Choosing a quality paper cutter is a difficult task. Yes, a large number of goods are sold in stores, and on the Internet you can order products from another country. But, despite the abundance of assortment, the effectiveness of some options leaves much to be desired. Therefore, it is important to select a device based on the purpose of the product, as well as its capabilities.

The editors of the YaNashla website have prepared for you a rating of the best paper cutters for 2022.

Types of paper cutters

What paper cutters are called depends on the area of use of the device. Models are divided into professional, office, and specialized types. Design differences divide paper cutters as follows:

- roller,

- saber,

- guillotine,

- curly.

Depending on the drive, the devices can be mechanical or electrical. How to use a paper cutter? The work of the former depends on the manual force exerted on the lever. The latter are activated by pressing a button.

Gas cutter device

The principle of operation is the combustion of the metal of the workpiece in a stream of chemically pure oxygen. Oxidation products from the cutting zone are blown out by the same jet.

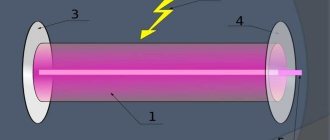

To ensure this process, the gas cutter for metal has the following design:

- trunk;

- tip.

Gas cutter device. East. https://rezhemmetall.ru/gazovyj-rezak-po-metallu.html.

Explanation of the figure. The barrel consists of the following components:

- handle with nipples for connecting oxygen and gas hoses;

- housing with gas and oxygen control valves. It also includes: an injector;

- mixing chamber;

- oxygen and fuel gas supply tubes.

The barrel is connected to the body with a union nut. The design of the tip is shown in the figure.

Head device. East. https://rezhemmetall.ru/gazovyj-rezak-po-metallu.html.

It consists of an internal (brass) and external (copper) mouthpiece.

The design of the mixing chamber is intuitively clear from the figure.

Mixing chamber design. East. https://rezhemmetall.ru/gazovyj-rezak-po-metallu.html.

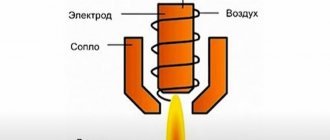

Gas burner: oxygen cutter

From a cylinder with a reducer, oxygen enters the cutter through a hose with nipples. In its body it branches into two channels:

- one part of the gas passes through the valve and enters the injector. It comes out of it at high speed and, creating a vacuum, sucks in flammable gas. As a result, a flammable mixture is formed in the mixing chamber. It, passing through the gap between the inner and outer mouthpieces, burns and forms a heating flame;

- the second part of the oxygen enters through the valve into the cutting gas tube. Coming out through the central channel of the internal mouthpiece, it forms a cutting jet.

Thus, to obtain a high-quality cut it is necessary:

- use a nozzle and mouthpiece of the “correct” size (corresponding to the brand and thickness of the material being processed);

- the gas pressure must correspond to the thickness of the material being processed;

- Constant care and cleaning of the nozzle channels is required. It is recommended to do this cleaning with copper rods.

Guillotine paper cutter

The most powerful, durable among paper cutting devices. Simultaneously processes up to 800 paper sheets with an ideal cutting line. The knife blade can be sharpened, which is one of the advantages of the model, as is the presence of protection for the cutting mechanism. This type has disadvantages: you cannot create decorative cuts or holes in the central part of the sheet.

The power lever that activates the structure does not require much physical strength. Tool manufacturers offer manual, semi-automatic, and automatic guillotine cutter models. The high cost of the model makes it optimal for use on an industrial scale.

So what should you choose?

- Paper cutters designed for home use and small offices

They are the most popular devices. The design of such equipment does not allow heavy loads. Rather, they are intended for occasional or frequent use, but with a small amount of paper. Characteristic features of this type of low-cost solution are a manual clamp, a plastic base and an integrated blade with a lever. Typically, you can cut 5-20 pages at a time.

For large offices and bookbinding shops, more advanced models are required. These devices are designed to operate continuously, often under higher loads. They are characterized by a separate upper blade and a frequently replaced lower blade. The base is usually metal, and the strong connection to the handle allows you to work longer with higher loads. In addition, the number of sheets that can be cut at one time ranges from 20 to 50. This type of equipment often also has an automatic or lever clamp for greater user convenience.

- For professional use

These are the most technologically advanced devices, ideal for printing houses, factories or bookbinding shops. Demanding paper cutters designed to withstand long periods of heavy-duty use can cut up to 500 sheets (a whole ream of paper) at a time. For this type of application, there are also electrical devices that allow automatic cutting.

When choosing a paper cutter, you need to decide where you will use it and how often. Equipment used occasionally and at home does not necessarily have to be high-end and have specialized functions. On the other hand, printing houses, factories and offices require modern, high-quality and expensive devices for professional use.

There is no standard electric or classic guillotine, as each manufacturer offers different solutions. You won't always need all of them, so it's worth taking a look at them. Among them you can find the option of automatic paper clamping. This prevents the sheet from moving during operation.

Standard models also have this solution. It is best to bet on functional, safe equipment with a sharp blade from reputable companies. They offer paper cutters at good prices - both advanced and basic equipment. Remember that the low price is only a one-time saving. Low quality guillotines are more dangerous and have low quality blades. In addition, their security system is not the best. It is also worth checking the opinions of consumers of these devices to be sure that the equipment we are interested in is really worth its price. Make sure it is solid enough, functional and has all the features that make working with it more enjoyable and efficient.

By following the advice in the article, everyone will definitely find equipment that will meet their expectations.

A good office guillotine makes work easier in many companies. It allows you to quickly cut paper, cardboard and other materials. Taking into account the needs of readers, we analyzed the market and user ratings of these devices, and we selected the best models.

Roller paper cutter

The number of simultaneously cut sheets does not exceed 15. Models of this type of paper cutting device exist in electrical and mechanical versions. The base of the device is wooden with a screwed ruler and markings. The roller knife is located on one side. The paper is placed under the bar and clamped. The knife can move in two directions. The large size of the working canvas is optimal for photo salons and printing industries. Advantages of models of this type:

- the minimum width of the cut strip is 0.5 mm;

- there are replaceable knives;

- the cutting line can be observed.

Minuses:

- a slot cannot be made;

- During operation, an error of up to 0.2 cm is possible.

Paper cutters

Preliminary cutting and trimming of paper, cutting the printed sheet into the desired format, cutting and trimming prints - the result of the work of an entire printing house often depends on the quality of these operations.

The central role here is played by a paper-cutting machine (BM) - a special unit, without which not a single completed printing process can be implemented.

The purchase of a cutter, like the purchase of a printing machine, always marks the beginning of a new stage in the development of any printing company. Quite often, both acquisitions are carried out simultaneously, since the labor intensity of cutting is comparable, and in some cases even exceeds the labor intensity of printing. The purchase of BM, of course, is made for a specific project, which determines the type and format of the necessary equipment. As a rule, these are single-knife cutters equipped with programming and automation tools. In this review, we will focus on small-format machines with cutting lengths from 500 to 800 mm, which are most in demand today, especially in small and medium-sized printing houses.

Printing dozen

The Russian (as well as any other) paper-cutting equipment market is quite conservative, which, of course, does not exclude the emergence of new names in the domestic printing space. This year, for example, printing specialists got acquainted with the products of the Chinese company Shen Wei Da (SWD). As can be seen from the summary table, there are cutters from twelve manufacturers on the market, three of which (Grafopat, EBA, Ideal) produce lightweight equipment. Others, with the exception of Polar, SEM and SWD, offer extremely heavy machines with solid frame weights of at least a ton. At the same time, despite the appearance of Chinese technology, as well as the presence of French (SEM), Polish (Grafopat) and Czech (Adast Blansko), the tone is still set by devices supplied by the birthplace of printing - Germany. These are EBA, Ideal, Eurocutter, Perfecta, Polar, Schneider Senator and Wohlenberg.

With a saber at the ready

| Rice. 1. Scheme of cutting a foot on a single-blade paper-cutting machine 1 - foot; 2 - desktop; 3 — clamping device; 4 - knife; 5 — knife holder; 6 - marzan; 7 - pusher (zatl). |

The essence of the paper cutting machine is simple. A stack of paper that has been pushed in advance (aligned along the two lateral – “true” sides) is placed by the cutter on the work table and is pushed with its right sides against the feeder (back) and one of the side stops of the machine’s work table (Fig. 1). After installing the back with the foot in the desired position, the foot is fixed on the table with a special clamp and then cut. This cut in absolutely all the machines under consideration is called a saber cut - a rectangular knife fixed in a holder at a slight angle a (about 1°) moves to the side during the cutting process and gradually turns to the same angle as it enters the stack of paper (Fig. 2). Since during saber movement the blade enters the foot gradually, as if gradually sawing it (the angle of inclination of the knife relative to the foot decreases from value a to zero), the loads in the machine increase smoothly, the shift of sheets in the foot decreases, cutting accuracy increases, and cutting forces decrease. Choosing the right type of knife and sharpening it is a whole science that should never be neglected (see sidebar “On the edge of a knife”).

| Rice. 2. Scheme for performing a saber cut a - the initial angle of inclination of the knife; q is the angle of the knife’s trajectory; 1 - knife; 2 - foot. |

Knife under control

Smooth cutting is ensured by the knife drive, which in the devices under consideration is of three types: electromechanical with a flywheel, electromechanical and hydraulic.

In powerful machines with long cutting lengths, where significant cutting forces are required, as a rule, an electromechanical drive with a flywheel is used, consisting of an electric motor, an inertial flywheel, which is spun by this motor, a gearbox and a friction clutch that transmit torque to the knife holder rod. The advantage of this scheme is that the rotational energy accumulated by the flywheel is virtually independent of the supply voltage source, and this allows cutting as smoothly as possible. Similar kinematic schemes are implemented in machines with a cutting length of more than 700 mm - machines Adast MAXIMA MS 80, MZE Eurocutter 780, Perfecta 76, Polar 78, in all SWD models with a cutting length of 780 mm under consideration.

The hydraulic drive is very effective, ensuring high smoothness of the knife and its instant stop in the event of activation of the built-in protection systems. As a result, the service life of the frequently activated braking system increases, the load on which becomes noticeably less. As can be seen from the table, a significant number of devices with cutting lengths from 510 to 670 mm and even 775 mm (Challenge Champion 305) are equipped with a hydraulic knife drive.

Manufacturers of lightweight automatic cutters (Grafopat, Ideal), successfully used in online printing, equip their knives with electromechanical drives. This significantly reduces the cost of the devices, without allowing them, however, to fully compete in cutting accuracy and stability with machines equipped with hydraulic or electromechanical drives with a flywheel.

Hold the blow

But a smooth cut without moving the foot is only half the battle. To ensure high-quality color registration during the printing process and flawless performance of one of the final operations - accurate cutting of printed sheets for short-run products, the following are required: a reliable drive mechanism and accurate positioning of the back, smooth and controlled pressure of the foot, and no vibration of the work table during the cutting process.

| Rice. 3. External view of the rear mounting system in a Polar car, assembled on the basis of a ball pair. |

The fastening mechanism is one of the most sensitive and vulnerable parts of the cutting machine. It is either a worm pair or a “screw-nut” pair, which implements the reciprocating movement of the comb pusher along the cutting table. When pushing the foot on the work table, many carvers hit it hard against the front surface of the backplate, which over time inevitably leads to beating (play) in the drive and, subsequently, to failure of the backplate mounting system. To prevent this undesirable phenomenon, cutter developers take different paths. One of them is the choice of the layout of the fastening mechanism.

Most of the paper cutting machines presented in the table have a central mounting pattern, when a trapezoidal screw (or worm pair) is located in the center of the work table. On small-format models, where the width of the table is relatively small, the back drive is sometimes installed on one side (Adast MAXIMA MS 62, Perfecta 62), more often on the right, which, if the carver is not left-handed, bears the main impact load.

Another way to increase the service life of the fastening mechanism is to use so-called ball pairs, where sliding friction is replaced by rolling friction. The principle of operation of such a pair is the continuous rotational movement of the balls of the supporting transmission chain inside spherical grooves cut along the drive screw. This guarantees virtually play-free coupling of the backplate holder with the drive screw, which, in turn, requires proper operation of the mechanism - a slight misalignment can cause the drive to jam. Such drives are used on all Polar cutters (Fig. 3) and can be installed on Adast, SEM and SWD machines

The most optimal way to combat backbeat is to take good care of the device. As Alexander Kazakov, technical director of the Fastprint company, said, with fairly intensive use of the Ideal 7228-95EC3 cutter (4-5 hours of daily work - this is quite enough to process incoming orders), replacing the back attachment unit (this relatively inexpensive device has a conventional “screw-on” mechanism) nut") was made after three years of its full operation.

Strong but neat

The clamping mechanism is of great importance for high-quality and accurate cutting. The optimal clamping force determines many things. Too strong leads to the finished product being set off, too weak - to displacement of the foot under the influence of the knife and, therefore, inaccurate cutting. It is very important to have a system for smoothly controlling the clamping force, which allows you to increase it as the knife enters the stack of paper. As can be seen from the table, paper cutting machines use two types of clamping mechanism drive - electric and hydraulic (not counting, of course, the preliminary mechanical one with a foot drive). In terms of control capabilities, hydraulics win here - the control range in this case is much larger. For example, the developers of SWD machines claim that the pressure can be adjusted to any value in the range from 5 to 3000 kg.

The clamping mechanism has one more function - removing air from the foot before cutting. For these purposes, in many machines (Adast, Eurocutter, Perfecta, Polar, SEM, Shenweida), the clamp is programmed without cutting - the cutter sequentially moves the foot under the clamping bar, which, “patting” the moving foot, compacts it.

Strong pressure also has its negative sides. Thus, when working with thin and “delicate” paper (cigarette, blotter, copy paper), clear traces of the “comb” of the pressing device remain on it. Therefore, almost all manufacturers supply flat clamping bars with their machines, which, however, increase the minimum value of the residual cut strip (since the projections of the back comb in this case do not fall into the counter clamping grooves). Moreover, to work with materials of different heights (corrugated cardboard, for example), many suppliers offer the use of soft rubber pressure strips. The designers of the Polar and Perfecta cutters even use "magnetic rubber" that is magnetically attached to the underside of the clamp to ensure a clean cut on embossed paper.

Right on target

Smooth running of the knife, powerful and precise blade drive, smoothly increasing adjustable pressure - three pillars of the precision cutting process. But no less important contributions to the overall performance are made by the cutter control system and the powerful cast frame, which dampens all external vibration influences. The weight of the bed is sometimes so significant that a number of manufacturers do not even consider it necessary to attach the cutter to the floor (MZE Eurocutter 780, SEM, Perfecta, Schneider Senator E-Line and others).

As for the control system, it provides high-precision positioning of the backplate, the minimum movement of which in the most advanced models is 0.01 mm. Of course, everyone understands that it is physically impossible to cut off a foot with such precision - you can remove at least 0.2 mm of chips from it, and the deviation in the total size will never be less than 0.1 mm. At the same time, the high accuracy of automatic positioning significantly facilitates obtaining the required cutting accuracy of 0.1 mm, since a very noticeable component of the total error disappears. It is not surprising that equipping a machine with such a system costs additional money - not all cutters are equipped with such a feature as standard (see table).

Cut to length

In addition to the listed technical issues, the choice of the most suitable BM is, of course, determined by the tasks facing the printing house. Here are three obvious criteria: length of cut, permissible foot height, type of materials allowed for cutting. Moreover, the longer the cut length, the more powerful the machine and, consequently, the greater the stack height and the wider the range of processed media. Ideally, the stated cutting length should not be much (20-30 mm) greater than the diagonal size of the foot, which allows the cutter to turn it over without extending it onto the front table of the machine.

Another, very significant criterion forces one to approach completely opposite results - price. It is he who should be “thanked” for the fact that in small and medium-sized printing houses the cutting length of the purchased BM is often selected not to match the diagonal of the foot being processed, but to its long side. An example is the already mentioned company Fastprint, where, to work with circulations produced on a MAN Roland 204 printing machine (format 520x720 mm, sheet diagonal - 888 mm), they recently purchased a Wohlenberg cut-tec 76 with a cutting length of 760 mm.

What do we cut?

The need to work with heavy materials - cardboard, metallized foil, thick laminated paper - may force you to purchase a machine with a deliberately longer cutting length. The reason is that only such cutters, equipped with hydraulic and electromechanical knife drives with a flywheel, as well as an adjustable hydraulic clamp, are able to cope with such work. Increasing the working length of the cut requires more powerful and precise mechanics; heavy, vibration-eliminating, one-piece frame; reinforced rear mounting and drive system. Such machines include Adast MAXIMA MS 80, MZE Eurocutter 780, Perfecta 76, Polar 78, SEM FL-76S, Schneider Senator E-Line, SWD SQZK 780, QZK 780 and QZX 780, Wohlenberg cut-tec 76. Loads when cutting dense materials are so large that there are even recommendations not to cut, for example, metallized foil on small-format machines.

Safety precautions

Working with such a formidable apparatus as a cutter, one of the most common synonyms of which is the word “guillotine,” certainly requires adequate safety measures. The first means of protecting the cutter is two start buttons located on the sides of the workbench, which must be pressed simultaneously. Next come mechanical and light protection systems, which, oddly enough, are not included in the basic equipment of a number of machines (see table). Since it is more expensive to save on protecting yourself (or rather, your cutter), the purchase of such configurations should not be considered even theoretically. Purchasing the most affordable protection system - a transparent plastic cap - is not always the best solution: its use in some cutter models (Polar is one of the exceptions) slightly narrows the maximum size of the processed foot.

The most universal solution is the so-called infrared light barrier (IR barrier), designed in the form of two “many-eyed ears” on the sides of the cutting machine’s work table. The more “eyes” the protection has, the lower they are to the table surface and closer to its front edge, the more reliable it is. Crossing the light barrier with your hand or any object leads to an instant stop of the knife and blocking of the pressure (with the exception of the preliminary one, which, by the way, can be very noticeable). In some machines, for example, SEM cutters, the protection system is as strict as possible for the inattentive cutter: following a violation of the protection during the cutting process, he, for “educational purposes,” must use a special screw to move the knife to its original upper position.

To make it convenient

Ease of use is of considerable importance when choosing a cutter. Purchasing air-cushion tables and additional side tables will greatly facilitate the work of the carver. In addition, on their basis (if there is sufficient production space, of course), it is possible to build production lines with sheet lifters and unloading devices (a number of companies, for example, Adast, MZE, Perfecta, Polar, Schneider Senator and SWD, offer similar equipment of their own production) . Enormous advantages come from installing an air cushion on tables, which makes moving heavy stacks of paper much more convenient. And cutting becomes more accurate - the sheets in the stack practically do not move as it moves along the air cushion. The chrome finish on the tables also helps. As Andrey Makushkin, director of the PrintHouse printing house, noted, when working on their Ideal cutter with a regular polished table, the cutter sometimes throws out the contaminated bottom sheet in the stack. And with the MZE Eurocutter in the printing house, which has a chrome-plated table that is more resistant to technical contamination, says Makushkin, this problem is eliminated. Of course, it is not only MZE that supplies chrome-plated tables for its cutters. These are also Adast, Perfecta, Polar, SEM, SWD

During the operation of the cutter, the design of the cutter drive becomes important. As is known, in many BMs its lead screw is located under the work table, which has a slot for moving the sleeve. As a result, there is a need to regularly remove paper dust flying into the slot and paper scraps that fall on the transport screw or worm pair. It is noticeably more convenient when the backplate is completely placed above the table (Eurocutter, Perfecta, SWD machines), and its leading screw is located in a separate assembly raised above the table.

Work according to the program

Fulfilling large orders, especially promotional products printed on offset machines, involves a huge number of cutting operations. This is where the ability to program a paper cutting machine comes to the aid of printing workers. As can be seen from the summary table, there are a large number of modifications of programmable cutters with a significant number of programs stored in memory (up to an unlimited number of them!). A number of manufacturers (Perfecta, Polar) even offer a very convenient, but rarely used function of transferring programs between machines using magnetic memory cards.

The programs themselves allow you to very quickly and accurately position the back of your head and automatically fix the foot with the required clamping force. As a result, the cutter can only turn or remove the foot in time and press the start buttons. In most programmable models, it is even possible to set the back of the foot to push out the foot - after the cut, it will automatically move forward along with the foot.

Working according to the program, of course, provides for preliminary adjustment of the rear positioning mechanism relative to the base coordinates. SWD machines are equipped with a very convenient function of “linearization” of the backing feed mechanism - the cutter enters two (or four to increase accuracy) real coordinates of the backing position, which are correlated by built-in automation with the internal coordinates of the machine. As a result, the linear dependence of the recalculation of basic and calculated cutting coordinates is constantly stored in the device’s memory.

Successful choice

To summarize, we can say that the choice of the required type of cutting equipment is quite obvious. The main thing is to find a reasonable compromise between the established upper price limit, which is determined by the budget allocated for the purchase, and the tasks set for the printing house. Of course, you should not skimp on a digital cutter control system and programming tools. Otherwise, pretty soon the cutters at your printing house will watch with white envy how quickly and easily their colleagues prepare the cutter for work, having long forgotten the difficulties of accurately setting the backing manually.

The author is deeply grateful to the specialists of the companies Fastprint, HGS Group, PrintHouse, terraPrint, YAM International, Aqualon, Animar Graphicpress, Apostrophe, Variant, Heidelberg-CIS, Nissa, New Idea, Office Printing", "Fert" and the PrintHouse printing house for their assistance in preparing this article.

On the edge of a knife

| Rice. 4. Scheme of double sharpening of a knife blade. |

The standard package of each BM usually includes two knives.

Since they are not always made of special hardened steel, it is recommended to immediately think about buying a pair of more durable knives. Usually these are knives made of so-called HSS steel (High Sweden Steel) or even with carbide tips (for example, HM knives from Polar). They are much (4-5 times) more durable than regular ones, which significantly increases the periodic sharpening interval. There is, however, one “but” here - sharpening the “hardest” imported knives requires special equipment, which may either not be available in a particular region or simply be inaccessible. The owners of such equipment are specialized companies or large printing houses, where customers turn. The cost of sharpening, as a rule, is purely symbolic - about 200 rubles per knife. With only two or three knives, a small printing house sharpens them either simultaneously or alternately, organizing a continuous cycle of work. TABLE 1. SHARPENING ANGLES RECOMMENDED BY SWD

The service life of a knife before sharpening naturally depends on the load and type of material being processed. Technical director Andrei Zaslavsky said that with a daily 10-12 hour load on their Perfecta 76 cutter (alternating cutting of cardboard and offset paper), they resharpen two HSS steel knives every 10 days. Over the past two years of using the cutter, I have not yet had to buy new knives. The production process is intensive in the printing house, where a Schneider Senator E-Line cutter was installed two years ago. Here they work with five knives, changing the knife on average weekly. In the case of cutting metallized paper (the printing house deals with silk-screen printing), the knife “shrinks” after just two hours of continuous operation.

The cutter at the Fastprint company is somewhat less loaded, where knives are sharpened every three weeks (offset, coated, textured, laminated paper is cut), and a knife made of ordinary steel was worn out, as they say, “to the root,” after three years of work.

Note that to increase the service life of a knife, its double sharpening is effective, when an additional chamfer is removed from the cutting edge (Fig. 4). TABLE 2. POLAR RECOMMENDED CUTTING PARAMETERS

| Note: 1 daN is a decanewton, a unit of force equal to 101 N. Approximately equivalent to 1 kgf. All contact pressure values refer to medium format sheets occupying more than 2/3 of the cutting width. |

It is useful to purchase knives sharpened at different angles along with the cutter (the denser the material, the greater the sharpening angle). Knives with different angles, for example, are immediately offered by Adast and Perfecta. You can, of course, resharpen the knife to the desired angle later, guided by the relevant requirements. In table 1, in particular, provides recommendations from SWD specialists. Even more detailed information from Polar cutter suppliers, even indicating recommended clamping forces, is included in table. 2. By the way, it is clear from it that for cutting the densest materials it is still better to use powerful cutters with greater clamping force (and length and cutting force, respectively) than the paper cutting machines considered in this review.

And finally, you need to purchase knives from a reliable and trusted supplier. As the director of the PrintHouse printing house Andrey Makushkin said, for example, a knife they bought from HSS steel, when cutting a magazine edition with seamless fastening (with glue), became covered with chips after cutting the first two reams (in total, it was only enough to cut 500 circulation copies). After purchasing a knife from another company, things went like clockwork.

back

Reciprocating paper cutter

The number of sheets that the desktop device cuts simultaneously does not exceed 50. How is a saber-type paper cutter different from others? The knife is equipped with a plastic handle on one side, and the other is attached to the base. For maximum cutting accuracy in this species, it is important to monitor the sharpness of the knife. The models are low cost. Advantages of the reciprocating cutter:

- marking on the surface of the base;

- working with cardboard up to 0.4 cm thick;

- fixing device for pressing sheets;

- backlight on some models.

Minuses:

- work process noise;

- difficult to sharpen blades;

- Thick paper quickly dulls the knife;

- error up to 0.2 cm when working with a large number of sheets.

Varieties

Paper cutters are a high-quality and unique product that will help you cope with large volumes of sheets. There are a large number of this tool in stores, but they can all be divided into three groups:

- Runners;

- Roller;

- Saber.

Each of the subspecies differs not only in external parameters, but also in capabilities. Therefore, in order to get an overall picture, you should familiarize yourself a little with the key features of each type.

Running cutters

As the name suggests, the main part of the mechanism is the runner knife. It is made in the shape of a triangle. The advantage of this design is the ability to cut paper in both directions. Smooth and safe movement of the blade is ensured thanks to a special groove located on the working surface. You can buy such models on AliExpress, but it is better to give preference to a trusted company - Fiskars. Because their product will last a long time, and the blade will not dull quickly.

The advantages of this option include:

- With one movement, a person can create a window (of different sizes) in postcards, as well as a passe-partout. This is due to the fact that the cut can be made from any point on the sheet, and not from the periphery. All models are equipped with a convenient ruler that allows you to make a cut of the required length;

- There is a special thin wire that indicates how the cut line will look. It is located along the measuring instrument, so it is in the person’s field of vision, which is convenient. A person will no longer have to calculate the distance from the edge of the paper to the cut;

- Often, such models are used to create beautiful and neat folds. This became possible thanks to the presence of a corresponding groove. The advantage of this fold is evenness and the absence of jams.

Not everything is so perfect with runner cutters, otherwise they would be used everywhere. Unfortunately, the device is not without its drawbacks, including:

- The blade deteriorates faster than other types of cutters. Of course, the problem can be solved by quickly replacing the sharp part, but this is an additional cost;

- Beautiful waves, perforations and other decorative solutions are not available to the user;

- The maximum number of sheets to be cut is 1-2, no more. Therefore, this product is not suitable for large office work.

Features of roller options

The device has a convenient sharp disk-shaped element. It is located on a special cassette. A rubber strip is used for rotation; in appearance it resembles a mat. The only thing that is important to remember is that the lower part wears out over time, so it is necessary to constantly turn it over.

Advantages of this implementation:

- A person can easily change the blade to a decorative one, which will allow him to create beautiful cutouts and decorate various envelopes;

- The product is suitable for cutting several sheets or paper at once; the product copes with the task with 5 points.

There are also disadvantages:

- The user will not be able to make a cut in the middle because the design works exclusively with the edges;

- There are no thin wires on the ruler here, so a person does not see the cutting line, which can complicate the work.

Reciprocating cutters

Many users like this option due to its convenience and simple mechanism of action. The model range of this design is quite wide, so every buyer will find a suitable product for him. The device consists of a special frame, a large and heavy knife is attached to it. Cutting sheets or paper will require a lot of physical effort.

Of course, this is not entirely convenient, but if we consider this option solely from the point of view of accuracy and volume, then the benefits of this cutter are obvious. Because the product allows you to work with large volumes of material with high precision (down to the millimeter). Professional equipment can handle 800 sheets of A4 format and standard density at a time. From this point of view, the product will become an indispensable assistant in the printing house.

In addition to classic reciprocating cutters, versions equipped with optical illumination are also available. Therefore, a person can clearly see the cut line. The equipment is completely safe, since the sharp element has a protective casing located on both sides. There is also no easy access to the cutter mechanism.

Advantages:

- The user gets a straight, neat line;

- Unlike the disk and runner options, here the knife does not become loose, but stays firmly in place;

- Cutting one stack is carried out with the movement of one hand; if desired, the equipment can easily cope with cardboard;

- The last advantage of the options is durability and reliability.

Not without its drawbacks:

- The installed blade cannot be replaced, but this cannot be considered a significant drawback, since the cutting element remains sharp for a long time, even if the device is used every day;

- The product is not intended for decorative cuts, only for printing work;

- It is not possible to make a slot or window in the middle of the sheet.

Which paper cutter is best?

Which paper cutter is better to buy, a roller cutter or a reciprocating cutter, depends on the intended use of the device. The roller type is suitable for home use, while the reciprocating type can be purchased for the office. The guillotine model is useful in a printing house or an enterprise with a large turnover of documentation. How to choose the right paper cutter? It is necessary to take into account such parameters as:

- cutting parameters;

- cutting type;

- type of paper fixation;

- desktop size;

- duration of the warranty;

- safety of use;

- the ability to change a simple blade into a curly one.

What other types are there?

In addition to dividing by type of design, it is important to know that the equipment also differs in size. Today the following options are available:

- Compact;

- Portable;

- Professional (desktop).

The compact cutter will be an excellent addition for organizations that create handmade cards, cards, notepads, etc. The advantage of the product is precisely its dimensions, so it is a pleasure to work with it. The only drawback is that the maximum paper width is 22 cm. Therefore, the product is not suitable for office work and printing, because it cannot handle A4 format.

Portable cutters impress not only with their convenience, but also with their ease of use. On the cut side, the product is still long, since the value is 30-35 cm. Unfortunately, the width of such equipment usually reaches 15 cm. If we talk about storage and transportation, then this model is convenient. It can be placed in luggage without any problems and it does not take up much space. In addition, a person can easily cut paper of various formats anywhere, even in a cafe at a table. To simplify the task, the manufacturer has equipped the product with a special ruler, which extends when needed and is easily removed after applying the design.

Tabletop versions are characterized by large dimensions in length and width. If we talk only about working with them, then they are better than previous copies, because they are stable. A person can place a large sheet on a surface and cut it without any problem. The product will be an excellent solution for printing houses or private craftsmen who constantly use cutters.

Paper cutter rating

Devices for cutting paper in the office under the following names are distinguished by consumers from the presented range of specialized retail outlets:

- KW-triO reciprocating cutter for 10, 15, 20 sheets. The tool has outstanding technical characteristics. To protect the operator, the design has a special screen.

- FELLOWES ELECTRON A4. The set includes running, dotted, and figured knives. Roller model, simultaneously cuts 10 paper sheets.

- FELLOWES NEUTRON PLUS A4. Roller cutter with a set of 4 different blades. The model has many positive customer reviews.

Top 5 best roller models

KW-triO 3016

A high-quality disk device that has automatic paper clamping. The maximum cutting length is 33 cm. The product copes with cutting various papers, as well as cardboard. The maximum number of sheets for simultaneous cutting is 10. The desktop has convenient markings, thanks to which a person can easily adapt to different formats. The device does not take up space on your desktop and is neatly designed.

Sold at a price: from 1,260 rubles.

KW-triO 3016

Advantages:

- Good workmanship;

- Convenient operation;

- Attractive appearance;

- Marking on the working surface;

- Cuts up to 10 sheets at a time.

Flaws:

- Not found.

Berlingo DRn_00010

Inexpensive office cutter. Which can easily handle 5 sheets in one pass. The cutting elements are made of durable materials, which guarantees a long service life. The maximum cutting length is 30 cm, which is a good indicator. The blade is placed in a special plastic cartridge, which indicates the safety of the product. A person will not cut himself even due to carelessness. There is only one knife in the kit; if it gets damaged, you will have to buy additional ones, but they are sold in various office supply stores.

The average cost is 850 rubles.

Berlingo DRn_00010

Advantages:

- Value for money;

- Smooth cut;

- Hands do not get tired even with prolonged use;

- Suitable for offices, photo studios and home use;

- Optimal cutting length.

Flaws:

- Not found.

Rexel SmartCut A100 (2101961)

A good disk-type model that will help a person cut paper in the desired way. This guarantees a neat cut, which can be difficult to achieve when using office scissors. The product can handle 5 sheets of format no larger than A4 at a time. The cutter will never fail, as it is made of durable materials.

All work is carried out with millimeter precision, so you don’t have to worry that the paper will be transferred in vain. Every user will be able to work with the device, since there are no complicated mechanisms here, everything is simple and clear.

Sold at a price: from 1,210 rubles.

Rexel SmartCut A100 (2101961)

Advantages:

- Works well even with thick paper;

- Does not take up much space on the table, but is stable;

- The kit includes a replacement blade;

- The sharp part slowly becomes dull;

- Low cost.

Flaws:

- You need to cut with a quick movement;

- Not suitable for trimming.

JIELISI/Bulros 949-1

A good roller version, which has a good assembly. Designed for quick cutting of photo paper, laminate and standard A4 sheets. The product is suitable for office and home use, there is nothing complicated, and maintenance is also time-consuming. If handled correctly, the structure will last a long time and will not require special care. Using this tool, a person gets a high-quality and even cut.

The average cost is 3,000 rubles.

JIELISI/Bulros 949-1

Advantages:

- Reliable design;

- Good surface stability;

- The sharp elements are made of durable steel;

- Small sizes;

- Complete operator safety;

- Reliable clamping mechanism.

Flaws:

- Not found.

Paper cutter ErichKrause, with mat

A convenient, portable model that is suitable for those who like to work in different places and not be confined to their home. Due to its small dimensions, the product does not require much storage space. The weight is only 345 grams, but despite this the device will cut up to 5 sheets at a time, inclusive. Therefore, the product cannot be underestimated. The cutter is made of durable materials, and for accuracy, the manufacturer included a rubber mat. Maximum format – A4.

Sold at a price: from 1,045 rubles.

Paper cutter ErichKrause, with mat

Advantages:

- Light weight;

- Mobility;

- Acceptable spiciness;

- High quality rug;

- Handles a stack of 5 sheets well;

- No bumps or irregularities;

- Handles photo paper.

Flaws:

- The ruler cannot be fixed;

- Pronounced plastic smell after unpacking.

Setting up a cutting torch

Before starting work, you should assemble the equipment and check its functionality in accordance with the “Operating Instructions”. Only after this can the metal processing process begin.

If you do not have access to the “Instructions”, then proceed in the following sequence. Before assembly, it is necessary to carry out an external inspection of the components and parts:

- check the condition of all rubber gaskets . If there are the slightest defects, they must be replaced;

- carefully inspect the oxygen valve . The slightest traces of oil or fat are not allowed on its surface - their presence can lead to an explosion;

- carefully inspect the fittings . The flammable gas connection must have a check valve. Defects on the fittings should be carefully corrected with a “velvet” file. If this is not done, then the rubber gasket of the gearbox will “poison” with all the ensuing consequences.

After inspection, gearboxes should be installed:

- blue – for an oxygen cylinder;

- red - for a propane tank.

If the cutter has injection, you should check its functionality:

- the check is carried out before connecting the flammable gas hose;

- the oxygen hose is connected to the corresponding fitting;

- open the oxygen reducer valve;

- open the oxygen and flammable gas valves on the cutter;

- Place your finger on the flammable gas fitting. If everything works, then it should be “sucked in”. In this case there will be no backlash.

Next, a propane hose is installed and gas is connected. The ratio of propane and oxygen is set to 1:10. For example, if the oxygen pressure is 5 atm, then the propane pressure should be set to 0.5 atm.

It is necessary to open and stop the gas supply in the following sequence:

- open each oxygen and flammable gas valves by 0.5 turns (the sequence cannot be changed). Set the mixture on fire;

- bring the torch to the metal and add oxygen until a “crown” appears;

- upon completion of work: the supply of flammable gas is stopped first, then oxygen (the sequence cannot be changed).

Shredder secrecy

Many shredder buyers are concerned about the reliability of document destruction and whether the information recorded on it can be restored.

The security level of a paper shredder is based on the degree of shredding of the sheets. The smaller the paper shredded into more pieces, the higher its level of secrecy.

Security levels

The DIN 66399 standard provides seven security levels.

| Privacy level | cutting technologies | Strip width | Fragment area |

| P1 | straight | 12 mm | |

| P2 | straight | 6 mm | |

| P3 | straight | 2 mm | |

| P4 | cross | no more than 160 mm² | |

| P5 | cross | no more than 30 mm² | |

| P6 | cross | no more than 10 mm² | |

| P7 | cross | no more than 5 mm² |

The first and second levels are recommended for documentation that is of no value; the third level is already associated with the great complexity of restoring commercial proposals, various kinds of presentations, and outdated price lists.

The fourth level is the most popular among users. It is the most universal; it is used to destroy banking and accounting documentation, documents with personal information, commercial or state secrets.

Level 5 secrecy is indicated by a sheet cut into 2 thousand fragments. At the seventh level, the leaf is crushed into more than 12 thousand parts, it is impossible to restore it.

The maximum level of destruction is achieved by placing the document in the slot with the narrow side. Cutting along the side of a document may leave legible text on pieces of paper.

DAHLE 440

The model can simultaneously cut up to 35 sheets of paper up to 3.5 mm thick. The cutting disc itself is made of high-alloy steel, which ensures precise cutting of paper or loose cardboard. The pressure roller efficiently and reliably presses the paper against the counter blade, which provides additional sharpening of the blade. Thanks to this, the knives will last a long time. The cutter is installed on a metal table with rubberized legs. The body has a division scale, automatic clamp, and two corner attachments with a rod.

Pros:

- High build quality;

- Cuts paper accurately and reliably without burrs;

- Sturdy metal table base;

- Sharp knives;

- Durable and high quality cutter.

Benefits of a paper shredder

The level of document destruction helps to avoid leakage of valuable information and maintain the secrecy and confidentiality of banking and accounting records. In addition, shredded paper, when supplied to factories that process recyclable materials, reduces its processing stages and saves office workers time in destroying important documents.

The importance of the levels of secrecy in the destruction of documents is well demonstrated in the film “Operation Argo,” the plot of which was the operation to seize the American embassy in Iran. Iranian intelligence services managed to restore documents destroyed by embassy workers using a shredder with a low level of secrecy.