Types of steels and features of their markings

Various areas of application of steel require that it have strictly defined properties - physical, chemical. In one case, the highest possible wear resistance is required, in others, increased resistance to corrosion, in others, attention is paid to magnetic properties.

There are many types. The bulk of the smelted metal goes into the production of structural steel, which includes the following types:

- Construction Low alloy steel with good weldability. The main purpose is the production of building structures.

- Spring. They have high elasticity, fatigue strength, and fracture resistance. Used for the production of springs and leaf springs.

- Bearing. The main criterion is high wear resistance, strength, low fluidity. It is used for the production of units and components of bearings for various purposes.

- Corrosion resistant (stainless). High-alloy steel with increased resistance to aggressive substances.

- Heat resistant. It is distinguished by its ability to work for a long time under load at elevated temperatures. Area of application: engine parts, including gas turbine engines.

- Instrumental. Used for the production of metal and woodworking and measuring instruments.

- Fast cutting. For the manufacture of tools for metalworking equipment.

- Cementable. It is used in the manufacture of parts and assemblies operating under high dynamic loads under conditions of surface wear.

Steel classification

When deciphering the designations, it is necessary to take into account that each of the types corresponds to a strictly defined letter in the marking.

Characteristics of steel grade St3kp

St3kp - Structural carbon steel of ordinary quality, welds well, welding is carried out without heating and without subsequent heat treatment, welding methods: manual arc welding, automatic submerged arc welding and gas protection, KTS, ESW. For thicknesses greater than 35 millimeters, heating and subsequent heat treatment are recommended; it is prone to flake sensitivity, and there is no tendency to temper brittleness. Cutting machinability in the hot-rolled state at HB 124 and σ = 410 MPa. Kυ tv.sp. = 1.8 and Kυ b.st. = 1.6, has found its application in lightly loaded elements, in welded and non-welded structures and parts operating at temperatures from -40 to 400 degrees, used in shaped profiles for cars, used in the same way as class A-I (A240) fittings . Forging at temperatures from 1300 to 750 0C, cooling is carried out in air. According to GOST 27772-88, steel St3kp corresponds to steel for building structures S235

Classification by chemical composition

The main alloying additives are metals. By varying the quantitative composition of additives and their mass fraction, a wide variety of steel grades are obtained. Pure iron itself has low technical properties. Low mechanical strength and high susceptibility to corrosion require the introduction of additional substances into the alloy composition, which are aimed at improving one of the qualities, or several at once.

Often, the improvement of some characteristics entails the deterioration of others. Thus, high-alloy stainless steels may have low mechanical strength, while high-quality carbon steels, along with high strength, receive weakened corrosion properties.

As mentioned above, one of the classifications of steel grades is its chemical composition. The main components of all steels without exception are iron and carbon, the content of which should not exceed 2.14%. Depending on the amount and proportions of additives, the iron content in the composition should be at least 50%.

Based on the amount of carbon contained, steels are classified into three groups:

- Low-carbon – carbon content less than 0.25%;

- Medium carbon – 0.25-0.6% carbon;

- High carbon, with a carbon content of more than 0.6%.

An increase in the percentage of carbon increases the hardness of the metal, but at the same time its strength decreases.

To improve performance, a certain amount of chemical elements is introduced into the alloy. Such steels are called alloyed. For alloy steels there is also a division into three groups:

- Low alloy, containing additives up to 2.5%;

- Medium alloyed, which contain from 2.5 to 10% alloying elements;

- Highly alloyed. The content of alloying impurities varies from 10 to 50%.

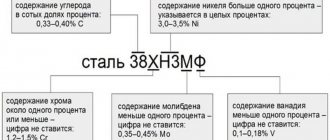

The marking of steels reflects the presence and percentage of alloying additives. When deciphered, each element is assigned a specific letter, next to which there is a number corresponding to its content as a percentage. The absence of numbers indicates that the additive is present in the alloy in an amount of less than 1-1.5%. The presence of carbon in the composition is not reflected, since it is included in all compositions, but its content is indicated at the very beginning of the labeling.

The marking can also indicate the purpose of the alloy. Since this classification also uses letter designations, the order of their arrangement is regulated - at the beginning, middle and end of the marking.

Classification of carbon steels

Steels are divided into carbon and alloy. According to their intended purpose, a distinction is made between structural steels with a carbon content of hundredths of a percent and instrumental steels with a carbon content of tenths of a percent. The largest volume of welding work involves the use of low-carbon and low-alloy structural steels.

The main element in carbon structural steels is carbon, which determines the mechanical properties of steels in this group. Carbon steels are smelted of ordinary quality and high quality. Carbon steels of ordinary quality are divided into three groups:

- group A - for mechanical properties;

- group B - according to chemical composition;

- group B - according to mechanical properties and chemical composition.

The following grades of steel are produced:

- group A - St0, St1, St2, St3, St4, St5, St6;

- group B - BSt0, BSt1, BSt2, BSt3, BSt4, BSt5, BSt6;

- group B - VSt0, VSt1, VSt2, VSt3, VSt4, VSt5.

According to the degree of deoxidation, ordinary quality steel has the following designation:

- kp - boiling,

- ps - semi-calm,

- sp - calm.

Boiling steel containing silicon (Si) no more than 0.07% is obtained by incomplete deoxidation of the metal with manganese. Steel is characterized by a pronounced uneven distribution of harmful impurities (sulfur and phosphorus) throughout the thickness of the rolled product. Local increased concentration of sulfur can lead to the formation of crystallization cracks in the weld and heat-affected zone. Boiling steel is prone to aging in the heat-affected zone and transition to a brittle state at subzero temperatures.

Calm steel is obtained by deoxidation with manganese, aluminum and silicon, and contains silicon (Si) of at least 0.12%; sulfur and phosphorus are distributed more evenly in it than in boiling steel. This steel is less prone to aging and has less reaction to welding heat.

Semi-quiet steel, in terms of its tendency to aging, occupies an intermediate place between boiling and calm steel. Semi-quiet steels with grade numbers 1–5 are smelted with normal and high manganese content, up to approximately 1%. In the latter case, the letter G is placed after the brand number (for example, BStZGps).

Group A steels are not used for the manufacture of welded structures. Group B steels are divided into two categories. For steels of the first category, the content of carbon, silicon, manganese is regulated and the maximum content of sulfur, phosphorus, nitrogen and arsenic is limited; For steels of the second category, the maximum content of chromium, nickel and copper is also limited.

Group B steels are divided into six categories. The full designation of steel includes grade, degree of deoxidation and category number. For example, VStZGps5 means the following: steel group B, grade StZG, semi-quiet, category 5. The composition of steels of group B is the same as that of steels of the corresponding grades of group B, 2nd category. Steels VSt1, VSt2, VStZ of all categories and degrees of deoxidation are produced with guaranteed weldability. Steels BSt1, BSt2, BStZ are supplied with a guarantee of weldability at the customer’s request.

High-quality carbon steel is produced in accordance with GOST 1060-74. Steel has a low sulfur content. Permissible deviation for carbon (0.03-0.04%). Steels with a carbon content of up to 0.20%, inclusive, can be boiling (kp), semi-quiet (ps) and calm (sp). The rest became only calm. For subsequent mild steels, the letters “sp” are not placed after the numbers.

Carbon steels in accordance with OST 14-1-142-84 are divided into three subclasses:

- low-carbon with carbon content up to 0.25%;

- medium-carbon with carbon content (0.25-0.60%);

- high-carbon with a carbon content of more than 0.60%.

Low-carbon steels are mainly used in welded structures.

In welding production, the concept of weldability of various metals is very important.

Weldability is the ability of a metal or a combination of metals to form, with the established welding technology, connections that meet the requirements determined by the design and operation of the product.

Based on weldability, carbon steels are conventionally divided into four groups:

- I - well welded;

- II - satisfactorily weldable, i.e., to obtain high-quality welded joints of parts made of these steels, strict adherence to welding conditions, special filler materials, certain temperature conditions, and in some cases, heating and heat treatment are necessary;

- III - limited weldability, additional heating, preliminary or subsequent heat treatment is required to obtain high-quality welded joints;

- IV - poorly weldable, i.e. welds are prone to cracking, the properties of welded joints are reduced, steels of this group are usually not used for the manufacture of welded structures.

All low-carbon steels can be welded well using existing fusion welding processes. Ensuring the uniform strength of the welded joint does not cause difficulties. The seams have satisfactory resistance to the formation of crystallization cracks. This is due to the low carbon content. However, in steels containing carbon at the upper limit, the probability of cold cracks increases, especially with increasing cooling rate (increasing metal thickness, welding at subzero temperatures, welding with small-section seams, etc.). Under these conditions, to prevent the appearance of cracks, preheating to 120–200 °C is used.

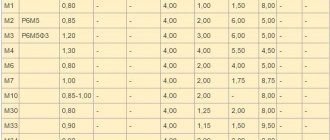

In table Table 1 shows the designation of chemical elements in the alloy steel grade, and Table 2 shows the composition of some steel grades. In table 3 shows the approximate purpose of various steel grades.

Table 1. Designation of chemical elements in alloy steel grade

| Element | Symbol | |

| in the periodic table | in steel grade | |

| Manganese | MP | G |

| Silicon | Si | WITH |

| Chromium | SG | X |

| Nickel | Ni | N |

| Molybdenum | Mo | M |

| Tungsten | W | IN |

| Selenium | Se | E |

| Aluminum | Al | YU |

| Titanium | Ti | T |

| Niobium | Mb | B |

| Vanadium | V | F |

| Cobalt | Co | TO |

| Copper | Cu | A |

| Bor | IN | R |

| Zirconium | Zr | C |

Table 2. Mass fraction of chemical elements in various grades of steel in%

| Brand | C | Mn | Si, no more | Ni | Cu | Cr | Ti | Al | Mo | S | P |

| St1kp, ps | 0,06—0,12 | 0,25—0,5 | 0,05 | <0,3 | <0,3 | <0,3 | — | — | — | <0,05 | <0,04 |

| St2kp, ps | 0,09—0,15 | 0,25—0,5 | 0,05 | <0,3 | <0,3 | <0,3 | — | — | — | <0,05 | <0,04 |

| St2sp | 0,09—0,15 | 0,25—0,5 | 0,15—0,3 | <0,3 | <0,3 | <0,3 | — | — | — | <0,05 | <0,04 |

| St3kp, ps | 0,14—0,22 | 0,3—0,6 | 0,05 | <0,3 | <0,3 | <0,3 | — | — | — | <0,05 | <0,04 |

| St3sp | 0,14—0,22 | 0,4—0,65 | 0,15—0,3 | <0,3 | <0,3 | <0,3 | — | — | — | <0,05 | <0,04 |

| St4ps | 0,18—0,27 | 0,4—0,7 | 0,05 | <0,3 | <0,3 | <0,3 | — | — | — | <0,05 | <0,04 |

| St4sp | 0,18—0,27 | 0,4—0,7 | 0,15—0,3 | <0,3 | <0,3 | <0,3 | — | — | — | <0,05 | <0,04 |

| St5ps | 0,28—0,37 | 0,5—0,8 | 0,05 | <0,3 | <0,3 | <0,3 | — | — | — | <0,05 | <0,04 |

| St5sp | 0,28—0,37 | 0,5—0,8 | 0,15—0,3 | <0,3 | <0,3 | <0,3 | — | — | — | <0,05 | <0,04 |

| St3Gps | 0,14—0,22 | 0,8—1,1 | 0,05 | <0,3 | <0,3 | <0,3 | — | — | — | <0,05 | <0,04 |

| St5Gps | 0,22—0,3 | 0,8—1,2 | 0,05 | <0,3 | <0,3 | <0,3 | — | — | — | <0,05 | <0,04 |

| St08kp, ps | 0,05—0,12 | 0,25—0,5 | 0,03 | <0,3 | <0,3 | <0,1 | — | — | — | <0,04 | <0,035 |

| St08Yu | up to 0.07 | 0,2—0,35 | 0,01 | <0,1 | <0,15 | <0,03 | — | — | — | <0,025 | <0,02 |

| St10kp, ps | 0,07—0,14 | 0,25—0,5 | 0,07 | <0,3 | <0,3 | <0,15 | — | — | — | <0,04 | <0,035 |

| St10 | 0,07—0,14 | 0,35—0,65 | 0,17—0,37 | <0,3 | <0,3 | <0,15 | — | — | — | <0,04 | <0,035 |

| St15ps | 0,12—0,19 | 0,35—0,65 | 0,05 | <0,3 | <0,3 | <0,25 | — | — | — | <0,04 | <0,035 |

| St15 | 0,12—0,19 | 0,35—0,65 | 0,17—0,37 | <0,3 | <0,3 | <0,25 | — | — | — | <0,04 | <0,035 |

| St20ps | 0,17—0,24 | 0,35—0,65 | 0,05 | <0,3 | <0,3 | <0,25 | — | — | — | <0,04 | <0,035 |

| St25ps | 0,22—0,27 | 0,25—0,5 | 0,03 | <0,25 | <0,3 | <0,25 | — | — | — | <0,04 | <0,04 |

| St20 | 0,17—0,24 | 0,35—0,65 | 0,17—0,37 | <0,3 | <0,3 | <0,25 | — | — | — | <0,04 | <0,35 |

| St25 | 0,22—0,3 | 0,5—0,8 | 0,17—0,37 | <0,3 | <0,3 | <0,25 | — | — | — | <0,04 | <0,035 |

| St45 | 0,42—0,5 | 0,5—0,8 | 0,17—0,37 | <0,3 | <0,3 | <0,25 | — | — | — | <0,04 | <0,035 |

| St55 | 0,52—0,6 | 0,5—0,8 | 0,17—0,37 | <0,3 | <0,3 | <0,25 | — | — | — | <0,04 | <0,035 |

| 08Х18Н10 | up to 0.08 | up to 2.0 | up to 0.8 | 9—11 | — | 17—19 | — | — | — | 0,02 | 0,035 |

| 08Х18Н10Т | up to 0.08 | up to 2.0 | up to 0.8 | 9—11 | — | 17—19 | 0,25—0,7 | — | — | 0,02 | 0,035 |

| 08Х18Н12Т | up to 0.08 | up to 2.0 | up to 0.8 | 11—13 | — | 17—19 | 0,25—0,6 | — | — | 0,02 | 0,035 |

| 12Х18Н10Т | up to 0.12 | up to 2.0 | up to 0.8 | 9—11 | — | 17—19 | 0,25—0,6 | — | — | 0,02 | 0,035 |

| 12Х18Н9 | up to 0.12 | up to 2.0 | up to 0.8 | 8—10 | — | 17—19 | — | — | — | 0,02 | 0,035 |

| 17Х18Н9 | 0,13—0,21 | up to 2.0 | up to 0.8 | 8—10 | — | 17—19 | — | — | — | 0,02 | 0,035 |

| 12Х21Н5Т | 0,09—0,14 | up to 0.8 | up to 0.8 | 4,8—5,8 | — | 20—22 | 0,25—0,5 | up to 0.08 | — | 0,025 | 0,035 |

| 10Х13Г18ДУ | 0,08—0,12 | 17—18,5 | up to 0.7 | up to 2 | 0,3—0,6 | 12,5—14 | — | — | — | 0,03 | 0,045 |

| 10X14AG15 | up to 0.1 | 14,5—16,5 | up to 0.8 | — | — | 13—15 | — | — | — | 0,03 | 0,045 |

| 10Х17Н13М2Т | up to 0.1 | up to 2.0 | up to 0.8 | 12—14 | — | 16—18 | 0,25—0,7 | — | 2—3 | 0,02 | 0,035 |

| 10Х17Н13М3Т | up to 0.1 | up to 2.0 | up to 0.8 | 12—14 | — | 16—18 | 0,25—0,7 | — | 3—4 | 0,02 | 0,035 |

| 20Х23Н18 | up to 0.2 | up to 2.0 | up to 1 | 17—20 | — | 22—25 | — | — | — | 0,02 | 0,035 |

Table 3. Approximate purpose of steel

| steel grade | Purpose |

| Carbon quality structural steel | |

| St08kp, St10 | Parts produced by cold stamping and cold heading, tubes, gaskets, fasteners, caps. Cemented and cyanidated parts that do not require high core strength (bushings, rollers, stops, copiers, gears, friction discs) |

| St15, St20 | Lightly loaded parts (rollers, pins, stops, copiers, axles, gears). Thin parts exposed to abrasion, levers, hooks, traverses, liners, bolts, couplers, etc. |

| St30, St35 | Parts experiencing low stress (axles, spindles, sprockets, rods, traverses, levers, disks, shafts) |

| St40, St45 | Parts that require increased strength (crankshafts, connecting rods, ring gears, camshafts, flywheels, gears, pins, ratchets, plungers, spindles, friction discs, axles, couplings, racks, rolling rolls, etc.) |

| St50, St55 | Gear wheels, rolling rolls, rods, bandages, shafts, eccentrics, lightly loaded springs and springs, etc. Used after hardening with high tempering and in a normalized state |

| St60 | Parts with high strength and elastic properties (rolling rolls, eccentrics, spindles, spring rings, clutch springs and discs, shock absorber springs). Apply after hardening or after normalization (large parts) |

| Low-alloy thin-sheet and broad-band universal steel | |

| 09G2 | For parts of welded structures made from sheets. Can be cut satisfactorily |

| 09G2S | For steam boilers, apparatus and containers operating under pressure at temperatures from -70 to +450 °C; for critical sheet welded structures in chemical and petroleum engineering, shipbuilding. They weld well. Can be processed satisfactorily by cutting |

| 10HSND | For welded structures in chemical engineering, shaped profiles in shipbuilding and carriage building |

| 15HSND | For parts of carriages, construction piles, complex profiles in shipbuilding. Has increased corrosion resistance |

| 15GF | For sheet welded structures in carriage building. Provides high quality weld seam |

| Alloy structural steel | |

| 15X | Piston pins, camshafts, pushers, cardan crosspieces, valves, small parts operating under conditions of wear due to friction. Well cemented |

| 20X | Cam couplings, bushings, spindles, guide bars, plungers, mandrels, copiers, spline rollers, etc. |

| 40X | For parts operating at medium speeds and medium pressures (gears, spindles and shafts in rolling bearings, worm shafts) |

| 45Х, 50Х | For large parts operating at medium speeds and low pressures (gears, spindles, shafts in rolling bearings, worm and spline shafts). Have high strength and toughness |

| 38ХА | For gears operating at medium speeds and medium pressures |

| 45G2, 50G2 | For large lightly loaded parts (spindles, shafts, gears of heavy machine tools) |

| 18ХГТ | For parts operating at high speeds under high pressures and shock loads (gears, spindles, jaw couplings, bushings, etc.) |

| 20ХГР | For heavily loaded parts operating at high speeds and shock loads |

| 15HF | For small parts subjected to case hardening and hardening with low tempering (gears, piston pins, etc.) |

| 40ХС | For small parts with high strength |

| 40HFA | For critical high-strength parts subjected to hardening and high tempering; for medium and small parts of complex configuration operating under wear conditions (levers, pushers); for critical welded structures operating under alternating loads |

| 35ХМ | For shafts, turbine parts and fasteners operating at elevated temperatures |

| 45ХН, 50ХН | Similar to the use of 40X steel, but for larger parts |

| Corrosion resistant steel | |

| 20Х13, 08Х13, 12X13, 25Х13Н2 | For parts with increased ductility and subject to shock loads; parts operating in mildly aggressive environments |

| 30Х13, 40Х13, 08Х18Т1 | For parts with increased hardness; cutting, measuring, surgical instruments, compressor valve plates, etc. (steel 08Х18Т1 has better stampability) |

| 06ХН28МТ | For welded structures operating in aggressive environments (hot phosphoric acid, sulfuric acid up to 10%, etc.) |

| 14X17H2 | For various parts of the chemical and aviation industries. Has high technological properties |

| 95Х18 | For high hardness parts operating under wear conditions |

| 08X17T | Recommended as a substitute for steel 12Х18Н10Т for structures not exposed to shock at operating temperatures not lower than -20 °C |

| 15X25T, 15X28 | Similar to steel 08X17T, but for parts operating in more aggressive environments at temperatures from -20 to 400 °C (15X28 - for joints with glass) |

| 20Х13Н4Г9, 10X14AG15, 10Х14Г14НЗ | Substitute for steels 12X18H9, 17X18H9 for welded structures |

| 09Х15Н8У, 07X16H6 | For high-strength products, elastic elements; steel 09Х15Н8У - for acetic acid and saline environments |

| 08X17H5M3 | For parts operating in sulfuric acid environments |

| 20X17H2 | For high-strength, heavily loaded parts exposed to abrasion and impact in mildly aggressive environments |

| 10Х14Г14Н4Т | Substitute for steel 12Х18Н10Т for parts operating in mildly aggressive environments, as well as at temperatures up to 196 °C |

| 12X17G9AN4, 15Х17AG14, 03Х16Н15МЗБ, 03X16H15M3 | For parts operating in atmospheric conditions (substitute for steels 12X18H9, 12X18N10T). For welded structures operating in boiling phosphoric, sulfuric, 10% acetic acid |

| 15Х18Н12С4ТУ | For welded products operating in air and aggressive environments, in concentrated nitric acid |

| 08X10H20T2 | Non-magnetic steel for parts operating in seawater |

| 04X18H10, 03X18H11, 03X18H12, 08X18H10, 12X18H9, 12X18H12T, 08X18H12T, 06X18H11 | For parts operating in nitric acid at elevated temperatures |

| 12Х18Н10Т, 12Х18Н9Т, 06ХН28МДТ, 03ХН28МДТ | For welded structures in various industries. For welded structures operating at temperatures up to 80 °C in sulfuric acid of various concentrations (55% acetic and phosphoric acids are not recommended) |

| 09Х16Н4Б | For high-strength stamped-welded structures and parts operating in contact with aggressive media |

| 07X21G7AN5 | For welded structures operating at temperatures down to –253 °C and in medium aggressive environments |

| 03Х21Н21М4ГБ | For welded structures operating in hot phosphoric acid, low concentration sulfuric acid at temperatures not exceeding 80 °C, nitric acid at temperatures up to 95 °C |

| ХН65МВ | For welded structures operating at high temperatures in sulfuric and hydrochloric acid solutions, in acetic acid |

| N70MF | For welded structures operating at high temperatures in hydrochloric, sulfuric, phosphoric acids and other reducing environments |

Classification by purpose

The classification of steel types by purpose has already been given above. Marking of structural steels includes the following designations:

- Construction - denoted by the letter C and numbers characterizing the yield strength.

- Bearing - designated by the letter Ш. Next comes the designation and content of alloying additives, mainly chromium.

- Instrumental unalloyed - denoted by the letter U and carbon content in tenths of a percent.

- High-speed - denoted by the letter P and symbols of alloying components.

- Unalloyed structural steel has the symbols Cn and a number indicating the carbon content in tenths or hundredths of a percent.

Classification of steel by purpose

The remaining varieties, including tool grades made of alloy steels, do not have special designations other than their chemical composition, so the decoding and purpose of individual types can only be determined from reference literature.

Foreign analogues of steel grade St3kp

| USA | A283A, A284Gr.D, A57033, A57036, A573Gr.58, A611Gr.C, K01804, K02001, K02301, K02502, K02601, K02701, K02702 |

| Germany | 1.0036, 1.0036, 1.0116, Fe360B, Fe360D1, RSt37-2, S235J2G3, S235JRG1, USt37-2, USt37-2G |

| Japan | SS400, STKM12A |

| France | 4360-40D, E24-3, E24-4, S235J0, S235J2G3, S235J2G4, S235JRG1 |

| England | 1449-3723CR, 235JRG1, 4360-40B, 4449-250, Fe360B, Fe360D1FF, HFS4, HFW4, S235J2G3 |

| Canada | 230G |

| European Union | Fe37-3FN, Fe37-3FU, Fe37B1FN, Fe37B1FU, Fe37B3FN, Fe37B3FU, S235J2G3, S235JRG1 |

| Italy | Fe360B, Fe360BFU, Fe360C, Fe360CFN, Fe360D, Fe360DFF, Fe37-2, S235J0, S235J2G3, S235J2G4, S235JRG1 |

| Belgium | FE360B, FED1FF |

| Spain | AE235B, AE235D, Fe360B, Fe360D1FF, S235J2G3, S235JRG1 |

| China | A3, Q235, Q235A, Q235A-F, Q235A-Z, Q235B, Q235B-Z |

| Sweden | 1311, 1312, 1313 |

| Bulgaria | BSt3kp, BSt3ps, Ew-08AA, S235J2G3, S235JRG1, WSt3kp |

| Hungary | A1, B38.24, B38.24B, Fe235BFU, S235J2G3, S235JRG1 |

| Poland | SS400, St3SX, St3SY, St3W |

| Romania | OB37, OL37.1 |

| Czech | 10216, 11373, 11378 |

| Austria | St37F |

- Structural steel

- Tool steel

Classification by structure

The structure of steel refers to the internal structure of the metal, which can vary significantly depending on heat treatment conditions and mechanical influences. The shape and size of grains depend on the composition and ratio of alloying additives and production technology.

The basis of steel grains is a crystal lattice of iron, which includes atoms of impurities - carbon, metals. Carbon can form solid solutions in the crystal lattice, or it can create chemical compounds, carbides, with iron.

Metal additives exist in the form of solutions, and many of them affect the state of the carbon solution.

The structure of steel changes with temperature changes. These changes are called phases. Each phase exists in a certain temperature range, but alloying additives can significantly shift the boundaries of the transition of one phase to another.

The following are the main phases of the state of the metal:

- Austenite. Carbon atoms are located inside the iron crystal lattice. This phase exists in the range of 1400-700 °C. If the composition contains from 8 to 10% nickel, the austenite phase can persist at room temperature.

- Ferrite. Solid solution of carbon in iron.

- Martensite. Supersaturated carbon solution. This phase is characteristic of hardened steel.

- Bainite. The phase is formed by rapid cooling of austenite to a temperature of 200-500 °C. Characterized by a mixture of ferrite and iron carbide.

- Perlite. Equilibrium mixture of ferrite and carbide. It is formed when austenite is slowly cooled to a temperature of 727 °C.

Steel structure

The phases of the metal structure characterize its physical properties, depending on which the class of steel is determined - structural, foundry, and so on.

Impact strength of steel St3kp

| Delivery condition, heat treatment | +20 | 0 | -10 | -20 | -30 |

| Sheets 10-12 mm thick | 89-100 | 60-85 | 12-69 | 13-53 | 6-10 |

| Sheets 16-20 mm thick | 40-140 | 15-71 | 9-16 | 8-12 | |

| Sheets 30-32 mm thick | 30-115 | 8-13 | 6-13 | 7-9 | |

| Sheets up to 12 mm thick (shaped rolled products) | 64-149 | 83-112 | 83-114 | 14-63 |

Quality classification

Alloyed and unalloyed steel within each grade differs in quality, which depends on the production technology and the quality of the starting materials.

The quality of steel is particularly affected by impurities that remain in it during the reduction of iron from ore concentrates. Phosphorus and sulfur mainly negatively affect the quality of steel. According to their content, steel of ordinary quality and high-quality steel are classified, at the end of which there is the letter A. The phosphorus content in high-quality steel does not exceed 0.025%.

Classification by deoxidation method

When steel is smelted, a certain amount of oxygen remains in it as part of the iron oxides. To reduce the amount of oxygen and restore iron from oxides, a deoxidation reaction is used, in which compounds that are more active in interacting with oxygen than iron are added to the molten metal. During the reaction, the released oxygen also reacts with carbon, resulting in the formation of carbon dioxide, which is released in the form of bubbles.

Depending on the amount of deoxidizing agents and the duration of the process, three types of the final alloy can be distinguished:

- Boiling steel. As a result of the minimal use of additives and reaction time, the yield of finished products is increased, which, at the same time, is of low quality;

- Calm steel. Metal that has completely undergone deoxidation processes. It is of high quality, but expensive to produce due to the high cost of reagents and reduced product yield;

- Semi-quiet steel. An intermediate option with the optimal combination of quality and cost.

When producing an assortment of steel grades from metal of varying degrees of deoxidation, special marking of materials is used, respectively, with the symbols “sp”, “kp” and “ps”.

Marking of steels according to Russian standards

Marking steel according to Russian standards makes it possible to determine the composition of the metal and, in part, whether it belongs to a certain type.

If the presence of carbon in steel is more than 1%, its amount is not indicated in the marking. The steel grade includes letter designations of alloying additives indicating their quantity in tenths and hundredths of a percent, but if the component content is less than 1.5%, then only the letter designation is present in the marking.

In addition to the chemical composition, the marking contains symbols characterizing the purpose of the steel and the degree of its quality.

We will advise you on any questions!

Have a question?

Our services

Any specialist who deals with metal is familiar with the concept of “steel grade”. Deciphering the markings of steel alloys makes it possible to get an idea of their chemical composition and physical characteristics. Understanding this marking, despite its apparent complexity, is quite simple - it is only important to know on what principle it is compiled.

Rarely does production operate without steel, so understanding its grades is extremely important

The alloy is designated by letters and numbers, which can be used to accurately determine which chemical elements it contains and in what quantity. Knowing this, as well as how each of these elements can affect the finished alloy, it is possible to determine with a high degree of probability exactly what technical characteristics are characteristic of a particular grade of steel.

Marking of steels according to American and European systems

Marking of steels produced domestically and in the post-Soviet space makes it possible to approximately determine the composition, purpose and characteristics without resorting to reference literature. In American and European standards, such decoding is, for the most part, absent. This is due to the large number of organizations involved in the standardization of metal products.

For the most part, the designation of steel according to American and European standards does not indicate the chemical composition. Types of steel according to their intended purpose are characterized by an alphabetic or digital code, which can be deciphered using reference literature.

Only in the European standard EN10027 there is an option for marking alloys by chemical composition, which is closely similar to domestic designations.

Designations of alloying elements

In order to recognize the qualitative and quantitative composition from the markings, letter designations are used for alloying elements.

Basically, Russian letters correspond to the names of elements, although there are exceptions, since there are elements that begin with the same letters. The table of alloying elements is as follows. Designation of alloying elements in steels

| IN | Tungsten | B | Niobium |

| TO | Cobalt | E | Selenium |

| M | Molybdenum | R | Bor |

| N | Nickel | F | Vanadium |

| T | Titanium | C | Zirconium |

| X | Chromium | YU | Aluminum |

| G | Manganese | A | Nitrogen |

| D | Copper | WITH | Silicon |

As can be seen from the table, it contains two non-metals - silicon and nitrogen, but no carbon. The presence of carbon is implied in the composition of any steel, therefore the designation indicates only its content

Deoxidation index

This process is a procedure for removing oxygen from a metal that is in a liquid state. According to this indicator, it is customary to distinguish 3 types of this material:

- calm. In this case, the process is carried out thanks to the participation of aluminum, silicon and manganese. This type is designated “sp”;

- semi-quiet - a link located between the first and third varieties. Species marking: “ps”;

- boiling. This type of steel is characterized by a reduced level of deoxidation. It is spelled "kp".

An increase in the strength coefficient of the metal is achieved by heating it under the influence of the highest possible temperatures. Due to such external influence, steel ceases to be viscous and ductile. Under this condition, the possibility of an easier process of cutting the material disappears.

The influence of alloying elements on the properties of steel

| Austenitic | |||||||||||||

| steel grade | Carbon % | Silicon% | Manganese % | Phosphorus % | Sulfur% | Nickel % | Chrome % | Copper % | Niobium % | Titanium % | Nitrogen % | ||

| AISI 304 | ≤ 0,08 | ≤ 1,00 | ≤ 2,00 | ≤ 0,045 | ≤ 0,030 | 8,00-10,50 | 18,00-20,00 | – | – | – | – | ||

| AISI 321 | ≤ 0,08 | ≤ 1,00 | ≤ 2,00 | ≤ 0,045 | ≤ 0,030 | 9,00-12,00 | 17,00-19,00 | – | – | ≤ 0,7 | – | ||

| AISI 201 | <0,12 | ≤ 0,75 | 8,50-10,50 | ≤ 0,060 | ≤ 0,030 | 1,00-1,50 | 14,00-16,50 | ≤ 2,00 | – | – | ≤ 0,020 | ||

| AISI 202 | ≤ 0,08 | ≤ 0,75 | 7,00-8,00 | ≤ 0,060 | ≤ 0,010 | 4,00-5,00 | 15,00-17,50 | ≤ 1,50 | – | – | ≤ 0,010 | ||

| NTKD 11 | ≤ 0,10 | ≤ 1,00 | 5,50-7,50 | ≤ 0,045 | ≤ 0,015 | 3,50-5,50 | 17,00-18,00 | 1,50-3,50 | – | – | – | ||

| Ferritic | |||||||||||||

| AISI 430 | ≤ 0,12 | ≤ 0,75 | ≤ 1,00 | ≤ 0,040 | ≤ 0,030 | – | 16,00-18,00 | – | – | – | – | ||

| SUS 430J1L | ≤ 0,025 | ≤ 1,00 | ≤ 1,00 | ≤ 0,040 | ≤ 0,030 | – | 16,00-20,00 | 0,30-0,80 | 1,0 | – | ≤ 0,025 | ||

| JYH21CT (21Cr-Ti) | ≤ 0,015 | ≤ 1,00 | ≤ 1,00 | ≤ 0,040 | ≤ 0,030 | – | 20,00-23,00 | ≤ 0,43 | – | ≤ 0,3 | ≤ 0,015 | ||

| NSSC180 | ≤ 0,02 | ≤ 1,00 | ≤ 1,00 | ≤ 0,040 | ≤ 0,006 | ≤ 0,60 | 19,00-21,00 | 0,30-0,60 | 0,30-0,80 | – | ≤ 0,025 | ||

| Martensitic | |||||||||||||

| SUS 420 L | 0,16-0,25 | ≤ 1,00 | ≤ 1,50 | ≤ 0,040 | ≤ 0,010 | – | 12,00-14,00 | – | – | – | – | ||

| SUS 420 J2 | 0,36-0,42 | ≤ 1,00 | ≤ 1,00 | ≤ 0,040 | ≤ 0,010 | – | 12,50-14,50 | – | – | – | – | ||

Color coding

Color marking of steels is used to indicate rolled products. This is convenient when storing materials in warehouses and transporting them. Steels are marked with marks in the form of dots or stripes made with indelible paint. The color of the designations is selected from the table according to the purpose of the steel. In this case, the steel group and the degree of its deoxidation are not taken into account.

Example of steel color marking

Mechanical properties St3kp

| Type of delivery | Size | Eg. | sв | sT | d5 | y | KCU | Heat treatment |

| — | mm | — | MPa | MPa | % | % | kJ/m2 | — |

| Pipes, GOST 8696-74 | 363 | 235 | 23 | |||||

| Pipes, GOST 10705-80 | 372 | 225 | 22 | |||||

| Rolled goods, GOST 535-2005 | 360-460 | 195-235 | 24-27 | |||||

| Thick sheet, GOST 14637-89 | 360-460 | 195-235 | 24-27 | |||||

| Fittings, GOST 5781-82 | 373 | 235 | 25 | |||||

| Wire rod, GOST 30136-95 | 490-540 | 60 |

Examples of decoding markings

To make the decoding clearer, some of the most striking examples of marking should be given. Based on the examples, determining the steel grade in comparison with already known ones will not be a difficult task. Here are some types of steel with decoding symbols:

- 30ХГСА - decoding of the steel grade indicates that the alloy contains 0.3% carbon, as evidenced by the number at the beginning of the designation. Steel contains chromium (X), manganese (G), silicon (C), but their content is less than 1.5%. The symbol “A” at the end of the designation indicates that the steel is high quality.

- U8GA – tool steel with a carbon content of 0.8%. High quality with added manganese.

- R6M5F2K8 – high-speed steel. Contains 5% molybdenum, 2% vanadium, 8% cobalt. Chromium is contained in all high-speed steels in an amount of about 4%, so it is not included in the designation. Tungsten is also always present, but its content can vary, so in this brand its amount is 6%.

- St3sp5 - unalloyed structural steel, completely deoxidized - calm, category 5, that is, it can be used for the manufacture of load-bearing welded structures.

- HVG – HVG steel contains chromium, tungsten and manganese in an amount of about 1% and additional alloying elements, but their content is less than 0.5%.

Mechanical properties of St3kp at elevated temperatures

| Test temperature, °C | σ0.2, MPa | σB, MPa | δ5, % | ψ, % |

| Sheets 12 mm thick as delivered (cross-sectional samples) | ||||

| 20 | 205 | 385 | 37 | 60 |

| 100 | 190 | 370 | 27 | 59 |

| 200 | 175 | 430 | 21 | 51 |

| 300 | 160 | 450 | 23 | 49 |

| 400 | 150 | 395 | 35 | 62 |