Steel U12, U12A – definition of steel grade, GOST, material characteristics

Steel grade – U12, U12A

Standard – GOST 1435

Substitute – U10, U10A

Steel U12

contains an average of 1.2% carbon, the letter

U

indicates that the steel is carbon.

Steel U12A

contains an average of 1.2% carbon, the letter

U

indicates that the steel is carbon, the letter

A

at the end of the brand means that the steel belongs to the high-quality category.

Unalloyed tool steels U12

and

U12A

are used for the manufacture of:

- hand taps, files, metalwork scrapers;

- cold stamping dies of cut and die-cutting of small sizes and without cross-sectional transitions, cold heading punches and stamps of small sizes, calibers of simple shape and reduced accuracy classes;

- tools with reduced wear resistance at moderate and significant specific pressures (without heating the cutting edge): files, razor blades and knives, sharp surgical instruments, scrapers, engraving tools.

| Mass fraction of basic chemical elements, % | |||

| C – carbon | Si – silicon | Mn – manganese | |

| 1,10-1,29 | 0,17-0,33 | 0.17-0.33 (U12) 0.17-0.28 (U12A) | |

| Temperature of critical points, °C | |||

| Ac1 | Ac3 | Ar1 | Ar3 |

| 730 | 820 | 700 | – |

| Technological properties | |

| Forging | Forging temperature, °C: beginning 1100, end 750. Slow cooling in air. |

| Weldability | Not applicable for welded structures. Welding method – resistance welding. |

| Machinability | Annealed at HB 207: Kv carbide = 1.0 Kv high speed steel = 0.9 |

| Flock sensitivity | Not sensitive |

| Tendency to temper brittleness | Not inclined |

| Physical properties | Test temperature, °C | |||||||||

| 20 | 100 | 200 | 300 | 400 | 500 | 600 | 700 | 800 | 900 | |

| Modulus of normal elasticity E, GPa | 209 | 205 | 200 | 193 | 185 | 178 | 166 | – | – | – |

| Modulus of elasticity under torsional shear G, GPa | 82 | 80 | 78 | 75 | 72 | 69 | 63 | – | – | – |

| Density ρn, kg/m3 | 7830 | 7809 | 7781 | 7749 | 7713 | 7675 | 7634 | 7592 | 7565 | 7489 |

| Thermal conductivity coefficient λ W/(m*K) | – | 45 | 43 | 40 | 37 | 35 | 32 | 28 | 24 | 25 |

| Electrical resistivity ρ, nOhm*m | – | 252 | 333 | 430 | 540 | 665 | 802 | 964 | 1152 | 1196 |

| 20-100 | 20-200 | 20-300 | 20-400 | 20-500 | 20-600 | 20-700 | 20-800 | 20-900 | 20-1000 | |

| Linear expansion coefficient α*106, K-1 | 10,5 | 11,8 | 12,6 | 13,4 | 14,1 | 14,8 | 15,3 | 15,0 | 16,3 | 16,8 |

| Specific heat capacity c, J/(kg*K) | 469 | 503 | 519 | 536 | 553 | 720 | 611 | 712 | 703 | 699 |

tekhnar.ru

Structural steel with increased cutting machinability A12 - characteristics, properties, analogues

This page shows the technical, mechanical and other properties, as well as the characteristics of A12 steel.

Classification of material and application of grade A12

Grade: A12 Material classification: Structural steel with increased cutting machinability Additional information about the material: Carbon sulfur steel. According to GOST 1414-75, rolled steel A12 is not allowed for use in newly created and modernized equipment Application: Axles, rollers, bushings, gears, pinions, pins, screws, bolts and other lightly loaded small parts of complex shape processed on automatic machines , and to which increased demands are placed on surface quality and dimensional accuracy.

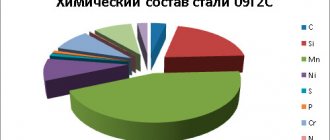

Chemical composition of material A12 in percentage terms

| C | Si | Mn | S | P | Cu |

| 0.08 – 0.16 | 0.15 – 0.35 | 0.7 – 1.1 | 0.08 – 0.2 | 0.08 – 0.15 | up to 0.25 |

Mechanical properties of A12 at a temperature of 20oC

| Assortment | Size | Eg. | sв | sT | d5 | y | KCU | Thermal change |

| – | mm | – | MPa | MPa | % | % | kJ/m2 | – |

| Hot rolled products, GOST 1414-75 | 410 | 22 | 34 | |||||

| The rental is calibrated. cold hardened, GOST 1414-75 | 460-510 | 7 |

Technological properties of A12

| Weldability: | not applicable to welded structures. |

| Flock Sensitivity: | sensitive. |

| Tendency to temper brittleness: | not inclined. |

Foreign analogs of A12

The table shows exact and similar analogues.

| USA | Germany | Japan | France | England | European Union | Italy | Spain | China | Sweden | Bulgaria | Poland | Romania | Czech |

| – | DIN,WNr | JIS | AFNOR | B.S. | EN | UNI | UNE | G.B. | SS | BDS | PN | STAS | CSN |

| 1212 | |||||||||||||

| B1112 | |||||||||||||

| B1113 | |||||||||||||

| B1114 | |||||||||||||

| G11080 | |||||||||||||

| Gr.1108 |

| 10S20 |

| 10SPb20 |

| 15S20 |

| 9S20 |

Explanation of symbols, abbreviations, parameters

| Mechanical properties : | |

| sв | – Short-term strength limit, [MPa] |

| sT | – Proportional limit (yield strength for permanent deformation), [MPa] |

| d5 | – Elongation at break, [%] |

| y | – Relative narrowing, [%] |

| KCU | – Impact strength, [kJ/m2] |

| HB | – Brinell hardness, [MPa] |

| Physical properties: | |

| T | – Temperature at which these properties were obtained, [Deg] |

| E | – Modulus of elasticity of the first kind, [MPa] |

| a | – Coefficient of thermal (linear) expansion (range 20 o– T), [1/degree] |

| l | – Thermal conductivity coefficient (heat capacity of the material), [W/(m deg)] |

| r | – Material density, [kg/m3] |

| C | – Specific heat capacity of the material (range 20o– T), [J/(kg deg)] |

| R | – Electrical resistivity, [Ohm m] |

| Weldability: | |

| no limits | – welding is performed without heating and without subsequent heat treatment |

| limited weldability | – welding is possible when heated to 100-120 degrees. and subsequent heat treatment |

| difficult to weld | – to obtain high-quality welded joints, additional operations are required: heating to 200-300 degrees. during welding, heat treatment after welding - annealing |

Other brands in this category:

Please note that this information about the A12 brand is provided for informational purposes.

The parameters, properties and composition of real A12 grade material may differ from the values given on this page. More detailed information about the A12 grade can be found on the information resource “Brand of Steel and Alloys”. You can check with our managers for information about the availability, delivery times and cost of materials. If you find inaccuracies in the description of materials or errors found, please inform the site administrators using the feedback form. Thanks in advance for your cooperation! www.c-met.ru

Macrostructure and contamination of steel 12Kh2NVFA

When checking for fractures in the longitudinal direction and transverse templates taken from finished rolled products, the macrostructure of steel should not have shrinkage cavities, friability, bubbles, cracks, delaminations, slag inclusions and flakes, as well as fracture defects listed in Appendix 3 of GOST 10243. Central porosity, point heterogeneity and segregation square should not exceed 1 point; layer-by-layer crystallization and light contour - 3 points of the GOST 10243 standard scales. All other defects provided for by GOST 10243 are not allowed. Contamination of steel with non-metallic inclusions should be no higher than the average score (in points): for point oxides 1.5, for line oxides 2.0, for brittle silicates 1.0, for plastic silicates 1.0, for non-deformable silicates 2.5 , for sulfides 2.5, for nitrides line and dot 1.0.

Steel A12 – State Enterprise Stalmash

reference Information

Material characteristics steel A12

Chemical composition in % of material steel A12

| C | Si | Mn | S | P |

| 0.08 – 0.16 | 0.15 – 0.35 | 0.7 – 1.1 | 0.08 – 0.2 | 0.08 – 0.15 |

Temperature of critical points of the material steel A12

| Ac1 = 735, Ac3(Acm) = 866, Ar3(Arcm) = 840, Ar1 = 685 |

Mechanical properties at T=20oC of the material steel A12

| Assortment | Size | Eg. | sв | sT | d5 | y | KCU | Thermal change |

| – | mm | – | MPa | MPa | % | % | kJ/m2 | – |

| The steel is hot rolled. | 100 | 410 | 22 | 34 | Delivery status |

| The hardness of the material is hot-rolled steel A12, | HB 10 -1 = 160 MPa |

| The hardness of the material is steel A12, calibrated cold-worked, | HB 10 -1 = 217 MPa |

Physical properties of the material steel A12

| T | E 10– 5 | a 10 6 | l | r | C | R 10 9 |

| hail | MPa | 1/Grad | W/(m deg) | kg/m3 | J/(kg deg) | Ohm m |

| 20 | 1.98 | 7830 | ||||

| 100 | 1.83 | 11.9 | 78 | 470 | ||

| 200 | 12.5 | 67 | ||||

| 300 | 1.66 | 479 | ||||

| 400 | 13.6 | 517 | ||||

| 500 | 14.2 | |||||

| 600 | 571 | |||||

| T | E 10– 5 | a 10 6 | l | r | C | R 10 9 |

Technological properties of the material steel A12

| Weldability: | not applicable to welded structures. |

| Flock Sensitivity: | sensitive. |

| Tendency to temper brittleness: | not inclined. |

Foreign analogues of the material A12 steel Attention! Both exact and closest analogues are indicated.

| USA | Germany | Japan | France | England | European Union | Italy | Spain | China | Sweden | Bulgaria | Poland | Romania | Czech |

| – | DIN,WNr | JIS | AFNOR | B.S. | EN | UNI | UNE | G.B. | SS | BDS | PN | STAS | CSN |

| 1212 | |||||||||||||

| B1112 | |||||||||||||

| B1113 | |||||||||||||

| B1114 | |||||||||||||

| G11080 |

| 10S20 |

| 10SPb20 |

| 15S20 |

| 9S20 |

Designations:

| Mechanical properties : | |

| sв | – Short-term strength limit, [MPa] |

| sT | – Proportional limit (yield strength for permanent deformation), [MPa] |

| d5 | – Elongation at break, [%] |

| y | – Relative narrowing, [%] |

| KCU | – Impact strength, [kJ/m2] |

| HB | – Brinell hardness, [MPa] |

| Physical properties: | |

| T | – Temperature at which these properties were obtained, [Deg] |

| E | – Modulus of elasticity of the first kind, [MPa] |

| a | – Coefficient of thermal (linear) expansion (range 20o – T), [1/degree] |

| l | – Thermal conductivity coefficient (heat capacity of the material), [W/(m deg)] |

| r | – Material density, [kg/m3] |

| C | – Specific heat capacity of the material (range 20o – T), [J/(kg deg)] |

| R | – Electrical resistivity, [Ohm m] |

| Weldability: | |

| no limits | – welding is performed without heating and without subsequent heat treatment |

| limited weldability | – welding is possible when heated to 100-120 degrees. and subsequent heat treatment |

| difficult to weld | – to obtain high-quality welded joints, additional operations are required: heating to 200-300 degrees. during welding, heat treatment after welding - annealing |

Brand of steel and alloys

yaruse.ru

Steel 12ХН3А – definition of steel grade, GOST, material characteristics

Steel grade – 12ХН3А

Standard – GOST 4543

Substitute – 12ХН2, 20ХН3А, 25ХГТ, 12Х2Н4А, 20ХНР

Steel 12ХН3А

contains an average of 0.12% carbon,

X

- indicates the chromium content in steel is approximately 1%,

H3

- indicates the nickel content in steel is about 3%, the letter

A

at the end of the brand means that the steel belongs to the high-quality category.

Steel 12ХН3А is used for the manufacture of large critical parts. Steel products are subjected to carburization followed by heat treatment; sometimes this steel is used for non-cemented parts. Steel with high strength, toughness and hardenability.

Gears, axles, shafts, worms, claw couplings, piston pins and other parts are made from steel 12ХН3А

| Mass fraction of basic chemical elements, % | ||||

| C – carbon | Si – silicon | Mn – manganese | Cr – chromium | Ni – nickel |

| 0,09-0,16 | 0,17-0,37 | 0,30-0,60 | 0,60-0,90 | 2,75-3,15 |

| Temperature of critical points, °C | |||

| Ac1 | Ac3 | Ar1 | Ar3 |

| 715 | 773 | 659 | 726 |

| Technological properties | |

| Forging | Forging temperature, °C: beginning 1220, end 800. Sections up to 100 mm are cooled in air, sections 101-300 mm are cooled in a pit. |

| Weldability | Limited weldability. Welding methods: manual arc welding, automatic arc welding, resistance welding. |

| Machinability | In the hot-rolled state at HB 183-187 and σв = 590 MPa: Kv hard alloy = 1.25 Kv high-speed steel = 0.95 |

| Flock sensitivity | Sensitive |

| Tendency to temper brittleness | Inclined |

| Physical properties | Test temperature, °C | |||||||||

| 20 | 100 | 200 | 300 | 400 | 500 | 600 | 700 | 800 | 900 | |

| Modulus of normal elasticity E, GPa | 200 | – | – | – | – | – | – | – | – | – |

| Modulus of elasticity under torsional shear G, GPa | – | – | – | – | – | – | – | – | – | – |

| Density ρn, kg/m3 | 7850 | 7830 | 7800 | 7760 | 7720 | 7680 | 7640 | – | – | – |

| Thermal conductivity coefficient λ W/(m*K) | – | 31 | – | – | 26 | – | – | – | – | – |

| Electrical resistivity ρ, nOhm*m | – | – | – | – | – | – | – | – | – | – |

| 20-100 | 20-200 | 20-300 | 20-400 | 20-500 | 20-600 | 20-700 | 20-800 | 20-900 | 20-1000 | |

| Linear expansion coefficient α*106, K-1 | 11,8 | 13,0 | 14,0 | 14,7 | 15,3 | 15,6 | – | – | – | – |

| Specific heat capacity c, J/(kg*K) | – | – | – | 528 | 540 | 565 | – | – | – | – |

tekhnar.ru

Production of metal structures at the North-West plant

ZMK "North-West" is a metal structures plant in St. Petersburg. The company's products are widely used in construction, the oil and gas industry, and the automotive industry. We produce metal products for retail and wholesale sales. We produce serial products and accept orders for individual production of non-standard designs. The product range includes metal foundations and trusses, mooring and port structures, lighting towers, containers and other products. The plant performs all types of metalworking - cutting, chopping, bending, rolling, galvanizing, milling and turning.

properties and characteristics of the brand, application. Steel A and its chemical composition.

Group A steels are classified as structural carbon steels of ordinary quality, but, most often, endowed with increased machinability. Strictly regulated mechanical characteristics and properties play a role here against the background of relative freedom in terms of the chemical composition of the metal. As a rule, steel A is used to create components and entire structures without initially undergoing forging, stamping or other hot or heat treatment. As a result, hot-rolled steel grade A always retains its original properties.

Steel A12 and A20

The most popular materials of this class are considered to be alloys A12 and A20, which are actually analogues of each other. These are structural materials of increased machinability, characterized by low cost and high manufacturability. This alloy is supplied to industrial enterprises in the following form (in accordance with GOST):

- GOST 1414-75, GOST 2879-2006, GOST 2590-2006, GOST 2591-2006 – long and shaped rolled products

- GOST 1414-75 and GOST 14955-77 – silver and ground rods.

- GOST 8559-75, GOST 1414-75, GOST 8560-78 – calibrated rods

Mechanical and physical properties of A12 steel

The hardness of this alloy is HB 10-1 = 160 MPa. The material is flake-sensitive and therefore requires strict adherence to smelting technology. However, it is not prone to temper brittleness and is not used as part of welded structures. The basic mechanical and physical properties of A12 steel can be found here:

Chemical composition of the alloy

The number 12 in the brand designation traditionally indicates the average percentage of carbon, expressed in hundredths of a percent. The chemical composition of A12 steel is the following set of elements:

- C – 0.08-0.16%

- Mn – 0.7-1.1%

- Si – 0.15-0.35%

- P – 0.08-0.15%

- S – 0.08-0.2%

- Cu – no more than 0.25%

Application of grade A steels

A12 (A20) steel is widely used in the creation of industrial equipment: bushings, rollers and axles are cast from it, and gears and gears are made from it. In general, this material is excellent for the manufacture of small bolts, screws and other small parts - complex shapes, lightly loaded, intended for processing using automatic machines. A rather important characteristic of the alloy can be considered its compliance with increased requirements for the dimensional accuracy of the resulting parts and the quality of their surfaces. In other words, this steel is a material with increased machinability.

fx-commodities.ru

Supply of 12X2NVFA

| Sheets and strips | GOST 11268-76, GOST 11269-76 |

| Steel pipes and connecting parts for them | GOST 21729-76, TU 14-3-967-80, TU 14-3-463-2005, TU 14-3-975-80 |

| Sheets and strips | GOST 82-70 |

| Classification, nomenclature and general norms | OST 1 90005-91 |

| Blanks. Blanks. Slabs | OST 1 90280-79, TU 1-92-156-90, TU 14-1-1278-75 |

| Long and shaped rolled products | OST 1 92049-76, TU 14-1-1885-85, TU 14-1-2854-79, TU 14-1-950-74, TU 14-1-3238-81, TU 14-1-3238-2006 , TU 14-1-1271-75 |

| Long and shaped rolled products | TU 14-2-490-82 |

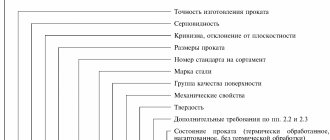

Steel A12 - characteristics, chemical composition, properties, hardness

Bulletin board | Steel A12 - characteristics, chemical composition, properties, hardnessSteel A12General informationSubstitute

Chemical composition

Mechanical propertiesMechanical properties

Mechanical properties at elevated temperatures

Mechanical properties depending on the degree of deformation

Technological properties

Critical point temperature

Physical properties

[ Back ] | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

s-metall.com.ua