Corrugated sheet is a type of flat steel sheet metal without a hollow internal area, produced using the hot-rolled method with the application of a convex pattern on one of the surfaces.

Corrugated steel sheet is manufactured in accordance with the requirements of GOST 8568-77 from ordinary quality carbon steel grades St0—St3, chemical. The composition of these brands must comply with GOST 380-94.

Convexities on the surface of such a steel sheet are called corrugations . The riffles are located at a certain angle relative to each other. Typically this angle is 90 degrees.

Advantages of corrugated steel sheet

When using a corrugated sheet, there is no need to carry out a whole range of measures aimed at ensuring high adhesion properties to the surface. This feature, in particular, makes it possible to ensure a high level of safety for personnel working in industrial production conditions.

At a low cost, corrugated steel sheets are a simple but very effective means of preventing various injuries due to shoes slipping on the surface.

Types of corrugated steel sheet

Depending on the shape and location of the corrugations, there are two types of production of corrugated steel sheet:

- Sheet with diamond corrugation. It is characterized by a certain arrangement of large diamond diagonals of 25-30 and 60-70 mm, and a standard corrugation configuration.

- Steel sheet with lentil corrugation. The riffles on it have an oval shape, reminiscent of plant grains, located at an angle of 90 degrees. to each other and 45 degrees to the sides of the sheet. The distance between adjacent riffles is 20, 25 or 30 mm.

There are also types of fluting such as duet and quintet, but they are not so common.

Depending on the purpose, corrugated sheets are manufactured:

- Measured length;

- Unmeasured length;

- Multiple measured length;

- Measured length with a remainder of no more than 10% of the batch weight;

- A multiple of the measured length with a remainder of no more than 10% of the batch weight.

Corrugated steel sheets are distinguished by manufacturing precision in thickness:

- Rolled high (A) precision;

- Rental of normal (B) accuracy.

General points

Steel sheets with different types of corrugation are produced by hot rolling. First, the workpiece is heated to high temperatures, then passed through heavy rollers on which a special pattern is applied. Subsequently, it creates a corrugation, which remains on one side of the rolled metal. The height of the riffle should be no higher than half a millimeter. In this case, it should be equal to 0.1–0.3 of the thickness of the base of the sheet without corrugation. For the production of such products, the same standard provides for aluminum, as well as the following types of steel:

- St0, St1, St2, St3.

- Stainless steel AISI 409, AISI 321, AISI 301, AISI 201, AISI 430, AISI 316, AISI 304.

The resulting rolled metal can be of high (A) and normal (B) accuracy classes. Deviations in size are allowed by a maximum of 0.2 mm. According to the technical specifications, there may be nicks on the side edges of the sheets. This is a common occurrence after pruning them. In this case, much attention is paid to surface quality. There should be no cracks, dirt, scale or any other defects.

Steel sheets are rolled on such machines

Corrugated steel sheet range

According to the requirements in accordance with GOST, corrugated steel sheets with a thickness of 2.5 - 12 mm are produced, the height of the corrugations must be at least 0.5 mm and lie within 0.1-0.3 of the main thickness of the sheet. Rolled products of this type are supplied in sheets or rolls. The dimensions of the manufactured sheets range from 1400–8000 mm for length and 600–2200 mm for width, gradation of size changes, both in length and width, is 50 mm. The most popular cut size is 1500x6000 mm.

From the above it is clear that the geometric dimensions of the corrugated steel sheet can have the following values:

- Width - 1400–8000 mm with gradation of 50 mm;

- The height of the corrugations can be 0.1–0.3 fractions of the thickness of the steel sheet, with the minimum thickness being 0.5 mm;

- Length - 600–2200 mm;

- Sheet thickness - 3 mm, 4 mm, 5 mm, 6 mm, 8 mm, 10 mm.

The document regulating the production of corrugated steel sheets is GOST 8568-77. Tolerances regarding the length and width of corrugated sheets, as well as deviations from the plane, are described in GOST 19903–74. Documentation for these products, their labeling and packaging are carried out in accordance with GOST 7566–69.

Thickness and weight of 1 m2 of corrugated sheet according to GOST 8568-77

| Diamond knurling | Lentil corrugation | ||||

| Sheet base thickness S, (mm) | Width of ribbed base b, (mm) | Weight of 1 m2 sheet, (kg) | Sheet base thickness S, (mm) | Width of ribbed base b, (mm) | Weight of 1 m2 sheet, (kg) |

| 2,5 | 5,0 | 21,0 | 2,5 | 3,6 | 20,1 |

| 3,0 | 5,0 | 25,1 | 3,0 | 4,0 | 24,2 |

| 4,0 | 5,0 | 33,5 | 4,0 | 4,0 | 32,2 |

| 5,0 | 5,0 | 41,8 | 5,0 | 5,0 | 40,5 |

| 6,0 | 5,0 | 59,0 | 6,0 | 5,0 | 48,5 |

| 8,0 | 5,0 | 66,0 | 8,0 | 6,0 | 64,9 |

| 10,0 | 5,0 | 83,0 | 10,0 | 6,0 | 80,9 |

| 12,0 | 5,0 | 99,3 | 12,0 | 6,0 | 96,8 |

Corrugated sheet

View price – Corrugated sheet

Steel sheets with rhombic and lentil corrugation GOST 8568-77 - rolled sheets and rolls with one-sided rhombic and lentil corrugation.

Corrugated metal sheets are used in construction, as an anti-slip coating, on construction sites, in garages, industrial premises, for the construction of fences for courtyards and gardens, apartments, balconies, and windows. The steps of metal stairs and various containers are made from this rolled product; sometimes it is used as a decorative design in the manufacture of various structures, as plugs for ventilation windows, and radiator linings. Corrugated sheet is used for strengthening walls and floors before plastering work and on highways for light-diffusing barriers.

Manufacturers of corrugated steel: OJSC Novolipetsk Iron and Steel Works (NLMK), OJSC Severstal, OJSC Magnitogorsk Iron and Steel Works.

Corrugated sheets are produced on the same mills as for hot-rolled steel, but the rolls on which the sheet is rolled have an uneven shape, a pattern is applied to them, thus engraving occurs on a smooth sheet. The result is a pattern with bulges - riffles. The height of the corrugations according to GOST must be at least 0.5 mm and 20-30% of the thickness of the base of the sheet. GOST 8568 assumes two types of corrugation: lentil and rhombic. Sheets with a rhombic pattern are made with diamond diagonals (25-30) x (60x70) mm. The configuration of the corrugations and the arrangement of diamonds on the surface of the sheet are determined by the manufacturer. Sheets with lentil corrugations are produced with a distance of 20, 25 or 30 mm between the corrugations; the choice of distance is set by the manufacturer.

Assortment of hot rolled corrugated sheets

Corrugated sheets are produced:

— width from 600 to 2200 mm with 50 mm gradation — length from 1400 to 8000 mm with 50 mm gradation

depending on purpose:

a) measured length b) length that is a multiple of the measured length c) measured length with a remainder of no more than 10% of the mass of the batch. The remainder is considered to be sheets of length within the unmeasured range that remain when cutting into dimensional and multiples of dimensional. d) length that is a multiple of the measured length, with a remainder of no more than 10% of the mass of the batch e) unmeasured length

The thickness of the sheets is divided into:

- high accuracy 3/4 A - normal accuracy 3/4 V

Corrugated sheets are produced in steel grades St0, St1, St2, St3 according to GOST 380-2005. In some cases, it is allowed to produce sheets using steel 09G2S. General requirements for thickness, sheet cutting, rolling accuracy must comply with GOST 19903 (hot-rolled sheets).

Table. Mass of corrugated sheet with lentil and rhombic corrugation.

| Sheet base thickness, S, mm | Width of the ribbed base, b, mm | Weight of 1m2 sheet, kg |

| Diamond knurling | ||

| 2,5 | 5,0 | 21,0 |

| 3,0 | 25,1 | |

| 4,0 | 33,5 | |

| 5,0 | 41,8 | |

| 6,0 | 59,0 | |

| 8,0 | 66,0 | |

| 10,0 | 83,0 | |

| 12,0 | 99,3 | |

| Lentil corrugation | ||

| 2,5 | 3,6 | 20,1 |

| 3,0 | 4,0 | 24,2 |

| 4,0 | 32,2 | |

| 5,0 | 5,0 | 40,5 |

| 6,0 | 48,5 | |

| 8,0 | 6,0 | 64,9 |

| 10,0 | 80,9 | |

| 12,0 | 96,8 | |

Note. The thickness of the sheets is determined by the thickness of the base of the sheet, S, in mm. The steel density is taken to be 7.85 g/cm3.

An example of marking a corrugated sheet:

LENTIL sheet B3/4K PU-3.0x1250x2500 st3sp GOST8568-77 - corrugated hot-rolled sheet with lentil one-sided corrugation, sheet thickness 3 mm, width 1250 mm, length 2500 mm, made of steel grade st3sp according to GOST 8568-77, normal accuracy in thickness B3 /4, improved flatness PU, with rolled edge K.

Buy corrugated steel sheet

From us you can purchase metal corrugated sheets of all types produced from warehouses of branches, warehouses in the Moscow region or directly from the factory. We provide services for cutting, delivery and assembly of sheets. Availability, dimensions of corrugated sheets, sheet price per ton can be found on the website. You can clarify the price of a corrugated sheet per piece, the weight of the sheet, calculate the quantity, issue an invoice and fill out an application, clarify payment options and request a certificate for a corrugated sheet by contacting the manager by phone

(8452) 57-00-18, e-mail: [email protected]

Application of corrugated sheet

Due to its worthy properties, corrugated steel sheet is widely used in various fields. First of all, it is used in the manufacture of anti-slip coatings, in places where there is an increased risk of injury. Stair steps, gangways, platforms, walkways, ladders, especially if they are located outdoors (in the open air), made from this rolled metal eliminate slipping and minimize the risk of injury. Based on these features, corrugated sheets are used on oil platforms, hydro and power plants, and in mining.

In general, corrugated steel sheets are used in both the construction and manufacturing industries. Thanks to the corrugated pattern, this steel sheet looks quite aesthetically pleasing and attractive, which allows architects to use it in solving various design problems.

In construction, rhombic corrugated sheets are used to strengthen surfaces before plastering work. It is also used to make barrier structures or use it as roofing material.

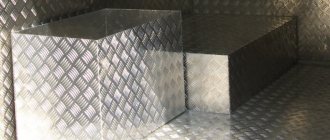

Corrugated steel sheets are used in agriculture for the manufacture of containers. If wholesale transportation of fragile items is required, corrugation of the bottom of the container will increase the reliability of transportation and simplify the work of loaders.

Thanks to such factors as good technical characteristics and low cost, the demand for such material as corrugated steel sheet is growing significantly in the modern metal rolling market.

Differences

A steel sheet with lentil corrugation differs from its counterpart with a diamond pattern in certain production standards. For example, the base size should be 3.66 mm. The weight of such a steel sheet can be from 20.1 to 96.8 kilograms per 1 m2. It all depends on the type of steel that is used to make the product. The distance between the notches can be 20, 25 or 30 millimeters.

Rolled products with a lentil pattern are made from carbon steel. The height of the pattern reaches 1.5 mm, the riffles begin at a distance of 40 mm from the side edge. The dimensions of such rental products depend on the wishes of the client, for example, the width can reach from 600 to 2200 mm, and the length - from 1400 to 8000 mm. Sheets with rhombic corrugation are produced with rhombus sides from 25 to 30 by 60–70 mm.

In addition to rhombic and lentil, there is another type of corrugation - notches. It comes in several options:

- “Diamond” – 1 riffle.

- “Duet” – 2 riffles.

- “Quartet” – 4 riffles.

- “Quintet” – 5 riffles.

The more notches on the surface of the sheet, the more pronounced its anti-slip properties will be.

Everyone has seen such a corrugated sheet with a “lentil” pattern at least once.