Metal forging, along with casting, is the most ancient technology for processing materials. Moreover, humanity began producing products in this way long before the advent of iron and steel. The first blacksmiths worked about 5-6 thousand years ago. Over time, the technology only improved and was supplemented with new techniques. Today, no production can do without metal processing by forging.

What does forging technology include, what equipment and techniques are used in the oldest form of metalworking?

Metal forging concept

In simple terms, forging is the processing of metal heated to forging temperature. The principle of the technology is based on the physical properties of any material that has a melting point. But before this threshold is reached, the structure of the substance will become softer.

Each metal has its own temperature, upon reaching which it becomes softer, and, therefore, more pliable for processing by forging.

However, there is also a metalworking technology where the workpiece is not heated, but forged cold. This technique allows you to obtain products that are no less durable; without heating, the workpiece is pressed and bent. The table shows the temperature limits at which a particular metal can be forged.

Types of forging

There are main types of metal forging:

- Free.

- Machine.

- Stamping.

Free forging means that the workpieces are not limited to any shape. Or the material will be fixed on one side on the anvil. This technological technique also includes hand forging of metal, when the product is shaped using a sledgehammer or hammer. Open forging is used both for the production of individual products and simply to improve the quality of the material.

When forging the surface of the workpiece, the properties of the metal improve. Large crystals of the material are crushed, the structure becomes more fine-grained and homogeneous. In addition, during forging, the internal shells are welded, strengthening the body of the workpiece.

Machine forging is a more modern processing option. This technology is used in mass, heavy industry. In this case, mechanized hammers (weighing from 40 kilograms to 5 tons), forging machines or presses are used. The weight of blanks and final forgings can sometimes reach several tens of tons.

VIEW Induction heater on AliExpress →

Stamping. This technological technique made it possible to make mass production. When making products, the metal is limited by stamps and, when deformed, receives the desired shape.

Stamping is used in mass production where it is important to obtain a large number of products. Open forging is typically used in small-scale and one-off production.

Equipment and tools

The centuries-long development of this type of metalworking has led to the emergence of a huge number of tools and devices.

But hot forging of metal retained the same technological line as thousands of years ago: heating, fastening, deformation, hardening. When making forged products by hand, they use almost the same sets of tools and equipment that craftsmen have used since the inception of this technology. The list is as follows.

- Blacksmith hearth → VIEW on AliExpress

- Anvil → VIEW on AliExpress

- Ticks.

- Hammer → VIEW on AliExpress

A forge or forge is used to heat the material to the desired temperature. There are many different types of this equipment.

- Stationary and portable.

- Closed and open hearths.

- Fuel or electric.

- Liquid, gas or solid fuel.

- With side air supply nozzles or central lance.

Anvils are massive metal tables where the workpiece is actually formed. They consist of a base, a horn and a casing with holes for bending. There are several varieties of this forging device, but a steel support with a weight of 30 kilograms or more is required.

In hand forging, the craftsman uses pliers to handle the workpiece during the work process.

Hammers, the main tool used in blacksmithing, can have different weights to work with workpieces of different sizes.

Why is cold forging used and what products are produced?

Using hot forging, you can forge a product of almost any shape - from a ship anchor and a cart axle to a metal rose and a grape vine.

Cold forging is used to produce a limited number of elements from which a talented designer can assemble a custom product.

A wide variety of products are made using the cold forging method. These are, first of all, elements of gratings and fences - both the rods themselves and the crossbars, tops, and decorations. From a distance of several meters it is difficult to distinguish it from a forged lattice. Any lattice will be enlivened by curls and spirals that form intricate patterns and ornaments. An ordinary fence, therefore, in addition to its utilitarian purpose, also acquires artistic value. For this you will need a bend, a snail and a torsion bar.

Wrought iron bench with table and lamp posts woven with vines

Forged stands for lanterns, railings for bridges over ponds, awnings and porches, tables and benches look great in the local area. And it’s a good idea to make the gazebo itself from a forged rod. Curls and spirals will give it unexpected lightness and airiness for harsh metal, and twisted supports will emphasize the upward desire.

Forged barbecues are also widespread today, also complementing the economic purpose with an aesthetic impression. The barbecue itself is lost among the canopy, patterned walls and supports, and the roof decorated with curls.

Parts of balustrades, staircase railings and balconies are also very popular. Curls and spirals are also widely used here, not only as decoration, but also as a structural element. A baluster twisted along the longitudinal axis looks very appropriate, and corner supports are often made from several rods twisted together. They also make the so-called on a torsion bar machine. “flashlight” - several rods bent in a spiral, connected at the ends by welding.

The next area of application of cold forging is details of room decoration and furniture. Door handles and latches, fireplace tools and hangers, umbrella stands and cornices for curtains and curtains - small curls and twisted rods are widely used here. Furniture is made both for garden furniture, which is not afraid of precipitation and changing seasons, and for home furniture, combining metal with wood and fabric.

Blacksmithing techniques

Basic forging operations used in metal forging technology:

- Sedimentary.

- Landing.

- Drawing.

- Break-in.

- Rolling out.

- Firmware.

- Overclocking.

Sedimentary forging work involves reducing the height of the workpiece and increasing its cross-sectional area.

Upsetting is essentially a partial settling of the workpiece. It is used when some thickenings need to be made on the metal surface. This is achieved by reducing the length of the workpiece.

Broaching is another technological method of processing metal using the forging method. This operation involves lengthening the workpiece. This reduces the cross-sectional area.

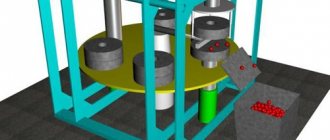

Rolling on a machine

Rolling in blacksmithing involves giving the workpiece the shape of a cylinder. During the process of metal deformation, the workpiece rotates around its axis.

Rolling - processing of a ring blank. When it is necessary to increase its internal and external diameters, the metal is rolled out on a mandrel by reducing the wall thickness.

In blacksmithing, broaching is used to produce a through hole through the use of a punch.

Dividing is the operation of obtaining a wider workpiece. Essentially, the metal for forging is flattened on the surface of the anvil with a hammer, moving across the axis of the product.

There are also many other techniques by which the required product shapes are obtained.

Draft

Upsetting is a technological operation that makes it possible to reduce the height of the original workpiece while simultaneously increasing its cross-sectional area. Upsetting is used, for example, to solve the following problems:

- increasing the cross-sectional diameter of the original workpiece, which has sufficient volume but small diameter;

- crushing, grinding the initial coarse-grained structure of the workpiece metal, including in carbide-class steels (for example, tool steels); reducing the score of carbide heterogeneity (grinding carbides, ensuring their more uniform distribution in the volume of the forging);

- obtaining a deformation texture (fibers of a certain direction) to improve the performance characteristics of the manufactured part;

- alignment of mechanical properties along and across the axis of the forging;

- brewing existing flakes in the metal;

- making the ends of the forging parallel to each other, for example, before the subsequent formation of a hole in the forging;

- removing scale before further deformation of the workpiece. As a result of upsetting, cylindrical workpieces take on a barrel-shaped shape (Fig. 1), while square ones get distorted cross sections, which tend to transform from a square into a circle.

Rice. 1. Upsetting diagram: a – initial position of the workpiece before upsetting; b – precipitation process; H and D are the height and diameter of the original workpiece, respectively; H1 and D1 are the height and average diameter of the workpiece after upsetting, respectively; D1 max – maximum diameter of the workpiece; τ – friction forces on contact surfaces; P – draft force

Rice. 2. Deformation zones in the upsetting cylindrical workpiece

The main reason for shape distortion is the friction forces that arise in the areas of contact between the ends of the workpiece and the rigid surfaces of the machine - tool (press, hammer). This is also facilitated by cooling the ends of the workpiece when they come into contact, for example, with cold strikers.

Three characteristic zones can be distinguished in the upset billet (Fig. 2): I – zone of intense deformation; II – zone of “difficult deformation”, consisting of two areas adjacent to the ends of the workpiece and under conditions of uneven all-round compression. These areas seem to wedge zone I in the axial and radial directions.

Zone III extends to the side surfaces of the workpiece. The intensity of deformation in this zone is greater than in the first and less than in the second zone. In zone III, tensile stresses arise, which limit the maximum degree of deformation of the workpiece during upsetting and are the initiators of the formation of cracks on its side, barrel-shaped surface when the deformation increases above the limit.

The degree of deformation is determined by the expression ε = ΔН/Н, which can vary from 0 to 1. The permissible degree of deformation is determined by the properties of the workpiece material at the upsetting temperature.

The diameter of the forging D1 is determined without taking into account the barrel shape according to the expression

(1)

where Vз is the volume of the original cylindrical workpiece.

Depending on the intensity of impacts on the workpiece, for example with a hammer, the degree of deformation of the upsetting workpiece, and the amount of friction acting at the ends of the workpiece, the latter acquires a different barrel shape, as shown in Fig. 3.

A “normal” barrel (Fig. 3, a) is formed when upsetting a cylindrical billet with a ratio N/D ≤ 2.5, when upsetting is performed with “heavy”, powerful hammer blows or in the case of slow press pressure. A concave (“glass-shaped”) barrel (Fig. 3, b) is obtained with short and light hammer blows; it is observed during the upsetting of high workpieces (H > 2D) on high-speed hammers, as well as on hammers with insufficient mass of falling parts, when the deformation does not have time to spread into the depth of the workpiece, and “riveting” of the end sections of the workpiece occurs.

A double barrel with a cylindrical part (Fig. 3, c) is formed with a low degree of draft. During further upsetting, the diameter of the cylindrical part increases and the workpiece takes the shape of a cylinder, to which end sections in the form of truncated cones are adjacent (Fig. 3, d).

Rice. 3. Forms of barrel formation during sediment: a – “normal” barrel; b – concave; c – double with a cylindrical part; g – cone-shaped; d – double

With increasing deformation (s = 40...50%), the diameter of the middle section grows more intensively and the workpiece takes on a “normal” barrel-shaped shape (Fig. 3, a). At large D/H ratios (<0.5), it is possible to obtain a “double” barrel (Fig. 3, e), which, with further settling, turns into a single barrel (Fig. 3, a).

Barrel formation is especially undesirable when forging highly alloyed, hard-to-deform alloys (heat-resistant, etc.), since in addition to distorting the shape of the forging, barrel formation leads to uneven distribution of deformations in the volume of the forging and, consequently, uneven mechanical properties of the metal.

To reduce barrel formation, successfully perform upsetting (eliminate defects in the form of forged folds, cracks, etc.) and reduce the required deforming loads, it is necessary to follow a number of rules, discussed below.

- A workpiece can be successfully upset if its height H does not exceed three diameters D. Usually the height is chosen equal to 2.5D. Larger ratios can cause the workpiece to buckle and require alignment.

- The ends of the upsetting workpiece should be as smooth as possible, parallel to each other and perpendicular to its axis (the higher the workpiece, the more important this condition is). Alignment of the ends is carried out with light hammer blows or gentle press pressure.

- To reduce the degree of barrel formation of forgings, heating of the sedimentary plates (strikers) is used; in some cases, gaskets made of ductile steel or non-ferrous metals are placed between the ends of the workpiece and the sedimentary plates (strikers), and various lubricants are used (Fig. 4).

- Before upsetting, the workpiece must be uniformly heated to the maximum permissible temperatures (upper limit of the forging temperature range).

- When settling on the hammer, it is necessary to take into account that the longer the workpiece, the shorter the working stroke of the hammer will be, and, consequently, the lower the impact energy. Therefore, it is necessary that at least 1/4 of the full stroke of the hammer head remains before impact.

- When upsetting, critical degrees of deformation should be avoided and the recrystallization diagram of the material being processed should be taken into account.

Rice. 4. Upsetting schemes that reduce or eliminate the formation of a barrel during upsetting: a – upsetting of the workpiece 1 using highly plastic solid spacers 2; b – the same, using ring gaskets; c – technological sequence of upsetting two workpieces with rotation and change of relative position

1.1. Varieties of sediment

Upsetting – upsetting of a part of the workpiece (Fig. 5). Upsetting produces a thickening of the end or middle zone of the workpiece. Before upsetting the end part of the workpiece, only the upsetting zone is heated, and when upsetting the middle part, the middle part of the workpiece subject to upsetting is heated.

Rice. 5. Upsetting the upper section of the workpiece: 1 – hammer head; 2 – workpiece after landing; 4 – matrix (backing ring)

Cold zones of the workpieces ensure the transfer of deforming force to the heated areas of the workpieces.

When planting thickenings (flanges) on long and heavy forgings of shafts, local heating of the zone of future thickening is performed. Planting is carried out using a steel rod suspended on a crane chain with a thickening 4 at the end, called a “falcon” (Fig. 6). (In some sources, the bar is called “romance”, and the planting process is called “romanation”.) By striking with a “falcon”, the heated area is planted.

Currently, hydraulic presses are produced equipped with devices that replace the function of a steel swinging rod.

Rice. 6. Upsetting the heated end of a long workpiece: 1 – stop; 2, 3 – strikers; 4 – suspended blank (“novel”, “falcon”)

Rice. 7. Settlement in the backing rings with metal flowing into the cavities of the rings: 1, 2 – strikers; 3, 4 – backing rings; 5 – upset billet

Upsetting in backing rings is used for the manufacture of blanks - forgings in the production of large-sized gears, turbine disks with bosses on both sides and similar parts. In this case, the workpieces are upset either with preliminary forging of shanks, which are placed in the holes of the rings, or with metal flowing into the holes of the rings (Fig. 7).