Despite the abundance of pipes made from modern and high-tech materials, ordinary VGP steel pipes still remain in demand and do not lose their top positions in the ranking of construction popularity. This situation is explained by several reasons. Firstly, it is simply technically impossible to use the same polymer pipes (and other varieties) in open spaces, where they are exposed to a number of negative factors. And according to safety rules, there are restrictions: unlike a steel pipeline, a plastic contingent will quickly fail. Secondly, according to all existing official regulations, gas can only be supplied through steel pipes that can withstand high pressure. These nuances determine the fairly widespread use of this type of materials in the organization of communications in residential and industrial premises at the present time.

Different sizes – different applications

Features of the VGP pipe

VGP pipe is a very relevant material, complying with GOST 3262. The pipe is famous for such qualities as wear resistance and strength, used for household and main gas pipelines.

It has many features, many of which can be attributed to the advantages of VGP.

- Galvanized VGP pipe is not subject to deformation due to the influence of different temperatures. It does not deteriorate even when the liquid freezes, which can occur at low temperatures.

- The material has a high level of strength, especially a product made of steel.

- High thermal conductivity, the pipe maintains the desired temperature for a long time.

- It is completely sealed, so gaseous and volatile substances can be transported in the VGP pipe.

It is not recommended to use non-galvanized pipes, as they quickly become corroded.

Description

Today you can buy a VGP pipe at an affordable price; you can find out what it is from the article. The described products are a group of water and gas pipes made of steel. Today there are non-galvanized and galvanized options. They can be cylindrical, hollow, with a longitudinal weld. This category has three wall thickness options, including:

- average;

- thick-walled;

- thin-walled.

Since the range of products described is quite wide, you can use them by choosing them for a specific project.

Manufacturing

The VGP pipe is made of carbon steel, which is the main component for the manufacture of this product. The manufacturing process corresponds to established technology and includes several stages.

- Initially, steel templates are prepared, which are called strips. These are long strips of metal that have certain parameters.

- A pipe is formed from the template; this process takes place on special equipment.

- The joints on the pipes are welded using electric welding.

The weakest point in the product is the seam, so it is subjected to X-ray examination. A seam is not a pipe defect, but very high requirements are placed on it.

The very process of manufacturing VGP pipes is also subject to high demands, since operation occurs in harsh conditions and the pipes are subjected to high loads.

Description and explanation of the abbreviation VGP

For a long time, VGP pipes have been indispensable elements in the construction of many facilities. They are used for supplying communications:

- gas pipeline;

- heating;

- water supply

The abbreviation VGP stands for water and gas pipes . They are considered very durable and are equal to the strength of an all-metal beam of identical diameter.

These products are made from carbon steel . They are always in demand, despite the fact that pipeline materials made of plastic and metal-plastic have now appeared. This is due to the fact that there are areas of communication networks where products made from other materials cannot be used. For example, gas pipelines cannot be laid using plastic products.

VGP products are produced using the technology of welding and forming metal strips. Rolled sheets are used as a workpiece. It is made from carbon hot-rolled structural steel. To ensure that such a material can withstand maximum loads, special attention is paid to the weld seam during the production process. Such finished products must be gas and waterproof. Depending on the wall thickness, products are divided into separate types :

- lungs;

- ordinary;

- reinforced.

They are produced in the form of material in measured and unmeasured lengths. Eight-meter long pipes are considered the most popular. There are also products with a length of 5.8; 7.8; 9 and 11.75 meters. Such parameters are related to the peculiarities of transportation and installation.

Requirements

The most important requirement for a VGP pipe is a seam defect, so it is checked most carefully. The product must meet certain requirements that are imposed after manufacture.

- There should be no swollen places, cracks or chips on the surface of the pipe;

- There should be no cracks or delaminated areas at the ends of the product;

- The material is cut at right angles;

- After cutting, burrs may remain, which should be no more than 0.5 millimeters.

Acceptable defects are minor dents and pockmarked spots; they should not affect performance. One of the most important factors is resistance to corrosion, which is why products are galvanized.

The zinc coating must be perfectly smooth, without bubbles or peeling areas. If the galvanization is poorly applied, then rust will be able to reach the pipe through micro-holes.

Weight of water and gas pipes

The thickness of the walls can also influence the weight of a linear meter. However, the weight of the pipe is also determined by its cross-section, which is the outer diameter. It does not matter what material the pipe is made of - galvanized or steel. The weight of a linear meter can be 21.63 kg maximum, while the wall thickness is equivalent to 5.5 mm with a diameter of 165 mm. The smallest weight per linear meter is equivalent to 370 g. The diameter in this case is 10 mm, the wall thickness is 1.8 mm.

After you have found out why the VGP pipe is needed, you should also inquire about the weight of the products. For example, galvanized pipes weigh about 5% more than steel pipes. The difference in weight is due to the presence of a 30-micron anti-corrosion coating. All of the above characteristics are stable, because the range is manufactured using the same technologies.

Varieties

VGP pipes have two types:

- VGP black steel pipe

- Galvanized VGP pipe

Galvanized VGP pipe has the best performance, including performance characteristics.

The range of pipes varies according to the following indicators:

- Length;

- Thickness;

- Diameter;

- Passage (DU);

The thicker the walls of the product, the greater the rigidity. The pipe can be lightweight, standard or reinforced. A galvanized steel pipe weighs more because it is coated with a thin layer of zinc, which protects it from corrosion.

Market prices

When purchasing, you need to know that the price is indicated not per unit of length, but per unit of mass; usually the price is stated for one ton. At the same time, you need to understand that galvanized products weigh 3% more than “black” ones.

Prices for steel models are formed taking into account technical properties, which are influenced by the internal diameter and thickness of the walls. The cost of light types with thin walls is lower than that of medium ones or those with thick walls.

Depending on the batch size, the total price may be adjusted. The larger the batch, the lower the price will be.

Application area

The main purpose of the VGP pipe is to transport water and gas. When installing the product, additional elements, threads, adapters, and so on are used. The most common area of application for VGP pipes is the domestic sector.

In addition to its main purpose, various structures in the form of furniture, fences and decorative elements are made from pipes.

- Installation and production of metal structures

- Scaffolding

- Bearing supports

- Walling

- Furniture and household items

- Screw piles

Precision groups and some other additional parameters

For the assortment and selection of VGP pipes, there are also so-called accuracy groups. There are only two of them:

- standard precision pipes;

- high precision products.

Pipes of the first type are made from steels whose characteristics are given in GOSTs 380 and 1050. In this case, neither the chemical composition nor the mechanical parameters are standardized. Standard precision steel pipes are used in domestic gas and water supply systems, as well as in heating systems during the construction and repair of residential and industrial premises, for organizing gas and water supply in summer cottages and private areas.

When producing high-precision products, the manufacturer is guided by GOST 1050; rationing is also not carried out. Pipes of this category are used for structural parts transporting water and gas.

- Wall thickness divides pipes into three more categories: lightweight pipe products, ordinary products and reinforced ones. The wall thickness is regulated by the provisions of GOST 3262-75. The last two types of steel pipes can, at the request of the consumer, be equipped with threads at both ends of the product (if the nominal bore of the pipe is 10 mm or more).

- The complete set of pipe rolling can also be different. A delivery option is available without a coupling and without a thread; it is also possible to obtain pipes with both.

Certification

The product quality certificate is a guarantee for the purchased product. Products must comply with established quality standards; GOST of VGP pipes is very important when choosing a quality product.

- A quality certificate is issued to products that have been subject to research and passed laboratory tests.

- The certificate specifies the galvanizing method; it can be done hot or cold.

- The product can also be subjected to sanitary and hygienic tests, after which the VGP pipe receives a hygienic certificate.

A product that has all the necessary certificates is in greater demand than a non-certified product.

Dimensions of water and gas products

If you come across a VGP pipe on sale, you should definitely find out what it is. Perhaps these products will be useful to you when carrying out certain work. One of the main parameters is the assortment. The product range can be sorted according to three parameters, such as:

- by lenght;

- by outer diameter;

- by wall thickness.

The length of the pipes can be 4 and 12 m. In other words, water and gas pipes are manufactured in the form of measured sections, the length of which can be 4 or 12 m. Industry standards, however, allow other sizes. This may be an unmeasurable length. As for the outer diameter, the range is divided into 17 standard sizes.

You may be interested in the outer diameter, it varies from 10 to 165 mm. Another criterion allows you to classify products by wall thickness. This parameter cannot be called secondary, since the internal diameters depend on it, and they, in turn, affect the strength and throughput, as well as the rigidity of the products.

If you are interested in the dimensions of the VGP pipe, what it is, you should definitely find out. According to the last mentioned parameter, the described products can be divided into:

- lungs;

- ordinary;

- reinforced.

In the former, the wall thickness can reach 4 mm, while the minimum value is 1.8 mm. Ordinary ones can have a wall thickness from 2 to 4.5 mm. But for reinforced pipes, the wall thickness reaches 5.5 mm, while the minimum value is 2.5 mm.

Advantages

Even modern polymer products cannot compare with galvanized VGP pipes, which have many positive qualities.

- Long service life.

- Ability to withstand extreme pressure.

- Resistance to impacts and mechanical damage.

- High temperature resistance.

- Detachable connection method.

- Possibility of bending up to ninety degrees.

- A wide range of.

Where is it used?

The scope of application of water and gas pipelines is cold and hot water mains, low pressure gas pipelines, heating systems. In water mains, VGP pipes are connected by welding or threaded connections.

Also, water-gas metal rolling is used in the agricultural sector and in the industry related to oil production.

In addition, steel pipelines are used in the manufacture of metal structures - fences, small architectural forms.

Tips for choosing

There is a large selection of manufacturers on the market that provide products of varying quality. Experts advise giving preference to galvanized HSV pipes, which are famous for their excellent anti-corrosion properties.

Only a VGP pipe that complies with GOST will have high performance and have a long service life. When purchasing a product, you need to pay attention to the length of the pipe; it can be from 4 to 12 meters, and also be unmeasured, but meet certain parameters.

When choosing a product, it is best to rely on the advice of experts and purchase a certified product.

Classification of pipes according to their accuracy class

Water and gas pipes are divided into two main categories according to their accuracy classes. The first category includes tubular products of ordinary precision. When producing products of this category, the following parameters are not standardized: the chemical composition of the manufacturing material, its mechanical characteristics. Pipes of this category are quite successfully used for arranging gas and water communications for domestic purposes.

The second category includes water and gas pipe products of increased precision. Galvanized pipes also belong to this category. From such pipes, for which both the chemical composition of the manufacturing material and its mechanical characteristics are standardized, parts for industrial pipelines are made with increased requirements for their reliability.

Requirements for high-precision pipes

Photo of VGP pipe

Technology for the production of longitudinal steel pipes

Unlike seamless pipes produced by cold and hot rolling by piercing a cylindrical blank with a carbide spike, electric welded pipes are made from sheet or tape in spiral-welded products. In straight-seam pipes, the welded joint is located along the entire length; in the manufacture of large-diameter products, due to limitations in the size of steel sheets, two welds are used connecting a pair of sheet blanks.

The technological process for the production of straight-seam electric-welded oil and gas pipeline and casing pipes consists of the following stages:

- The steel, wound into rolls of the required length, arrives at the enterprise's warehouse; the inspector checks its markings for compliance with the technical conditions and the dimensional parameters of the sheets. A small fragment is cut out of the rolls of one batch, which is examined in the factory laboratory for the chemical composition and physical characteristics of the metal.

- Using a crane, the rolls are moved to the slitting area, they are placed in an unwinder and, after straightening, they are cut into strips - narrow strips of width equal to the circumference of the pipes. After cutting, the finished strips are checked by quality control department and wound into rolls.

- Next, the strips enter the mill into an unwinder and are fed into a five-roll punching machine, which is a unit with rollers between which a metal strip passes. The rollers straighten the strip, giving its surface a geometrically correct shape.

Rice. 2 Technological process for manufacturing longitudinally welded pipes

- After straightening, the strip goes to the welding machine table, where its ends are trimmed with scissors and welded in an inert gas environment with two torches simultaneously from different sides of the strip.

- Then the tape is sent to the looper, which acts as a material store to ensure continuous operation of the welding machine.

- Next, the strip enters the forming mill, which includes 8 forming units (stands) with shaped rollers, where it is gradually twisted into a pipe blank.

- The longitudinal edges of the pipe sleeve connected together are welded using an electric welding machine with high frequency currents of 220 kHz.

- After the workpiece has cooled, the outer deburrer cuts off the protruding weld seam from the outer pipe shell, and the internal deburrer performs a similar operation.

- The treated pipe sleeve is supplied to the control section, which carries out non-destructive ultrasonic testing of the welded joint.

- Next, the weld is normalized - heat treatment to relieve local stress, improve physical characteristics, and align the internal structure.

- The pipe enters a sizing mill and a straightening stand, which gives it the specified geometric dimensions. After straightening, the marker paints the batch number on the pipe casing, and the automatic pipe cutter of a continuously moving pipe cuts pieces of the required length.

Rice. 3 Procedure for bending a sheet into a circle

- The chips remaining after removing the internal burr are removed by washing the pipe walls from the inside with a stream of water under pressure, after which the pipe is sent to a cross-roll straightening machine with three pairs of rolls, where further normalization of its geometric shape occurs.

- A fragment is cut from each batch of tubular products in dimensions regulated by state standards and sent to the factory laboratory for testing.

- After the cross-section straightening machine, the steel pipes are sent for cutting the ends at an angle of 90 degrees and removing their outer and inner chamfers with cutters.

- After facing, the workpiece is sent to an ultrasonic testing unit, which checks the condition of its shell and the weld along its entire length.

- If necessary, threads are cut into the pipe ends using a mechanical unit with numerical program control with further control of its geometric parameters.

- To carry out hydraulic tests, a sealing lubricant is applied to the threaded surface, the coupling is screwed on, and hydraulic tests of the pipes are carried out under high water pressure.

- Pipes are checked by weight and their length is measured; if necessary, by agreement with the customer, a black waterproofing coating is applied to the outer surface.

- To protect the thread from corrosion during long-term storage and mechanical damage during transportation, polymer rings or nipples are placed on it. Next, automatic branding and marking of pipes is carried out by applying paint through a stencil to the outer pipe casing.

Rice. 4 The process of forming and normalizing the round pipe shell during production

Weight of welded pipes

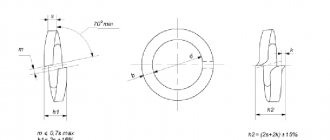

The weight of a welded steel pipe, if you do not have a special table at hand, can be calculated using the following formula using the simplest calculator.

Video

- m is an indicator of the theoretical weight of m/p or its specific indicator, indicated in kilograms.

- Pi is a stable value, which is equal to 3.14.

- d is the external volume shown in millimeters.

- s – wall thickness, indicated in millimeters.

- R – shows the specific gravity of steel in g/cubic meter. cm.

To automate the weight calculation system, you can use an online calculator. It allows you to select the material of the welded product being produced in order to obtain the most accurate indicator of its weight.

GOST standards

Video

https://youtube.com/watch?v=L8jKviVA1eI

- Welded products are ordinary, non-galvanized, of unlimited length with a UD of 20 mm, a wall size of 2.8 mm without threading and a coupling 20 x 2.8 GOST 3262-75.

- The same options with coupling M-20 x 2.8 GOST 3262-75.

- The same products of a dimensional type with a threaded connection R-20 x 2.8 - 4000 GOST 3262-75.

- The same options with galvanization, of unmeasured length, with threaded threads C - R- 20 x 2.8 GOST 3262-75.

- The same options with galvanization, measured length, with threaded Ts - R - 20 x 2.8 - 4000 GOST 3262-75.

Manufacturers

Video

- Pipe rolling plant in Chelyabinsk. It has been operating since 1942 and is a large group in the pipe products market. It produces all types of pipes, and on special orders can subject products to a hydraulic test of 5 MPa.

- Novotrubny plant in Pervouralsk. The company was founded at the beginning of the 18th century. Its products include a couple of thousand varieties of pipe rolling products.

- Pipe plant in Seversky. The plant was founded in 1739, and began producing pipes in the 60s of the twentieth century. During its operation, the plant has implemented modern methods and technologies. Currently, the company holds numerous permits and licenses, including foreign ones.

- Royal Pipe Factory. It has been operating since 2004 and is a major seller of metal and metal products in the Central region.

- Metallurgical plant in Magnitogorsk. Since its founding (1932), this enterprise has become a leader in the ferrous metallurgy. In production, they independently prepare raw materials and produce metal products from them.

This list can be continued for a long time, because manufacturers of this line of products are widely available in our country, and they all produce high quality products.

Without steel pipe materials, no construction can be carried out. And their main advantage is the ability to install them in an open area, which is not the case with their plastic counterparts.

Video