In making knives, the most important thing is the material from which the blade is made. Widely used for these purposes from the middle of the last century to this day remains X12MF - a steel whose characteristics are suitable for the manufacture of parts for machines, gears, punches and for cold forging of knives, saws, cutters and cutters. Manufacturer Bob Dozier used this metal all his life to make knives, considering it the most worthy. An identical analogue of X12MF in America is D2 steel.

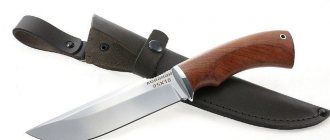

Knife made of steel X12MF.

Description of steel

Knives, when using X12MF steel, acquire a sharp cutting edge, and are able to maintain this quality in any adverse conditions. This alloy was originally developed for the needs of the engineering industry. But it should be taken into account that X12MF steel is not resistant to corrosion. Therefore, after using the knife, it should be dried and treated with Vaseline oil.

Explanation of the name

According to GOST 5950-2000, X12MF steel is classified as an alloyed ledeburite grade, which indicates a high carbon content. The decoding of the abbreviation includes the properties of steel of this grade. The letters mean the following:

- X – presence of chromium;

- 12 – percentage of chromium;

- M – presence of molybdenum;

- F – presence of vanadium in steel.

Owner reviews

Igor R., Leningrad region: “I have several knives for hunting and tourism. Experience has shown that X12MF steel is just right! I have a folding knife from this brand. All summer I went foraging for mushrooms, went fishing, but didn’t pay much attention to its care. The knife is still sharp, no signs of corrosion.”

Sergey N., Penza region: “Most of my knives are from X12MF. They darken a little, but there is no corrosion. With frequent use, sharpening lasts for 2 years. I recommend to everyone!"

Due to their high performance qualities and low cost, products made from X12MF steel are widely used in production and everyday life. They can serve a person for a long time without losing their properties. To do this, it is necessary to use knives for their intended purpose and take proper care of them.

Chemical composition

The exceptional quality of the metal alloy is due to its special composition:

| C, % | Si, % | Mn, % | Cr, % | V, % | Mo, % | Ni,% | S,% | P,% | Cu,% |

| 1.45-1.65 | 0.1-0.4 | 0.15-0.45 | 11.0-12.5 | 0.15-0.30 | 0.4-0.6 | up to 0.35 | up to 0.03 | up to 0.03 | up to 0.3 |

The alloy contains a small amount of sulfur and phosphorus. They are harmful impurities that reduce performance characteristics. And they make steel brittle. But you can feel the negative impact of unwanted additives only with an increase in the percentage of carbon.

Table: the importance of chemical elements in steel

| Chemical elements and their significance in the composition of knife steel: | |

| Carbon (C) | Without enough carbon it is very difficult to obtain a suitable hardness. This is the most important element in steel, it increases its strength. |

| Chromium (Cr) | gives the alloy increased anti-corrosion properties, chromium carbides increase wear resistance and hardenability. The high chromium content in the alloy affects its brittleness. |

| Manganese (Mn) | increases wear resistance and strength. Its content has a positive effect on the grain structure of the alloy and also contributes to excellent hardenability. |

| Molybdenum (Mo) | prevents steel from becoming brittle and allows it to maintain strength at high temperatures. Also increases corrosion resistance, strength, toughness. |

| Silicon (Si) | increases the strength and wear resistance of steel, like manganese, it makes steel more stable and reliable. |

| Vanadium (V) | forms the structure of carbides in such a way as to increase wear resistance, survivability and hardenability. |

| Nickel (Ni) | increases corrosion resistance and prevents steel from rotting. Increases the strength of steel. |

| Niobium (Nb) | the best carbide former, which provides corrosion resistance, ductility, and wear resistance. |

| Tungsten (W) | increases the wear resistance of steel, increases its stability during hardening and resistance to high temperatures. |

| Cobalt (Co) | enhances the effects of other individual elements in more complex alloys. Increases strength and hardness. |

| Sulfur (S) | is a harmful impurity, leading to the formation of cracks and tears. Typically, the sulfur content of high-quality steel is limited. The presence of sulfides is unacceptable for critical parts. |

| Phosphorus (P) | worsens the plastic properties of the alloy, causing the phenomenon of cold brittleness. In steels, phosphorus content is allowed in very small quantities. |

The best Russian masters of damask knives

It is believed that products made of alloy steel compete with damask knives in the modern market.

But is this really so, and are there craftsmen in Russia today capable of making forged knives that have no equal in quality? It turns out there is. The secret of high-quality damask steel is held by such masters as I. Pampukha and A. Biryukov. Their products are famous not only in Russia, but also abroad. Blacksmith I. Pampukha has been famous in Russia for his knives made of damask and Damascus steel for almost two decades. A master blacksmith in the third generation, he is one of the few who keeps the secret of real damask steel and follows all the necessary technologies for forging, casting and sharpening. His stainless steel knife, made using modern technology, retains the properties of classic steel and is highly resistant to corrosion. His hunting knives, having passed the test for cutting and blade strength upon impact, showed that the damask steel of his production is much superior to the alloy steel of knife blades from leading manufacturing companies. The knives of I. Pampukha also deserve the title of highly artistic execution. For the handles, the master chooses not only such expensive materials as walrus tusk and ebony, but also decorates them with precious stones and mother-of-pearl inlay.

Andrey Biryukov's forge is also famous for its tradition of high-quality damask knives, which are distinguished by high cutting quality and resistance to corrosion. However, not only these qualities, but also quite reasonable prices make them popular among damask steel lovers. Such private craftsmen as S. Baranov, S. Lunev and the Arkhangelsky family make blades from Damascus steel with fairly high quality and reasonable prices, but they are still inferior to the products of I. Pampukha in durability and cutting, and are more suitable for collecting or for use in everyday life. For example, in the kitchen.

Alloy production

The alloy is produced strictly following the technological process. Be sure to adhere to the algorithm corresponding to GOST. In this case, the characteristics of the materials are taken into account. Production is carried out as follows:

Steel strips X12MF.

- Casting of molten metal into a finished mold takes place in some cases in accordance with customer requirements. Allowances for further processing of the workpiece must be taken into account;

- An obligatory step is firing, since when the alloy cools, the process of its dendritation is possible. Which can cause uneven deposition of carbides, this affects the uniformity of the metal alloy;

- improvement in the quality parameters of steel is obtained during the forging process of the part. This treatment refines the grains and helps fill all the voids in the crystal lattice of the alloy.

The X12MF alloy, which is produced using a vacuum-arc remelting procedure, is quite highly valued. The process is quite complex and it will not be possible to cast it according to GOST in a home workshop. The alloy is produced only from trusted manufacturers.

Material X12MF Chelyabinsk

Not a single production can operate without steel, be it heavy engineering or the manufacture of household electrical appliances. There are many brands of this product, as well as a large number of dispensing forms. Our company sells X12MF material in large quantities and with a minimal margin. To clarify the properties and characteristics of a particular brand, you can contact the company’s managers.

Like all products, X12MF material is purchased from leading manufacturers. Therefore, we are ready to provide a quality guarantee with full responsibility. The minimum number of intermediaries determines the low cost. Coupled with fast delivery, this enables our business partners to conduct stable and mutually beneficial cooperation.

In addition to tempering, in the form of one or another part (blank), our company carries out metal processing. All events undergo strict control for compliance with GOST and rules. The specialists of our company carry out such work as galvanizing, creating parts according to customer drawings, producing castings, manufacturing various profiles and much more.

Having the latest equipment and vast experience in our arsenal, we can offer product testing for a number of parameters, such as strength characteristics, chemical composition, alloy purity, and so on.

Each buyer is offered a huge range of products in various formats, as well as current services and works. To quickly understand and choose a product that meets your needs, you need to contact the company manager and receive detailed information on all issues of interest.

Pros and cons of steel

The positive and negative characteristics of Kh12MF steel can be considered in the following table:

| pros | Minuses |

| To manufacture the alloy, available components are used and their cost is not high. Knives made from X12MF steel are low in cost. | It is almost impossible to carry out technological operations with steel at home. If the steel is not heated to the required forging temperature, it simply crumbles. |

| Steel can withstand a high temperature range. If you follow the necessary rules for caring for metal, the knife will predictably delight you with its characteristics for a long time. | Without special equipment it is impossible to sharpen a cutting edge. |

| Very high wear resistance. The hardness of the blade is achieved at 63-64 HRC. | Steel is weak in bending. If there is a strong lateral load, the knife may break. For this reason, knives of limited length are made from this steel. |

| There is no need to strictly maintain the steel. Items made from X12MF steel practically do not rust. | The alloy is susceptible to pitting corrosion. Frequent contact of the blade with salts and acids is not recommended. |

| The blade does not require constant polishing; there is no need to coat it with special anti-corrosion liquids. Additional polishing is also not required. | It will not be possible to polish the blade to a shine; it will not shine. These are the characteristics of steel. |

| The sharpness of the cutting edge is maintained for a long time, even with active use of the tool. | To edit a knife in the field, a simple stone will not be enough. The metal is quite hard and will require special diamond stones. |

Advantages and disadvantages

| PROS | MINUSES |

| Low production cost. The material contains simple components, so products made from it are affordable. | Loss of shine upon contact with acidic foods. It will not be possible to polish the blade to a shine; it will remain cloudy |

| High cutting properties. | Special sharpening tools are required. In field conditions, it will not be possible to straighten the knife due to its high hardness. |

| Long retention time. The ideal sharpening angle is 35 degrees. | Strict temperature requirements during manufacturing. If the temperature is not maintained, the blade will become fragile. |

| Resistance when interacting with moisture. It is impossible to call completely stainless steel. However, it has high anti-corrosion properties. | Does not tolerate fracture loads well. May break if struck by a bone or a thick tree trunk. |

Comparing X12MF and 95X18

The main advantage of 95X18 steel over the X12MF alloy is its corrosion resistance. This property is better suited for knives of constant use.

A 95X18 blade will withstand constant contact with vegetables, meat and other products.

These knives are most suitable for working in the kitchen. It is quite difficult to determine which steel is better, 95X18 or X12MF. This is due to the fact that the working properties of the alloys are very different. The quality characteristics of 95X18 are as follows:

- Steel refers to stainless steel.

- Holds an edge perfectly.

- Hardness during hardening 57-59 HRC.

Is Damascus better?

When comparing Damascus steel with X12MF alloy, professionals give a clear answer. And it is not in favor of Damascus. The reason for this is low resistance to corrosion processes.

Damascus begins to rust if it does not come into frequent contact with water. With such characteristics, the blade requires constant care. You will have to dry the blade and treat it with special liquids.

Blanks for future knives, X12MF steel.

Comparison with analogues D2 and K340

The Russian analogue of X12MF steel is alloy 95X18.

Initially, 95X18 steel was used to strengthen building structures, and later began to be used for the manufacture of knives. This knife is easier to sharpen than a blade made from X12MF. But the latter will be stronger.

Among the foreign ones, American D2 and K340 steel from the Austrian-Swedish concern Bohler Uddeholm are similar in composition and characteristics.

Knives made of D2 steel.

Experts believe that D2 and X12MF are similar in chemical composition and mechanical properties; there are no significant differences. You can choose a knife from one steel or another, based simply on personal impressions, which one you like best.

D2 steel is also a high carbon alloy steel. Originally developed for the production of cutting teeth. The Rockwell hardness of this steel ranges from 57 to 61 units.

K340 steel is more resistant to corrosion; the alloy does not contain harmful sulfur and phosphorus. The hardness of steel is 62-64 units. The main disadvantage of the K340 is its high cost.

| BRAND | ADVANTAGES | FLAWS |

| X12MF | High cutting ability, wear resistance, low price. | Does not withstand shock loads |

| D2 | Holds an edge very well, high strength. | Low corrosion resistance |

| K340 | Great mechanical strength | High price |

Physical properties of alloy Kh12MF

Products made from X12MF alloy are not intended for throwing or bending. Violation of the production process, incorrect temperature applied, can affect the quality of steel in the most unpleasant way. In this case, the blade will be easy to break. When properly processed, the knife has the following properties:

- there is no need to sharpen the product frequently;

- the blade copes well with planing;

- steel can work perfectly in the temperature range from -40 to +40 degrees;

- short-term thermal exposure will not lead to damage to the product;

- the presence of vanadium extends the service life of the blade;

- good resistance to oxidation;

- the homogeneous structure will not allow the knife to break or crumble.

When and how did damask knives originate?

During his campaign in India, Alexandra the Great especially noted the quality of the knives and combat sabers of the Indian noble warriors. Their blades easily cut through not only armor, but also weapons, and the sharp blades of their knives ripped through chain mail like butter. These were the first mentions of damask knives by Indian craftsmen. The unusual metal of Indian foundries was famous not only for its hardness, but also for its flexibility. Some craftsmen, using copper sulfate, which was added to the steel during processing, obtained white, green and blue blades.

Do not confuse damask steel with Damascus steel; these are completely different metal casting technologies. Damascus steel is more flexible than damask steel, although it is as strong as damask steel. Those who think that the appearance of blades differs from ordinary ones in that they have patterns depicted on them are mistaken. Damask steel casting technology makes it impossible to depict designs on the blade. The main difference between the two types of rare steels can only be determined in practice by an experienced craftsman or an experienced hunter.

As for the appearance of damask steel in Rus', it must be said that foundry as a craft existed in our country back in the 9th-10th centuries. Steel in Rus' was famous for its strength; not only weapons, but also household items were made from it. During the development of industry (XVII-XIX centuries), steelmaking in Russia, namely in Tula, Nizhny Tagil, Verkh-Isetsk, Zlatoust and other centers, made a powerful leap forward. It was at the Zlatoust plant that metallurgist P. Anosov, after much experimentation, found a method for producing damask steel. For many centuries before him, foundry masters tried in vain to learn the secret of making a blade that could easily cut through any steel and not become dull. After the discovery of Peter Anosov, it turned out that damask steel is just ordinary carbon iron, which, after a special method of crystallization, cooling and a certain set of materials, acquired unique qualities.

Mechanical properties

Steel grade X12MF has the following mechanical properties:

- corrosion resistance;

- excellent strength;

- excellent cutting abilities.

Piece production of knives is quite labor-intensive and not every craftsman can handle it. But there are exclusive products in nature. The unusually sharp blade is in great demand among hunters. With this knife you can quickly cut up an animal carcass.

Examples of knives made of X12MF steel.

Characteristics of steel

The mechanical characteristics of steel depend on the chemical composition of the alloy. Proper heat treatment is also very important. Any steel has 5 main characteristics:

- hardness - resistance to physical influences;

- rigidity - resistance to mechanical damage (chips, cracks);

- wear resistance;

- anti-corrosion resistance - resistance to rust;

- duration of use of the blade without sharpening.

For knife steels, the most important characteristic is Rockwell hardness. The higher it is, the longer the product will last and the sharpening will last. For the X12MF brand, this figure varies in the range of 61 - 64 units. This is quite a high value.

Analogs

The American analogue of steel is an alloy called D2. Its structure is almost identical to X12MF steel. But the concentration of chromium in it is slightly higher. The Japanese analogue is labeled as SCD11. It is used in the manufacture of knives and other cutting objects.

But this steel contains a little more carbon, which affects its toughness.

Germany also has a similar alloy with the marking - LO-R 4528. Among the Russian analogues we can name the alloys: Kh6VF, Kh12VM and Kh12F1. But they are more substitutes than analogues. Their hardness indicators are lower and their sharpening sharpness is somewhat lower. But they are more resistant to oxidizing agents.

Types of damask knives

Damask knives, like others, are divided into two categories: with an open (fixed) blade and folding. Damask steel ones are popular not only among knife lovers; they are used by:

- Hunters and fishermen. Hunting knife made of damask steel is one of the most popular categories. They are used not only by professional hunters and fishermen, but also by the military;

- Tourists (especially the category of extreme tourists who like to spend time in the mountains or taiga). In their arsenal you can find not only damask knives with a fixed blade, but also folding ones;

- Simple housewives and professional chefs. Although there are no special kitchen knives made of damask steel, nevertheless, such models cope much better not only with slicing vegetables, but also with cutting meat and fish;

- Collectors and simply weapon lovers.

The latter prefer beautifully decorated handmade damask steel knives, but hunters and professional chefs value them for their high quality of cutting.

Alloy Application

Steel grade X12MF belongs to the category of knife alloys. It was used to make woodworking tools. It was also used to make knives and cutting accessories for the printing industry.

In Soviet times, it was indispensable in engineering production.

A few more examples.

Manufactured electrical equipment and cold forming tools. Also, since the middle of the last century, they began to produce knives for hunting, kitchen and tourist purposes. Today it is used for the manufacture of:

- rolling dies;

- body and molding dies;

- all kinds of matrices;

- drawing boards;

- rollers of various shapes;

- instrumental cutters.

X12MF steel is also used in aircraft, motorcycle and shipbuilding. Many household tools are made from this alloy.

Areas of application for x12MF steel

The characteristics of x12MF allow us to classify this steel as stamped tool steel. And the entire set of useful properties of this brand determines the main direction of its application - the engineering industry, and to be more precise, heavy engineering. Steel x12MF is used as a starting material for the production of:

- drawing boards;

- portages;

- peepholes for calibrating bar metal for thread rolling;

- bending and forming dies;

- complex sections of body dies (during hardening they should not be subject to significant volumetric changes and warping).

Also, stampings of active parts of electrical machines and electromagnetic systems of electrical devices are made from steel x 12MF. Currently, the use of this steel for domestic purposes, in particular, for the production of hunting knives, is becoming increasingly important.

Use of steel x 12MF for making knives

Perhaps this is why more and more men are choosing knives made of x12MF steel. Then it will be interesting to know what unique characteristics such steel has and why it is better than similar materials?

The main characteristics of x12MF include a set of qualities that are given by the chemical elements present in steel. Without exaggeration, this is a unique alloy containing only 14.5-16.5% carbon.

Carbon makes steel hard, and its amount affects the wear resistance, and therefore the safety of the cutting part of the knife. The higher this indicator, the longer the period you can use the knife without sharpening. Of course, there are always two sides to a coin, and increased carbon content in steel can lead to corrosion.

x12MF steel contains chromium

And that is not all. During the production and calcination of steel, molybdenum is added to it. It is used as an alloying additive in the steelmaking process, which increases abrasion resistance and enhances the interaction of elements with chromium, which increases the hardenability of steel and makes the alloy more uniform.

What benefits do x12MF get from this feature? A blank of steel, which in the hands of a blacksmith has turned into a knife from the tip of the blade to the handle, will allow you to have homogeneous steel, identical in every millimeter

It is very important. After all, the strength of a chain is in its weakest link.

In this case it is not there. Steel x12MF is almost uniform in every millimeter of the blade cut.

This brand also contains vanadium. It is added to all high speed and tool steels because vanadium improves their hardness and strength. Thanks to its use, knives become much more durable.

compensates for the effects of carbon in terms of corrosion

But the most interesting part comes from how steel works in practice. Numerous experiments carried out on knives made from the x12MF brand showed the following results.

During the experiments:

- made more than 300 cuts of synthetic rope with a diameter of 2 cm;

- we tested the strength of the cutting part by making 100 cuts on an oak block;

- opened cans;

- planed wooden branches;

- they hit a metal rod with a blade, and also tested the steel by chopping the spines and bones of a wild boar.

The steel handled all the tests perfectly. As one would expect, no serrations appeared on the blade of the knife. The most amazing thing happened later, when the knife cut the newspaper under its own weight! Without any tears or tears in the paper. This is such a miracle steel. And this after 300 cuts of rope, hitting a wooden and metal block with a dozen open tin cans!

Rules for caring for X12MF steel

To extend the service life of products made from X12MF steel, they should be looked after. The optimal sharpening angle for such knives is 35 degrees. It should be noted that the sharper the blade, the faster it becomes dull. By following these rules, your blade will serve you for a long time:

- Using the blade as a lever can break it, be careful. The base of the handle may also become loose. You should not put force on the butt, cutting hard and blunt objects.

- Frequent use of the blade in acidic and alkaline environments can cause pitting corrosion. The appearance of the product changes greatly in a negative direction. Before the darkened spots begin to catch your eye, you should carry out preventive polishing of the knife. It is done once every six months, using fine-grained diamond belts.

- After using the knife, you should wipe it dry and lubricate it with mineral oil, Vaseline or Ballistol.

- The wooden handle should be coated with antiseptic agents to prevent the spread of bacteria and fungus.

- The knife should not be used as a throwing weapon. X12MF steel is not designed for such loads; the blade may break.

- Keep your knife in a sheath to protect the sensitive blade from corrosion.

By following these simple rules, your blade will last you longer. You need to order edged weapons only from trusted craftsmen. Overheated or, conversely, underheated steel does not have the advantages that were mentioned above.

How to care

In order for knives made from this steel to serve for a long time, you need to follow simple care rules:

- wash and dry after each use. You need to wash it especially thoroughly if it has been in contact with acidic foods;

- lubricate the blade with oil once a month;

- To sharpen a knife, use a special whetstone with diamond chips;

- keep the blade in a sheath to prevent fungus from developing;

- treat the handle with an antiseptic.

Sharpening a knife is a very important process, so you need to use a high-quality diamond stone.

With proper care, the product will last a long time and retain its properties. Many people use such knives for more than one season, and no serious shortcomings are identified.

Knives made of steel X12MF

Kitchen knives made of X12MF steel are rare. This alloy is mainly used to make hunting tools. It is often used for the production of Yakut knives.

Bakhycha

The product is lightweight and fits perfectly in your hand. The handle contains duralumin elements, which give the knife a magnificent appearance. The knife is used for skinning an animal, and can also be used to cut fish, meat and other food products. Blade characteristics:

- handle – 115 mm;

- blade – 110x36x4 mm;

- blade steel grade – X12MF;

- handle material – walnut;

- the shape of the descent on the blade is straight;

- type of sharpening - one-sided.

Small Bakhych knife.

Cervical

A universal tool, used to perform various business operations. Planing, cutting, making holes is the main direction of the blade. They can also be used to cut up food perfectly. The sheath and loop allow the blade to be worn around the neck, hence its name. Blade characteristics:

- handle length – 110 mm;

- blade parameters – 110x22x4 mm;

- blade steel grade – X12MF;

- handle material – Karelian birch;

- bolster - cupronickel;

- the descent of the blade is straight;

- sharpening is one-sided.

Yakut knife - neck knife.

Khotonoh

The knife is used for hunting; it is excellent for deboning meat and cutting fish. The set includes a sheath made of genuine leather. All blades are tested and have a quality certificate. A warranty period of 12 months is also required. Blade characteristics:

- handle length – 122 mm;

- blade parameters – 120x26x4 mm;

- blade steel grade – X12MF;

- handle material – Karelian birch;

- the descent of the blade is straight;

- sharpening is one-sided.

Cutting hotonoh.

Bychak

The knife is a universal tundra product. The rounding at the tip of the blade is not very sharp. This is done to prevent cutting the skin when cutting the animal. The blade comes in different sizes, depending on its purpose. Blade characteristics:

- metal – alloy grade X12MF;

- handle length – 135 mm;

- blade parameters – 150x25x4 mm;

- handle material – birch bark and wenge;

- prityn - duralumin;

- sharpening – one-sided;

- The descent of the blade is straight.

Universal tundra knife goby.

The best manufacturers in Russia

In Russia, knives made of X12MF steel are very popular. This is due to the fact that blades made from it are highly durable and can be sharpened for a long time. The cost of the products is very affordable.

We also recommend that you familiarize yourself with the current rating of the best steels for knives.

If the production technology is violated, steel loses some of its properties!

Therefore, you need to buy products only from trusted manufacturers, otherwise the knife may not withstand the first serious use. Excellent blades are made, for example, by the Albion forge (Nizhny Novgorod region), LLC PP Kizlyar, . These enterprises use both the latest production technologies and the experience of old, honored masters. Therefore, the products are of high quality.

Production at the forge

conclusions

If you primarily need toughness and strength in a knife, the knife is intended to be used for batoning, opening cans, digging around fire pits, etc. and money is short, look towards the good old carbon. It's cheap and cheerful. If your budget allows, look towards CPM3V or PGK powder steels.

If you prefer to kayak or are a fisherman, then naturally look towards stainless steel. Constant dampness in a boat or while fishing will quickly cause the knife to bloom in a lush red color. If you don’t have a lot of money, look towards domestic stainless steel, and if your budget is larger, then it’s better to choose N690.

If you prefer aggressive cutting, and for a long time, then powder steels are your choice. At the moment they are more than available, at least the basic brands. At Hansa, you can easily select a strip of steel of interest and negotiate with the craftsman about heat treatment and production of the entire knife. A designer knife from Elmax or M390 can confidently fit into a budget of 6-8 thousand, and this is a very good choice. Monsters cost closer to 15-18 thousand per knife.

If you like beautiful patterns on the blade, your choice is Damascus and damask steels; their consumer properties are very much inferior to modern tool steels, but they can be beautiful. Just remember that real damask steel costs as much as an airplane wing.