Types of cutting wheels

Classification by purpose

- Metal discs. Scope of application: cutting reinforcement, profile pipes, steel angles, channels, sheet steel.

- Circles on wood. Also used for cutting plastic pipes, window profiles, plasterboard and MDF boards. Made from high-strength steel, the outer edge of the disc is equipped with sharp teeth.

- Cutting discs for stone. Designed to work with products made of sand-lime brick, paving slabs, stone structures, paving stones, asbestos-cement sheets.

Classification by production technology

Abrasive discs

The base of the metal disc consists of at least two layers of fiberglass mesh, on top of which a mass of abrasive materials is applied:

- corundum;

- silicon carbide;

- electrocorundum.

The technology for manufacturing cutting wheels for metal involves heat treatment, after which the product becomes resistant to destruction. The disc is baked in an oven at a temperature of +2000C.

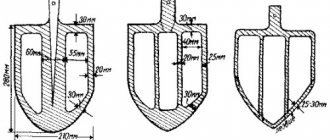

Depending on the shape, abrasive consumable tools are divided into two types:

- flat disks;

- circles with a concave sleeve.

Diamond wheels

Area of application: cutting particularly durable materials:

- concrete,

- granite,

- marble,

- red brick,

- asphalt,

- stone

Made from steel. An abrasive mass containing diamond chips is applied to the end part of the circle. The width of the diamond-bearing layer varies from 1.5 to 3 mm.

In large-diameter circles intended for pass-through work, the width of the layer of diamond chips can reach 1-2 cm.

There are three types of diamond cutting discs on the market:

- Solid. Designed for wet cutting of materials, it is a solid disc with a continuous diamond edge.

- Segmented. Used for dry cutting. The cutting diamond edge is divided into separate segments.

- Turbo disc. The diamond-bearing edge is made in the shape of a wave. The presence of inclined grooves reduces the contact area with the working material, resulting in natural cooling. The universal wheel is used for wet and dry cutting.

Application of cutting discs for metal

Certain wheels are used when cutting samples of varying degrees of hardness. It could be:

- brick;

- concrete;

- metal;

- granite, difficult to cut.

How to choose cutting discs for an angle grinder for metal

You can also perform grinding at any level, stripping metals, cleaning surfaces from paint, corrosion and adhesives.

Cutting discs can be selected for small, medium and large grinders. When choosing, the main attention should be paid to the selection of external and internal diameters. The depth of the cut will depend on the size of the circle.

Cutting wheels for metal

Also important is the number of teeth – cutting segments, which varies from 24 to 100 and is responsible for the cutting speed. The greater the number of teeth, the higher the speed.

When cutting metal, discs with a diameter of 200–300 mm are most often used. They are used for cutting aluminum and steel profiles, sheet steel, fittings and non-ferrous metals.

Characteristics of cutting wheels

Bundle type

The strength, productivity and quality of the cut depends on the type of bond. In the production of discs, organic and inorganic binders are used. The first type includes vulcanite and bakelite, the second - ceramic.

Vulcanite binder is a mass of rubber and sulfur that has undergone heat treatment. Discs based on it are characterized by a dense structure and elasticity.

The strength of the vulcanite bonded wheel allows for operating cutting speeds of 50,60 and 80 m/s.

The basis of the bakelite binder is powdered and liquid phenol-formaldehyde resins with fillers. Cryolite, alabaster, and pyrite are used as fillers.

Abrasive wheels on a bakelite bond are characterized by high bending and compressive strength, but they are not resistant to the effects of alkaline cooling water (the alkali content in the liquid should not exceed 1.5%).

The operating speed of circular rotation is over 80 m/s.

The disadvantage of bakelite binder is its low heat resistance: when heated to 2000C, it becomes brittle, and when the temperature rises to 250-3000C, it burns out.

The starting materials for creating a ceramic bond are:

- fire-clay;

- talc;

- liquid glass;

- chalk;

- quartz;

- feldspar.

The ceramic binder increases the water resistance of the abrasive tool; it is characterized by high fire resistance and resistance to chemicals. Disadvantages include sensitivity to impact loads and low bending strength.

Outer and inner diameter of cutting wheels

The market offers cutting discs with outer diameters from 115 to 500 mm. The following are in demand in everyday life:

- diameter 115 mm – designed for small-sized grinders;

- diameters 125, 150 mm – used in angle grinders of medium power and size;

- diameters 180, 230 mm - intended for professional tools.

The diameter of the seat for household tools is most often 22 or 32 mm.

Grain

The characteristic displays the cutting ability of the cutting wheel. The fraction of the abrasive substance varies in the range from 100 to 2000 microns. The higher the grain size, the better the cutting quality.

But at the same time, large abrasive grains reduce the strength of the consumable tool.

Abrasive substance

The performance quality of cutting discs is influenced not only by the grain size, but also by the shape and characteristics of the abrasive substance.

The shape of electrocorundum particles is most suitable for cutting steel products; harder grains of silicon carbide are intended for working with non-metallic materials or alloys of non-ferrous metals.

An important parameter is the heat resistance of the abrasive. Corundum abrasives have the best heat resistance; the operating temperature range of the substance is from 1700 to 19000C.

Diamond abrasives and boron carbide are characterized by the lowest heat resistance - 700-8000C.

Thickness of cutting wheels

The thickness of household cutting discs ranges from 1-5 mm. It is rational to use thin wheels when working with low-power angle grinders.

The smaller the height of the disk, the easier and faster the cutting process occurs - due to the lower resistance of the material. Cutting with a thick wheel will require more effort.

Consumable tools with medium and small outer diameters can have any thickness, circles with large diameters can only have the maximum thickness.

How to cut a pipe with a grinder

To cut pipes with a grinder, it is recommended to use cutting wheels with a thickness of no more than 1 mm, otherwise the cut will be more difficult, and there will also be too many sparks and flying hot particles.

The technology for carrying out the work is as follows:

- The pipe is secured in a vice or secured in another way. In this case, the cut part should hang down. It is not allowed to place the workpiece between two supports and make a cut in the middle, as the cutting blade will jam (due to sagging pipe).

- Markings are applied using a strip of paper and masking tape. The ends of the tape should meet as accurately as possible. Home craftsmen recommend lowering the pipe into the liquid at the required angle, and then marking the cut line along the dry and wet boundary.

- The cut should be made from the top of the pipe, gradually lowering the angle grinder lower. The cutting disc should go along the very edge of the glued strip.

A large diameter pipe is cut a little differently, since the working part of the circle does not allow this to be done in one go. The wall is cut sector by sector, and the pipe is turned to the desired side.

Advantages

The main advantages of abrasive wheels:

- the porous structure ensures natural cooling of the consumable tool;

- the disc does not become dull during operation;

- affordable price;

- large selection of products.

Positive qualities of diamond cutting blades:

- high cutting precision;

- wear resistance;

- there is no strong burning smell;

- minimum number of sparks during operation.

Voting for the best diamond blade

Which diamond blade would you choose or recommend?

HUSQVARNA 5748362-03

16.67 % ( 2 )

BOSCH 2608603241

8.33 % ( 1 )

GRAFF GDD 18 350.10

0.00 % ( 0 )

PRACTICE 030-771

8.33 % ( 1 )

BISON 0515001

0.00 % ( 0 )

Hilberg Super Metall 520350

0.00 % ( 0 )

MESSER 01-61-126

0.00 % ( 0 )

MESSER 01-26-230

16.67 % ( 2 )

Diam Granite—Elite 000202

25.00 % ( 3 )

KEOS DBP01.115

8.33 % ( 1 )

Di-Star 1A1R Hard Ceramics (11120048015)

8.33 % ( 1 )

Flaws

The negative qualities of abrasive consumables are:

- formation of a sheaf of sparks during operation;

- the appearance of a strong characteristic odor when cutting;

- rapid wear.

Disadvantages of diamond wheels:

- expensive;

- low heat resistance.

How to choose cutting wheels

The main designations influencing the choice of product are:

- type of compatible equipment (hand tools, stationary equipment);

- best before date;

- abrasive grain size (the smaller the numerical value of the grain size, the larger the grain fraction);

- outer diameter of the circle and seat size;

- thickness of consumable tool;

- maximum number of revolutions (the parameter should not exceed the rotational speed of the power tool);

- operating speed (indicated as a numerical value or marked with a transverse color stripe: yellow indicates speed up to 63 m/s, red – up to 80 m/s, green – up to 100 m/s);

- type of ligament, presence of a reinforcing element;

- purpose of the tool (the type of working material is indicated in the form of a graphic image or color designation).

Color designation of the type of working material

For abrasive wheels:

- green color - stone;

- blue color – steel.

Marking of diamond blades:

- green color – granite;

- blue color – marble, concrete;

- yellow color – tiles, alabaster;

- orange color – brick;

- gray color – granite, ceramics, tiles.

Comparative characteristics of diamond blades

See the product characteristics in the table to make your choice:

| Name | Bore diameter, mm | Circle thickness, mm | Circle diameter, mm | Diamond blade weight, grams | Manufacturer country | Price in rubles |

| 22.2 | 1.6 | 180 | 300 | Russia | From 745 |

| 25.4 | 1.6 | 200 | 360 | Ukraine | From 1500 |

| 22.2 | 1.4 | 115 | 120 | South Korea | From 1310 |

| 25.4 | 1,6 | 250 | 645 | China | From 2673 |

| 22, 23, 25.4 | 1.6 | 230 | 600 | Russia | From 4256 |

| 22.2 | 2.8 | 125 | 160 | Russia | From 1609 |

| 20, 25.4 | 2.7 | 350 | 1194 | Russia | From 7161 |

| 22.2 | 2.2 | 230 | 660 | Russia | From 575 |

| 22.23 | 3 | 150 | 170 | Russia | From 1290 |

| 20 | 3.4 | 350 | 700 | Belarus | From 7161 |

| 22.23 | 2 | 150 | 2180 | Germany | From 7483 |

| 25.4 | 2.4 | 230 | 1710 | Sweden | From 16300 |

Which ones are better

The ideal cutting wheel is:

- Bakelite bonded product with a reinforcing element.

- Type of abrasive: for ferrous metals - simple electrocorundum, for stainless steel products - white electrocorundum.

- The average thickness of a cutting disc for metal is 1.6-2 mm.

- The universal outer diameter for a metal circle for household use is 125 mm.

- For cutting steel structures, it is better to use discs with a fine fraction of abrasive particles.

Diamond cutting

- For dry cutting of structures made of concrete, granite, brick, the ideal consumable tool would be a segmented diamond disc with an outer diameter of 230 mm and a diamond-bearing layer width of 2.5-3 mm.

- To organize furrows for the purpose of further laying utilities, it is better to choose a segmented circle with a diamond-bearing layer of 3.5 mm and a diameter of 350 mm.

- For working with ceramic tiles and marble, a solid diamond-coated cutting wheel is suitable. This cutting method requires mandatory cooling with water.

- For cutting reinforced concrete structures, it is better to use a diamond turbo disc.

Wood cutting wheel

- The best consumable tools for cutting wooden products are carbide discs reinforced with soldering with a high content of tungsten or cobalt carbides.

- The typical thickness of a wood disc is 3.2 mm.

- The universal size of the outer diameter is 130-250 mm.

- The ideal number of teeth for a cross cut is 80-90 cutters, for a longitudinal cut - no more than 60 cutters.

- The optimal angle of inclination of the teeth: for longitudinal cutting - 15-200, for cross cutting - 5-150.

The optimal cutting speed is selected depending on the type of wood:

- for soft rocks – from 50 to 90 m/s;

- for hard rocks – from 50 to 80 m/s;

- joinery wood – 60-80 m/s;

- exotic breeds - 80-85 m/s.

How to choose the right one for an angle grinder?

First of all, you need to decide what type of material you will have to work with and what size the surface to be processed will be. This affects what kind of circle design is needed. Most cutting wheels are designed for cutting non-metallic materials, such as glass, concrete or brick, but there are also those that are made specifically for metal work. Therefore, you need to take into account that for each type of working surface there is its own type of cutting wheel.

One of the basic rules for choosing discs is that for “soft” materials, purchase wheels that have a cutting surface with a hard diamond surround; for “hard” materials, on the contrary, with a “soft” one. The reason is that when cutting hard materials, diamonds wear out very quickly, and new ones must appear to replace them as quickly as possible. On the contrary, in a hard cutting strip, diamond inclusions will last much longer.

Exploitation

Working with abrasive cutting equipment involves high rotation speeds and requires compliance with safety measures. Before starting work, read the safety precautions specified by the manufacturer.

- Minors and people in a state of intoxication are not allowed to work with cutting devices. The presence of children and animals is not allowed near the work site.

- Carry out cutting work away from flammable materials.

- Use cutting discs only for their intended purpose.

- Before starting the operation, inspect the disc; do not use consumable tools with signs of damage (chips, cracks).

- Do not use expired wheels.

- Follow the rules for storing consumable tools.

- When working with power tools, use personal protective equipment.

Operating rules:

- Before starting cutting work, securely secure the wheel in the power tool.

- Use a tool that has a protective casing that can withstand the impact of a wheel break and catch any splinters.

- When cutting metal, secure the metal structure on only one side; this will help prevent excessive heating and deformation of the material, and, as a result, jamming of the abrasive disc.

- When cutting, keep the wheel straight, applying only radial pressure.

- If intense sparking occurs, cutting work should be stopped for 10-15 seconds, after the specified time has elapsed, continue working at a lower cutting speed.

Installing a cutting wheel into an angle grinder:

- Unplug the power tool.

- Using the special button, lock the rotation shaft.

- Install the disk into the seat.

- Tighten the lock nut and secure with a wrench.

- Before starting cutting work, check the functionality of the disc for 1 minute.

How to properly cut metal with a grinder. Practical tips and advice

If long pipes lie on supports, you need to cut off their overhanging edge. If you cut them in the middle, then due to its own weight the metal will bend and jam the disk.

If you do not have the skills to handle an angle grinder, then before starting work you should learn how to cut unnecessary parts.

The cutting wheel only takes radial forces. Attempting to change the cutting plane while the blade is inside the metal part will result in its failure.

The heel of the disc (the near lower part of the circle) cuts metal more efficiently.

In order for the grinder and discs to serve for a long time, every 5-7 minutes of work you need to take a break for 20-30 minutes. This rule is especially important for low-power angle grinders who are afraid of overheating.

To increase the service life of discs, especially expensive ones, and to cool the metal, the cut area should be watered with water. It is advisable to carry out the work together.

Aluminum is a very viscous metal. When cutting a piece of large thickness, you need to drip kerosene into the seam, observing fire safety rules.

For molding, cutting tin, and figured carvings, you should use worn out disks - “bits”, so you shouldn’t throw them away right away.

It is correct to cut the corner not in one step, but separately both shelves.

If pipes, angles, or fittings are long enough to rest on supports, cut the overhanging edge correctly. If you cut between the supports, the part will bend due to its own weight and jam the disk.

Parts of large thickness are cut only in a straight line. If you need to cut out a shaped part, first straight cuts are made, then the remaining unnecessary parts are removed.

You should not put pressure on the grinder. This will lead to jamming or breakage of the disc and overheating of the angle grinder. If the cutting process is slow, the blade should be replaced.

The resulting cut should not be processed with the side of the disk. A different type of disk is used for this.

Molten particles of metal and abrasive, falling on plastic products, glass and car headlights, stick to them, and then it is almost impossible to remove them. Therefore, they must be removed or protected before work begins.

Manufacturers of cutting wheels

Bosch

The company occupies a leading position in the market of power tools and related products. The range includes abrasive cutting discs for wood, metal and stone, diamond wheels and universal models.

The quality of the company's products meets international quality standards.

Dremel

American brand products are sold in more than 60 countries around the world. The company's product range includes not only high-quality power tools, but also a wide selection of attachments.

Dremel produces cutting wheels for cutting wood, plastic, and metal. Diamond-coated discs can handle concrete, ceramics, marble, and porcelain.

FIT

The Canadian company specializes in the production of tools for household and professional use. The product range includes a wide selection of cutting disc models for metal and stone for household power tools.

FUBAG

The main direction of the German company is the production of high-quality professional equipment for repair and construction work.

The brand's production bases are located in Germany and Switzerland, the company's operating experience is more than 40 years. The catalog offers the consumer high-quality diamond blades for wet and dry cutting.

Husqvarna

Consumable tools from a Swiss manufacturer are characterized by high performance and durability. The company's product range includes a large selection of cutting diamond blades, as well as abrasive products for cutting metal.

The disadvantage of the Husqvarna brand is its rather high cost.

Makita

The company offers a large range of high-quality abrasive discs and segmented diamond-coated wheels. In the catalog you can find both budget models and products belonging to the middle and high price categories.

Master

The company has been supplying construction equipment for 15 years. The product catalog includes consumable tools for cutting metal and wood.

MESSER

The company's catalog includes many models of consumable tools with a wide range of applications:

- segmented diamond blades for cutting concrete and asphalt;

- circles with a continuous edge for cutting ceramic products, marble, porcelain stoneware;

- carbide blades for cutting high carbon steel;

- turbo rims.

Metabo

The German brand specializes in the production of professional power tools and cutting equipment.

The range of consumable tools includes a wide variety of abrasive and diamond discs for angle grinders, as well as saw wheels for wood.

Scope of use

Wheels are widely used for sharpening, grinding and cutting metal and hard non-metallic surfaces.

They are equipped with:

- petrol cutters;

- angle grinders;

- tile cutters;

- stone cutting stations;

- wall chasers;

- cutting machines;

- other special equipment.

Divided into the following categories:

- Sharpening. They have found their application for sharpening hard alloy tools. They feature a continuous working surface and fine grain size for a high-quality surface.

- Cut-off. Flat shape, mainly used for cutting metal products. The working part can be segmented or solid.

- Grinding. Scope of use: removing old paint layers, sanding various surfaces, roughing work, and so on. Available in dish-shaped or bowl-shaped.

Based on the type of cutting edge, devices are divided into:

- Turbo segment. The cuts and notches are combined.

- Segmented. The cutting surface is equipped with cuts that divide it into segments. They are distinguished by fast cutting and quality of work.

- Turbo. The working part is equipped with notches along the edges. Visually resembles a turbine. This allows for improved heat dissipation, thereby increasing performance.

- Solid. The cutting surface is solid, which makes it possible to make precise and high-quality cuts, but slightly reducing productivity.