Mechanization makes the welder’s work easier, especially when work is carried out on large structures with extended welds. The main advantage of mechanization: the human factor is minimized, the repeatability of the shape and quality of welds is increased, the productivity and economic benefits of welding work are increased.

1 / 1

Regulatory acts used when carrying out welding work

The list of main State standards dedicated to mechanized welding includes:

- GOST 2601-84 Welding of metals . Terms and definitions of basic concepts;

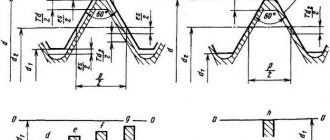

- GOST 14771-76 Gas-shielded arc welding . Welded connections. Main types, structural elements and dimensions;

- GOST 19521-74 Welding of metals . Classification;

- GOST 3.1705-81 Unified system of technological documentation . Rules for recording operations and transitions. Welding;

- GOST 11969-79 Fusion welding . Basic provisions and their designations;

- GOST 29273-92 Weldability . Definition;

- GOST 30430-96 Arc welding of structural cast iron . Requirements for the technological process;

- GOST 2.312-72 Unified system of design documentation . Conventional images and designations of seams of welded joints;

- GOST R ISO 17659-2009 Welding . Multilingual terms for welded joints;

- GOST R ISO 857-1-2009 Welding and related processes . Dictionary. Part 1. Metal welding processes. Terms and Definitions;

- GOST 8713-79 Submerged arc welding . Welded connections. Main types, structural elements and dimensions.

Features of the welding robot device

Many models of welding robots use elements that allow them to function fully for a long time. This is achieved through the introduction of special electronic systems, which have a technically advanced device. This is what prevents the robot from stopping its work process during power outages and unstable voltage.

Welding robots can independently position parts in automatic mode, which has a positive effect on the quality of the joint. The dimensions of the workpieces are not important, because the robot’s arm can adapt to any parameters of the welded workpieces.

It is worth noting! An automated robot welder is a unit that is mounted on a base. It is equipped with a hinge mechanism that ensures easy rotation and direction of the device in the desired direction.

The base of the equipment contains important elements from the list below:

- current source;

- converter;

- feeder;

- display and programming console;

- a cylinder filled with inert gas;

- manipulator. It can lift parts weighing up to 25 kilograms.

Each type of mechanized welding has specific software. It is there that the control panel sets the parameters of the welding process and the metal workpiece that needs to be welded. Often, in addition to the device, special books and video materials are provided for self-study.

Additionally, special holders may be included. They allow the robot to position and fix the workpiece during the process. Robot welding can not only connect parts, but also clean them, as well as chamfer and cut. The equipment performs everything independently, including preparatory operations.

Mechanized welding is capable of performing any type of welding and cutting. Robots often perform spot, electric arc and argon arc welding, including submerged arc welding. In addition, when using robotic devices, the risk of danger to human health at work is greatly reduced, because they are not involved in the process.

Area of use

This type of technological work is widely used in production:

- ship hulls , components and workpieces in shipbuilding;

- tanks for storing oil and petroleum products;

- steel pipes and main pipelines;

- metal and reinforced concrete structures in construction;

- individual vehicle parts in the automotive industry;

- bridges;

- household metal products (gates, fences);

- when repairing agricultural and automotive equipment , etc.

Minuses

- • In some cases, as a result of mixing the base material with the added material, a deterioration in practical properties is observed;

- • if the mode is chosen incorrectly, the deformation caused by high temperatures can be excessive, which requires taking additional measures to preserve the geometry of the workpiece;

- • the master solving the problem needs to have theoretical knowledge in the field of metal compatibility in order to make the coating not just uniform, but with the desired properties;

- • a small number of combinations compared to the same spraying;

- • it is difficult to cover small elements of complex shapes - the bath has to be constantly moved and it is not always possible to do this smoothly.

Mechanized processing technology

First, the surfaces to be treated are prepared. They carry out straightening to eliminate deformations of the rolled product, apply markings, and perform metal cutting and edge processing. The edges are machined using abrasive materials (tools) of high hardness.

Next, select the welding mode. Determine the strength, type and polarity of the current, arc voltage, welding speed, ambient temperature, number of passes, spatial position of the seam.

Electricity is supplied to the electrode, and the workpiece is grounded to initiate and maintain the arc. When these objects come into contact, a welding current is generated. Under the influence of heat, the metal of the electrode and the edge of the product melt. Molten particles of one and the other substance enter the weld pool, where they are mixed into a single mass. In this case, molten slag is formed, which rises to the surface and forms a protective film. Solidification of the metal promotes the formation of a weld.

The quality of the joint is affected by the presence of air. To ensure that the seam remains strong, the location is treated with a protective gas formed during the combustion of carbon, or with flux.

general information

Robotic welding is a type of automatic welding process, the main essence of which is the use of programmable robots in production instead of conventional welders. This type of welding is widely used in large enterprises where various metal products are constantly produced in large volumes. Robots make it possible to weld and produce large batches of parts and structures in a short period of time.

The use of automated machines makes welding automated, which ultimately ensures a permanent connection between metal workpieces. In addition, thanks to them, the workpieces are constantly moved and processed, all of which has a positive effect on the quality of the seam. But to ensure full operation of this equipment, additional human participation is required. The operator must prepare materials for welding, as well as program the device.

Note! In modern production, welding robots are usually used when working with an electric arc in a shielding gas environment. These products are perfect for laser, plasma, resistance, and hybrid welding methods.

Partially mechanized welding technology

Partially mechanized welding involves manually moving the torch and/or workpiece and loading and unloading parts. But the supply of filler metal occurs mechanically. Manual adjustment of welding parameters is possible.

There are left and right gas welding methods . The left method involves moving the burner from right to left, while also moving the filler rod in front of the flame. Ideally, the movement should be zigzag, perpendicular to the seam.

Right-hand welding involves straight-line movement of the torch from left to right. The flame is located in front of the rod and directed towards the molten bath. The metal seam does not cool down as quickly as in the first case. Because of this, the strength of the connection and productivity increase, and gas consumption decreases.

Advantages of robots for welding

Robotic welding has made life much easier for large enterprises that constantly need to produce large volumes of metal products. Thanks to this process, the speed performance of similar connections has increased without reducing quality.

The use of welding robots ensures precise positioning of parts and their precise movement, and the presence of programmed systems in the devices makes the process continuous and accurate. All this allows these devices to replace several professional welders, and they can also operate continuously for a long time.

Robotic gas shielded welding has other equally important advantages:

- Robots can perform the same types of work consistently without compromising quality. But people cannot perform the same type of work for many hours.

- Automated machines produce high quality seams and can be reconfigured mid-production.

- Robots are a profitable proposition for large enterprises. They pay for themselves fairly quickly, this is due to their high performance indicators.

- Devices of this type require only maintenance. But people need to pay wages, and don’t forget about taxes.

- Robots are easy to customize. If the operator has studied all the features of setting up the device, he can do this in a matter of minutes. Even beginners can do this work, but it’s worth first studying the connection algorithm and setting up the robot to the parameters of the selected welding and parts.

- Robots are capable of working for a long time without interruption. All this increases the quantity of products produced. An ordinary welder is limited in his capabilities; after long work, he definitely needs rest. Also, the quality of work depends on his physiological state. But robotic technology never fails; it accurately performs assigned tasks without interruption or interruption.

- The use of this device allows you to obtain thin and even seams. This is ensured by maintaining the arc at a distance of 2 mm.

- The equipment allows you to save voltage and consumables.

- Provides increased productivity growth with predictable results, no need for frequent quality control.

welding equipment

The production of welds is carried out using automatic and semi-automatic devices.

The automatic device includes:

- gas reducer;

- acid cylinder;

- heater;

- dehumidifier.

The main element of the machine is the welding head. The speed of melting depends on the speed at which it feeds the electrode wire (constant or variable).

Approximate cost of automatic devices on Yandex.market

The semi-automatic machine provides wire feeding mechanically. The movement of the arc in the direction of the seam is carried out manually.

Semi-automatic equipment includes:

- electric holder;

- cassette;

- control cabinet;

- welding torch;

- power supply;

- the wire.

Approximate cost of machines for semi-automatic welding on Yandex.market

The main element of the mechanism is the electric holder. It keeps the electrode in a certain position and provides current to the welding area. The arc is activated by a short circuit or a trigger button located on the handle of the holder.

Types of mechanized surfacing

Today the following methods are relevant:

- • submerged;

- • in a protective gas environment;

- • electrical contact;

- • electroslag;

- • vibro-arc;

- • plasma.

Now let's look at each of them in more detail.

Submerged arc work is convenient because when it is carried out, the air does not affect the hot metal, which helps to avoid pores and generally makes work easier. Plus, there is no spattering, the generated heat is used more efficiently, and alloying can be done.

The process itself is distinguished by its productivity, and there are two reasons for this:

- • The overhang is relatively small, so the current (not per unit area of the rod) is 7-8 times higher than with manual arc welding.

- • The resulting slag helps to minimize losses of the base material, which has a positive effect on the final soldering coefficient (increases it by 1.5-2 times).

The role of the electrode is performed by a solid wire with a cross-section of 1-6 mm; its feed speed is regulated by an automatic device and ranges from 100 to 300 km/h. The “plus” is supplied to it from the source (through a copper mouthpiece), while the “minus” is supplied to the workpiece itself (but the current still passes through the frame and the puller).

In this case, the flux can be glassy, representing a crushed mixture of silicates (AN series), and only protect the base material from air. Or contain alloying, binding, slag-forming, deoxidizing additives and change the physical and chemical properties of the applied coating.

Mechanized surfacing of the surfaces of parts in a protective gas environment is carried out in a space filled with a mixture of argon and water vapor or CO2. The first is expensive, so factories use CO2 by default when repairing bodies, cabin elements and tails, and many other parts in it.

The process proceeds as follows: carbon dioxide supplied to the working area displaces air, preventing oxygen or nitrogen from negatively affecting the created seam. The only problem is that the arc heats up to 6000 0C, and at this temperature the bonds in CO2 are broken, and the reaction of its disintegration provokes the burnout of alloying substances and carbon in the applied coating. To mitigate possible harm, you should use a special filler wire from the Sv series, which contains additives of titanium, silicon, and manganese.

This option has four advantages:

- • allows you to obtain an even, dense and even aesthetic layer (without slag), which does not require any subsequent processing;

- • makes it possible to resolve the issue 1.5-3 times faster than manually;

- • provides all conditions for visual control of the process;

- • promotes parallel cooling of the workpiece, which is why the surface of the workpiece does not warp.

Among the disadvantages we will write down the relative fragility of the seam and the relatively large spattering.

But the method is easy to implement in practice: a standard 40-liter carbon dioxide cylinder is enough for 20 hours of work. It is not a problem to neutralize the moisture contained in it with a desiccant - copper sulfate. An ordinary oxygen reducer would be an excellent reducer. All operations must be carried out with a current of reverse polarity.

There are both classical and modern mechanized methods of welding and surfacing of parts. Electrical contact rather belongs to the second category, since it is performed on modernized equipment. To implement it, machines are used that weld wire or strip metal in one or several passes, and thus create a uniform coating of the required thickness (up to 3 mm). It is more rational if there are 2-4 layers: this will preserve all physical and mechanical properties, excluding overheating during work.

Mixing of the main and additional material tends to zero, especially when using intermediate additives - PG-SR powders. At the same time, it is quite possible to maintain productivity at the level of 2-4 kg/h.

The electroslag method allows you to repair even heavily worn elements, for example. It ensures high quality welds, and the work can be done really quickly; a figure of 30 g/Ah is quite realistic.

The scheme is as follows:

- • the flux is heated by an arc, after which a current is passed through it;

- • under such conditions, the electrode melts and forms a pool together with the base metal;

- • The crystallizer moves upward at a certain speed, and the lower layers gradually cool down.

Please note that the working area in this case is completely protected from the influence of air, so nothing prevents you from introducing alloying additives and using the generated heat with maximum efficiency.

The technique and technology of mechanized surfacing using the vibration-arc method comes down to the use of a filler rod that creates vibrations with an amplitude of 1 to 3 mm and a frequency of 50 to 100 Hz. As a result, the entire process becomes a series of three cyclically repeating stages:

- • combustion;

- • idling;

- • short circuit.

Moreover, in the first step, up to 9/10 of the total heat is released, and in the third – only 1/10. This is explained by the fact that 12-20 V, i.e., at a low voltage of the current source, there is inductance in the circuit, which means the arc remains stable, and its voltage is already 30-35 V.

For maximum efficiency, it is worth connecting the current with reverse polarity and performing work in a cooling liquid environment. An aqueous solution of glycerin (10%) or soda ash (5%) applied 40 mm from the filler rod works well. As a result of heating, it will turn into steam, which will take away harmful nitrogen compounds. In addition, Ca will make combustion more stable, and C3H8O3 will prevent cracks from appearing.

Yes, the method is good due to its small temperature rise zone and almost complete absence of losses of alloying elements and allows you to obtain a thin but durable coating, but it also has a drawback. The downside is that the fatigue strength of the workpiece is reduced due to the appearance of pores in the applied layer, which partially limits applications.

If we consider modern mechanized surfacing methods, then plasma technology is considered the most progressive. In accordance with it, the restoration of a worn surface is carried out under the influence of highly heated and richly ionized gas - argon, helium, air, nitrogen with additives.

It can be carried out according to one of three schemes - with an open, closed and combined jet. In the first case, the role of the anode is played by the workpiece, in the second by a burner or nozzle, in the third by both.

There are also two implementation options:

- • plasma captures the powder and deposits it evenly onto the surface;

- the additive is immediately introduced into the stream.

The method has five practical advantages:

- • due to the concentration of high temperature, the thermally affected zone narrows;

- • thanks to it, it is possible to apply a variety of wear-resistant materials, even plastic, to steel;

- • allows you to precisely adjust the layer thickness - from thin, 0.1 mm, to 2-3 mm;

- • has a relatively high arc efficiency – reaches 45%;

- • it can also be used for surface hardening.

Mechanized submerged arc welding

Flux is a powdery substance for welding that complies with GOST 8713-79. Its properties resemble electrode coating, and the main substance is manganese silicate.

Flux can be fused or unfused. The former include substances that have undergone high-temperature treatment in ovens. The second category includes fluxes of ceramic origin and powders, sintered and crushed to a certain size.

Most often, submerged arc welding is used to join high-alloy and stainless steel, aluminum and copper alloys.

Approximate cost of flux on Yandex.market

The essence of mechanized surfacing and its purpose

In general, this is the application of a layer of material to the surface of the workpiece. It is necessary:

- • to restore or change the original dimensions (geometry) of an element, which is especially important if it is a tool, for example, a cutting edge;

- • or imparting new properties, for example, improving anti-corrosion characteristics or increasing abrasion resistance.

Well, in the situation we are considering, the process should also be half or fully automated.

Disadvantages of seams

Defects in welding seams occur due to:

- differential heating of a metal product;

- shrinkage of the molten substance;

- structural changes in a chemical element.

To prevent welding imperfections, parts are secured in special tools. This option is ideal for viscous compounds that do not cause cracking.

Some welders use the reverse strain method or the method of complete (partial) elimination of internal stresses.

The classic case of eliminating deficiencies is heat treatment through high tempering. The product is heated to 650°C and after a short exposure is slowly cooled.

pros

- • it is possible to create coatings of considerable thickness (up to 2-3 mm) and thus return the original geometry even to heavily worn products;

- • productivity is 1.5-3 times higher than with any of the manual methods;

- • the equipment used is relatively reliable and easy to transport;

- • there are no restrictions on the size of objects - blast furnace cones, nuclear reactor vessels and other large objects can also be effectively protected and restored;

- • each method is quite easy to implement;

- • the applied layer can be of any composition, from pure copper to combined plastic;

- • it is not a problem to combine surfacing with other processing methods, for example, with nitriding or plasma hardening.

Gas equipment for semi-automatic welding

The gas equipment for semi-automatic welding includes: a cylinder, a reducer, a rotameter, a heater, a dryer, a gas mixer, and hoses.

Cylinders store and transport compressed gases. The gas contained in the cylinder can be recognized by the color and inscription on the cylinder.

Reducer (pressure regulator) The reducer is attached to the cylinder valve, designed to reduce the pressure from the cylinder to the working one and constantly maintain it

zhaniya. To regulate gas flow (pressure), the flywheel on the gearbox is rotated.

Heater

When welding in a carbon dioxide environment, the reducer is additionally equipped with a gas heater to avoid freezing of the reducer.

With a higher consumption of carbon dioxide, a sharp decrease in temperature is observed, which leads to freezing of the moisture contained in the carbon dioxide in the reducer. The heater operates from direct (20 V) and alternating (36 V) current.

Cylinders

Compressed gases are stored and transported in cylinders. The gas contained in the cylinder can be recognized by the color and inscription on the cylinder.

Reducer (pressure regulator)

The reducer is attached to the cylinder valve and is designed to reduce the pressure from the cylinder to the working one and constantly maintain it. To regulate gas flow (pressure), the flywheel on the gearbox is rotated.

Heater

When welding in a carbon dioxide environment, the reducer is additionally equipped with a gas heater to avoid freezing of the reducer.

With a higher consumption of carbon dioxide, a sharp decrease in temperature is observed, which leads to freezing of the moisture contained in the carbon dioxide in the reducer. The heater operates from direct (20 V) and alternating (36 V) current.

Dehumidifier

To absorb moisture contained in carbon dioxide, gas equipment sometimes includes a high or low pressure desiccant. The high pressure dryer is installed before the reducer, and the low pressure dryer is installed after the reducer. A special substance absorbs moisture - aluminum glycol or silica gel. The properties of both substances can be restored by piercing at a temperature of 250-300 ºC.

Rotameter

Rotameters are used to determine shielding gas flow rates when the gearbox does not have a pre-installed flow meter.

Sleeves (hoses)

Flexible tubes made of vulcanized rubber reinforced with linen fabric. With their help, shielding gas is transported to the burner and other parts of gas equipment.

Gas mixer

A gas mixer designed for preparing a mixture of gases when supplied from several cylinders.

Semi-automatic welding technique

Semi-automatic welding of butt joints

Parts with a thickness of no more than 0.8-4 mm are welded without cutting edges, fixed in assembly and welding fixtures. Thin metal is welded on linings made of the same metal as the product or on copper and stainless steel removable linings. Metal with a thickness of over 4 mm can be welded either on weight or on supports.

When welding with a semi-automatic machine, thin metal is much easier to weld when in a vertical position. Welding is carried out at an angle backwards, and the torch is moved in the direction from top to bottom. At the same time, the welder can clearly see the formation of the seam and the welding zone.

For welding thick metal, it is better to use gases that increase the thermal power of the arc - helium or mixtures of helium and argon. In this case, you need to monitor the position of the burner relative to the seam. A slight deviation of the torch from the vertical can lead to non-fusion of the edges of the welded parts.

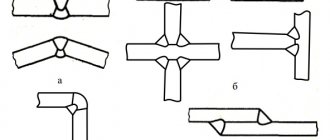

Semi-automatic welding of corner and T-joints

It is preferable to carry out corner welding when the welded parts are arranged in a boat. In this case, the output of electrode wire is increased by 10-15% compared to welding butt seams in the lower position.

Welding fillet and tee welds is complicated by poor observation of weld formation due to the torch nozzle. Distance e = 0, with a metal thickness of up to 5 mm, and e = 0.8-1.5 with a metal thickness of over 5 mm.

Welding lap joints

Welding of lap joints with a metal thickness of less than 1.5 mm is performed on a copper or steel backing in one pass.

Welding of parts with a thickness of more than 1.5 mm is carried out on weight in several passes.

Semi-automatic welding of horizontal seams

Welding of horizontal seams is carried out at a “forward angle” without transverse oscillatory movements of the torch. Metal with a thickness of more than 6 mm is welded in several passes.

Welding of parts up to 3 mm is carried out at a right angle to the torch axis relative to the welded parts, without cutting the edges.

Welding parts over 3 mm in a horizontal position is welded with the top edge grooved, and the torch is tilted relative to the top part at an angle of approximately 70º.

Welding vertical seams

It is recommended to weld vertical seams with wire with a diameter of 0.8-1.2 mm with free formation of the seam. You can use the technique of frequent short circuits or use pulsed arc sources. It is better to weld parts up to 4 mm thick using a top-down method without oscillatory movements. If you plan to weld with a one-sided seam, it is better to assemble parts with a gap.

Welding ceiling seams

Ceiling seams thicker than 6 mm are best welded in several passes. It is recommended to semi-automatically weld aluminum and its alloys at a forward angle, and weld steel, copper, titanium and other metals at a backward angle.

Methods for proper pipe welding

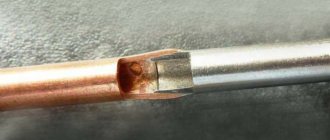

There are various methods for properly welding polypropylene pipes and products made from other materials using the electric arc method:

- end-to-end - in this case the pipeline elements are located opposite each other;

- in a T-bar - in this case, the pipe sections are located perpendicular to each other (in the shape of the letter “T”);

- overlap - this method involves flaring one of the pipes, allowing it to be put on the other;

- angular method, in which the elements are placed at an angle of 45° or 90° relative to each other.

In the process of proper pipe welding, the following types of seams are obtained:

- horizontal (with a vertical arrangement of pipeline elements);

- vertical (if the pipes are located vertically);

- ceiling (with the electrode placed above the welder’s head, in the lower part of the workpiece);

- lower ones (you have to bend over to do this).

If it is necessary to connect steel pipes, the butt method is used. In addition, the joint must be welded to the thickness of the workpiece wall. A bottom turning seam is best for this.

To obtain a high-quality welded joint during the work process, you should adhere to the following recommendations:

- During welding, the electrode should be positioned at an angle of 45° or slightly less. This will reduce the amount of molten metal entering the pipeline element being welded.

- For T-welding or butt welding, 2-3 mm electrodes will be required. A high-quality welded joint will be obtained with a current varying from 80 to 110 amperes.

- To get a reliable overlap connection, you will need to increase the current to 120 amperes; 2-3 mm consumables (electrodes) are also suitable.

- The weld seam should rise 3 mm below the surface of the workpiece being welded, after which we can talk about completing the work.

Correct welding of profile pipes is carried out spot-welding, that is, first two points located on opposite sides of the profile are welded, then two other points, continuing work until the entire pipe is heated. Next, a welding seam is formed along the entire perimeter of the workpiece.

How to choose electrodes for proper pipe welding

Before you start welding heating pipes or any other pipes, you need to stock up on electrodes. Their quality directly affects the reliability of the resulting connection, the tightness of the structure, as well as the welding process itself.

Electrodes are a thin steel rod with a special coating that provides a stable arc during operation and forms a weld that prevents oxidation of the metal.

VT-metall offers services:

Electrodes are qualified by the type of core and outer coating.

Depending on the type of core, electrodes are divided into:

- consumables with a non-melting center made of graphite, electrical coal or tungsten;

- with a melting center - wire, the thickness of which varies depending on the type of work performed.

Based on the type of external coating, electrodes are divided into the following groups:

- With cellulose coating (grade C). Designed for proper welding of large diameter pipes; they are used to install gas and water mains.

- With rutile acid coating (RA). Used to work with metal heating or drainage pipes. The resulting weld is covered with a small layer of slag, which is removed by tapping.

- Rutile coated (RR). Allows you to obtain neat welding seams with slag that can be easily removed from the surface. These electrodes are used for corner joints, as well as when welding the second or third layers of metal.

- With rutile cellulose (RC) coating. They can be used for correct welding of pipes in any planes, for example, when creating a long vertical seam.

- With base coat (B). These are universal consumables suitable for working with thick-walled pipes and parts intended for use at sub-zero temperatures. Allows you to obtain a high-quality plastic seam that is not subject to cracking or deformation.

Before starting welding work, it is worth obtaining advice from welding specialists regarding their preferred brands of electrodes. At the same time, there can be quite a lot of recommendations, and consumables may vary depending on the store or city.

We recommend articles on metalworking

- Steel grades: classification and interpretation

- Aluminum grades and areas of their application

- Defects in metal products: causes and search methods

There is a direct connection between the cost and quality of consumables. With cheap electrodes it is difficult to weld pipes correctly and obtain a high-quality weld. Therefore, there is no need to save on these consumables.

Cored wire

We are talking about the so-called “flux-cored” wire for mechanized welding, produced in accordance with the requirements of GOST 26101-84 and having a complex structure. It contains a special shell, partially filled with a charge, due to which individual wire samples reach 40 mm in diameter.

After melting this type of active additive, components are added to the charge to ensure the following tasks:

- protection of the processed metal from the oxygen contained in nitrogen;

- maintaining an even and stable arc;

- obtaining a high-quality seam.

It should also be noted that during mechanized welding, such wire can be used in conjunction with flux and carbon dioxide.

Preliminary work for proper pipe welding

Before you begin to properly weld plastic and metal round pipes, you need to pre-process the joints and clarify a number of nuances. First of all, they diagnose the pipe’s compliance with certain technical characteristics that apply to the installed system, in particular to the water supply system.

Necessary:

- observe geometric dimensions;

- have a quality certificate, especially if a pipeline for drinking water supply is to be installed;

- so that the pipe is perfectly round in shape, since defects, a flattened or oval section of the workpiece are not acceptable;

- control the wall thickness along the entire length of the pipe - it should be the same;

- The chemical composition of the part must comply with the requirements of GOST - this information is contained in the technical documentation or is determined in the process of laboratory research.

After this, you can begin preparing the pipes for joining and welding.

During the preparation process, you must complete the following steps:

- check the evenness of the cut at the end of the pipe, it should be 90°;

- thoroughly clean the end of the workpiece to be welded and the 10 mm area around it until a metallic sheen appears;

- remove residual oils, rust, paintwork from the surface of the pipe, degrease the ends of the element.

In addition, you should ensure that the end has the correct configuration. The opening angle of the edge should be 65°, the dullness index should be 2 mm. The required parameters can be obtained through additional processing.

Automation and semi-automatic

Fully mechanized or automatic electric welding is a welding option where the arc appears without the effort of the welder. Thus, the welder is not directly involved in the work at all.

The welding flow is controlled and adjusted by commands that are sent to the actuators according to programs specially developed for these purposes.

The functioning of mechanized arc welding systems involves obtaining a specially designed metal connection.

Under the action of an electrode melted by an arc, a special welding layer or pool is formed on the surface of the metal being processed, in which all components are present in a liquid and well-mixed form.

Such a liquid mass is formed with the help of auxiliary additives (fluxes), which fundamentally distinguishes this class of welding from the manual method.

Under the influence of these additives, the metal first intensively oxidizes and then goes into the alloying stage.

When an arc is formed automatically, it moves along the edges of the metal being welded, thereby activating the entire weld pool.

After the machine passes through and the bath cools down, a fairly smooth and high-quality seam remains in its place.