STATE STANDARD OF THE USSR UNION

FORGINGS FROM STRUCTURAL CARBON AND ALLOY STEEL

GENERAL TECHNICAL CONDITIONS

GOST 8479-70

USSR STATE COMMITTEE ON STANDARDS Moscow

STATE STANDARD OF THE USSR UNION

| FORGINGS FROM STRUCTURAL CARBON AND ALLOY STEEL General technical conditions Structural carbon and alloyed steel forgings. General specifications | GOST 8479-70* Replaces GOST 8479-57 |

Resolution of the Committee of Standards, Measures and Measuring Instruments under the Council of Ministers of the USSR dated January 15, 1970 No. 59 established the introduction date

from 01.01.71

Decree of the State Standard of June 23, 1986 No. 1671

validity period extended

until 01/01/92

Failure to comply with the standard is punishable by law

This standard applies to general-purpose forgings with a diameter (thickness) of up to 800 mm from structural carbon, low-alloy and alloy steel, manufactured by forging and hot stamping.

The standard establishes groups of forgings and basic technical requirements for their acceptance and delivery.

The standard does not replace the current standards and technical specifications for certain types of forgings, which are subject to special requirements regarding the production method, surface quality, the use of special types of heat treatment, etc.

Forgings. Definition, standards, types

Forging, forged blank is an intermediate product of metallurgy, obtained as a result of plastic deformation of metal: forging, or hot stamping in forging and stamping production.

Production, taking into account the weight of products, their shapes, allowances, and quality of processing, is carried out in accordance with the following standards:

- GOST 1133-71 for round and square forgings

- GOST 8479-70 for forgings made of structural carbon and alloy steel

- GOST 7505-89 for steel stampings

- GOST 26645-85 for castings

If the dimensions of the required part significantly exceed the standards for long products, it is advisable to obtain the initial workpiece using the forging or stamping method. For example, huge shafts and rings, the mass of which can reach about 10-350 tons. Such critical parts must meet a number of technical characteristics and requirements.

Separately, it is worth noting forgings with the Sea and River register, which are manufactured with preliminary mechanical processing and subsequent ultrasonic testing. They are used for the production of propeller shafts, pistons, lifting and mast devices, coamings and other parts used in shipbuilding.

Types and shape of forgings

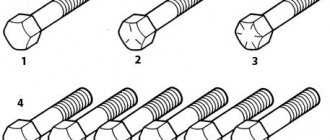

According to the cross-sectional shape, forgings are:

- round (forged circle, forged axles and shafts..)

- square

- rectangular

- rings, discs (with and without holes, rolled out)

- cylinders (with and without hole)

Advantages of forgings over cast billets:

- Forgings have better mechanical properties: higher strength and toughness, and are more resistant to fatigue loads. Therefore, forgings are better suited for parts that require high strength, toughness and resistance.

- Forged blanks are less susceptible to wear and can withstand high loads well

- Forgings are better machined.

Preparation method

Forging comes in a variety of shapes, depending on the shape of the press. Forgings from square blanks are most often used.

They are produced in two ways:

- by cold or hot stamping. The main instrument of this production is the press;

- using machine forging, this type of metal processing differs little from hand forging. The production technology is the same, the only difference is that not human force is used, but machine power.

Using a press, you can produce forgings at a lower cost, since productivity increases due to the processing of all surfaces of the product at once. This method also allows you to achieve precision in the manufacture of forgings.

During the forging process, the parts are more durable, since the metal is in a free position at the time of processing. As a result, it becomes very strong, but at the same time such forging is characterized by high ductility.

Characteristics of forgings and stampings.

Forging is a metal blank formed by mechanical action by forging or die stamping on primary metal blanks.

Using forging or stamping, the workpiece is given the required shape and dimensions, after which the forging is sent for further processing to obtain the finished product.

Forgings represent a wide variety of parts with rather complex configurations. For large production volumes, it is economically profitable to produce various elements and workpieces from forgings .

Open-die forgings are produced in a variety of ways. There is free forging, during which the workpiece is processed by numerous hammer blows, with each face of the forging being formed separately.

Unlike open forging, hot die forging allows the simultaneous formation of several surfaces of stamped forgings due to the presence of the required number of surfaces in the die.

In addition, the stamp prevents the workpiece metal from spreading during pressure treatment. Stamping provides a higher speed of obtaining forgings , and therefore greater productivity, compared to free forging.

The use of hot die forging makes it possible to obtain forgings with a uniform structure and a clean surface. At the same time, stamping ensures high dimensional accuracy of the forging and allows one to obtain quite complex product shapes, which is impossible when using free forging.

The weight of forgings can be almost anything - from a few grams to several tons, depending on what parts the workpiece will be used to produce.

Forgings are produced by two methods: press and hammer.

Forgings are classified

by type of metal and purpose.

Types of forgings by purpose

:

— forgings for the automotive industry

(cardan shaft forks, gears, crosspieces, flanges, levers, shafts, connecting rods, crankshafts, etc.);

— forgings for car building and fastening railway tracks (sectors, rings, washers, bolts, linings, fastenings, etc.);

— forgings for diesel locomotive construction

(pistons, piston heads, levers, valves, nuts, counterweights, etc.);

— forgings for other industries (vice jaws, flanges, anchors, bolts, nuts, washers, etc.).

Steel forgings are metal blanks made from various grades of steel.

Most steel forgings are produced by forging with hammers, crank hot forging presses, and automatic machines with closed and open dies.

Steel forgings are produced in various forms: in the form of disks, shafts, rings, bandages, and are subsequently used to produce these types of parts.

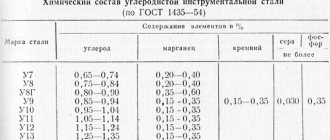

For the manufacture of steel forgings, various grades of steel can be used: carbon, tool and structural alloyed and others, depending on the required properties of the parts that will be produced from these blanks.

GOST 8479-70 Forgings made of structural carbon and alloy steel. General technical conditions

GOST 7829-70 Forgings made of carbon and alloy steel, produced by hammer forging. Allowances and tolerances.

Stampings

are called forgings (blanks) obtained by processing metal under pressure in presses using hot or cold stamping.

Steel stampings are steel forgings obtained as a result of metal deformation using presses, that is, by stamping. The production of steel stampings is carried out by hot and cold stamping.

In hot stamping, stamping is obtained by preheating the metal, which ensures its greater ductility and easier shaping of the metal into any desired shape. When metal is processed in a press without preheating it, we speak of obtaining stamping using the cold stamping method.

They also separate volumetric and sheet stamping: in the process of volumetric stamping, stampings of almost any volumetric shape required by the customer are obtained, and during the processing process several are simultaneously formed, which ensures the high productivity of this method of producing stamped forgings.

To produce volumetric stampings by hot stamping, rolled round or square profiles are used, pre-cut into blanks of a certain size in accordance with the dimensions of the stamp.

To obtain stamped forgings of flat shape, small thickness and almost any size, the sheet stamping method is used.

With sheet stamping, it is possible to produce flat-shaped stampings or spatial parts of almost any size (from a few millimeters to several meters) with a perfectly smooth surface that does not require further processing.

Stampings are produced in different projection areas and weights, and also have a wide variety of geometric shapes.

Among the most popular stamped blanks there are stamped forgings of the following forms: round stampings (blanks for wheels, flanges, gears); elongated shape (shafts, levers, etc.) or arbitrary spatial shape.

To improve performance properties, stampings as blanks for future parts are subjected to various types of heat treatment (normalization, annealing, hardening, etc.). The resulting stampings must undergo ultrasonic testing, control of geometric dimensions, metal structure, as well as tests of metal properties in various temperature environments.

Most often, stampings are made from structural carbon, alloy and low-alloy steels, tool steels and alloys with different physical properties. only slightly changes its thickness during the stamping

Sheet stamping allows you to produce parts of any size - from fractions of millimeters to several meters. It can also be used to obtain spatial details, which is possible with the high ductility of the metal. Due to this requirement , low-carbon steel, ductile alloy steel, copper, aluminum, titanium, etc. are used stamping You can also give shape to non-metallic products using a stamp - leather, plexiglass, textolite and other materials.

Sheet stamping is convenient in that it allows you to produce parts of any size, even the smallest, with a smooth surface that does not require further processing, while the required dimensions and shapes of the product are observed as accurately as possible. Thanks to its simple automation process, stamping can be used in both small and large volume production. Products obtained through the sheet stamping are used in almost all areas of production - automotive, aviation, electrical industry, instrument making and other industries.

To implement the stamping , special devices are used - presses (in other words, mechanical impact on the material).

As a rule, stamping is distinguished by the type of equipment used:

stamping in tool dies,

· stamping with elastic media,

· pulse stamping:

o magnetic pulse,

o hydro-pulse,

· Explosion stamping.

Forgings and stampings are very diverse in shape and there is no classification on this basis.

They are usually divided according to

1 from steel grades from which they are manufactured

2 as intended.

For forgings and stampings of each type there are GOST standards developed by TU, which are attached to the drawing.

Example: Carbon and alloy steel forgings, produced by open forging

forgings from structural alloy steel

According to the standards, they are classified into certain groups depending on their purpose.

The higher the group number, the more responsible the forging

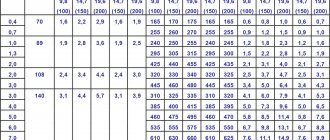

Forgings are classified according to strength into categories. Strength values are given in accordance with the standards.

Manufacturing accuracy is required (allowances for machining) are also given in GOSTs.

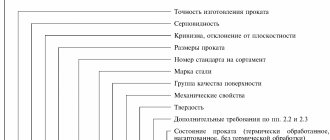

Forgings and stampings are ordered according to a drawing, in which, in addition to the shape, dimensions, manufacturing accuracy must be indicated

1. steel grade and GOST, which it must comply with

2. test group

3. strength category in accordance with GOST

Dimensions are not indicated in orders, but only permissible deviations from the dimensions according to GOST.

Forging is a metal blank formed by mechanical action by forging or die stamping on primary metal blanks.

Using forging or stamping, the workpiece is given the required shape and dimensions, after which the forging is sent for further processing to obtain the finished product.

Forgings represent a wide variety of parts with rather complex configurations. For large production volumes, it is economically profitable to produce various elements and workpieces from forgings .

Open-die forgings are produced in a variety of ways. There is free forging, during which the workpiece is processed by numerous hammer blows, with each face of the forging being formed separately.

Unlike open forging, hot die forging allows the simultaneous formation of several surfaces of stamped forgings due to the presence of the required number of surfaces in the die.

In addition, the stamp prevents the workpiece metal from spreading during pressure treatment. Stamping provides a higher speed of obtaining forgings , and therefore greater productivity, compared to free forging.

The use of hot die forging makes it possible to obtain forgings with a uniform structure and a clean surface. At the same time, stamping ensures high dimensional accuracy of the forging and allows one to obtain quite complex product shapes, which is impossible when using free forging.

The weight of forgings can be almost anything - from a few grams to several tons, depending on what parts the workpiece will be used to produce.

Forgings are produced by two methods: press and hammer.

Forgings are classified

by type of metal and purpose.

Types of forgings by purpose

:

— forgings for the automotive industry

(cardan shaft forks, gears, crosspieces, flanges, levers, shafts, connecting rods, crankshafts, etc.);

— forgings for car building and fastening railway tracks (sectors, rings, washers, bolts, linings, fastenings, etc.);

— forgings for diesel locomotive construction

(pistons, piston heads, levers, valves, nuts, counterweights, etc.);

— forgings for other industries (vice jaws, flanges, anchors, bolts, nuts, washers, etc.).

Steel forgings are metal blanks made from various grades of steel.

Most steel forgings are produced by forging with hammers, crank hot forging presses, and automatic machines with closed and open dies.

Steel forgings are produced in various forms: in the form of disks, shafts, rings, bandages, and are subsequently used to produce these types of parts.

For the manufacture of steel forgings, various grades of steel can be used: carbon, tool and structural alloyed and others, depending on the required properties of the parts that will be produced from these blanks.

GOST 8479-70 Forgings made of structural carbon and alloy steel. General technical conditions

GOST 7829-70 Forgings made of carbon and alloy steel, produced by hammer forging. Allowances and tolerances.

Stampings

are called forgings (blanks) obtained by processing metal under pressure in presses using hot or cold stamping.

Steel stampings are steel forgings obtained as a result of metal deformation using presses, that is, by stamping. The production of steel stampings is carried out by hot and cold stamping.

In hot stamping, stamping is obtained by preheating the metal, which ensures its greater ductility and easier shaping of the metal into any desired shape. When metal is processed in a press without preheating it, we speak of obtaining stamping using the cold stamping method.

They also separate volumetric and sheet stamping: in the process of volumetric stamping, stampings of almost any volumetric shape required by the customer are obtained, and during the processing process several are simultaneously formed, which ensures the high productivity of this method of producing stamped forgings.

To produce volumetric stampings by hot stamping, rolled round or square profiles are used, pre-cut into blanks of a certain size in accordance with the dimensions of the stamp.

To obtain stamped forgings of flat shape, small thickness and almost any size, the sheet stamping method is used.

With sheet stamping, it is possible to produce flat-shaped stampings or spatial parts of almost any size (from a few millimeters to several meters) with a perfectly smooth surface that does not require further processing.

Stampings are produced in different projection areas and weights, and also have a wide variety of geometric shapes.

Among the most popular stamped blanks there are stamped forgings of the following forms: round stampings (blanks for wheels, flanges, gears); elongated shape (shafts, levers, etc.) or arbitrary spatial shape.

To improve performance properties, stampings as blanks for future parts are subjected to various types of heat treatment (normalization, annealing, hardening, etc.). The resulting stampings must undergo ultrasonic testing, control of geometric dimensions, metal structure, as well as tests of metal properties in various temperature environments.

Most often, stampings are made from structural carbon, alloy and low-alloy steels, tool steels and alloys with different physical properties. only slightly changes its thickness during the stamping

Sheet stamping allows you to produce parts of any size - from fractions of millimeters to several meters. It can also be used to obtain spatial details, which is possible with the high ductility of the metal. Due to this requirement , low-carbon steel, ductile alloy steel, copper, aluminum, titanium, etc. are used stamping You can also give shape to non-metallic products using a stamp - leather, plexiglass, textolite and other materials.

Sheet stamping is convenient in that it allows you to produce parts of any size, even the smallest, with a smooth surface that does not require further processing, while the required dimensions and shapes of the product are observed as accurately as possible. Thanks to its simple automation process, stamping can be used in both small and large volume production. Products obtained through the sheet stamping are used in almost all areas of production - automotive, aviation, electrical industry, instrument making and other industries.

To implement the stamping , special devices are used - presses (in other words, mechanical impact on the material).

As a rule, stamping is distinguished by the type of equipment used:

stamping in tool dies,

· stamping with elastic media,

· pulse stamping:

o magnetic pulse,

o hydro-pulse,

· Explosion stamping.

Forgings and stampings are very diverse in shape and there is no classification on this basis.

They are usually divided according to

1 from steel grades from which they are manufactured

2 as intended.

For forgings and stampings of each type there are GOST standards developed by TU, which are attached to the drawing.

Example: Carbon and alloy steel forgings, produced by open forging

forgings from structural alloy steel

According to the standards, they are classified into certain groups depending on their purpose.

The higher the group number, the more responsible the forging

Forgings are classified according to strength into categories. Strength values are given in accordance with the standards.

Manufacturing accuracy is required (allowances for machining) are also given in GOSTs.

Forgings and stampings are ordered according to a drawing, in which, in addition to the shape, dimensions, manufacturing accuracy must be indicated

1. steel grade and GOST, which it must comply with

2. test group

3. strength category in accordance with GOST

Dimensions are not indicated in orders, but only permissible deviations from the dimensions according to GOST.

MARKING, TRANSPORTATION, STORAGE

3.1. The marking location is indicated on the forging drawing. The marking must be clear and contain the information specified in the table. 5.

Table 5

| Group number | Type of marking | |||

| Stamp of the technical control department | Part drawing number | Heat number or steel grade | Forging number | |

| I | Indicated | Indicated | – | – |

| II | Same | Same | Indicated | – |

| III | Same | Same | Same | – |

| IV | Same | Same | Same | – |

| V | Same | Same | Same | Indicated |

Note. The type of marking of stamped forgings is established by agreement between the manufacturer and the consumer.

(Changed edition, Amendment No. 1).

3.2. For forgings weighing up to 10 kg, batch marking on a tag is allowed.

3.3. Each batch of forgings or forgings accepted by technical control is accompanied by a quality document, which indicates:

name or trademark of the manufacturer;

Order number;

number of forgings in a batch and their weight (for group V – forging number);

drawing number;

steel grade and designation of standard or technical specifications;

chemical composition;

heat number;

group of forgings;

strength category for groups IV and V or hardness standards for forgings of groups II and III and the designation of this standard;

type of heat treatment;

test results provided for by this standard;

results of additional tests provided for in the forging drawing or order conditions.

Note. The content of accompanying documents for forgings produced by die forging is established by agreement between the manufacturer and the consumer.

3.2; 3.3. (Changed edition, Amendment No. 3).

3.4. Forgings must be stored in dry, closed warehouses.

It is allowed to store forgings under a canopy or on trestles.

3.5. (Deleted, Amendment No. 2).

Receipt methods

Manufacturing forgings is a rather complex technological process. There are two methods for obtaining blanks:

- Forging. This method of producing forgings is characterized by preheating the metal to a plastic state. After this, the workpiece is given the desired shape using the impact load of a hammer or press. A feature of the process is the free position of the workpiece during processing. Forgings produced by forging are distinguished by high machining allowances. This figure is almost 2 times higher than that for stamped products. Bending, drawing and drawing are also types of forging.

- Stamping. The main role in the production process is played by special equipment called a die. The matrix exerts high pressure on the workpiece. Its shape completely follows the contours of the finished product. The function of the power element is performed by the punch. The production process can take place in both cold and hot modes. The method is highly productive. No highly qualified workers are needed to service the equipment. Compared to forging, the finished product has more accurate dimensions and less surface roughness. The only disadvantage of stamping is the high cost of the equipment. It is advisable to use it only in mass production.

Application area

Forgings are quite widespread. This can be explained by the versatility of the form. They can be made of steel with different characteristics, depending on this forgings are used:

- to produce products with high strength, forgings made from carbon steel are used;

- forgings are used where increased ductility of the workpiece is required; they have found their application in mechanical engineering; stamping forgings are also often used in this industry;

- shipbuilding, as well as the electrical industry, use square forgings made from stainless steel;

- forgings, in the production process of which alloy steel was used, are of increased quality, and especially durable parts are made from them.

The use of parts for mechanical engineering and other industries in the manufacturing process allows several times to reduce the costs of production and processing of the product.

Moreover, the higher the dimensional accuracy of the forged workpiece, the easier it is to produce the final product from it. Tweet

Forging manufacturing process

Regardless of the method of obtaining the finished product, the production of forgings consists of the following stages:

- Cutting rolled metal into pieces of the required size. The standard size and cross-section of the feedstock depends on the capabilities of the suppliers. It can be a circle, square, polyhedron, and even a channel or I-beam.

- Metal deformation. During forging, the workpiece is ground under the action of repeated blows. Stamping is characterized by uniform pressure on the forging, resulting in the formation of a finished surface.

- Normalization and tempering of the workpiece.

- The quality of the finished product is determined by technical control specialists.

Advantages and disadvantages of the process

Hot stamping has some advantages and disadvantages relative to forging.

Advantages of GOSH:

- high productivity exceeds forging hundreds of times;

- production of finished products of complex configuration;

- relative simplicity of a specialist’s work and faster training in the necessary skills;

- fewer tolerances and allowances, since only the contacting surfaces of the parts are machined, and the remaining surfaces have satisfactory geometric parameters and roughness. After calibration, tolerances are only 0.05 mm.

The disadvantages are:

- the weight of the finished product does not exceed 3.5 tons;

- the high cost of a special die tool in contrast to a forging tool. The die is made on the basis of high-quality steel and is used exclusively for a certain size of forging;

- the need to use more powerful equipment due to the deformation of the entire workpiece, and not part of it, which requires an increase in the impact force. And also the walls of the die cavity experience pressure during the flow of metal, which affects its wear resistance.

DETERMINATION OF THE WEIGHT AND DIMENSIONS OF THE INITIAL FORGING BLANK

Determination of the weight of the initial blank for forgings made from rolled products is made taking into account inevitable technological losses, i.e. metal waste for trimming and waste. The weight of the initial blank for forgings made from rolled products is determined by the formula

The volumes of forgings of simple shape (cylinder, ball, cone, etc.) are determined using stereometric formulas.

The specific gravity for carbon and alloy steels is 7.85 g/cmg. Metal volumes for small and medium forgings are usually calculated in cubic centimeters. The weight of the metal is accordingly obtained in grams.

To determine the volume of a forging that has a complex shape, the forging in the drawing is divided into sections that have the simplest and most convenient geometric shape for calculation.

After calculating the volumes of individual parts in cubic centimeters, they are summed up and the volume of the forging is obtained. Then the volume of the forging is multiplied by the specific gravity and, dividing this product by 1000, the weight of the forging in kilograms is obtained.

If there is a finished forging, its weight and then its volume are determined by weighing. The weight of waste for Go6 shearing (including waste for offcuts) is determined depending on the shape of the forging and the operations performed, provided for by the technological process. The weight of waste waste Gyz is determined depending on the weight of the heated metal and the number of heatings. Therefore, when determining the weight of the initial workpiece, the weight of waste waste is taken on average from 2 to 3% of the weight of the heated metal for full heating and from 1.5 to 2% for each heating. When heated in furnaces, where the fuel is in direct contact with the heated metal, the waste reaches 4-5% for each complete heating. Due to the difficulty of determining their value, waste from cutting and waste is usually taken on the basis of practical

ical data. The total weight of waste for trimming and waste for various forgings as a percentage of the weight of the forgings is approximately:

1) for forgings such as a square bar, a round roller, produced by broaching, cutting and straightening, 6-7%;

2) for forgings such as a roller with a round or square head, produced by broaching, rounding, cutting and straightening, 7-8%;

3) for forgings such as earrings, staples, produced by broaching, cutting, bending and straightening, 8-10%;

4) for roller-type forgings with double-sided shoulders, produced by broaching, notching and cutting, 9-10%;

5) for forgings of handles produced by broaching, notching, cutting and straightening, 12-13%;

6) for forgings such as a crank shaft, manufactured by broaching, notching, cutting and straightening, 15-18%.

In the case of using several heatings in these examples, it is necessary to add metal for waste to the total percentage (for each heating from 1.5 to 2%).

The initial cross-section of the workpiece is determined depending on the selected technological process.

For forgings produced by the upsetting method, the workpiece is selected in such a way that the ratio of height to diameter for round workpieces or height to side of a square for workpieces of square section is no more than 1.5-2.5. If the ratio of the height of the workpiece to the diameter or side of the square is more than 2.5, then it is possible that it will bend during upsetting.

For forgings produced by drawing, the cross-section of the workpiece is determined from the condition of ensuring the required forging size, i.e.

After calculating the required cross-section of the rolled billet, a workpiece of the required cross-section is selected according to GOST tables. If these tables do not contain the required section size, then the nearest larger size is taken.

The length of the workpiece is determined by its volume and the cross-section of the original workpiece.

The volume of the workpiece is determined by the formula

content .. 31 32 36 ..

Application benefits

The production of the products in question is carried out by foundries. They are supplied with forging blanks, where they undergo a full technological cycle, including heat treatment. The finished product has the following advantages:

- excellent performance characteristics;

- stable mechanical properties;

- high Brinell resistance;

- low cost.

The workpiece does not require special storage conditions. If necessary, they can even be stored on an open construction site. They retain their properties for a long time.