Brick, wood and concrete are classic materials for the construction of buildings, but construction cannot do without rolled metal. Most structures require profiled meshes, beams, and profiles.

Any structure can be created from corrugated pipes, and connections created by welding will be no less strong than a solid metal mass. In addition, metal parts can be forged, deformed and bent under pressure. Metal structures of any size and shape will be more compact and lighter than those built from stone and reinforced concrete. With quality care and proper assembly, they will be much more durable. The range of rectangular pipes expands over time, which allows them to be used for different purposes.

Areas of application

Where is profiled stainless steel used:

- Mechanical engineering and shipbuilding - mufflers for vehicles, hydraulic cylinders, outlet pipes of gas turbines and engines, parts of various shafts and valves, accessories for cars.

- Furniture production - legs, stands and frames of furniture.

- Construction - supports, posts, truss columns, chimneys, stairs and stair railings, frames for cornices and awnings.

- Food industry - processing plants (especially for chocolate, mayonnaise), grills, oven heat exchangers.

- Production of commercial equipment - shelving, equipment for bars, restaurants.

- Chemical and oil refining industries - installations for the production of alkalis, acids, ring collectors.

- Department of Housing and Utilities.

- Medicine - manufacturing of equipment, various implants.

Technical characteristics and properties

Parameters of stainless steel profile pipe:

- Type of rolled pipe profile.

- Geometric dimensions of width, height and length of a segment.

- Wall thickness.

- Weight of 1 linear meter.

- Steel grade and its characteristics.

For the production of profile stainless steel products, the grade of austenitic steel AISI 304 (Russian analogue 08Х18ХН10) is mainly used. This is an acid-resistant material, not subject to corrosion, and can withstand short-term temperatures up to +900 °C. The metal density is 7.9–7.93 g/cm2, the elastic modulus is 193–200 GPa, and the shear modulus is 86 GPa.

Life time

Stainless steel profile metal can be used for at least 50 years without losing its original properties.

Rectangular pipe GOST - basic parameters and characteristics that you need to know

In order to understand the entire available range of rectangular profiles, you need to know all the basic characteristics. There are only four main characteristics:

- Geometric dimensions, which include the width and height of each side;

- Thickness of metal at the walls of the product;

- Mass (weight);

- Protective layer of zinc (present or absent).

To choose the right pipe, you need to know its width, height, and the length of the entire product. The last indicator can be changed by welding an additional part, or vice versa, cutting it off. The width and height can no longer be changed. Therefore, purchase the product in strictly required sizes.

The next quite important indicator that is worth considering is the wall thickness. This characteristic will directly depend on the geometric dimensions. The larger the standard sizes, the greater the thickness. Although there are a number of rectangular pipes, where the wall thickness is specially increased. Thickness and size also affect weight. The greater these indicators are, the greater the mass of one linear meter of the profile will be. GOST has a table that lists the mass for each type of pipe.

Knowing the metal thickness, as well as the basic dimensions, you can easily calculate the weight per linear meter. Now you can compare this indicator with what is indicated in the table. The tables indicate the theoretical mass, which is calculated taking into account the specific density of a particular steel grade. If these indicators are almost the same, then everything is fine, but if these two indicators differ significantly, then you should think about it. It is possible that these products are made from a different grade of steel.

Coating with a protective layer is an important parameter that you should pay attention to. In most cases, products are coated with a layer of zinc. This is necessary in order to protect the material from corrosion and other external destructive influences. Electric welded products are most susceptible to corrosion, so they must be treated with zinc.

How are they produced?

Profile pipes are made from stainless steel using two technologies:

- The finished product is formed from a blank in the form of a metal strip (strip).

- A round pipe is profiled.

Strip manufacturing technology

The method makes it possible to obtain a profile pipe made of stainless steel with a seam. Welding of sheet steel strips is carried out using high-frequency electric welding, laser or plasma welding in a conventional environment, as well as tungsten electrodes in inert gas (TIG welding). The production process itself is as follows:

- The strip is cut from stainless steel sheets on special rolling mills and fed into a sheet bending mill.

- The metal strip is formed on the rollers of a sheet bending mill into a round blank with open edges.

- The edges are welded using one of the selected types of welding. Excess metal (grant) is removed with cutters.

- The workpiece is calibrated on rollers to a given profile shape.

- The finished product is cut into pieces of the required length.

To relieve internal stress, the stainless steel profile pipe is subjected to heat treatment (annealing). The workpiece is heated to +550…650 °C for 60–90 minutes, followed by gradual cooling (tempering). As a result, it becomes stronger and more durable.

Profiling

This technology for the production of profile stainless pipes involves the use of seamless cold- and heat-deformed pipes of round cross-section as initial blanks. They acquire the desired profile shape when passing through calibrating rollers in a cold or heated state.

Next, the cold-deformed profile pipe is subjected to heat treatment. At the last stage, the rolled metal is cut into pieces and undergoes surface quality control, tensile tests, and geometric dimensions testing.

Rolled steel pipes

A rectangular metal pipe can be made of any metal, but most often carbon or alloy steel, and in some cases stainless steel, are used for production.

Production conditions and technical characteristics are regulated by GOST 13663-86.

The requirements of GOST 8645 - 68 for the shape and dimensions of steel rectangular pipes apply to products manufactured using the following methods:

- Thermoforming. To take shape, the seamless tubular blank is heated to high temperatures and passed through rollers.

- Cold molded.

The pipe blank passes through the rollers in a cold state. Attention! To increase ductility, cold-deformed steel pipes of rectangular cross-section are additionally subjected to a firing procedure. - Electric welding. The formation of a seam occurs during resistance welding, induction welding and welding with high-frequency currents, as well as electric arc welding using flux or shielding gas.

- Electric welding and cold forming. A metal rectangular pipe is rolled without heating, the edges of the workpiece are welded using one of the already mentioned types of welding.

- Furnace welding method. The deformation of the workpieces occurs in a hot state when passing through drive rolls that have a short forming zone length.

- Electric welding and reduction (calibration) using the hot method. A metal rectangular pipe is formed on a continuous mill from a steel sheet, then heated and welded with high frequency current. Next, the workpiece is reduced and calibrated.

The length of steel rectangular pipes, external profile dimensions, wall thickness and maximum deviations in parameters are regulated by GOST 8639-82

.

| Types of steel rectangular pipes | Profile dimensions, mm | Wall thickness, mm | Length, m | ||

| Unmeasured | Measured | Multiple of measured | |||

| seamless hot-formed | 60-180 | 4-14 | 4-12,5 | 4-12,5 | 4-12.5 with an allowance of 5 mm for each cut |

| seamless cold-deformed | 10-120 | 1-8 | 1,5-11 | 4,5-11 | 1.5-11 with an allowance of 5 mm for each cut |

| electric welded | 10-100 | 0,8-5 | 1,5-11 | 5-9 | |

| electric welded calibrated | 100-180 | 4-14 | 1,5-14 | 5-9 | |

| furnace welded pipes | 40-70 | 3-5 | 4-8 | 4-8 | |

Regulations

Technical production conditions, chemical composition of raw materials, geometric parameters for each cross-sectional shape of profile stainless steel pipes are regulated by several regulatory documents (GOSTs).

Standards and GOSTs

Russian manufacturers producing profile pipe products made of corrosion-resistant steel, depending on the technology used, use the following standards:

- GOST 11068-81 - for electric-welded pipe products.

- GOST 9940-81 - for seamless pipes manufactured using the profiling method.

The range and standard sizes of profiled stainless steel pipes are established by the following regulatory documents:

- GOST 8639-82 - for square profile.

- GOST 8645-68, GOST 8645-78, GOST 8645-86 - rectangular section.

- GOST 8642-68 - for oval pipes.

Types, assortment: sizes and sections

There are different types of stainless steel profile pipes depending on the cross-sectional shape. She may be:

- Oval.

- Rectangular.

- Square.

- Flat oval.

- Drop-shaped.

- With hollow ribs.

Stainless steel pipes and other profile configurations are also produced: in the form of a trapezoid, rhombus, parallelogram, triangle, hexagon, etc. But they are mainly produced by foreign companies according to European or American standards.

The classification of profile pipes by type of surface treatment is as follows:

- Polished.

- Matte.

- Polished to a mirror finish.

Square

Square profiles are highly durable and reliable. Their advantage is the presence of four stiffening ribs, which increase resistance to bending loads. The production of pipes with a square profile and their assortment is regulated by GOST 8639-92, according to which the external dimensions of the edges range from 10 × 10 mm to 180 × 180 mm. The minimum wall thickness is 0.8 mm, the maximum is 14 mm. The length of the products can be:

- Unmeasured. Seamless hot-deformed - from 4 to 12.5 m, seamless cold-deformed and electric-welded - from 1.5 to 11 m.

- Measured. Seamless hot-deformed - from 4 to 12.5 m, seamless cold-deformed - 4.5–11 m, electric welded - from 5 to 9 m.

- Multiple measured. With an allowance for each cut of 5 mm.

Rectangular

Stainless steel pipes with rectangular profiles can withstand high loads, the same in magnitude as solid products. In addition, it is convenient for installation, transportation and storage. It is used in the construction industry and mechanical engineering for the manufacture of frame metal structures and support posts.

Standard profile dimensions for rectangular pipes are shown in the table.

| Section parameters, mm | Wall thickness, mm |

| 15×10; 20×10; 35×30; 60×20 | 2 |

| 20×15; 25×10; 25×15 | 2,5 |

| 30×10; 30×15; 30×20 | 3 |

| 35×15; 35×20; 35×25 | 3,5 |

| 40×15; 40×20; 40×25; 40×30; (42)x20; (42)x30; 45×20; 45×30; 50×25; 50×30; 50×35; 50×40; 80×50; 100×60 | 4 |

| 60×25; 60×30; 60×40 | 5 |

| 70×30; 70×40; 70×50 | 6 |

| 80×40; 80×60; 90×40; 90×60; 100×40; 100×50; 100×70; 110×40; 110×50; 110×60 | 7 |

| 120×40; 120×60; 120×80; 140×60; 140×80 | 8 |

| 140×120 | 9 |

| 150×80; 150×100 | 10 |

| 180×80; 180×100; 180×150 | 12 |

Regulatory documents provide for the possibility of producing stainless rectangular pipes with non-standard dimensions, for example, an extended range of wall thickness from 0.8 to 20 mm and edge sizes from 28 × 25 mm to 230 × 100 mm.

The length of the segments according to GOST 11068-81 is:

- Measured (5–9 m).

- Unmeasured (1.5–9 m).

- Multiple measurements (no more than 9 m with an allowance of 5 mm for each cut).

Matte

Profile pipes with a matte outer surface are used as structural elements, the decorative appearance of which does not require high requirements. For example, for installation:

- Production shelving.

- Work sites.

- Support structures, etc.

Sanded

Polished stainless steel profile pipes combine aesthetic appearance with high strength, wear resistance and durability. They have no planar or structural flaws; they are in demand in areas where impeccable smoothness of surfaces is required.

To process stainless steel profiles, 2 technologies are used:

- Electrochemical. The workpiece is immersed in a solution of concentrated acid. If the outer surface is polished, then the product is then surrounded by round electrodes. To treat the internal surface, the electrode is inserted into the cavity of the pipe. Electric current is then applied to them.

- Abrasive. For primary processing, coarse abrasives with a grain size of 180–320 microns are used; a polished surface is obtained by using abrasive materials with a finer grain size. For final polishing, felt sanding belts are used.

Stainless steel pipes with a polished surface are endowed with decorative qualities, therefore they are used for interior decoration, the manufacture of cabinet furniture elements, fences, and railings.

Pipe wall thickness: what is the importance of this parameter

The dimensions of the ribs of stainless steel profile pipes are important for assembling structures, but the strength characteristics of rolled metal and its load-bearing capacity depend only on the wall thickness. The larger it is, the more resistant the finished product is to various types of deformations and loads.

Standard sizes and markings

Marking of profile stainless steel products is applied to their outer side at the factory after manufacturing. It consists of information about the standard size of the product, as well as the steel grade and the manufacturer’s trademark.

For example, let’s decipher the marking 100×100x5 09G2S:

- The first two positions indicate the size of the ribs in mm. In this case, 100 mm and 100 mm, since the pipe has a square profile.

- The third is the thickness of the walls.

- The fourth is the steel grade (set if necessary).

Rectangular profile pipes: dimensions and weight

The table below shows the dimensions and weight of the most common types of profile rectangular pipes.

| Pipe sizes | Length | Weight, mp |

| 20x10x1.2 | 6 | 0,501 |

| 20x10x1.5 | 6 | 0,605 |

| 25x10x1.5 | 6 | 0,723 |

| 28x25x1.2 | 6 | 0,934 |

| 28x25x1.5 | b | 1,15 |

| 28x25x2 | 6 | 1,48 |

| 30x15x1.5 | 6 | 0,959 |

| 30x20x1.5 | 6 | 1,08 |

| 30x20x2 | b | 1, з9 |

| 40x20x1.5 | 6 | 1,31 |

| 40x20x2 | b | 1,70 |

| 40x25x1.5 | 6 | 1,43 |

| 40x25x2 | 6 | 1,86 |

| 40x25x2.5 | 6 | 2,27 |

| 50x25x1.5 | b | 1,67 |

| 50x20x2 | 6 | 2,02 |

| 50x25x2 | b | 2,17 |

| 50x30x2 | 6 | 2,32 |

| 50x30x2.5 | 6 | 2,86 |

| 50x40x2.0 | 6 | 2,65 |

| 50x40x2.5 | 6 | 3,25 |

| 50x40x3.5 | 6 | 4,39 |

| 60хЗ0х2 | 6 | 2,65 |

| 60x30x2.5 | 6 | 3,25 |

| 60x30x3 | 6 | 3,83 |

| 60x40x2 | b | 2,96 |

| 60x40x3 | 6 | 4,30 |

| 60x40x3.5 | 6 | 4,94 |

| 60x40x4 | 6 | 5,56 |

| 80x40x2 | 6 | 3,59 |

| 80x40x5 | b | 4,43 |

| 80x40x3 | 6 | 5,25 |

| 80x40x4 | 6 | 6,82 |

| 80x60x3 | 6 | 6,19 |

| 80x60x4 | 6 | 8,07 |

| 100x50x3 | 12 | 6,66 |

| 100x50x4 | 12 | 8,70 |

| 100x50x5 | 12 | 10,65 |

| 100x60x3 | 12 | 7,13 |

| 100x60x4 | 12 | 9,33 |

| 100x60x5 | 12 | 11,44 |

| 100x80x4 | 12 | 10,59 |

| 100x80x5 | 12 | 13,01 |

| 120x60x3 | 12 | 8,07 |

| 120x60x4 | 12 | 10,59 |

| 120x60x5 | 12 | 13,00 |

| 120x80x4 | 12 | 11,84 |

| 120x80x5 | 12 | 13,01 |

| 120x80x6 | 12 | 17,22 |

| 140x60x4 | 12 | 11,84 |

| 14х60х5 | 12 | 14,58 |

| 140x100x4 | 12 | 14,35 |

| 140x100x5 | 12 | 17,72 |

| 140x100x6 | 12 | 20,99 |

| 150x100x5 | 12 | 18,50 |

| 150x100x6 | 12 | 21,93 |

| 150x100x8 | 12 | 28,53 |

| 160x80x5 | 12 | 17,72 |

| 160x120x5 | 12 | 20,86 |

| 160x120x6 | 12 | 24,76 |

| 180x100x6 | 12 | 24,76 |

| 180x100x8 | 12 | 32,29 |

| 200x120x5 | 12 | 24,00 |

| 200x120x6 | 12 | 28,53 |

| 200x160x5 | 12 | 27,14 |

| 200x160x6 | 12 | 32,30 |

| 230x160x8 | 12 | 46,11 |

Advantages and disadvantages

Stainless steel profile pipes have the following qualities and advantages:

- High strength characteristics with low weight.

- Due to the flat edges, they are more convenient to install than round profile pipes.

- Resistant to temperature changes.

- The ability to withstand any type of load (transverse, tensile and torsional), since they are distributed to the walls at right angles.

- High corrosion resistance, long service life.

- Heat resistance.

- Good weldability.

- Aesthetic appearance.

- Wear resistance.

- Frost resistance.

- Completely inert to chemical influences.

The disadvantages of profile products include:

- Relatively high cost.

- Inability to use for water supply pipelines and heating system wiring.

Economic feasibility of using a pipe with a rectangular profile

The advantage of using rolled metal pipes with a rectangular cross-section for the manufacture of various types of metal structures is due to:

- Resistant to any type of load (transverse, torsion and tension). The load distribution in this case occurs at right angles to the planes. This allows a hollow rectangular pipe with four stiffening ribs to withstand the same loads as solid metal profiles of the same size. Reducing metal consumption by using rectangular metal pipes makes it possible to obtain significant savings in production.

- A range with a large number of standard sizes, allowing you to choose the most economical option for different purposes.

- Manufacturability. Hollow metal pipes of rectangular cross-section with flat side surfaces are easier to cut than solid rods, and it is easier to attach connecting elements and other parts to them.

- Efficient use of warehouse space during storage. The products are stacked tightly against each other with flat edges connected at right angles and take up less space during storage and transportation.

Attention! Rectangular metal pipes are not used for transporting liquid and gaseous media, as they are less resistant to internal pressure, especially for products with a welded seam.

1.1. Applications of rectangular metal pipe

- Construction - load-bearing structures of hangars, industrial buildings, residential buildings, canopies, gazebos, fences, various small architectural forms.

- Automotive industry - power frames (frames) to which all body elements, engine, gearbox, drive and other large components are attached.

- Furniture production - furniture frames, legs of tables, desks and chairs.

Tips on how to choose

Stainless steel profile pipes should be selected taking into account operating conditions, based on the following indicators:

- Maximum load.

- Duration and intensity of mechanical, thermal and chemical influences.

Depending on these parameters, the technical characteristics of the products are selected:

- Steel grade.

- Profile shape and dimensions.

- Wall thickness.

- Production technology.

The quality of purchased stainless steel products must be confirmed by factory certificates.

Approximate price and best manufacturers

The price of a stainless steel profile pipe depends on the grade of material, length of the section, wall thickness, type of surface treatment and manufacturer. The volume of the supplied batch can influence the final cost of the product.

The price range is quite large. For example, the price of a matte stainless square profile pipe can range from 3 to 30 dollars per meter, while rectangular steel pipes range from 4.5 to 42 dollars per meter.

Types of products and areas of their use

For the production of profile stainless steel pipes, complex alloy steel grades with a high content of chromium (17 - 19%) and carbon impurities (0.8%), titanium (0.5%), and nickel (8-10%) are used.

The alloying elements included in the alloy give these products:

- unusually high resistance to corrosive destruction;

- increased strength and wear resistance;

- good weldability;

- high technology;

- long service life without changing the original properties;

- aesthetic appearance;

- resistance to thermal influences;

- good impact strength;

- resistance to low temperatures;

- complete passivity to chemicals.

1.1. Types of rolled pipes

Stainless steel pipes are manufactured with a cross section of different shapes, depending on which there are:

- round;

- oval;

- square;

- rectangular.

According to forming technology, rolled stainless steel grades are divided into:

- welded;

- hot rolled;

- heat-deformed;

- cold drawn pipes.

Depending on the type of surface treatment, they can be:

- polished;

- matte;

- polished to a mirror finish.

Attention! High-quality products on the outer and inner surfaces should be free of cracks, deep marks, over-etching, penetration, flaws and caps.

1.2. Application of stainless steel pipes

Durability of use and excellent technical characteristics of rectangular pipes made of stainless steel alloys make them in demand in many areas of the national economy

:

- in the construction industry;

- automotive industry;

- furniture production;

- oil and gas industry;

- public utilities;

- production of medical instruments;

- for the construction of pipeline systems and equipment in chemical and food industries.

However, there are some restrictions on the use of certain types of pipes. For example, welded products with a rectangular and square cross-section cannot be used for the construction of pipelines intended for transporting media under high pressure.

Stainless steel pipes with a matte surface are used for the manufacture of metal structures, for which there are no special requirements for aesthetic appearance.

Products with a mirror surface are endowed with decorative qualities, so they are used in the manufacture of furniture and interior design. Mirror pipes 30x10x 1.5 mm can be purchased for installing fences, railings, cornices and canopies.

Stainless steel pipes with a rectangular profile and low weight have high strength characteristics and resistance to torsional forces.

They are used for the manufacture of:

- load-bearing metal structures: racks, beams, columns, trusses;

- frames of various configurations;

- vaulted structures;

- supports for equipment;

- stairs, etc.

How to bend stainless pipes

When bending such products, it is important to prevent changes in the original cross-sectional configuration and the formation of creases on their inner surface. Deformation will weaken the load-bearing capacity of such a part, reduce its throughput, and increase the likelihood of corrosion.

In industrial conditions, bending of stainless steel pipes is carried out in the following ways:

- Run-in.

- Winding.

- Rolling.

- Drawing.

- Hydrostatic.

- By pushing.

- Using two supports.

Such pipe bending technologies allow you to obtain high-quality results, but require special equipment.

At home, you can bend a stainless steel profile using a manual pipe bender. In this case, to support the walls from the inside, the following is used:

- Clean dry sand and two plugs. First, one of the plugs is installed. Then the pipe at the future bend is filled with sand through the free end, carefully compacted and clogged with another plug. Next, the pipe is bent around a blank of the required size.

- A bundle of wire. The pipe cavity is filled to capacity with pieces of thick wire. After bending, the wire is removed one by one.

- A spring of the appropriate shape. It should be wound from wire 2–4 mm thick in such a shape that it fits freely into the cavity of the pipe at the bend. At the end of bending, the spring is removed using a wire previously left outside.

To bend a profile with a significant bending radius, the walls are preheated with a blowtorch or gas torch. Heated metal bends more easily.

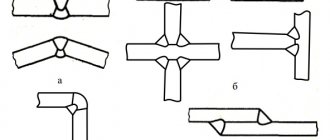

Installation Tips

When assembling metal structures from stainless steel profile pipes, the parts are connected by welding or fastening with clamps. The elements can be fixed using electric arc, gas or resistance welding.

When arc welding, it is important to choose the right electrode. The quality of the weld depends on its diameter. If it is too thin, the welding process will be interrupted; if the electrode cross-section is too large, a thin-walled pipe can be burned.

Electric arc welding should not be performed in open areas. Such work is carried out in special premises. In this case, the ends of the parts to be welded must first be cleaned and degreased.

The contact type of welding forms a welding seam of increased reliability. There are no restrictions on ambient temperature and other weather conditions for its use.

General recommendations for carrying out any type of welding are as follows:

- When choosing a welding temperature, you should proceed from the thickness of the metal, since profile products are more susceptible to deformation than round ones.

- To maintain the internal clearance of the profile, it is necessary to prevent molten metal from entering the stainless steel profile pipe.

- When performing welding, it is necessary to carefully check the geometric coincidence of the ends of the parts being welded so that distortions do not occur in the metal structure.

Alternative to profile pipes

The use of profile stainless pipes is not always technically and economically feasible. It's not cheap. In addition, it cannot be used for laying pipelines transporting liquid and gaseous media under high pressure. This is especially true for electric-welded products with a seam: due to the presence of different angles inside such pipelines, blockages can quickly form at the bends. For the installation of such communications, only round pipes are used. And it doesn't have to be stainless steel.

Modern pipe products made of reinforced polypropylene are not inferior in a number of technical characteristics to stainless steel, but are much cheaper. Profiles made of plastic are more often used as ventilation ducts. They are available in white, so they fit more harmoniously into the interior of kitchens and bathrooms.

An alternative option for constructing a chimney could be a galvanized sandwich pipe. Galvanized steel is just as fire-resistant and fireproof as stainless steel, but is less resistant to corrosion from condensation. But the price of galvanized sandwich chimneys is much lower, as is the cost of installation. And in order to slow down the corrosive destruction of the metal, the surfaces of the chimney are coated with a special heat-resistant paint for galvanizing.

Aluminum pipes are also of good quality. They are lightweight, corrosion-resistant, and are a good option for making indoor decorative elements, furniture parts and other lightly loaded structures.

Rectangular pipe assortment and production classification

The most important classification category by which the division is made is the main method of production. There are three ways:

- Hot deformation (rolling) method. In this case, seamless products are obtained. The production process consists of heating the workpiece to a plastic state and then rolling it on special machines to the required shape;

- Cold deformation (rolling) method. This also produces a seamless pipe. Only in this case does the metal workpiece deform in a cold state;

- Electric welding method. A steel sheet is used as a blank, which is cut into strips of certain sizes. Next, these strips are welded together.

All conditions and technological stages of production are specified in the relevant GOST. They must be strictly observed to ensure that the end result is a product of adequate quality. GOST has a detailed table with all sizes and assortments.

The following classification group:

- Suture. They have a weld along the entire length. The seam can be either straight or spiral;

- Seamless. There is no welded joint on the surface. They have greater strength and rigidity compared to rolled metal, which has welded seams.

Profile products can be simple or galvanized. A layer of zinc helps protect the surface from the destructive effects of corrosion and various aggressive environments. Galvanized pipes are used under severe operating conditions, as well as in the chemical industry.

Features of operation

Structures made from profile stainless steel pipes do not lose their load-bearing capacity and presentable appearance over time. They do not need painting and can be easily washed with household chemicals that do not contain chlorine. Dried stains cannot be scraped off or removed with a wire brush: use only a soft cloth or foam sponges.

Possible problems

In some cases, rolled stainless steel may be subject to corrosion. Foci of rust appear on the walls of products after prolonged contact with a concentrated chlorine solution. To eliminate the cause of corrosion, it is necessary to thoroughly rinse off the chlorine-rich liquid. The rusting process of stainless steel parts will slow down, and they will retain their anti-corrosion properties.

Packaging, transportation and storage

For ease of transportation, profiled stainless steel pipes are bundled or tightly placed in wooden containers lined with waterproof paper. The packages are tied with wire or metal tape in three or four places depending on the weight. For strapping during loading and unloading operations, bags and containers are equipped with special clamps.

They can be transported by any type of transport. The packages are placed on the floor of the car or in the body of the car in stacks, separating the rows with spacers.

Profile stainless steel products are stored on racks in closed warehouses or under a canopy, where they will be protected from atmospheric moisture.