AD1 is technical aluminum, hardened only by pressure, with high anti-corrosion properties and high ductility, but its strength is low. A huge number of semi-finished products are produced from technical aluminum of this brand. It deforms well, is difficult to cut and lends itself well to all types of welding. The purity of technical aluminum guarantees its high anti-corrosion properties, due to which it is often used as a cladding material for high-strength aluminum and duralumin alloys that are less resistant to corrosion.

Aluminum sheets AD1M

AD1M aluminum sheet is produced and supplied in rolls or in the form of sheets cut to a certain size.

Sheets are produced by rolling AD1M aluminum. The strength and physicochemical characteristics of AD1M aluminum sheets are determined by the content of impurities in the AD1M source material.

The chemical composition of aluminum sheets meets the requirements of GOST 4784-74, and their dimensions comply with GOST 21631-76.

According to these regulatory documents, AD1M aluminum sheets consist of 95.5 - 99.7% aluminum, and the admixtures of some non-ferrous metals and silicon amount to 0.3 - 0.5%.

Description

AD1 aluminum is used : for the production of flat ingots cast by semi-continuous or continuous casting and intended for rolling into sheets, strips and other semi-finished products (strips, plates, profiles, panels, rods, pipes, drawn wire, stampings and forgings) using the hot or cold method deformation, as well as ingots and slabs; sheets used in the printing industry; extruded profiles for the manufacture of radiators for cooling semiconductor devices; foil used for the manufacture of capacitors; pressed large-sized pipes; special profiles using cold extrusion method; cold-formed profiles for building envelopes; pressed pipes with controlled internal diameter from 14 to 42 mm for heat exchangers; heat exchangers of evaporators and condensers with a double-sided blowing channel, used in household refrigerators and freezers; rolled foil used for thermal, hydro and sound insulation; cold-rolled foil intended for packaging food products, medicines, medical products, cosmetics products, as well as for the production of packaging materials based on it; bimetallic sheets with steel grade 08Х18Н10Т; tapes in rolls, clad with copper on one side (APM-1) and intended for various products in the electrical industry; round wire for cold heading.

Note

According to ISO 209−1, aluminum grade AD1 is designated A199.3.

Application of AD1M aluminum sheet

A variety of products used in everyday life and industry are made from AD1M alloy. For the electrical and instrument-making industries, the following are manufactured from AD1M aluminum sheets:

Electrical clamps, terminals, contact devices and busbars for DC and AC power circuits.

These products have good electrical conductivity, so when electric current passes through them, they do not heat up to high temperatures.

Cooling radiators for power semiconductor devices: transistors, thyristors, diodes. Good thermal conductivity of AD1M ensures effective heat removal from semiconductor elements and prevents them from overheating;

Housings and fastening clamps for electrolytic capacitors used to smooth out rectified current ripples in power supplies for radio-electronic devices.

Panels, panel covers and control cabinets for various electrical installations, which must be operated in difficult climatic conditions, withstand the aggressive influence of the atmosphere and have minimal weight.

Due to its low weight, ductility, resistance to corrosion and aggressive environments, AD1M aluminum sheets are widely used for the production of various structures, heat-reflecting screens and individual parts in aerospace engineering, river and marine fleets, electric transport and energy.

In the petrochemical industry, AD1M aluminum sheets are used for the production of various containers, tanks, ventilation ducts and pipelines for transporting gaseous and liquid products.

For the needs of the food industry, durable aluminum cookware is made from AD1M aluminum sheets by stamping. Cookware made from AD1M aluminum sheet does not emit harmful substances when heated, is durable and low in cost.

It is also used to make a variety of containers for packaging and transporting meat and dairy products, pipelines for transporting milk, vegetable oil and wine and vodka products of food enterprises.

Aluminum sheets are widely used in the construction and furniture industries to create decorative partitions, roofing, display cases, shelves, and lightweight and weather-resistant building cladding.

Sieve grids are made from perforated aluminum sheets for sifting bulk materials of various fractions, including grain.

They are widely used for the production of equipment for public catering and trade enterprises, medical and pharmaceutical equipment.

Characteristics and properties

Aluminum alloy combines high strength qualities, corrosion resistance and is characterized by:

- light weight;

- high electrical and thermal conductivity;

- pliability to any type of processing;

- resistance to corrosion processes;

- absence of toxic emissions;

- antibactericidal properties;

- durability

- is paramagnetic.

The following characteristics are established for cold-worked ad1n products:

- temporary resistance - 145 MPa;

- relative elongation - 3...5%;

- sheet ad1n weight 1 m2 - 2710 kg.

Environments to which aluminum is resistant:

- industrial emissions;

- water from natural fresh water bodies at t=18°C;

- caustic soda, hydrochloric acid, soda;

- solutions of chromic and sulfuric acid with concentrations up to 10%;

- ammonia;

- sea water;

- 1% phosphoric acid solution;

- concentrated nitric, boric, sulfuric, acetic acids;

- sour juices of fruits and berries, wine.

Aluminum exhibits instability in the following environments:

- dilute nitric, sulfuric acid;

- hydrochloric, hydrofluoric, oxalic, formic, hydrobromic acids;

- solutions of caustic alkalis;

- aqueous with admixtures of mercury salts, copper, and chlorine ions. like copper, gold, silver.

In the field of cable and conductor materials, the combination of low density and weight with high electrical conductivity allows aluminum to compete with copper. The cold-worked AD1N sheet conducts electricity worse than grades of annealed alloys, but is used in electrical engineering.

Classification and designations of AD1M aluminum sheet

Sheet aluminum, depending on its properties and manufacturing methods in accordance with the requirements of GOST 21631-76, is divided according to the following characteristics:

1) According to the condition of the material.

The letters AD in the marking mean that AD1M aluminum sheets are made of easily deformable aluminum. The letter M indicates that it is an annealed, soft material.

If the quality and accuracy of the annealed sheets corresponds to regulatory documents, then additional heat treatment may not be necessary. In this case, when marking, the letter M is enclosed in brackets - (M). The absence of the letter M indicates that no heat treatment was carried out.

The technological operation of cold hardening is carried out directly during the production of aluminum sheets. Its essence lies in increasing the hardness of sheet aluminum by treating its surface with increased pressure. Hardening is carried out during cold rolling or in shot blasting chambers. The plasticity of the material after this operation is slightly reduced.

Semi-hardening is a similar process, but with less mechanical impact, and therefore the hardness is lower, but the ductility is higher.

Hardening is designated by the letter N, semi-hardening is designated by H2, and the aluminum sheet is marked as AD1N or AD1N2.

2) Depending on the manufacturing method: clad and unclad.

Plating means covering sheets with an additional thin layer of chemically pure aluminum, which increases anti-corrosion properties. Clad aluminum sheets have the letters B, A or U in their designation, which corresponds to technological, normal or thickened cladding, respectively.

3) To designate aluminum sheets with a high quality of finishing, the letter B is used, with a high quality finish, the letter P is used, with normal finishing, there is no letter marking.

Description of mechanical symbols

| Name | Description |

| Section | Section |

| sT|s0.2 | Yield strength or proportional limit with tolerance for permanent deformation - 0.2% |

| σB | Short-term strength limit |

| d5 | Elongation after break |

| d10 | Elongation after break |

| d10 | Elongation after break |

Production of rolled aluminum sheet AD1M

The production of aluminum and rolled products from it has several stages. First, alumina is obtained - the feedstock for electrolysis plants. Alumina is produced by mixing crushed bauxite aluminum ore heated with hot steam and alkali.

From this mixture, after chemical reactions occur, aluminum oxide Al2O3, called alumina, is formed in an alkaline solution. It is then thoroughly mixed and fed into electrolysis baths. In baths, in the melt of cryolite NaAlF4, at a temperature of 950°C under the influence of a current of several hundred amperes, the process of electrolysis occurs to produce molten aluminum.

The resulting melt is treated with fluxes, refined and filtered.

After these technological operations, aluminum contains no more than 1% impurities, and is called technical. Its designation begins with the letter A. After passing through a degassing installation, the metal is poured into special molds, from which, after solidification, aluminum ingots are extracted, intended for further use.

In the second option, to produce hot-rolled aluminum sheets, liquid aluminum is fed through an inclined chute to a continuous casting line.

Depending on the existing technological scheme and equipment at the enterprise, the further process of rolling AD1M aluminum sheet can occur in two ways:

1) First, by hot rolling, strips of aluminum sheet AD1M with a thickness of 4–12 mm are produced, and then the resulting strip is compressed to smaller thicknesses in the stands of a cold rolling mill.

2) Rolling of assortments of any thickness only in the cold way;

In the first method, molten aluminum passes through a distribution nozzle, from which the liquid metal enters the hot rolling cage and enters the space between the rotating mold rollers. As a result of contact with the rollers, it cools and crystallizes. The metal strip obtained at the exit of the stand is fed by pulling rollers to a winding device, where it is wound into rolls of a certain length. In this way, you can obtain a strip with a thickness of 4-12 mm and a width of 1000 to 1600 mm.

The resulting coils serve as the starting material for producing thinner sheets in cold rolling mills. Before rolling, rotating shears cut the rolls into strips of a certain width and length.

Next, the strips enter a single or multi-stand cold rolling mill, where the final stages of producing AD1M aluminum sheets are carried out. Then annealing is carried out, if necessary, the rolls are cut to the required size and transferred to packaging. When producing hard cold-worked aluminum sheets, no annealing operation is performed. To eliminate the influence of the heating of the rolls on the dimensions of the aluminum sheet, rolling is carried out using a cooling lubricant.

Aluminum sheets with a thickness of 0.3 - 10.5 mm are produced from deformable alloy AD1M in cold rolling mills. The elongation factor during cold rolling varies from 40 to 100.

The production of AD1M aluminum sheets using the cold method requires increased pressing forces and the installation of higher-power rolling stand drive motors. The AD1M aluminum sheet obtained by cold and hot rolling meets all the requirements for this grade.

The production of aluminum itself, given the energy intensity of electrolysis, requires a powerful energy source. Therefore, aluminum smelters are usually located near thermal power plants that supply them with electricity and steam.

The AD grade of aluminum sheets is very common in the metalworking industry; in popularity it is second only to black rolled sheet materials.

Aluminum sheets must meet the technical requirements of GOST 21631-76 in terms of chemical composition, manufacturing accuracy, surface cleanliness, mechanical and physical properties. Their surface should not have cracks, cavities, or heterogeneous inclusions. The plating should not have visible scratches or other damage, the edges should be cut at right angles and not have sharp burrs or torn edges.

At AD1M aluminum sheet manufacturing enterprises, strict quality control of manufactured products is observed: samples are taken from each manufactured batch to control the dimensions, flatness of surfaces and chemical composition.

Marking is applied by stamping aluminum sheets or with permanent paint. Special requirements for packaging - it must not be susceptible to corrosion and reliably protect the product from direct exposure to the atmosphere.

Production and composition of AD1N sheets

Aluminum sheet most often arrives to the consumer in a cold-worked state, that is, it has been hardened by cold plastic deformation by rolling. In industry, cold hardening or controlled hardening is carried out in automated devices - shot blasting units. To perform strengthening, the workpiece is exposed to a flow of balls made of cast iron, steel or ceramics with a diameter of 0.4 to 2 mm, which move in the chamber at a speed of up to 70 m/sec.

The operating mode of the installation is programmed and controlled using electronic devices: the feed speed and the amount of shot are regulated. Equipment for cold hardening can be general or special purpose. Special installations are designed for processing bolts, springs, and pipes.

As a result of cold plastic deformation under the influence of load, stress arises in the internal structure of the alloy, the crystal lattice changes, and the spatial arrangement of the crystals is ordered. The crystal axes, which have maximum strength, are oriented parallel to the direction of deformation, and the metal will remain in this state even after processing is stopped. To re-deform the workpiece, you will have to apply even more force.

After such treatment, strength increases, but impact strength and ductility decreases. Cold hardening is especially relevant when it is necessary to increase the resistance to surface cracking and prevent the manifestation of metal hardening processes. If necessary, cold hardening can be removed by heat treatment of products made from AD1N alloy.

Impurities in AD1M alloy sheets, chemical composition, protective coatings

The AD1M material from which aluminum sheets are rolled contains a very high aluminum content - no less than 95.5%.

Along with aluminum, it contains impurities of certain elements in strictly regulated quantities. For example, iron and silicon, which give the metal hardness and strength, should not contain more than 0.3%. An increase in the percentage of these elements leads to a decrease in ductility below normal.

In addition to these elements, AD1M contains zinc with a percentage of up to 0.1%, the permissible content of manganese is 0.05%, and copper and magnesium are 0.03% each.

The titanium content, which increases strength and resistance to corrosion, is allowed no more than 0.15%, other impurities of natural origin - up to 0.03% in total.

To give AD1M products additional strength and corrosion resistance, the application of a protective oxide film to them is widely used. This process is called anodizing. The film is applied by electrochemical electrolysis in solutions of various acids. Film thickness can reach 250 microns, which guarantees high mechanical strength of the coating.

In addition, anodizing is widely used for decorative purposes - the applied films can have a variety of colors, depending on the composition of the electrolyte.

Recently, instead of anodizing, film deposition using plasma installations has been used. Such coatings have much higher hardness and many beautiful shades.

Material AD1 Chelyabinsk

Not a single production can operate without steel, be it heavy engineering or the manufacture of household electrical appliances. There are many brands of this product, as well as a large number of dispensing forms. Our company sells AD1 material in large quantities and with a minimal margin. To clarify the properties and characteristics of a particular brand, you can contact the company’s managers.

Like all products, AD1 material is purchased from leading manufacturers. Therefore, we are ready to provide a quality guarantee with full responsibility. The minimum number of intermediaries determines the low cost. Coupled with fast delivery, this enables our business partners to conduct stable and mutually beneficial cooperation.

In addition to tempering, in the form of one or another part (blank), our company carries out metal processing. All events undergo strict control for compliance with GOST and rules. The specialists of our company carry out such work as galvanizing, creating parts according to customer drawings, producing castings, manufacturing various profiles and much more.

Having the latest equipment and vast experience in our arsenal, we can offer product testing for a number of parameters, such as strength characteristics, chemical composition, alloy purity, and so on.

Each buyer is offered a huge range of products in various formats, as well as current services and works. To quickly understand and choose a product that meets your needs, you need to contact the company manager and receive detailed information on all issues of interest.

Assortment and characteristics of AD1M sheet

The geometric dimensions of AD1M aluminum sheets, depending on their design, lie within the following limits:

- thickness – from 0.3 to 10.5 mm;

- width – from 600 to 2000 mm;

- length – from 2000 to 7000 mm.

AD1M aluminum sheets have a good appearance and do not require additional mechanical processing. To increase ductility, AD1M sheets are subjected to heat treatment, which improves weldability and facilitates the production of stamped products of the most complex shapes. To best meet the requirements of manufactured products, AD1M aluminum sheet is available in several modifications:

1) Food grade aluminum. It is used for the production of stamped tableware, containers for packaging and transportation of food products. Food AD1M is subject to increased requirements for chemical composition - the content of metals hazardous to human health such as lead, arsenic, zinc, and beryllium should not exceed permissible standards. The permissible concentration of these substances is regulated by the standards for food grade aluminum alloys GOST 17151-2019, GOST 51016–97.

All products that come into contact with food are subject to mandatory certification.

2) Corrugated aluminum sheet. Available in rolls and sheets, with rounded or rectangular corrugations. It has high resistance to atmospheric influences and durability. Products made from corrugated sheets can be used in humid and tropical climates, which determines their use for the manufacture of fences, building cladding, etc.

3) Perforated sheet. This is an aluminum sheet in which symmetrical holes of the same size are punched across the entire surface. Perforation can be applied during rolling or before use on special machines. Its advantages include durability and especially low weight. It has a variety of applications in the construction and furniture industries.

Designations

| Name | Meaning |

| Designation GOST Cyrillic | AD1 |

| Designation GOST Latin | AD1 |

| Translit | AD1 |

| By chemical elements | — |

| Name | Meaning |

| Designation GOST Cyrillic | 1013 |

| Designation GOST Latin | 1013 |

| Translit | 1013 |

| By chemical elements | 1013 |

Sale of aluminum sheet AD1M

sells rolled metal to all regions of Russia. For Moscow consumers, delivery of ordered products can be carried out by the company's vehicles, or over longer distances - with the involvement of specialized transport organizations. The company's warehouses always have a wide range of AD1M aluminum sheets and other types of rolled products. At the request of the customer, the company cuts the assortment to the required size. The warehouse is located in Elektrostal.

You can place an order using the company’s website, or by calling the contact phone number indicated at the top of the website page. When ordering, you need to indicate the brand of aluminum sheet, quantity, delivery time and assortment - the company will do the rest.

The order is shipped within 24 hours after payment of its cost. guarantees compliance of the supplied products with the regulatory documents regulating their characteristics - GOSTs and TUs (technical conditions under which this type of product is manufactured).

AD1N for the food industry

Cooking requires high temperature, a humid environment - these qualities, as well as hypoallergenicity, the ability to retain nutrients and vitamins without reacting with the ingredients of dishes, are demonstrated by food-grade aluminum.

According to current standards, the following are produced from sheet or rolled AD: pots, stewpans, frying pans, cutlery - how can one not recall Napoleon, at whose dinner parties aluminum cutlery was served to especially important guests. Nowadays, the most famous jewelers work with aluminum, which makes the products especially valuable.

However, the AD1N alloy, due to hardening, is able to withstand heavy loads, and it is irrational to use it for the production of food foil, like the A5 alloy. But for the production of devices operating at temperatures up to 400°C and high pressure, cold-worked aluminum ad1n is indispensable.

It is made from:

- heat exchangers;

- gas tanks (for storing liquefied methane);

- liquid air distillers;

- containers for the production of hydrogen peroxide, nitric and acetic acids;

- internal lining of vessels made of carbon steel;

- in the production of dairy products - tanks.

Especially valuable for the food industry are the alloy’s corrosion resistance to food organic acids, the absence of toxic components in corrosion products, and the color stability of food products when stored in AD1n aluminum containers. Sheets of cold-hardened aluminum are used to cover work surfaces for preparing dishes and shelves for storing food and semi-finished products.

Price for aluminum sheet AD1M

The cost of the order is determined based on its parameters: quantity, weight, brand, type of execution, overall packaged dimensions, etc. Price formation is influenced by logistics: transportation distance, the need and timing of storage at the company’s warehouse or intermediate warehouses, the presence and number of cargo transshipments, packaging (for transportation by road, rail or sea). In addition, the price may depend on the size, seasonality of delivery and the ruble exchange rate established at the time of conclusion of the contract.

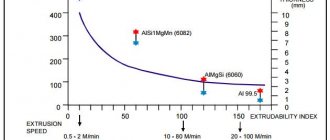

Wrought aluminum alloys

AMts (1.0-1.6% Mn, 0.6% Si 0.7% Fe) has high ductility ( Table 2.7 ) in the annealed state (AMtsM) and low in the cold-worked state (AMtsN), can be welded well by gas, atomic -hydrogen and resistance welding, used for the manufacture of tanks, gasoline and oil pipelines, necks of brackets, pipes and flanges of necks and lightly loaded parts. It is not hardened by heat treatment. Annealing at 350-410° C, cooling in air. Forging and stamping temperature is 420-475° C.

AMg (2.0-2.8% Mg, 0.15-0.40% Mn, 0.4% Si, 0.4 Fe) has the same plastic properties as AMts, and is well welded by atomic-hydrogen and resistance welding , satisfactory - gas. In the annealed state it has unsatisfactory machinability, while in the semi-worked and cold-worked state it has satisfactory machinability. It is used for the manufacture of tanks, gasoline and oil pipelines, walls of inlet pipes, guide cones of plugs and other moderately loaded aircraft parts. It is not hardened by heat treatment. Annealing at 350-410° C, cooling in air. Forging and stamping temperature is 420-275°C.

AMg5P (5.2 Mg, 0.4% MP) has high ductility in the annealed state, is not strengthened by heat treatment, is satisfactorily welded by atomic hydrogen, spot and gas welding, has high corrosion resistance, is supplied in the form of wire, and is used for the manufacture of rivets for riveting structures made of magnesium alloys. Rivets are installed in an annealed state. Annealing temperature 340-410°C with air cooling.

AB (0.2-0.6% Cu, 0.45-0.95% Mg, 0.15-0.35% Mn, 0.5-1.2% Si) has high ductility in the annealed state (AVT ) and medium after hardening and aging (AHT), can be welded well by spot and atomic-hydrogen welding, satisfactorily by gas welding, and is used for the manufacture of parts that require good ductility in the cold and hot state of stamped and forged parts of complex shapes. Forging and stamping temperature 470-475° C

Heat treatment: hardening from 010-525 ° C in water, natural or artificial aging at 150 ° C for 6 hours, annealing at 350-370 ° C, cooling in air (Fig. 2.2 ).

D18P (2.6% Cu, 0.35% Mg) - duralumin with increased ductility.

It is used for the manufacture of rivets, which are installed after hardening and natural aging. Hardening at 490-505° C in water and natural aging for at least 4 days (Fig. 2.3) .

D3P has high ductility in the annealed state; used for the manufacture of rivets, which are placed in a freshly hardened state no later than 3 hours after hardening (D3P alloy is replaced by D18P alloy). Heat treatment: hardening at 490-500°C in water, natural aging for at least 4 days, annealing at 340-370°C, cooling in air.

B65 (4.2% Cu, 0.2% Mg, 0.4% Mn) is an alloy for rivets that are installed in a hardened state and aged, since its ductility is satisfactory and the rivets do not need to be softened by installation. Replaces alloys D1 and D16. Heat treatment: hardening at 510-520° C in water, aging at room temperature for 10 days at a temperature of 50° C for 3 days

D7A alloy for chassis wheel rims, used after hardening and aging.

D1 (4.3% Cu, 0.6% Mg, 0.6% Mn, >=0.7% Si, >=0.7% Fe) has average ductility table. 2.8 Cutting machinability is satisfactory after hardening and aging (D1T) and reduced after annealing. It is used for the manufacture of power elements of medium strength: frame parts, stamped fastening units, screw blades, rivets (the latter are installed in a freshly hardened state no later than 2 hours after hardening). Heat treatment: hardening at 490-510°C in water and natural aging for at least 4 days, annealing at 350-370°C, cooling in air.

D16 (3.8–4.9% Cu, 1.2–1.8 Mg, 0.3–0.9% Mn)—high-strength duralumin. Plasticity in the annealed and freshly hardened state is average, machinability of D16T and D16TN is satisfactory, D16M is reduced. It is used for the manufacture of load-bearing structural elements: frame parts, sheathing, frames, ribs, spars, rivets. When manufacturing heavily loaded parts, it is recommended to replace them with alloy B95. Rivets are placed in a freshly hardened state no later than 20 minutes after hardening. Heat treatment: hardening at 495-505°C in water, natural aging for at least 4 days, annealing at 350-370°C, cooling in air. Annealing of D16TN should be preceded by heating at 450-500° C.

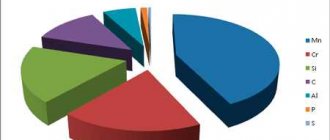

B95 (5-7% Zn, 1.8-2.8% Mg, 1.4-4.0% Cu, 0.2-0.6% Mn, 0.10-0.25% Cr) - high strength aluminum alloy ( Table 2.9 ). Plasticity in the annealed and freshly quenched states is the same as that of the D16 alloy in the same states. In an aged state it is much lower. Cutting machinability and weldability by spot welding are good, while gas welding is unsatisfactory. It is used for the manufacture of structural structural parts: spars, stringers, frames, skins, ribs. Heat treatment; hardening from 465-475°C, cooling in water, artificial aging of clad products at 120°C for 24 hours, unclad ones - at 140°C for 16 hours, annealing at 420°C, cooling in an oven to 150°C and then in the air.

AK4 (1.9-2.5%, Cu, 1.4-1.8% Mg, <=0.2 Mn, 1.0-1.5% Fe, 0.5-1.2% Si, 1.1-1.6% Ni) is a heat-resistant deformable aluminum alloy, has reduced ductility in the hot state, and can be welded satisfactorily by atomic-hydrogen welding. Machinability is satisfactory. It is used for the manufacture of engine parts and other products operating at temperatures up to 350°C. Heat treatment: hardening at 515±5°C, in water, aging at 170°C for 16 hours.

AK4-1 (1.9-2.5% Cu, 1.4-1.8% Mg, <=0.2% Mn, 1.0-1.5% Fe, 1.0-1.5 Ni ) is a heat-resistant wrought alloy. Modifications of AK4 alloy. It has higher (compared to AK-4) strength characteristics, has satisfactory ductility in a hot state, can be welded and processed satisfactorily by cutting. Heat treatment: hardening from 525-535°C, artificial aging at 170°C for 16 hours.

AK6 (1.8-2.6% Cu, 0.4-0.8% Mg, 0.4-0.8% Mn) - high-strength aviation material (Table 2.10), used for the manufacture of stamped and forged parts of complex shape and medium strength: compressor and fan impellers, intakes, diffuser blades and other parts. Heat treatment: hardening at 500-515°C in water and artificial aging at 150-160°C for 12-15 hours.

AK6-1 (2.2% Cu, 0.6% Mg, 0.6% Mn, 0.9% Si, 0.1% Ti, 0.2% Cr) alloy is more ductile than AK6 alloy; used for the manufacture of forged and stamped parts of complex shapes: compressor wheels, impeller intakes and other parts.

AK8 (4.4% Cr, 0.6% Mg, 0.7 Mn, 0.9 Si) is an alloy with high strength but worse than AK6-1. It is processed by hot pressure and therefore can be used for stamping highly loaded aircraft parts of less complex shapes: frames, fittings, etc.

The disadvantage of the alloy, which limits its use for thin-walled parts, is the tendency to intergranular corrosion in an artificially aged state.

Order aluminum sheet AD1M from the Resurs company

The Resurs company provides many additional services that make it easier to meet customer requirements. Their list includes:

- constant availability in the company’s warehouses of a wide range of assortments of all desired standard sizes;

- Shipment to a Moscow customer is carried out within 24 hours, for non-resident customers - within the same time frame to the appropriate transport terminal.

- at the request of the customer, additional processing of the workpieces is carried out, including applying perforation, cutting aluminum sheets to the required size, as well as bending and giving the workpieces the desired shape;

- Along with wholesale, small wholesale and retail sales are carried out;

- the company supplies at manufacturer prices;

- Payment is possible in various options; payments to regular customers are made on individual and preferential terms;

- the company provides free services of experienced consultants on technical and financial issues;

- delivery of goods is carried out to any region of Russia, without restrictions;

- a wide selection of packaging, depending on transportation conditions (PVC, PET film, wrapping with oiled or high-strength packaging paper);

- by agreement with the customer, selected and packaged products can be stored for the required period in the company’s warehouse;

- the company calculates and agrees on the cost of transportation, and transportation of products to the terminal is free.

- Products are returned in accordance with the legislation of the Russian Federation.

Application

- Heat exchangers and household radiators have high thermal conductivity. Among household radiators, devices with an anodized surface are especially popular. They have better heat dissipation than cast iron batteries.

- As an electrical conductor, the electrical conductivity of aluminum is 4 times higher than that of iron, which makes it in demand in this area.

- In the chemical and oil and gas industries - corrosion resistance and stability even in concentrated environments. Equipment, containers, and pipelines are made from AD1n sheet.

- In cryogenic devices - plasticity at ultra-low temperatures.

- For high-quality mirrors, the excellent reflectivity of polished aluminum is important, and the low price makes AD1N sheet an excellent replacement for silver and iridium.

- There is no toxicity in the manufacture of utensils and equipment for medicine and the food industry. The material perfectly takes and holds its shape, can be stamped, and does not emit harmful substances when heated and cooled. Now it is used to make professional and household kitchen appliances, dishes, and cutlery at budget prices.

- In automobile and aircraft construction - low weight, strength and the formation of an oxide film in the air on the metal surface, which prevents corrosion. Alloy car wheels, various engine parts, internal communications, aluminum interior trim are found in both budget and luxury models.

The low strength of aluminum determines its limited use in construction - only as a finishing material and unloaded rolled products.

With additional processing by grinding, polishing, and roughing, the surfaces of the sheets are given varying degrees of roughness and texture, which makes it possible to use ad1n aluminum sheets for the production of construction and finishing materials, furniture, and jewelry.

The main consumers of AD1n sheet are factories in the food and chemical industries. Due to its low weight, transportation of sheet aluminum does not require high costs, flattening provides additional strength, and plasticity - the ability to give any shape using hot and cold working methods. The material is very environmentally friendly - it is 100% recyclable and can be re-manufactured for food grade sheets.