The store recommended white spirit to degrease the bathtub before enameling. I doubt he's suited for this job. Am I right?

It should be noted that there are other names for this substance, such as nefras (labeling C4-155/200) and another name, which is called Stoddard’s solvent.

First, let's look at it - what is white spirit? This is a hydrocarbon mixture - a product obtained from the distillation of oil, a gasoline solvent, in fact - kerosene, its light grade. It is perfect as a solvent for bitumen and rubber mastics, varnishes and enamels (alkyd) and, what is important for answering the question, oil paints. So, it dissolves all fats and oils perfectly, it is clear that you can degrease the bathtub with white spirit before enameling.

White spirit does not damage the metal, since it does not react with it, and it is safer than another product used in everyday life - a mixture of acetone, kerosene and gasoline, and all due to its lower volatility (evaporation). Its price is very affordable - up to 100 rubles per liter and therefore, economically, it is preferable. The smell, however, as they say, is specific and very persistent, but this is for domestic samples; there is imported odorless white spirit. If you degrease aluminum (or alloys with it), then there may be problems, just like with plastic, so be careful with such materials if they are on the bathroom.

It would not be amiss to recall that white spirit, in terms of the degree of danger to humans, belongs to the 4th class and is of little danger, but still it would not be amiss to be careful and, if the work is not carried out on the street, wear a respirator, or at least , protective mask.

Degreasing metal surfaces

Degreasing consists of removing conservation oils, cutting fluids, paint residues, and various stains from the surface. The importance of this stage cannot be underestimated. Especially when it comes to preparing a metal surface for painting. After all, only a perfectly clean surface can be considered the key to high-quality painting.

White spirit is widely used in the process of preparing a car body for painting. As a rule, it is necessary to remove contaminants such as bitumen, rubber, and mastic stains. Kerosene was previously used for these purposes. White spirit also belongs to the so-called light kerosene. However, there is a significant difference between them.

After degreasing the body surface with white spirit, most of the solvent evaporates. Part of the substance in the form of a film that remains on the cleaned surface does not impair the quality of painting. Regular or heavy kerosene is not removed as easily without consequences. In addition, it is difficult to wash off with water.

Experienced craftsmen practically no longer use acetone or gasoline to degrease the body. These substances are highly flammable. In contrast, white spirit, having less pronounced volatile properties, is a safer product to use for such purposes. In addition, it is chemically neutral to metal and does not pose any danger to it.

Another important advantage of this solvent is that it does not dissolve the paintwork of the body, even if there are scratches and abrasions. Therefore, most body painters use white spirit. When working with it, you must follow a number of rules, which will be discussed below.

Glass

Glass is also indifferent to more aggressive liquids than white spirit, and here it is unnecessary to be careful. The question is: why is degreasing carried out? If its purpose is bonding (for example, when replacing a cracked rear view glass), then white spirit is quite suitable. But if you wash the windshield from oily substances before tinting or gluing the film, then it is better to turn your attention to other solvents.

The fact is that white spirit leaves behind quite noticeable, slightly oily stains. It is especially undesirable to use it under film - such patterns will remain with you forever. And even if they are not too noticeable, visibility will still be somewhat impaired.

If we summarize the experience of many generations of car enthusiasts, then the question of whether it is possible to degrease with white spirit can definitely give a positive answer. You just need to do this necessary and painstaking process in a well-ventilated garage or even on the street, in the open air. And it wouldn’t hurt to wear a special protective mask or respirator.

Degreasing plastic with white spirit

To degrease plastic parts, it is also recommended to use white spirit. In this case, degreasing of the surface is carried out, as a rule, before gluing or soldering plastic surfaces. Less often, before applying paints and varnishes.

The surface of plastic has poor adhesion to other materials. In other words, it has low adhesive properties. Therefore, all foreign elements must be carefully removed from it.

The technology for performing the work is the same as when processing other surfaces:

— wipe the working surface of the plastic with a damp cloth; - then treat it with a sponge soaked in white spirit; - After drying, you can start painting or gluing.

Glass and wood surfaces

White spirit is also used to degrease surfaces of materials such as wood and glass. The processing of wooden products before painting consists of several stages. First it is cleaned with sandpaper, then degreased, and then a layer of paint is applied.

Glass is a chemically resistant material and can be degreased with other liquids, even aggressive ones. However, in this case, the type of solvent is selected based on the task ahead. In particular, when gluing glass, white spirit is most suitable.

Another thing is when we need to degrease the windshield, which we are going to tint or cover with light-protective film. For these purposes, it is better to look for another solvent. It is better not to use white spirit. After wiping the surface of the glass with it, you will then have to free it from oily stains. The presence of such patterns will negate all the work.

Now about the safety requirements when working with this solvent:

1. Work only in a ventilated area. 2. You must wear rubber gloves. 3. Work only in appropriate clothing and a respirator. 4. Store in compliance with the rules for the safe storage of flammable compounds. 5. Protect from direct sunlight.

The need to prepare metal products for painting is due to an increase in the adhesion characteristics of the substrate to the paint and varnish material and the resistance of the metal to corrosion processes. All this will have a positive effect on the service life of the painted products. However, most owners are much more concerned about the presence of rust, which must be removed during the metal preparation process, than about degreasing, which is why painting work is carried out without this important and mandatory operation.

Wood treatment agent

There is also nothing complicated with wood, only before treating with special means or applying conventional universal solvents it is necessary to remove varnish or paint. This can be done with a steel brush, sandpaper, or a plane.

You need to clean the surface very carefully - if you thoroughly clean the base layer of paint, you don’t even need to degrease it. Special products and solvents are applied with a roller to spread them evenly on the surface.

PLEASE NOTE! Anyone who, out of stupidity, laziness or simple ignorance, treats wood coatings with gasoline or diesel thinking that “the same will work with wood”, then no, because the composition of paints and varnishes applied to wood is significantly different from those applied to plastic or metal.

What is defatting

The essence of the procedure is to remove fatty substances from the surface of the substrate, which are often present in cooling emulsions, mineral oils, preservative lubricants, and polishing compounds. Degreasing of the metal surface before painting also has to be done to remove residues from washing and etching, traces of sweat and fingers. All these contaminants can extremely negatively affect the quality of surface wetting with paints and varnishes, as well as harm film formation and other properties of the coating.

Depending on the amount of fatty impurities present per square meter, several degrees of surface contamination can be distinguished:

- Weak - up to 1 g;

- Medium - from 1 to 5 g;

- Increased - more than 5 g.

When processing fats with chemical reagents, several sequential processes occur on the surface:

Depending on the ability of fats to be destroyed under the influence of solvents, several types of contaminants are distinguished:

- Non-destructible - for example, emulsions.

- Pollinated - polishing materials, lubricant residues.

Chemical methods

The main type is organic solvents, which allow you to quickly remove grease and oily areas from metal parts.

They are most widely used in individual production, although sometimes they are used in serial production, but not often due to their high explosion and fire hazard. The desired effect, namely the dissolution of oil and fat deposits, is achieved at the moment of contact of organic solvents with them. The quality of surface degreasing is directly affected by the degree of solvent contamination, since the more fats are contained on the surface, the worse the chemical’s ability to dissolve existing deposits becomes. Most often, aliphatic and chlorinated solvents are used to remove fat and oil areas. Despite their high efficiency in metal cleaning, they have a serious drawback - these compounds are not able to remove abrasive materials and other mineral contaminants from the surface.

Necessity of procedure and methods

- Mechanical. This method is labor-intensive and time-consuming. Used to obtain a rough base that gives better grip. The layer of contamination is removed using electric and manual tools. This option does not give an ideal result, so it is often complemented by other methods.

For mechanical cleaning, you can use a grinder or drill with special attachments, a hand-held metal brush, as well as ordinary sandpaper. - Chemical. The most popular method to degrease the desired element. This is explained by the fact that the work process does not require much physical effort and does not take much time. During this procedure, the selected liquid product is applied to the surface. Depending on the degree of exposure, the substance washes away oils and fats or destroys their structure.

Chemical degreasers are divided into two main types: organic and inorganic - Electrochemical. This option is subject to special conditions that are only available to industrial enterprises. The bottom line is that the base is exposed to an electric charge and certain chemicals. The method allows for complete cleaning, but any deviations from the technology lead to damage to the processed metal.

Aqueous solutions

How to degrease metal before painting

In domestic conditions, owners, as a rule, use proven “old-fashioned” products - gasoline, kerosene, acetone, alcohol.

But today more modern and technologically advanced formulations are available. Among them, Nefras (White Spirit), Solvent 646 are quite popular. They have a lot of advantages - affordable price, increased level of environmental friendliness, the ability to form films that are more resistant to paintwork, which helps prevent the development of corrosion processes.

The problem for many owners is that the substrate after degreasing does not match the chosen paint. This can be avoided by purchasing a solvent suitable for the coating being treated. But more often than not, such problems do not arise when using solvent No. 646 . Consumer reviews talk about its versatility, so there is no need to carry out additional operations.

Another popular type of solvent is Antisilicone. These compounds are in high demand among craftsmen, who use them to degrease the car body before subsequent painting. However, safety rules must be observed during operation. In the room where degreasing work is carried out, windows and doors must be opened. Such solvents can be used as far as possible from sources of ignition and always wearing personal protective equipment.

Welcome to our site!

When comparing solvent and white spirit, you must immediately make a reservation that these are two solvents with similar properties, which are produced mainly from crude oil by distilling it in cracking columns at oil refineries. Without access to oxygen, at temperatures from 130 to 150C, hydrocarbons are evaporated, from which a solvent (solvent) is produced. In the same cracking columns, mixtures of hydrocarbons called white spirits are evaporated at temperatures from 155 to 200C. Aromatic hydrocarbons are evaporated from oil at low temperatures and in solvent form up to 56% of the total mass. The mass of such hydrocarbons in white spirit should not exceed 16%.

In addition to oil cracking, the production of solvent is established when producing coke from coal, when light aromatic fractions of hydrocarbons are released when heated in the form of coke oven gas, collected when passing through an exhaust pipe, condensed while passing through coolers, and the output is xylene, quite suitable for consumption, toluene and solvent. This coke oven gas contains up to 60% light aromatic hydrocarbons. Due to the higher content of aromatic hydrocarbons, the solvent, unlike white spirit, has a sharper characteristic odor, which evaporates quite quickly, however, when working with the solvent for a long time in a closed, unventilated room, it can cause a headache and even hallucinations in a person.

The content of hydrocarbons of different volatility gives both solvents slightly different properties, for example, solvent may have a yellowish tint, white spirit is always transparent, solvent dries within 10-20 minutes, white spirit dries within 1-2 hours, solvent gives paints a glossy surface , and White Spirit makes the paint matte with an additional film on top. Solvent has found application not only for diluting paints, it is also actively used for cleaning metal parts (including car bodies) before painting them. White spirit is more actively used by paint manufacturers and consumers at home. Similar properties include the ability of both solvents to dissolve oil paints and fats. In addition to oil paints, the solvent dissolves nitro paints well. Both solvents are used in the production of glyphthalic, pentaphthalic, alkyd and bitumen paints and varnishes, when removing old dried paints and when removing grease stains before painting. Due to its low odor and low drying speed, white spirit is more actively used in the production of paints. Using solvents, rubbers, bitumens and polyesteramides are dissolved. Sometimes solvent is used to obtain poison from rats and beetles, but this is rather an exception.

Read also: How to find out the type of light bulb base

Both solvents are flammable substances with a low flash point, and both have the ability to accumulate static electricity, which can cause an explosion. The density of the solvent is higher than the density of white spirit, and they are 0.86 and 0.79, respectively.

Despite assurances of development and improvement of the quality of both solvents, at the moment not a single oil refinery in the Russian Federation produces solvents that comply with GOST 1978 and 1979, which determine their regulatory compliance. This happened for a number of reasons:

- GOST allowed the presence of aromatic hydrocarbons, which made both solvents so odorous that they did not find their use abroad, that is, they are not sold for export. Western analogues do not have the smell and color, which is provided for in the regulations of these countries, so our solvents are very inferior to them.

- Increasing consumer demands for solvents has led to an increase in the flow of imported solvents. Transparent and completely odorless solvent produced at coal processing plants in Alsace and White Spirit distilled in Norway greatly displaced the production of domestic solvents, making its production unprofitable.

- The deepening of the oil refining process created conditions when it became possible to distill the fraction of solvents and white spirits with a boiling point from 120 to 200C into more expensive benzenes and gasolines, replacing solvents with inexpensive orthoxyols and toluenes. Today, the production of solvent and white spirit according to GOST standards is not economically profitable, and all oil refineries that sell solvents produce them based on their own specifications. Such solvents do not have the density of the declared solvents and have overly strong odors.

- Modern developments in chemistry have made it possible to obtain solvent and white spirit by simply mixing various hydrocarbons. As a result, it turned out to be much easier and cheaper to achieve the properties of solvents by adding various hydrocarbons than to carry out complex and costly oil refining processes.

- Many manufacturers are trying to replace solvent and white spirit with various kerosene-based solvents. Such attempts are quite successful and will probably soon make it possible to completely abandon the centuries-old dependence on petroleum solvents.

The need to prepare metal products for painting is due to an increase in the adhesion characteristics of the substrate to the paint and varnish material and the resistance of the metal to corrosion processes. All this will have a positive effect on the service life of the painted products. However, most owners are much more concerned about the presence of rust, which must be removed during the metal preparation process, than about degreasing, which is why painting work is carried out without this important and mandatory operation.

Popular solvents

How to degrease a metal surface before painting is a pressing question for many owners. To degrease metal surfaces, today you can use not only affordable and time-tested compounds, but also modern solvents.

White spirit

Among degreasers, white spirit is most often used. It looks like a transparent, colorless liquid with a characteristic odor of fuel and lubricants.

It is sold in stores under the name “Nefras-S4” and is available in various modifications. The main reason for its popularity is due to its versatility.

This solvent can easily remove any oils and fats, as well as many organic compounds. It is often used to dilute oil paints, enamels and varnishes. White spirit also has one more positive property - after treating the surface, you do not need to wait for it to dry; you can immediately proceed to applying a primer or paint material. The solvent evaporates very quickly, and this is what gives it superiority over other cleaning compounds.

Solvent 646

This type of degreaser is widely used when preparing for painting.

It is a yellowish liquid with a strong characteristic odor. It has a fairly wide range of applications. With this composition you can not only dilute paints, but also degrease metal surfaces. It is especially effective when you need to remove old layers of paint. Can be used for washing painting equipment and tools.

Best suited for diluting the following types of enamels:

- nitrocellulose NC;

- glypthal GF;

- melaninoamide MPs;

- acrylic;

- epoxy.

When using the degreaser, it is necessary to observe the temperature recommended by the manufacturer from + 5 to + 30 degrees Celsius, while the air humidity should not be higher than 85%. Then, after treatment, the metal surface will acquire a shiny, glossy appearance without stains or streaks.

Please remember that Solvent 646 is a flammable and explosive product. You can work with it only while wearing respiratory, eye and skin protection. When carrying out work indoors, it is necessary to ensure the supply of fresh air through windows and doors or through working exhaust ventilation.

Acetone: classic

Another fairly common metal degreaser. In terms of its composition, it is a transparent liquid with a strong characteristic odor. Excellent for removing oil and grease stains, as well as tar.

Acetone can be used to dilute varnishes, enamels, paints and primers. Sometimes it is added to the composition of some solvents. The main component is alcohol, which is highly volatile.

To protect metal surfaces from corrosion processes, they must be specially treated before applying paint. Dyeing technology requires an operation such as degreasing. It can be performed using various solvents and degreasing compounds.

Among them there are both traditional and more modern and technological ones. The choice of the most suitable composition for degreasing should be made taking into account the nature and scale of the tasks at hand, as well as the purpose of the metal product.

At the same time, it is important not to forget about safety rules during degreasing work. Many formulations are unsafe due to the content of compounds harmful to health. Therefore, when carrying out work indoors, it is necessary to ensure constant access to fresh air. You also need to remember that there are no flammable sources nearby.

Application area of kerosene

This flammable liquid is in demand in the rubber industry, for various types of glue, for washing parts and repairing equipment, in dry cleaning of fabrics and fur, in the production of artificial leather and for strengthening and cleaning natural hide. Kerosene is also ideal for cleaning metal products from oxygen oxides (rust) and displacing H₂O if the iron has been sitting under water for a long time.

Kerosene is essential for high-quality varnishes and oil paints. No wonder it is also called “Greek wax”. If you need to dilute oil paint to the desired consistency or alkyd paint, then you need an oil solvent - Greek wax, which, although it has a very peculiar smell, is not worth looking for better for this action!

Despite the fact that this distillation product is slightly yellowish, this will not affect the color after dilution.

Of course, using rocket and aviation fuel in large quantities is very wasteful, but anyone can afford to clean their favorite pants that have been stained with alkyd or oil paint. Kerosene does not “fight” with the fabric, which guarantees the safety of both the pants themselves and their color.

Purpose

Degreasing metal before painting is the most important procedure that is mandatory before applying acrylic, powder, or alkyd paint. The fat film slows down the adhesion of paint compositions to the surface on which they are applied.

Body treatment before painting

Traditional degreasers

Often, when servicing a car, the most common degreasers are used. For the initial treatment of small areas of contamination, you can successfully use gasoline, kerosene and even diesel fuel.

Primary treatment consists of preparing the surface of the iron for degreasing. For example, the manufacturer recommends using BR-2 solvent, also known as Galosh gasoline, for washing metal products.

This recommendation can be successfully applied to kerosene and diesel fuel (“diesel fuel”). By the way, gasoline or kerosene can be used to thoroughly clean and degrease leather and fabric products. The only drawback is that the smell will take a long time to dissipate.

This is interesting! What is drying oil: types, composition, technical characteristics and application features

Emulsion compositions

If it is necessary to remove stains of grease, oil deposits, or other particularly dense contaminants, use a metal degreaser that works by emulsification. The composition is combined. It contains emulsions of organic solvents, aqueous alkaline solutions and surfactants, combining their strengths. Acting together, the components of the composition are able to cope with the most persistent stains. The concentration of hazardous substances in it is reduced, so it can be used at home.

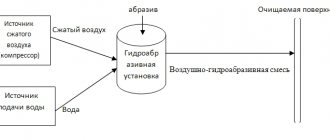

Sandblasting

Before using certain compounds to degrease the part, it is subjected to mechanical processing. This allows you to remove mechanical impurities, rust, and partially old paint and varnish coatings and facilitates the work of the degreaser.

To do this, use sandpaper or abrasive wheels driven into rotation by an angle grinder. This method is good for small parts. If you need to prepare a large part for painting, sandblasting comes into play.

High-pressure air passing through the nozzle carries along the sifted grains of sand, they hit the surface with force and act as an abrasive material. The flow of sand grains removes all mechanical impurities, rust and old paint from the part. The surface remains rough, which improves its adhesion to glue or paint. In addition to metal, sandblasting is used for hard plastics, wood and stone.

Sandblasting

After sandblasting, the part must be washed with clean water under pressure to wash away any remaining sand and dust and dried with compressed air. Now you can start degreasing.

After the surfaces have been cleaned before gluing, they are washed in clean water to remove small particles, dried thoroughly and degreasing begins.

Acetone

Acetone, as a degreaser, is also widely used. Colorless transparent liquid with a sharp specific odor. Excellently dissolves oil and grease stains, various resins.

Used to thin primers, paints, enamel and varnish. Included in some solvents. It is made on an alcohol basis. Has high volatility.

When working with acetone, it is imperative to take measures to protect the skin, eyes and respiratory organs. It is strictly prohibited to use open fire or be near operating electrical appliances. For ease of working with acetone, it is best to use a spray bottle.

Solvent

Can also be used as a degreaser. In the retail chain it may go under the name "Nefras F-130/150". Transparent colorless or slightly yellowish liquid. It is made on the basis of petroleum fractions. Less often - coal. When painting a car, it can be used not only as a degreaser, but also as a paint thinner. Excellently removes all auto-preservatives.

At the same time, rubber bitumen and oil shale automotive mastics are diluted with a solvent. Solvent-based paints have unique properties. Thanks to their high adhesion, they create a durable coating. When working with solvent, it is necessary to strictly observe safety precautions.