Hot rolled sheet

- /

- home

- Rolled metal

- Sheet metal

/

/

GOST 19903-74

Hot-rolled sheets GOST 19903-74

Upon delivery, hot-rolled sheets are divided into:

*sheets;

*rolls.

The standard applies to hot-rolled sheets with a width of 500 mm or more, manufactured in sheets with a thickness of 0.4 mm to 160 mm and rolls with a thickness of 1.2 to 12 mm.

Hot-rolled sheets in the warehouse of the MetalTechService Company are presented in the following assortment, steel grades st3sp/ps, st.09G2S, st.20, st.45, etc.:

| Size, mm | Opening, mm |

| 2 | 1250x2500 |

| 3 | 1250x2500; 1500x3000; 1500x6000 |

| 4 | 1500x3000; 1500x6000 |

| 5,6,7,8,10,12 | 1500x3000; 1500x6000 |

| 14,16 | 1500x3000; 1500x6000 |

| 18,20,22,25 -160 | 1500x3000; 1500x6000 |

To independently calculate the mass of the sheet, use the following information:

Weight of 1 square meter of sheet (based on the specific gravity of 7.85 g/cm3)

| Thickness (mm) | 0,5 | 0,55 | 0,6 | 0,7 | 0,8 | 0,9 | 1,0 |

| Weight kg/m2 | 3,925 | 4,32 | 4,716 | 5,5 | 6,28 | 7,06 | 7,85 |

| Thickness (mm) | 1,2 | 1,4 | 1,5 | 1,7 | 1,8 | 1,9 | 2,0 |

| Weight kg/m2 | 9,42 | 10,99 | 11,77 | 13,34 | 14,13 | 14,91 | 15,7 |

| Thickness (mm) | 2,5 | 3,0 | 3,5 | 4,0 | 5,0 | 6,0 | 7,0 |

| Weight kg/m2 | 19,62 | 23,55 | 27,47 | 31,4 | 39,25 | 47,1 | 54,95 |

| Thickness (mm) | 8,0 | 9,0 | 10 | 12 | 14 | 16 | 18 |

| Weight kg/m2 | 62,8 | 70,65 | 78,5 | 94,2 | 109,9 | 125,6 | 141,3 |

| Thickness (mm) | 20 | 22 | 25 | 30 | 40 | 50 | 60 |

| Weight kg/m2 | 157 | 172,7 | 196,25 | 235,5 | 314 | 392,5 | 471 |

| Category | steel grade |

| 1 | St0, St2kp, St2ps, St2sp, St3kp, St3ps, St3sp, St5ps, St5sp, St5Gps |

| 2 | St2kp, St2ps, St2sp, St3kp, St3ps, St3sp, St3ps, St3sp, St5Gps |

| 3 | St3kp, St3ps, St3sp, St3Gps, St3Gsp, St4ps, St4sp |

| 4 | St3ps, St3sp, St3Gps, St3Gsp |

| 5 | St3ps, St3sp, St3Gps, St3Gsp |

| 6 | St3ps, St3sp, St3Gps, St3Gsp |

Hot rolled sheets, GOST 19903-74

This standard applies to hot-rolled sheets with a width of 500 mm or more, manufactured in sheets with a thickness of 0.4 to 160 mm and rolls with a thickness of 1.2 to 12 mm.

The standard fully complies with ST SEV 1969-79 for structural unalloyed rolled products of ordinary quality and low alloy with a thickness of 1.00 to 2.80 mm in sheets and rolls and ST SEV 3901-82 for rolled products with a thickness from 3.00 to 160 mm in sheets .

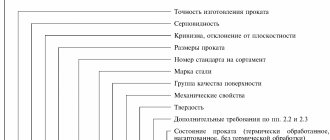

Rolled sheets are divided into:

a) in terms of rolling accuracy for thicknesses up to 12 mm:

increased accuracy - A; normal accuracy - B;

b) by flatness:

- especially high flatness - PO;

- high flatness - PV;

- improved flatness - PU;

- normal flatness – PN;

c) by the nature of the edge:

- with unedged edge - BUT;

- with edged – O;

d) by size:

- indicating the dimensions of thickness, width and length;

- indicating dimensions by thickness;

- indicating dimensions that are multiples of the width and length of the dimensions specified in the order;

- indicating the measured dimensions.

At the request of the consumer, the thickness difference in rolled products produced in rolls in one cross section should not exceed half the sum of the maximum deviations in thickness.

Maximum deviations in the width of rolled products with cut edges, manufactured in rolls, must not exceed:

+ 5 mm – with a width from 500 to 1000 mm inclusive;

+ 10 mm – for widths over 1000 mm.

Maximum deviations in the width of rolled products with cut edges, manufactured in sheets, should not exceed the standards specified in table. 1.

| Rolled width, mm | Rolled thickness, mm | Maximum deviations for the width of rolled products |

| Up to 800/over 800 | up to 3.9 | +6/+10 |

| Up to 1500/over 1500 | 3.9 to 16 | +10/+15 |

| All widths | 16-60/60-100/100-160 | +25/+50/+75 |

For sheets over 8 m with a thickness of up to 12 mm, maximum deviations in width should not exceed 0.2% of the length.

By agreement with the consumer, maximum deviations in the width of rolled products with cut edges, manufactured in sheets, should not exceed:

+ 5 mm – for widths up to 1000 mm inclusive;

+ 10 mm – for steel widths over 1000 mm.

Maximum deviations in the width of sheet metal, rolled sheet-by-sheet and manufactured with an unedged edge, should not exceed by more than 50 mm the maximum deviations in width specified in Table 1.

By agreement between the consumer and the manufacturer, other maximum deviations are allowed to ensure that the consumer receives sheets with the dimensions specified in the order.

Maximum deviations in the width of rolled products rolled on continuous mills and manufactured with uncut edges must not exceed:

+ 20 mm – for widths up to 1000 mm;

+ 30 mm – for widths over 1000 mm.

Maximum deviations along the length of rolled sheets must not exceed the standards specified in Table 2.

| Rolled length, mm | Rolled thickness, mm | Maximum deviation along the length of rolled products, mm |

| Up to 1500 / Over 1500 | up to 3.9 | +10/+15 |

| Up to 2000 / Over 2000 up to 6000 | 3.9 to 16 | +10/+25/+35 |

| Up to 3000 / St 3000 to 6000 | 16 to 60 | +15/+25/+40 |

| All lengths | 60 to 100 >100 >160 | +50/+75 |

Maximum deviations along the length of rolled products rolled on continuous mills and cut into sheets must not exceed the standards specified in Table 3.

| Rolled length, mm | Rolled thickness, mm | Maximum deviation, mm |

| Up to 1500 / Over 1500 | up to 3.9 | +15/+20 |

| Up to 4000 / Over 4000 | 3,9 | +20/+25 |

Deviations from flatness per 1 m length of rolled products manufactured in sheets should not exceed the following standards:

a) Particularly high flatness

- Sheet thickness 0.4-1.4 mm – 8 mm.

- Sheet thickness is 1.5-3.9 mm. – 8 mm.

- Sheet thickness 4 mm or more – 5 mm.

b) High flatness

- Sheet thickness 0.4-1.4 mm – 10 mm.

- Sheet thickness is 1.5-3.9 mm. – 10 mm.

- The thickness of sheets 4 mm and more is 8 mm.

c) Improved flatness

- Sheet thickness 0.4-1.4 mm – 15 mm.

- Sheet thickness is 1.5-3.9 mm. – 12 mm.

- Sheet thickness 4 mm or more – 10 mm.

d) Normal flatness

- Sheet thickness 0.4-1.4 mm – 20 mm.

- Sheet thickness is 1.5-3.9 mm. – 15 mm.

- The thickness of sheets 4 mm and more is 12 mm.

Rolled sheets with particularly high flatness are produced by agreement between the consumer and the manufacturer.

When producing rolled products in sheets and rolls with uncut edges, tears and other defects (if they are present on the edges) should not exceed half of the maximum deviations in width and lead the sheets beyond the nominal size along the width specified in the order. Rolled products produced in rolls should not have twisted and crumpled ends. Curved edges at an angle of no more than 90 degrees are allowed in some places.

The telescopicity of rolled products produced in rolls should not exceed the following standards:

— for rolled products up to 2.5 mm thick and up to 800 mm wide – 50 mm.

— for rolled products up to 2.5 mm thick and over 800 mm wide – 100 mm.

- for rolled products with a thickness of over 2.5 mm and a width of up to 800 mm - 35 mm.

— for rolled products with a thickness over 2.5 mm and a width over 800 mm – 70 mm.

According to the agreement between the manufacturer and the consumer, the telescopicity of rolled products in rolls up to 2.5 mm thick, width St. 800 mm should not exceed 70 mm. The excess of one internal or one external turn above the surface of the roll end is not telescopic. A loose fit between the two outer turns of the roll is allowed.

The thickness of rolled products is measured:

- on sheets - at a distance of at least 100 mm from the ends and at least 40 mm from the edges;

- on rolls - at a distance of at least 40 mm from the edges and at least 2 m from the end of the roll.

The width of rolled products produced in rolls is measured at a distance of at least 2 m from the end of the roll. Partial width ends should not exceed the width of the roll. At the request of the consumer, ends of partial width must be trimmed.

Rolled products may consist of no more than two pieces (separate or connected by a weld). The length ratio of the roll should not be less than 1:5. In agreement with the consumer, rolls with a large number of pieces or welds are produced.

The internal diameter of the roll must be no less than 650 mm and no more than 1000 mm. The maximum weight of each roll should not exceed 20 tons. By agreement between the consumer and the manufacturer, rolls of other weights are allowed.

back to list

Sheet 16 mm

Home->Directory->Assortment of rolled metal products->Sheets->Hot-rolled steel sheets

Sheet 20 mm Sheet 14 mm

Price of sheet 16 mm

Assortment of hot-rolled sheet 16 mm GOST 19903-74

| Sheet width, mm | Weight 1 m, kg |

| 1000 | 125,60 |

| 1100 | 138,16 |

| 1250 | 157,00 |

| 1400 | 175,84 |

| 1420 | 178,35 |

| 1500 | 188,40 |

| 1600 | 200,96 |

| 1700 | 213,52 |

| 1800 | 226,08 |

| 1900 | 238,64 |

| 2000 | 251,20 |

| 2100 | 263,76 |

| 2200 | 276,32 |

| 2300 | 288,88 |

| 2400 | 301,44 |

| 2500 | 314,00 |

| 2600 | 326,56 |

| 2700 | 339,12 |

| 2800 | 351,68 |

Steel sheet 16 mm is classified:

1. According to rolling accuracy -

- A - increased accuracy

- B - normal accuracy

2. By flatness -

- Software - especially high flatness

- PV - high flatness

- PU - improved flatness

- PN - normal flatness

3. By the nature of the edge -

- BUT - with unedged edge

- O - with cut edge

4. In terms of dimensions - Maximum deviations in the width of a 16 mm steel sheet with a trimmed edge supplied in rolls must not exceed:

- +2 mm - for widths from 500 to 1000 mm

- +5 mm - with a width of St. 1000 to 1600 mm

- +7 mm - with a width of St. 1600 mm

with cut edge supplied in sheets must not exceed:

- +6 mm - for widths up to 800 mm

- +10 mm - with a width of St. 800 mm

with uncut edge - should not exceed +20 mm

Maximum deviations along the length of a steel sheet rolled sheet by sheet must not exceed:

- +10 mm - for sheet lengths up to 1500 mm

- +15 mm - with a sheet length of St. 1500 mm

on continuous mills and cut into sheets, should not exceed:

- +15 mm - for sheet lengths up to 1500 mm

- +10 mm – at customer’s request

- +20 mm - for sheet lengths over 1500 to 3000 mm

- +25 mm - for sheet lengths over 3000 mm

At the request of the consumer, 16 mm steel sheets are manufactured with the following maximum length deviations:

- +5 mm - for sheet lengths up to 1500 mm

- +6 mm - with a sheet length of St. 1500 to 2000 mm

- +10 mm - with a sheet length of St. 2000 to 3000 mm

- +20 mm - with a sheet length of St. 3000 mm

16 mm steel sheet refers to thick sheets, most often rolled from carbon and low-alloy steel. It can also be rolled from special grades of steel that have anti-corrosion, heat-resistant and other special properties. According to GOST 14637, rolled plates of ordinary quality carbon steel are manufactured in the form of sheets from steel grades St0, St2kp, St2ps, St2sp, St3kp, St3ps, St3sp, St3Gps, St3Gsp, St4ps, St4sp, St5ps, St5sp, St5Gps in accordance with GOST 380. According According to the standardized characteristics, steel sheet is divided into categories from 1 to 6. The category number is added to the brand designation, for example St3ps1.

| Category | steel grade |

| 1 | St0, St2kp, St2ps, St2sp, St3kp, St3ps, St3sp, St5ps, St5sp, St5Gps |

| 2 | St2kp, St2ps, St2sp, St3kp, St3ps, St3sp, St3ps, St3sp, St5Gps |

| 3 | St3kp, St3ps, St3sp, St3Gps, St3Gsp, St4ps, St4sp |

| 4 | St3ps, St3sp, St3Gps, St3Gsp |

| 5 | St3ps, St3sp, St3Gps, St3Gsp |

| 6 | St3ps, St3sp, St3Gps, St3Gsp |

Sheets from categories 1 to 5 are produced hot-rolled, category 6 - hardened. All categories of rolled products can be subjected to heat treatment. It is permissible to manufacture steel sheets of categories 1–5, strengthened by rolling heating, or after controlled rolling. Sheet 16 is used in construction, engineering, shipbuilding and bridge construction. Depending on the grade of steel, it can have various special properties and be used in conditions of high or low temperatures, aggressive external environments, as well as increased loads. For example, low-alloy sheet 16 09G2S can be used in the low temperatures of the Far North, sheet RS B 16mm, resistant to sea water and other adverse environmental factors - in shipbuilding, for the manufacture of underwater and surface structures, icebreaker hulls, drilling platforms. For shipbuilding, sheet 16 is made of normal and high-strength steel, which is resistant to the influence of the aquatic environment. Marine metal products are produced under the control of the Maritime and River Registers of the Russian Federation. Ship sheet 16 mm is rolled from steel grades: A, B, D, E - normal strength; A27S, D27S, E27S, A32, D32, E32, A36, D36, E36, A40, D40, E40, A40S, D40S, E40S - increased strength. Marking “RS” means that the sheet complies with the requirements of the Register. The ship sheet is manufactured in widths of 1000–3200 mm and lengths of 4.5–12 m.

Sheet 1 mm Sheet 1.5 mm Sheet 10 mm Sheet 100 mm Sheet 110 mm Sheet 12 mm Sheet 120 mm Sheet 14 mm Sheet 140 mm Sheet 16 mm Sheet 18 mm Sheet 2 mm Sheet 20 mm Sheet 22 mm Sheet 25 mm Sheet 3 mm Sheet 30 mm Sheet 32 mm 09G2S Sheet 35 mm Sheet 36 mm Sheet 4 mm Sheet 4 mm 09G2S Sheet 40 mm Sheet 45 mm Sheet 5 mm Sheet 50 mm Sheet 6 mm Sheet 60 mm Sheet 70 mm Sheet 8 mm Sheet 80 mm Sheet 90 mm