Knives for fishing, hunting, surgical, gardening, throwing, kitchen, stationery. There are a large number of piercing and cutting products from different manufacturers on the market. So how can you accurately choose a product that will satisfy your functional needs? The first thing you should pay attention to is the hardness of the blade steel. It is this that affects the strength, wear resistance and reliability of the knife.

The balanced hardness of the blade maintains the factory sharpening for a long time, reducing the risk of breakage, deformation and crumbling of the metal during operation.

How does steel grade affect a knife?

The knife community's literacy has increased significantly, but debate about what grade of steel should be continues. In addition to hardness and resistance to moisture, it must hold the cutting edge, cut cleanly, be easy to sharpen, and have low fragility. The shape and purpose of the knife, its durability and practicality depend on what steel is selected.

Manufacturers sometimes copy a successful knife model from competitors, but due to the difference in steels and hardening, only external similarities emerge.

For example, a knife made of simple budget steels like 420 can be sharpened into the sharpest razor, but it will not hold an edge - it will become dull to a moderately sharp state after only 10-15 cuts. This does not mean that such a product is of poor quality. Some manufacturers, for example Buck, deliberately use this steel on their expensive models, since their credo is practicality. “Soft” steels are easy to sharpen and practically do not rust.

Elite super steels do not provide a solution to all problems: knives hold an edge and have the greatest hardness, but their edges can be brittle and chip, and sharpening such steels without diamond abrasives is difficult.

Most of the knives made from super steels are flagship exhibition models, not designed for harsh use: they are more suitable for decorating a shelf than for cutting up a moose carcass in the middle of a snow-covered taiga.

There is no ideal steel and cannot exist: for a durable machete, high-carbon rusting steel SAE 1070 is suitable, for an urban warehouseman for every day - inexpensive stainless steel AUS-8 or 8Cr13MoV, and if you give it to a connoisseur, you should choose CM154 or M390.

Characteristics of knife steels

Steel grades have a set of characteristics, but some of them are understandable only to metallurgists and blacksmiths. For beginners, we will highlight the main ones:

- Hardness

- an objective characteristic that is expressed in units on the Rockwell scale. It is indicated in the numerical value HRC. For modern knives, the norm is from 55 to 60. Only powder supersteels have a hardness of over 60 points without increasing the brittleness of the material, but their limit is 65-68 HRC, after which the material inevitably loses strength. Hardness is determined not only by the type of steel, but also by its hardening. So even the most expensive ones can be damaged by inept sharpening on a grinder or sharpening wheel.

- Abrasion resistance

- a characteristic that depends on the crystalline structure of the steel and is responsible for the rate of dulling of the knife. Powder steels, which have a uniform fine-crystalline structure, take longer to sharpen and dull than unforged soft steels with a heterogeneous structure.

- Plastic

- the reverse side of hardness. It determines how the knife resists impacts and bending loads. Where a hard blade made of high-carbon steel will crumble, a ductile steel will only have a repairable edge jam.

- Corrosion resistance

- even stainless steel will rust under the “right” conditions, let alone high-carbon steels. In addition to the corrosive destruction of the blade, there is a chemical dulling of the edge: some types of steel with a weak oxide film like D2 or 8Cr13MoV can lose their sharpness over time - moisture from the air causes processes on the cutting edge and destroys it. Corrosion resistance is increased by additives added to the detriment of other qualities, and truly stainless knives have rather modest cutting characteristics.

High-quality knife steel is a compromise between these mutually exclusive characteristics, and therefore they have not yet come up with a brand that would be the best of the best.

Knife steel alloy composition

The characteristics of knife steels are regulated by the stages of production: from steelmaking to casting, forging, hardening and even sharpening - every little detail is important. But these parameters are set by the composition of the alloy, in which each element works for the overall plan.

Below we will talk about the purpose of alloying elements so that you can understand the properties of the alloy by reading its composition:

- Carbon (C)

- what makes iron steel. The more of it, the harder the blade, the longer it retains its sharpness, but the more fragile and susceptible to rust. The optimal content in modern steel is about 0.5%. There is a lot of carbon in traditional Yakut knives, puukko, higonokami - and here this is a tribute to tradition, but not a practical necessity.

- Chromium (Cr)

- main anti-corrosion additive. It significantly affects the crystal lattice of the material, forming large grains - carbides - with carbon and increasing abrasive resistance. A large amount of chromium can increase the brittleness of the metal, but powder steels are much less susceptible to this drawback due to the finely dispersed equal distribution of grains throughout the entire volume. Stainless steels start at 13% chromium content.

- Manganese (Mn)

is another key additive that increases hardness and hardenability, but can make the alloy brittle.

- Vanadium (V)

— chrome assistant. It complements the properties of Cr and increases the ductility of the alloy.

- Molybdenum (Mo)

— increases plasticity, compensates for the fragility of other additives. It increases the alloy's ability to harden.

- Nickel (Ni)

- reduces the fragility of the alloy, increases refractoriness and hardening ability.

- Cobalt (Ko)

- binds all the elements of the alloy, facilitates the creation of chemical bonds and increases the hardness of the metal.

The remaining elements are used for the stability and quality of the steel during the welding stage. They do not affect the cutting properties of the knife themselves.

Now, having seen the X50CrMoV15 steel grade, you can understand that this is a standard easy-to-sharpen stainless steel with 0.5% carbon and 15% chromium and a small content of alloying additives. And domestic 95Х18 is a high-carbon (0.95%) and high-chromium (18%) steel with high hardness, weakness to impact and a tendency to corrosion in an aggressive environment.

Differences in material composition

Any grade of steel contains a mixture of iron and carbon. To improve its characteristics, alloying elements are also added:

- chromium – protects products from corrosion;

- nickel – enhances strength properties and prevents metal from rotting;

- manganese - allows you to make the blade of the desired shape. Allows metal forging;

- vanadium – increases strength, increases service life;

- silicon – creates high strength;

- tungsten – enhances corrosion properties, increases strength indicators.

The carbon concentration determines the type of metal. He can be:

- low carbon;

- medium carbon;

- high carbon.

If additional chemical elements are included in the alloy, it becomes alloyed. When the concentration of these substances exceeds 10-50%, the steel is called high-alloy.

To increase the strength of the metal and give it additional toughness, alloying with molybdenum is carried out. For example, in Japanese blades its concentration is 8%.

The blade becomes harder with vanadium and tungsten additives (8%). If the chromium concentration exceeds 13%, cutting characteristics improve and the blade becomes resistant to rust.

Stainless steel for knives 440C deserves special attention. The blade retains its original sharpness for a long time. When the molybdenum concentration is 4%, the alloy is elastic and wear resistance is greatly improved. A striking example of such material is BG-42.

Which one is better to choose?

An important role in any knife is played by the cutting blade, which differs in certain parameters. The quality of sharpness, anti-corrosion resistance, hardness, strength, flexibility and other important characteristics of the tool depend on the grade of steel used for its production.

For kitchen

Carbon steel is a common material for kitchen knives; our grandmothers used such products. Among the advantages are low cost, sharp blade, and ease of sharpening. However, this popular material is not without its drawbacks - it quickly dulls during use, is susceptible to corrosion, the metal tends to darken and transfer its flavor to products.

Experts recommend choosing steel for the kitchen that has an optimal balance of hardness and flexibility. These parameters must meet a number of criteria:

- high resistance to deformation and penetration of another solid into the material;

- the ability not to collapse, not to crumble;

- the knife does not lose shape and weight with constant friction;

- bending resistance;

- ease of cutting, without any effort.

In Russia, kitchen knives are made from steel 65X13. The metal contains a large percentage of chromium, so the products never become rusty. Most cheap cutting tools are made from this alloy.

65X13 is considered mild steel. It sharpens easily. Sometimes domestic manufacturers heat treat the blade, increasing its hardness. However, this happens quite rarely and is considered an exception to the general rule. The steel grade manufactured in the USA – 425Mod – has similar qualities.

The group of mild steels includes alloy 40Х12. The material is easy to process, but it cannot be hardened. The blades of such kitchen knives quickly become dull and bend easily. Due to the high chromium content, the products never rust. It is advisable to use musat for editing. An analogue is foreign steel - 420.

The best Russian companies, as well as professional craftsmen, choose alloy 95X18 for kitchen knives. The products have a beautiful appearance and never rust. In domestic conditions, sharpening is complicated. However, the factory sharpness lasts for a long period of time.

50Х14МФ is a universal steel, the production of which requires compliance with the technological process. It is used only in large enterprises that have the necessary equipment. After heat treatment, knife blades become very strong and elastic.

65Х13

95Х18

50Х14МФ

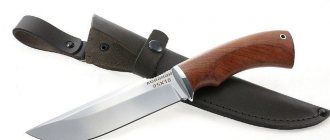

For hunting

A hunting knife is considered a multifunctional tool. With its help, a huge number of various operations are performed. Therefore, high-strength alloys with HRC 58-60 units are chosen for its manufacture. It is impossible to indicate a specific steel grade for a hunting specimen. Manufacturers use various variations, both domestic and foreign.

In America, 155 CM steel is chosen for the production of such products, the Japanese choose ATS 35. However, damask steel and Damascus steel occupy a special place. Their blade hardness exceeds 62-64 units. Such products are very expensive, but with such a knife it is easy to perform any operation, for example, planing, cutting, and so on.