based alloys, this alloy is superior in mechanical and lubrication properties, but it is worth noting that tin is superior in casting properties.

Take note! In order to prevent your pipes from corroding, you need to enrich such an alloy with iron, nickel and manganese alloys.

Advantages in the quality of produced bronze alloys can make it possible to produce other elements in addition to pipes: plugs, connections and others.

Advantages of tin alloy material: in the field of foundry, lubricating features, rust-resistant, cutting processing. They are almost always replaced by other types of bronzes, which have the best qualities and performance in the field of technology.

Here are some examples:

- An alloy based on beryllium (it contains from 1.8-2.3) is the most stable, elastic and long-lasting. If you want to install just such pipes, then it is suitable for a room in which the environment is aggressive;

- An alloy based on silicon (it contains from 3% to 4%), but some nickel, manganese and zinc are added to it. It has similar advantages to steel alloy;

- Lead-based alloy (contains approximately 30%) is described as having better lubricating properties.

Copper-based alloys are marked with the following letters: Br, L. These letters identify the materials that make up the alloy, and the numbers next to them indicate their content in the form of percentages. Let's give an example: BrMts1A8L bronze is 1% manganese, 8% aluminum, copper alloy (the letter L indicates that it is a cast alloy).

Engineering Requirements

Pipes of this type must comply with these engineering requirements:

- The pipe must be clean inside and outside and inspected from all sides, including the inside. There should be no flaws on the surface and inside, that is: shells, crevices, films, discrepancies and bubbles.

- It is acceptable if there are minor defects on the outer surface of the pipe, for example, dents, small and invisible scratches, traces of cleaning of small defects, but upon final cleaning, the dimensions of the manufactured pipes must correspond to the standard.

- The outer surface of the pipeline can be made of a ring type and the presence of a tan color is allowed.

- The alloy of such a pipe should not have any defects inside the product (non-alloy metal composition, cavities, pressed ties, cracks, delaminations, etc.).

- There should be no burrs on the pipeline sections that are noticeable by visual inspection.

- The oval shape must comply with all standards; there should be no difference between the dimensions and wall thickness of the pipelines.

Top stunned View all

Thick-walled seamless steel pipes, seamless, retail

Building / repair » Rolled metal / fittings

25 UAH

Dnipro, Kirovsky Today 10:35

Thick-walled pipes can be used on posts

Household / repair » Other building materials

4 UAH

Thick-walled steel pipe st45, 40X, 30hgsa, retail

Building / repair » Rolled metal / fittings

26 UAH

Dnipro, Kirovsky Sogodni 11:48

Knowledge is stunned

Do you want to sell swedes? Be aware, yak

Thick wall pipe

Building / repair » Rolled metal / fittings

20 UAH

Thick-walled steel pipe st45, 40X, 30hgsa, retail

Building / repair » Rolled metal / fittings

26 UAH

Dnipro, Kirovsky Sogodni 11:48

Thick-walled seamless steel pipes, seamless, retail

Building / repair » Rolled metal / fittings

25 UAH

Dnipro, Kirovsky Today 10:35

Aluminum pipe, thick-walled duralumin D16T, and anode AD31T5

Building / repair » Rolled metal / fittings

130 UAH

Kiev, Podilsky Sogodni 10:20

Selling seamless thick-walled pipes and forgings

Household / repair » Other building materials

1 UAH

Dnipro, Babushkinsky Sogodni 09:16

Thick-walled steel pipe, retail, cutting,

Building / repair » Rolled metal / fittings

27 UAH

Dnipro, Krasnogvardiysky Today 08:18

Thick-walled pipe for 15 rubles/kg

Home and garden » Garden / city

8 UAH

Thick-walled pipe

Building / repair » Rolled metal / fittings

2,200 UAH.

Thick-walled pipes can be used on posts

Household / repair » Other building materials

4 UAH

Thick-walled pipes

Building / repair » Rolled metal / fittings

1,000 UAH

New thick-walled pipe 273x40x515mm – 118.3 kg for 23 UAH, etc.

Business and services » Sirovina / materials

Seamless hot-rolled thick-walled pipes 129-86, 103-73.

Building / repair » Rolled metal / fittings

22 UAH

Thick-walled metal pipe!!

Building / repair » Rolled metal / fittings

1,200 UAH.

Thick-walled metal pipe

Household / repair » Other building materials

2 100 UAH.

Thick-walled pipe, diameter 89 mm,

Building / repair » Rolled metal / fittings

15 UAH

Thick-walled pipe, cut off pieces

Building / repair » Rolled metal / fittings

20,000 UAH.

thick-walled stainless steel pipe.

Building / repair » Rolled metal / fittings

75 UAH

Lugansk, Artemivsky 3 blk.

Thick-walled asbestos pipe

Building / repair » Burning

800 UAH

Thick-walled aluminum pipe

Building / repair » Rolled metal / fittings

35 UAH

Thick-walled pipe, gate post, etc.

Home and garden » Other household goods

450 UAH

Selling a metal well. Thick-walled pipe.

Home and garden » Garden / city

350 UAH

thick-walled pipe 60mm.

Building / repair » Rolled metal / fittings

15 UAH

Kropyvnytskyi, Kirovsky district 3 blk.

Seamless thick-walled hot-rolled, cold-rolled pipe GOST 8732

Building / repair » Rolled metal / fittings

32 UAH

seamless thick-walled pipe

Building / repair » Rolled metal / fittings

31,900 UAH.

Thick-walled seamless steel pipe 132mm, thickness 4mm

Building / repair » Rolled metal / fittings

350 UAH

Thick-walled pipe 5.2 m

Building / repair » Rolled metal / fittings

1,800 UAH

Steel pipe 220 thick-walled

Building / repair » Rolled metal / fittings

400 UAH

Thick-walled pipe

Building / repair » Rolled metal / fittings

16 UAH

Krivy Rig, Dolgintsevsky 1 black.

Plastic pipes, diameter 450mm, thick-walled

Household / repair » Other building materials

1,500 UAH.

Thick-walled metal pipe, fence posts

Building / repair » Rolled metal / fittings

9 UAH

Thick-walled pipe section

Building / repair » Rolled metal / fittings

750 UAH

New plastic thick-walled pipes

Household / repair » Other building materials

180 UAH

Steel pipe 220 thick-walled

Building / repair » Rolled metal / fittings

600 UAH.

Thick-walled watering pipe 16 mm. / 1.5 mm – 50m/p

Home and garden » Garden / city

100 UAH

Thick-walled plastic pipes

Household / repair » Other building materials

20 UAH

Thick-walled steel pipe

Building / repair » Rolled metal / fittings

9 UAH

Thick-walled pipe 5740 mm

Building / repair » Rolled metal / fittings

300 UAH

The pipe is thick-walled.

Building / repair » Rolled metal / fittings

100 UAH

Zaporizhzhya, Komunarsky 28 herbs.

Steel pipe, seamless, thick-walled with threaded ends

Building / repair » Rolled metal / fittings

400 UAH

Production Features

A brass pipe can be made from alloys of various grades, which may include alloying additives to improve their quality characteristics. In addition to differences in chemical composition, the brass from which tubular products are made may also differ in their phase state. According to this criterion, such alloys are divided into cast and wrought.

Brass pipes are produced in three ways: horizontal casting, hot (pressed) or cold (drawn) deformation

Depending on the wall thickness, pipes for the manufacture of which brass alloys are used are divided into thick-walled and thin-walled. Thick-walled products, produced in one-piece design, without the use of welded seams, are used in cases where they must transport gaseous and liquid media under significant pressure. Naturally, it is not advisable to use such brass pipes for the installation of domestic water supply: they are mainly used for installing communications at large industrial enterprises.

Thin-walled pipes, for the manufacture of which brass alloys are used, are optimally suited for use in domestic conditions. Such pipe products are used for installing water supply systems, for arranging boiler systems, as well as for solving many other problems related to the transportation of liquid and gaseous media. Thin-walled brass products are produced using two technologies: cold rolling and pressing. The high popularity of such products is explained by their exceptional corrosion resistance combined with fairly high strength.

Areas of application of brass pipes

From brass alloys of various grades, pipes are produced not only with round, but also with square, rectangular, hexagonal and oval cross-sections. They can be easily processed in various ways and are well connected by soldering; they are actively used not only in the construction industry, but also in the production of furniture, finishing work, and also for the manufacture of decorative interior structures.

Varieties of cross-sections of brass pipes

Use for installation of plumbing systems

The most traditional types of pipes used in plumbing systems are steel, plastic, metal-plastic and, in some cases, copper. A brass pipe for arranging water supply lines is used when it is necessary to ensure the minimum weight of their elements. In all other cases, it is better to use rolled pipes made from other materials for installing a water supply system.

If pipes made of brass alloys are used infrequently when arranging water supply systems, then fittings made of this material are used very actively. The reason for the popularity of brass connecting elements is that, having a sufficiently high rigidity, they are able to provide the required tightness and reliability of the formed connection. It is also convenient that fittings made of brass are very easy to install: there is no need to use special equipment that requires exposure to high temperatures.

The use of brass fittings allows for quick and high-quality installation of communication systems made of steel, plastic and metal-plastic pipes.

Application and installation features of systems

These products are relevant for the mechanical engineering and shipbuilding sectors. It is also used in instrument making. Pipes of different diameters are needed for shell-and-tube heat exchangers, for cable laying or electrical wiring. But most often, copper and brass round pipes in accordance with GOST 617-2006 are used when installing pipelines.

For plumbing and hot water supply

Brass is used in plumbing and heating systems as an alternative to pipes made from any other metals. It has a low specific gravity , due to which the load on the building is not heavier.

Before starting installation work, it is necessary to perform a full hydraulic calculation of the parameters.

It includes:

- choice of sizes;

- choice of diameters;

- formation of a wiring diagram for the pipeline system.

Installation work cannot be completed if you do not stock up on connecting elements in advance.

These include:

- brass pipe diameters (mm): 12, 15, 18.

- reduction and connecting coupling (in the required quantity, which is calculated in advance at the design stage);

- adapter for working with inch threads;

- 90 degree bend;

- prefabricated calibrated elements that provide transition to a brass pipe with an inch thread;

- tees (regular and transitional).

Brass coupling DN 40

In addition, the plumbing system includes faucets and valves. Their number and location points are also calculated during the preparation of the project. In order to be able to secure them, “water outlets” are needed.

The connection is made using electric arc or gas welding. Before welding begins, the ends of the pipes are cleaned. Moreover, cleaning must be done both outside and inside.

Important!

All welding work must be carried out at temperatures below 50 degrees Celsius.

Before joining, the prepared products must be washed and degreased with special compounds.

Gas welding

To implement this technique, an acetylene-oxygen flame is used. This is an effective method of joining, but it is fraught with the formation of microscopic pores at the site where the seam is formed. Such a connection cannot be called high-quality. A variety of deposits can accumulate in the pores, which over time will begin to have a destructive effect on the system. To avoid such consequences, an oxidizing flame is used.

Upon completion of the work, the joints are forged:

- if the joint is 5 mm or less - without heating;

- if the joint is more than 5 mm, use the heating method to 400 degrees Celsius.

Only after this is annealing carried out under heating conditions of up to 650 degrees Celsius. The final stage is cooling.

Brass pipe: where it is used, how to select and install it yourself

Brass pipe can be used for various purposes: from the construction of pipelines for domestic and industrial purposes to the manufacture of frame structures, since the material is resistant to corrosion and other aggressive environments, durable and easy to install.

Pipes made of brass

Advantages and scope of brass pipes

Pipes made of brass differ:

- strength, which allows them to be used in pipelines with increased internal pressure, as well as for the construction of gas pipeline systems;

- resistance to a number of factors:

- to the formation of corrosion, which is the main factor when selecting pipes for water supply;

- to temperature changes (domestic and industrial heating systems);

- to the negative impact of aggressive environments (oil and gas industries, chemical production, etc.);

- immunity to mechanical damage and ease of installation, which leads to such applications as the manufacture of building frames, small architectural forms (gazebos, greenhouses, etc.), stairs and other types of fences.

Laying out brass water pipes

Rules for choosing brass pipes

The selection of brass pipes should be based on determining the following parameters:

- pipe wall thickness. Brass pipes can be produced by several methods: drawing, pressing and cold rolling. Depending on the manufacturing method, pipes can be thick-walled or thin-walled. Pipes with larger wall thicknesses are mainly used for the manufacture of industrial pipelines and high-pressure pipelines. Thin-walled ones are used in everyday life for the construction of water supply systems, heating systems, and so on;

Pipes with different wall thicknesses

- form. Products made of brass can have a round, oval, square, rectangular and so on cross-section. A round pipe is used for the construction of pipelines, and a profile pipe (of a shape other than round) is used for the construction of frames, crafts, furniture, and so on;

Round and profile brass pipes

- diameter. The dimensions of brass pipes are manufactured in accordance with GOST 494-90. The diameter can vary from 3 mm to 100 mm, and the length is 1 – 10 m. The most popular in everyday life are pipes with a length of 6 m and a diameter of 32 mm, since it is from them that household water supply and heating systems are made;

- condition of the material. Pipes produced by cold rolling and drawing methods can be soft, semi-hard or soft and semi-hard with increased elasticity. It is more expedient to use them for the construction of furniture and other crafts, as well as laying heated floors and other similar systems;

- precision manufacturing. According to GOST, pipes can have normal, increased and high strength. Products with high strength are used for the manufacture of devices, and pipes with normal and increased strength are suitable for the construction of pipelines.

The main characteristics of brass pipes are indicated in the markings.

Determination of pipe parameters by marking

Rules for installing brass pipes

Installation of pipes made of brass can be done in two ways:

- welding;

- threaded fittings.

Welding brass pipes

The connection can be made:

- gas welding using oxygen acetylene. Welding can be done butt welding or using fittings;

Welding with acetylene oxide using fittings

- electric arc welding with tungsten electrodes;

Butt welding of pipes using electrodes

- soldering using hard solders made of silver or an alloy of copper and zinc, as well as fittings of various shapes.

Connecting pipes by soldering

The welding connection technology is the same, regardless of the method, and is performed in the following sequence:

- Preparation. At this stage, pipes are cut, deburred and removed from dirt and other types of similar deposits;

- heating and direct connection;

- cooling period, during which the pipes must remain stationary.

How to solder brass pipes, watch the video.

Connection with threaded fittings

The easiest way to assemble brass pipes is to make a threaded connection, which requires threaded fittings. As a rule, connecting elements are also made of brass, but in some situations, for example, when building a water supply system in a country house with minimal water consumption and a minimum level of pressure, HDPE fittings can be used.

Threaded brass fittings

The installation technology is as follows:

- preparatory stage: cutting in accordance with the pipeline system diagram, cleaning from dirt, dust and other deposits, deburring;

- thread cutting. The work is done using taps (for internal threads) and dies (for external threads). The size of the tools used must correspond to the size of the thread on the connecting fitting;

Preparation for installation with threaded fittings

- sealing the connection. For water supply and heating systems, for example, FUM tape, flax thread or Tangit Unilok thread can be used as insulating materials;

Thread insulation with Tangit Unilok thread

- connection of elements. Tightening the thread.

Properly selected and installed brass pipes can last more than 50 years. If you can’t do the installation yourself, you can use the help of specialists.