Bronze coating (bronzing).

One of the possibilities for replacing precious metals (see “Silver plating process. Part 1.” and “Silver plating process. Part 2.”) is the use of copper-tin alloy coatings ( bronzing ).

The chemical composition and appearance of coatings during bronzing can vary widely. With a content of 2 - 3% tin, the precipitates during bronzing resemble copper in color, with 15 - 20% tin they become golden yellow, and with 35% tin they have a silvery-white color. Bronzing processes have found practical application for decorative and special purposes , making it possible to obtain coatings containing 20 and 40% tin. Coatings obtained by bronzing have high microhardness, a low coefficient of friction, are easily polished, have strong adhesion to the base metal and retain ductility at any thickness. The bronzing process is carried out on steel, cast iron, copper and zinc alloys.

Bronzing coatings containing 20% tin are used:

- for local protection against cementation;

- as corrosion protection for steel parts;

- to improve antifriction properties in the production of bearings.

White bronze, obtained through the bronzing , has a beautiful decorative appearance; unlike silver, it does not darken in air, since it does not react with hydrogen sulfide, therefore alloys containing more than 40% tin are applied to cutlery, wind instruments, and jewelry.

The white bronze coating obtained by bronzing can be painted black by anodic oxidation in a 20% sodium hydroxide solution.

In terms of electrical properties, white bronze obtained by bronzing is inferior to silver and copper coatings, but its transient electrical resistance is more stable. When bronzed, the coating is not subject to the growth of threadlike crystals and does not turn into a powder modification, like tin.

The potential difference between copper and tin is 0.5 V, therefore, to obtain an alloy during bronzing, only complex salts can be used.

In practice, when bronzing, stannate cyanide electrolytes are used, in which copper is in the form of a cyanide complex, and tin is in the form of a stannate complex, since it does not form cyanides. The starting components of the bronzing electrolyte are copper salt, cyanide and tin stannate.

The chemical composition of the alloy during bronzing is influenced by the relative content of tin and copper in the electrolyte, as well as the concentration of free sodium hydroxide.

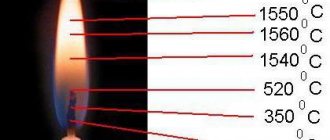

When bronzing, the temperature of the electrolyte is important: high-quality coatings are obtained at 60 – 65 0 C. An increase in current density leads to a decrease in the tin content in the alloy and a decrease in current efficiency.

Composition of stannate cyanide bronzing electrolyte, g/l:

T = 65 0 C, DC = 3 A/dm 2, tin content 40%.

Due to the high toxicity of cyanide electrolytes for bronzing (see “Safe electroplating”), pyrophosphate electrolytes for bronzing have recently been used, in which the ratio of Cu 2+ to Sn 2+ is 100:120, and the content of potassium pyrophosphate is 300 – 350 g/l, t = 20 – 30 0 C, DC = 0.5 – 1 A/dm 2, pH = 7 – 8, bronze anodes. The copper content during pyrophosphate bronzing increases with increasing copper concentration and temperature. The electrolyte requires stirring.

Source

Do-it-yourself electroplating at home: technology and equipment

Galvanics is also a branch of applied science “Electrochemistry”, which studies the processes that occur during the deposition of metal cations on a cathode placed in an electrolytic solution, and the technological process. Electroplating at home or performed in production allows you to apply a thin layer of metal to the surface of the workpiece, which can act as a protective or decorative coating.

Home electroplating installation

Yellow bronze finish.

The issues of deposition of tin alloys have been discussed previously (“Coating with zinc alloys”, “Deposition of tin alloys”, “Brass plating process”). The possibility of electrolytic deposition of the alloy is determined by the potential difference of the components.

In this case, the potential difference between copper and tin is 0.5 V, so their approach is possible only through complexation. That is why, when applying bronze coating, stannate cyanide electrolytes are more often used, in which copper is in the form of a cyanide complex, and tin is in the form of a stannate complex.

Recently, cyanide electrolytes for bronze coating have been replaced by safer ones - sulfuric acid, pyrophosphate and fluoroborate, in which the convergence of potentials is achieved by the introduction of surfactants.

The chemical composition and appearance of bronze coatings can vary depending on the copper content in the alloy: in the presence of 15–20% tin, the deposits become golden yellow, and in the presence of 35% tin they are silvery-white.

General information

Theoretically, any material can be bronzed: metal, wood, leather, fabric, plastic. After all, the process consists of placing the object to be bronzed in a solution of a special composition (depending on the type of bronze), and then electrodes are lowered into it and current is passed through. As a result, particles of metals: copper, tin and others, settle on the surface of the object and are firmly fixed on it. The thickness of the applied layer, color, or rather shade, can be adjusted using the composition of the solution and the duration of current transmission.

By the way, now it has become very fashionable to bronze, or as they say, to immortalize some little things that are valuable to people: a child’s first tooth that falls out, a first shoe, a pacifier or a favorite toy. After this procedure, these items turn into cute souvenirs that time has no control over. The metal coating is reliably protected from moisture, UV aging, and mechanical destruction.

Another direction is covering monuments, park and garden sculptures, and small forms with bronze composition. This allows you to give them a more presentable, expensive look without high costs.

Bronzing of decorative interior elements.

Our store sells heated towel rails and heating radiators with bronze and gold coatings; we are also pleased to offer metal bronzing services and are ready to promptly tell you the price for an element (from 150 rubles) coated in different shades of bronze. The coating is applied using titanium nitride technology (metalization) and has an excellent appearance and a 3-year guarantee for resistance to external mechanical influences.

What is needed to prepare the electrolyte?

To safely store at home the chemical reagents from which the electrolyte for electroplating will be prepared, as well as the finished solution itself, you will need glass containers with ground-in lids. The amount of chemical reagents from which the electrolytic solution is prepared must be measured with an accuracy of one gram. To solve this problem at home, even inexpensive electronic scales, which can be purchased at any hardware store, are suitable.

The finished electrolyte can be poured into a plastic bottle, but for acidic compounds you need to use glassware

If you decide to apply electroplating to various products at home, you will probably encounter the problem of purchasing chemical reagents from which the electrolytic solution is prepared. The fact is that organizations that produce and sell such chemicals can only sell them to those who have the appropriate permits. It is problematic to purchase such chemical reagents for a private person or even an organization that does not have such documents.

To apply decorative metallized coatings, you can purchase special kits consisting of all the necessary components

You can order bronzed ones from:

For connoisseurs of exquisite furnishings, there are no interior details; every detail is significant for creating the desired style in a room, be it a private cottage, apartment, office or public place. For many years now, the craving for antique-style space design, vintage and retro solutions has not waned, but only intensified - this is a sure-fire way to create a cozy and unique atmosphere.

You can add a retro twist in a variety of ways, and one of the most effective is bronzing items. Things decorated using this technology will decorate not only rooms decorated in Baroque or Classicism styles, but can also become a wonderful contrasting solution in the design of modern trends.

Process Features

The coating formed on the workpiece using galvanization can be applied for technological purposes or perform decorative, protective, or both functions at once. For decorative purposes, a thin layer of gold or silver is created, and to ensure reliable protection of the surface of the workpiece from corrosion, galvanizing or galvanic copper plating is performed.

Electrolysis process diagram

It is not difficult to do electroplating even at home. This procedure is performed as follows.

- Two anodes are lowered into a dielectric container with electrolyte, connected to the positive contact of the electric current source. The material used to manufacture such anodes must be metal, the layer from which must be formed.

- Galvanization, that is, the process of transferring metal molecules from the electrolyte to the cathode product, begins to occur at the moment when the resulting electrical network is closed.

The workpiece itself, connected to the negative terminal of the electric current source and thus acting as a cathode, is placed in the electrolyte between the anodes.

As a result, a thin and uniform layer of metal is formed on the treated surface, which was originally contained in the chemical composition of the electrolyte.

Galvanic installation diagram

When is bronzing applied?

The use of antique items carries with it some complexity associated with the age of such items. They are often quite worn, scuffed, scratched, and their use requires expensive restoration work. However, big expenses can be avoided if such a thing is bronzed. With the help of this technology, the desired piece of furniture can be completely restored, after which it can serve for a long time.

Bronzing today is increasingly used to create unique interiors. This method helps to achieve almost any desired shade in the decor of metal parts. The shade of old bronze has become the most popular lately.

How to properly prepare the product for the procedure

After you have made your electroplating apparatus, found all the necessary equipment and chemical components, you can begin such an important process as preparing the product that will be subjected to electroplating. The importance of such a process is very difficult to overestimate, since the quality of its implementation largely determines what characteristics the finished coating will have.

In most cases, preparing a product for electroplating is not limited to just cleaning its surface from dirt and degreasing it. Sandblasting and subsequent grinding using sandpaper and special pastes are also performed.

Bronzing methods

There are two main methods to bronze things: galvanizing and metallization. To obtain metallized objects, their surface is covered with a thin layer of metal, which not only improves their appearance, but also adds strength and wear resistance. Through the use of innovative technologies of infrared ovens, products receive a margin of reliability and durability.

Bronzing by electroplating metal is the most popular method of processing objects, both decorating and protecting them. It not only serves as a means of decoration and makes things corrosion-resistant, but is also capable of changing their physical characteristics, for example, making them more ductile, which increases strength. The bronze layer obtained by electroplating has an increased level of microhardness and adhesion to the base; this coating is resistant to friction, performs well when polished, and does not lose ductility at any thickness.

The bronze coating obtained by these methods is very beautiful and decorative, it does not darken in air like silver, and thread-like crystals do not appear in it.

In our online store you can buy or coat a wide variety of interior items with bronzing: faucets, towel rails, sockets, panels, profiles, keys and buttons, hooks, grilles and many other accessories. Bronze elements will help bring the design of your premises to perfection and add sophisticated charm to your surroundings.

The timing of the work is determined based on the characteristics of the product, but as a rule does not exceed 10 working days. Options for gold heated towel rails can be seen HERE, bronze heated towel rails HERE. Write your questions and suggestions here.

To strengthen the process of estimating the cost of work and materials, please send photos with product dimensions.

Source

Fake gold and silver

It is known that wooden, metal and other surfaces can be given the appearance of gold or silver by covering them with a layer of these metals. For this purpose, there are sheets of real gold on sale, called gold leaf, or red gold, and fake gold - yellow potal.

Fake silver is called white gold leaf; aluminum is also used quite often.

The preparation for plating items with gold and silver is almost the same and depends a lot on whether the item to be gilded or silvered will be exposed to outside air or not. So, for exterior work, oil preparation is usually done, and for interior work, glue or French preparation is usually done. In the first case, they do this: if the object to be gilded is wooden, plaster or any porous material, then the pores must first be filled with heated drying oil. Allow each layer to dry and repeat priming several times until a sufficiently shiny surface is obtained.

Using gold plating technology, irregularities and depressions are filled with oil putty and polished as usual. After this, painting is done, which is done with white for silver, and with yellow oil paint for gold with an admixture of drying oil and turpentine.

Gold plating at home should be done in such a way that the paint is applied in as thin and even a layer as possible, leveling each time with a flute. After drying, sand with pumice powder or thin glass sandpaper, and the last layer with crocus or horsetail.

This treatment is repeated until a completely smooth surface is obtained, which is covered with drying oil or special Mordan varnish. The latter forms an adhesive surface to which gold leaf adheres tightly. Mordan consists of a mixture of wax, lard and Venetian turpentine, which should be applied warm.

Safety requirements

Any galvanic operation (zinc plating, chrome plating, nickel plating, copper plating, etc.) is a dangerous technological process, therefore, when performing it at home, it is necessary to strictly follow safety requirements. What makes electroplating dangerous are both toxic chemicals and the high temperature of the electrolyte, as well as the risks associated with any electrochemical processes.

To carry out electroplating at home, it is better to allocate a non-residential premises, which can be a garage or a workshop. It must have high-quality ventilation. All electrical equipment that you will use to do electroplating must be grounded.

Rubber gloves, goggles and a respirator are the minimum necessary protective equipment

Personal safety is the most important rule that should be strictly adhered to when performing electroplating at home. Measures that can ensure such security include:

- use of a respirator to protect the respiratory tract;

- protect your hands with soft and durable rubber gloves;

- use of an oilcloth apron and shoes when working that can protect the skin of your feet from burns;

- protection of the organs of vision with the help of special glasses.

In addition, during the galvanization procedure you should not eat or drink anything, so as not to accidentally ingest harmful fumes.

To be prepared for any surprises that may arise during such an operation, it is better to first read specialized literature or even watch a training video on this topic.