Aluminum sheets, as a corrosion-resistant, ductile and durable material, are widely used in various areas of production. Lack of rust, light weight, the ability to take the most complex shapes during processing, durability, resistance to low and high temperatures, fire safety - these are the advantages of the material. Corrugated aluminum is used in automobile, aircraft, shipbuilding, household appliances, architecture and design.

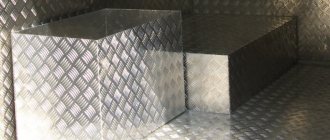

Aluminum sheet with corrugation

Aluminum is a lightweight, corrosion-resistant metal that has gained popularity in households and industrial production.

Physical properties of metal:

- density - 2.7 g/cm3;

- plastic;

- resistivity 0.027 Ohm • mm2/m;

- thermal conductivity 203.5 W/m • K;

- melting point 660ºС.

Due to their light weight, aluminum sheets are preferable to rolled steel in reconstructed and repaired buildings, since aluminum puts less load on foundations and other supporting structures.

Plasticity and low melting point make it possible to easily process metal and give products complex shapes. The lack of brittleness at ultra-low temperatures has expanded the field of application to cryogenic technology.

In industries associated with the formation of flammable and explosive gases, aluminum is used as a spark-proof material in the construction of floors, panels, and enclosures of lifting and transport equipment cabins.

Aluminum's ability to conduct heat is 3 times higher than that of steel; it is widely used in heat exchangers with high and low temperatures, as well as kitchen utensils and air conditioners.

Its electrical conductivity is less than that of copper, but due to its lower specific gravity it conducts 2 times more electricity than copper wire with equal weights. This characteristic is used in conductors, transformers, and high-voltage power lines.

Alloys with other metals

Perhaps the only negative quality of aluminum is its low strength, but modern metallurgy has found a way to overcome this characteristic: alloys with copper, magnesium, manganese, chromium, silicon, and other metals are comparable in strength to some types of steel.

An oxide film forms on the surface of aluminum products. Thanks to it, the metal exhibits unique anti-corrosion qualities. In combination with nickel and iron, the protection weakens; in combination with manganese, it increases. Corrosion resistance expands the possibility of using aluminum structures and products in the chemical industry and transportation of aggressive liquids. Contact with halogens, chlorine and bromine, weak nitric acid, alkalis, mercury leads to the destruction of oxide protection.

The presence of a protective film complicates welding; it is performed with tungsten electrodes, and the procedure itself is carried out in an inert gas environment.

Aluminum does not form compounds harmful to human health, does not participate in the metabolism of warm-blooded creatures, and therefore is widely used in the manufacture of packaging for long-term storage of food products.

Pure aluminum has low strength and is plastic; alloys are used in almost all areas of production and everyday life, and sheets of alloys are corrugated - a three-dimensional pattern is applied, which makes them anti-slip and decorative.

Manufacturing technology of corrugated aluminum sheets

Regardless of the number of corrugations on a sheet, they are all produced using identical rolling technology: hot-rolled or cold-rolled. The first manufacturing method is used in cases where it is necessary to make a product whose thickness is 3-4 mm. if a thin sheet is required, then cold-rolled steel is used.

The process goes like this:

- previously prepared aluminum alloy ingots weighing 2-3 tons go through preparatory operations;

- the material is put into the machine where the product is rolled and the output is corrugated sheets;

- then the workpiece is subjected to heat treatment and finishing measures.

But not all alloys are heat treated. Thus, an alloy of magnesium and aluminum does not require thermal exposure. Another method of cold processing is used: cold hardening. Due to its implementation, the strength of the material increases.

Standards for corrugated aluminum

To produce sheets, they do not use laboratory-grade aluminum, but alloys. The presence of various alloying additives in the sheet composition (copper, magnesium, manganese, iron, silicon, titanium, chromium, zinc, other elements) without loss of positive qualities additionally strengthens and makes it possible to join by welding. All characteristics of products made of corrugated aluminum depend on the brand and are prescribed in GOST 21631-76.

A little about alloys

The first aluminum alloy, which revolutionized aircraft manufacturing, was named after the German city of Duren, where its industrial smelting began - duralumin or duralumin.

The duralumin alloy includes copper (2.2-5.2%), magnesium (0.2-2.7%), manganese (0.2-1%), products made from it are used in aviation, transport, and space technology. After hardening, duralumin becomes 7 times stronger than laboratory-grade aluminum, while weighing 3 times less than steel.

AMg2

The greatest corrosion resistance, strength, ductility and weldability are characterized by an aluminum alloy with 2-4% magnesium AMg2. Sheets are processed using different methods and used in construction, technology, and vehicles.

AMts

The compound with manganese (up to 1.5%) provides anti-corrosion resistance to corrosion and ductility, which determines the use of the material for internal and external cladding in shipbuilding, chemical production, and food production.

VD1

Aluminum alloyed with copper (2-5%) and magnesium (0.4-1.6%). It is characterized by high strength and toughness, and anti-corrosion properties when processed by cladding. Used in aircraft, automotive and construction industries.

Silumin is aluminum alloyed with silicon (4-13%, sometimes up to 23%) for the manufacture of complex-shaped products for the aircraft and automotive industries.

GOST 21631-76 dictates the characteristics, size range, markings, method and quality of surface treatment.

Hot and cold rolled

Aluminum corrugation is produced by hot or cold rolling with or without further processing.

Hot rolling consists of annealing large-sized ingots in a shaft furnace to give the metal a uniform structure, and then passing it between paired cylindrical shafts, reducing the clearance between them and simultaneously applying relief. The hot method produces sheets with a thickness of over 3 mm. The disadvantage of hot-rolled products is the uneven geometric dimensions.

The technology for producing hot-rolled corrugated aluminum includes 5 operations:

- Ingots weighing 3-8 tons are cast from alloys obtained by alloying aluminum.

- The workpieces are transported to a shaft furnace, where homogenizing annealing is carried out for 4-5 hours at a temperature of 20-40ºC to obtain metal with a homogeneous structure.

- The prepared ingots are sent to rolling mills with cylindrical rolls with a relief installed in pairs, and the gap between them gradually decreases, giving the sheet the desired shape and relief pattern.

- The resulting sheets undergo heat treatment (annealing) to relieve internal stress.

- The final finishing of the sheet consists of grinding, cutting to specified sizes, and applying coatings.

Cold rolled products are produced without preheating using more powerful equipment. The sheets have a constant geometry with a clear corrugation pattern. Rolled products are heat treated to relieve internal stresses in the metal, then the sheets are ground and cut to specified sizes.

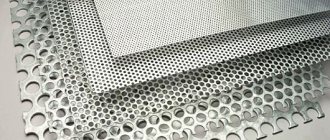

Cladding

Corrugated aluminum sheets for anti-corrosion protection are clad - covered with a layer of pure aluminum, especially duralumin alloys, the process is carried out partially.

The GOST establishes cladding markings:

| Cladding quality | % cladding thickness from sheet thickness | Marker |

| Technical (forms protection against microcracks) | 1.5% at any thickness | A |

| Normal | 4% at ρ≤ 1.9 mm 2% at ρ≥1.9 mm | B |

| Thickened | 8% at ρ≥ | U |

Uncoated sheets have no markings.

Definition of aluminum sheet, its varieties and technical characteristics

Aluminum sheet is a semi-finished product that is made from aluminum, and sometimes with the addition of other metals, by hot deformation followed by cold working. Among the main competitive advantages of the assortment, which determine its use in upholstery of the body and interior of a car, the following can be distinguished:

- resistance to corrosion;

- possibility of further mechanical processing;

- good tolerance to sub-zero temperatures;

- resistance to harsh weather conditions;

- moderate strength of the material;

- stylish appearance.

Treatment

There are different types of processing:

- Thermal or its absence, products without heat treatment do not have a marker; heat-treated (or annealed) sheets receive the letter “M” in the brand. The entire range of aluminum grades, except VD1, can be annealed.

- The annealing procedure is used to eliminate excess strength of the sheet, which it may acquire during processing.

- cold-worked (H) - with an outer layer compacted by special machines or shot peening;

- semi-hardened (H2) - with a lower degree of compaction;

Cold-worked or semi-hardened metal under the influence of high pressure in a low-temperature environment is strengthened with a partial loss of ductility. At higher pressures, a high degree of hardening is achieved.

Products made from cold-worked material cannot be welded or bent due to the possibility of cracks, but they are used in high-strength building structures.

Semi-hardened sheets are welded and bent.

Hardening and aging

Tempering gives corrugated aluminum sheets additional tensile strength. The technology consists of sudden cooling after high-temperature exposure:

- a hardened and naturally aged sheet receives the letter “T”, the natural aging process takes 4-5 days without heat treatment;

- hardened and artificially aged - “T1”, aging is forced, at t = 150ºC for several hours;

- cold-worked after hardening and artificial aging - “TN”.

Surface finish quality

Corrugated aluminum sheet may have:

- high finish with the designation “B”;

- increased finishing - “P”;

- regular trim that is not marked.

High finishing involves the use of A7 grade aluminum as a raw material for the production of corrugated sheets; A6; A0; AD00; AD0; AD1; HELL; AMts grade alloys; AMg2. Advanced and regular finishes do not have requirements for the grade of metal or alloy.

The surface texture of the sheet can be glossy or matte.

Types of corrugation

By type of riffles, the most common patterns are:

- lentil (also known as diamond or diamond) - the simplest corrugation of parallel rows of convexities perpendicular to each other;

- duet - stripes of paired riffles;

- quintet (from the Latin fifth - 5) - groups of 5 riffles, also with a perpendicular direction to the other, form a chess pattern.

The type of corrugation affects strength, since the protrusions of the corrugations play the role of stiffening ribs, and gives an anti-slip effect: the quintet corrugated sheet has it to the greatest extent, therefore it is more popular in the manufacture of various horizontal surfaces - platforms and steps of stairs, ramps, light floors. The type of corrugation affects the cost of the sheet; more complex corrugations are more expensive.

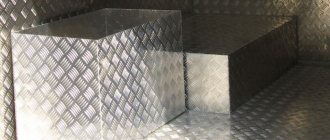

Aluminum body trim

Jigsaw with blades for metal

Here is a description of the process of manufacturing overlay panels from corrugated aluminum for the body of a UAZ31519.

Three metalheads meet. The first one says: “Guys, I bought an apartment yesterday, I already decorated it all with metal inside - METAL.” - Yesterday I bought a car, covered the whole car with metal - METAL. - Yesterday I bought a frog! The two are at a loss. - I put him in an aquarium and poured water into it! - Well, so what? - He MET spawn there.

The prerequisites for this are the following: - strengthen the hood so that it becomes possible to walk on it; — protect the sides from damage from branches; — patch holes in the bottom of the doors; — give UAZAUR a more off-road look. Of the entire list, the last argument was the strongest. Having read the address of the Alros company, which sells aluminum corrugated sheets, on UAZBUK, I went there. A corrugated sheet “Quintet” 1.5 mm thick measuring 1.2x3 meters cost 1,750 rubles (03/12/04). The most difficult thing was to bring the sheet home, because when driving above 60 km/h the sheet tried to come off along with the trunk. You can cut the sheet on the spot, but at that time I didn’t even know the approximate dimensions. On a sunny Saturday afternoon I went to take measurements of the UASAURU. I cut the sheet with a jigsaw - it turns out very easily and neatly. At the market, instead of metal blades, they sold me wood blades, but there were no problems with cutting. The sheet was placed on rubber-bitumen mastic BODY 930 (according to UAZbook) - I hope that there will be less moisture between the sheet and the body. The sheets were fastened with rivets with a diameter of 4 mm (10 and 8 mm long) with a pitch of about 15-20 mm along the edge and several rivets in the center of the sheet. As a result, UAZAUR actually acquired a more combative appearance. However, if you jump on the hood, it still collapses - but walking has become calmer. The plans are to finish covering the UAZAUR around the entire perimeter (along the bottom) and lay the flooring in the cabin.

Source

Assortment

Size range of sheets:

- thickness from 0.3 to 10.5 mm;

- width from 0.6 to 1.8 m;

- length - up to 7.2 m.

The height of the elevation of the corrugation above the surface of the sheet is not included in the standardized thickness of the sheet. The greatest demand is for sheets up to 3 mm thick and up to 3 m long with a width of 1.2 m. All such panels can be transported by one person

To determine the weight of one product, you need to calculate the average thickness of the sheet, taking into account the height of the riffle, multiply by the length, width of the sheet and volumetric weight. Volumetric weight, depending on the brand of alloy, is given in reference books and ranges from 2.7 to 2.81 g/cm3. The weight of one sheet ranges from 15 to 40 kg.

GOST also standardizes the accuracy of geometric parameters and the thoroughness of processing the edges of the slabs.

Quintet or Galaxy

The domestically produced corrugated quintet sheet has an external resemblance to its analogue from Serbia, mainly under the Galaxy trademark. The main differences between Russian and imported sheets are lower price and high impact strength.

Standard requirements

Rolled aluminum sheets with a corrugated cross-section profile, as specified in GOST 21631-76, are produced in the form of rectangular-shaped products, on which protrusions are specially applied, located at an angle to each other and forming a specific pattern. Such protrusions, as well as the very low weight of sheet aluminum, are precisely the most significant features of such a material.

You can familiarize yourself with the GOST requirements for sheet aluminum by downloading the document in pdf format from the link below.

GOST 21631-76 Sheets of aluminum and aluminum alloys. Specifications

The projections formed on the surface of the aluminum sheet are called corrugations. The corrugated surface consists of groups of adjacent protrusions formed from varying numbers of corrugations. Thus, a sheet whose corrugated surface is formed from groups of protrusions, each of which contains five corrugations, is an aluminum sheet quintet, two corrugations are a duet, one is a diamond. It is not difficult to distinguish sheets with different types of corrugation; to do this, just look at the photo of the product.

Types of corrugation of aluminum sheet

GOST specifies the basic geometric parameters of corrugated aluminum sheets:

- length of finished sheets – 200–600 cm;

- width of sheet products – 100–150 cm;

- thickness of rolled aluminum sheets – 1.5–4 mm (it should be borne in mind that this parameter does not include the height to which the corrugations rise above the sheet).

The weight of one linear meter of corrugated aluminum sheet is calculated using a special formula. It is necessary to know the following geometric parameters of such a product: the maximum and minimum dimensions of the sheet in terms of its thickness and width and the density of the alloy from which such a sheet is made. The provisions of GOST provide the following method for determining the weight of one linear meter of corrugated rolled aluminum sheets of various types.

- The largest and smallest values of sheet thickness are added together, and the total is divided by two.

- The average sheet width is calculated by adding the minimum and maximum values of this parameter and dividing the resulting amount by two.

- Then, to determine the average volume of one linear meter of corrugated aluminum sheet, the obtained values are multiplied.

- The result of this multiplication must be multiplied by the density of the aluminum alloy from which the sheet in question is made, and then divided by 1000.

Approximate weight of 1 m2 aluminum sheet

In the event that it is necessary to calculate the weight of corrugated aluminum sheets made from alloys of grades B95, B95-1 and B95-2, the formula takes into account the density of the material equal to 2.85 g/cm3. When calculating the mass of corrugated aluminum sheets from material of other grades, the following conversion factors are used:

- 0.947 – for AB grade alloys;

- 0.937 – AMg3;

- 0.926 – AMg6;

- 0.94 – AMg2;

- 0.95 – AMg5;

- 0.954–0.982 – D1, D12 and D16;

- 0.97 – AKM;

- 0.958 – AMts, AMtsS and MM;

- 0,972 – 1915.

All of the above indicators of conversion factors are stipulated by the provisions of GOST 21631-76, the link to which is presented above.

The practicality of sheet aluminum, as a rule, is used for purely utilitarian purposes

Corrugated sheet quintet

Basic characteristics of corrugated aluminum quintet:

- Light weight, reducing the load on the frame and foundations of buildings, structures, and equipment.

- Corrosion resistance.

- The anti-slip effect prevents shoes from slipping on wet surfaces.

- No harmful emissions, safety for people.

- Resistant to most aggressive environments.

- Intrinsically safe.

- Resistance to low and high temperatures without loss of strength.

- Durability.

- Aesthetic appeal.

- High light reflectivity.

Where is it used?

Aluminum quintet is used in mechanical engineering to make protective covers for various mechanisms, and is used in fencing elevator cabins, crane equipment, and removable ceilings. In shipbuilding, the quintet can be seen on gangways and the inner lining of ship engine rooms. In industrial refrigerators, quintet corrugated sheets are used to make the floor covering: the corrugations perfectly hold moving carts and prevent staff shoes from slipping.

During construction, lightweight aluminum corrugated sheets quintet are indispensable in the construction of platforms and steps of metal external and internal stairs for the evacuation of personnel or inspection of equipment, various transition platforms, ramps, bridges. The quintet is necessary in explosive industries, as it is intrinsically safe. For use in food production and the pharmaceutical industry, there is a special brand of AD1N quintet.

Fans of tuning personal cars use a quintet to cover bodies and trunks, and in public transport, a quintet floor will ensure the safety of passengers in winter, when there is snow and ice on the shoes.

Corrugated aluminum is also used for cladding facades, landscape design - verandas, gazebos, piers, advertising structures, stairs, ramps.

Advantages and disadvantages of rental of the presented type

Aluminum sheets are easier to process. That is, they can be used to create frames of almost any shape. Cooking Quintet sheets is also easy and pleasant . However, the products are quite strong, thanks to the corrugated surface. They can easily withstand a person's weight.

You can create frames of almost any shape from Quintet aluminum sheets

Another positive feature is that the sheet does not spark when struck by stones or metal objects. In addition, rust does not appear on it, and the material weighs little. The appearance of the product is defined as solid and presentable.

Aluminum sheets Quintet are durable and do not deteriorate under the influence of precipitation. They are mainly used to create various types of anti-slip coatings. It is actively used to create stairs, industrial premises and ramps . Nevertheless, it is ideal for tuning vehicles and for decorative finishing of premises.

Quintet aluminum sheets are easier to process

Also read materials:

Despite the fact that in comparison with ferrous metals, aluminum is a non-ferrous metal, and, accordingly, costs more, it is very popular. Sheets made from it have excellent performance properties and look amazing. Flooring made from them lasts a long time.

The product has few disadvantages. The main one is the rapid appearance of deformation under sudden mechanical stress. Also, if prolonged pressure is applied to one section of the sheet, a depression may appear in it.

Quintet sheets are mainly used to create various types of anti-slip coatings