It is impossible to achieve the desired welding quality without the correct choice of electrodes. A clear understanding of the market will help you avoid mistakes. It is necessary to know about the types of products from different manufacturers, recommendations regarding the use of a specific brand, and the principles of marking electrodes.

- Consumable and non-consumable electrodes

Purpose of welding electrodes

The role of electrodes is reduced to forming an arc in electric arc welding. The quality of the electrodes directly affects the efficiency and results. How stable the arc will be, how deeply the metal will heat up, how easy it is to ignite the arc and other nuances during welding are determined by the choice of electrodes. They have to:

- maintain a stable arc during operation;

- melt evenly;

- form a neat seam with the desired chemical composition;

- create conditions to minimize the splashing of hot metal;

- help improve the efficiency of welding work;

- ensure joint strength;

- have a low degree of toxicity.

In addition, the slag that is formed during the welding process should be easily removed.

What types of electrodes are there for welding?

All electrodes presented on the domestic market are divided into types that are designed to work with various metals. There is a separate group of products for welding for different grades of steel, cast iron, non-ferrous metals, aluminum and its alloys. Thanks to this division, it is easier for the welder to choose equipment and the optimal mode when working with a specific metal. There is also a separate group of electrodes that are used exclusively for the so-called “metal surfacing”.

Features of manual technological operations are also a determining factor that affects the classification of electrodes. After all, welding work can be performed with different electrode locations, degrees of metal penetration, weld pool depth and other features.

The thickness of the electrode determines whether it belongs to thin (M), thick (D) or medium-sized products (C). Depending on the type of coating, products are divided into four groups:

- sour – marked A;

- cellulose – C;

- main – B;

- rutile - P;

- combined or mixed. It is marked depending on what types of coatings are used - RB, RC, AR or others.

If the electrode has a coating that goes beyond the above classification, it is designated by the letter “P” - other. The composition of the coating includes additives that are intended to improve the quality of the weld made of a particular material. For example, the rutile coating of the electrode prevents the formation of voids and cracks in the weld area. Electrodes are also classified depending on the polarity of the supply current, voltage, diameter, and length of the rod.

In case of emergency, electrodes can be made independently. To do this you will need steel wire with a diameter ranging from 1.6 to 6 mm. Segments about 35 centimeters long are made from it. A mixture of chalk and silicate glue is suitable for coating.

We select high quality components

Modern welding equipment is manufactured in accordance with GOST. Electrodes are no exception. According to the standards, the rod is made of high-quality material. The latter is purchased from a supplier who provides all certificates for it.

Speaking of coating components, manual arch welding requires the use of electrodes without defects that are visible to the naked eye. They should not have large cracks with a diameter of more than 2 cm.

While the rod is melting, it should not crumble or burn unevenly. Spraying occurs smoothly, without visible deviations. The standards depend on the specific type of coating.

It is important that the rod does not bend under load. It must be resistant to heavy weight. The connection will be strong, without obvious pores. By checking these points, you will be able to choose the right welding rod for your job.

Classification of electrodes according to GOST 9466-75

Coated metal electrodes intended for manual arc welding are divided into groups according to several parameters: purpose, chemical composition and mechanical properties, thickness and type of coating applied. In addition, welding and technological indicators are also taken into account.

Types of electrodes by purpose

Depending on the scope of use, the products are intended:

- for working with carbon or low-carbon materials, the degree of tensile strength of which does not exceed 600 MPa. They are marked with the letter “U”;

- for joining workpieces made of structural alloy steel, the tensile strength of which does not exceed 600 MPa. Electrodes are marked with the letter “L”;

- for welding alloy steel, resistant to high temperatures. Products are designated by the letter “T”;

- for welding high-alloy steel with special characteristics. The visual marker is the letter “B”;

- to create a deposited layer on the surface of materials with special properties. The electrodes are designated with the letter “H”.

The listed standards divide electrodes into types depending on the chemical composition of the deposited metal and in accordance with the mechanical characteristics of the material being processed. The marking contains numbers indicating the minimum tensile strength in kgf/mm2: E42, E42A, E50 and others. The letter after the digital marker indicates high plastic characteristics, good viscosity and limitations on chemical components.

By coating thickness

This indicator provides for the division of products taking into account the D/d ratio, where D corresponds to the diameter of the coating, and d to the circumference of the metal rod. It is customary to distinguish electrodes by coating thickness:

- thin . The diameter ratio is less than 1.2. Marked with the letter “M”;

- average . The result is in the range 1.2 < x < 4.5. Indicated by the letter “C”;

- thick _ The coefficient is less than 1.8, but more than 1.45. Marker - “D”;

- especially thick . The number obtained by dividing the two diameters is above 1.8. The “G” marking is a distinctive feature of the product.

According to the provisions of GOST 9466 - 75, it is divided into three groups that differ in quality. It is determined by the condition of the coating, the precision of the coating and the rod, the content of phosphorus and sulfur in the deposit.

Types of electrode coating

The values are shown in the table below:

| Coverage type | Designation according to GOST 9466-75 | International ISO designation |

| Sour | A | A |

| Basics | B | B |

| Rutile | R | R |

| Pulp | C | C |

| Mixed coatings | ||

| Acid-rutile | AR | AR |

| Rutile-basic | RB | R.B. |

| Rutile-cellulose | RC | R.C. |

| Other (mixed) | P | S |

| Rutile with iron powder | RJ | R.R. |

According to the spatial location of the float

Electrodes should be selected depending on the spatial location of the joint:

- recommended for work in any position - designated “1”;

- the location of the weld in any position except the top-down direction is allowed - “2”;

- for the following spatial arrangement: vertical, horizontal, bottom and vertical from bottom to top - “3”;

- for working in the lower position, including the boat method - “4”.

By type and polarity of current

All values are collected in table form:

| Recommended DC Polarity | Open circuit voltage of AC source, V | Designation | |

| Rated voltage | Maximum deviation | ||

| Reverse | — | — | 0 |

| Any | 50 | ±5 | 1 |

| Straight | 2 | ||

| Reverse | 3 | ||

| Any | 70 | ±10 | 4 |

| Straight | 5 | ||

| Reverse | 6 | ||

| Any | 90 | ±5 | 7 |

| Straight | 8 | ||

| Reverse | 9 | ||

Selecting the electrode diameter depending on the thickness of the metal being welded

As a rule, the diameter can be selected based on the thickness of the metal of the product. As mentioned above, the greater the thickness of the metal, the larger the diameter of the electrode should be. It is worth noting that the choice of diameter is influenced not only by the thickness of the metal, but also by its properties. Basic recommendations for choosing the electrode diameter.

- For parts with a thickness of 1.5 to 2 mm, a Ø 2 mm electrode is suitable.

- To connect workpieces 3 mm thick, electrodes Ø 2.5 or 3 mm are suitable.

- If the thickness of the parts to be welded is from 4 to 5 mm, products with a diameter of 3 or 4 mm should be used.

- For structures with a thickness of 6 to 12 mm, it is best to choose electrodes Ø 4 or 5 mm.

- If the thickness of the elements to be welded exceeds 13 mm, then products with a diameter of 5 or 6 mm should be used.

When the workpiece thickness is less than 1.5 mm, manual welding, as a rule, is not used.

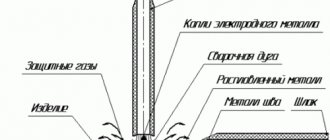

What does a welding electrode consist of?

By and large, an electrode is a piece of wire through which electric current passes during welding. The surface is covered with a special chemical composition that determines the properties of the product. There are electrodes that are just a piece of wire and do not have any additional coating. They are called uncovered.

Consumable and non-consumable electrodes

The rod inside the electrodes is made of metal and, less commonly, of copper rod. Its task is to fill the weld pool with a melt that connects two workpieces to each other. The coating around the metal rod determines the chemical characteristics of the electrode and contains substances that improve the quality of the seam.

Non-consumable electrodes are made from powdered materials. The most commonly used are coal or tungsten. They improve the quality of adhesion of the parts being connected. The weld is formed without melting the metal rod, and the electrode material is consumed as filler wire. The most common material used in the production of such electrodes is amorphous carbon. The finished product is an elongated oval rod.

This kind of carbon electrodes is used to form seams with high aesthetic values. They are also in demand for air-arc cutting of thick metal workpieces.

Electrodes for spot welding

Separate attention should be paid to equipment intended for spot welding. Features of the technology are to preserve the initial shape of the parts being connected and ensure the required degree of electrical conductivity.

To solve problems of this kind, special devices are provided that work without conventional electrodes. Their role is replaced by special copper contacts made in the form of pointed rods. At home, such contacts can be made independently. For example, use waste tips from powerful soldering irons.

For a beginner welder

The most suitable consumables for beginners when welding with an inverter are rutile-coated electrodes MP-3 and ANO-21. For welding stainless steel, you can use products of the OZL-8 and TsL-11 brands. Consumables UONI-13/55 with a basic coating are more difficult to master, but are capable of providing high-quality and durable seams.

Most often, novice welders are recommended to use MP-3 electrodes. They ensure that a decent quality seam is obtained even with little experience. This is achieved due to easy ignition of the arc and fairly simple control of the weld pool, as well as its good protection from oxygen. Possibility of welding on contaminated and oxidized surfaces. Another advantage is the ability to weld in any spatial position, except vertical from top to bottom. They can cook both on direct current when connected to inverters or rectifiers, and on alternating current using transformers.

Types and composition of coating of welding electrodes

For manual arc welding, electrodes are used, consisting of rods 25-45 cm long, on the surface of which a layer of special coating is applied. There are several classes of them on the market:

- stabilizing . They contain elements that perfectly ionize the welding arc. In most cases, the coating is applied to the rods in a thin layer - thin-coated electrodes;

- protective _ The covering is made from a mixture of different materials. The main task of the composition is to protect the melt zone from exposure to atmospheric air. In addition, they promote stable arc burning, refine and alloy the seam;

- magnetic . They are applied to the rod directly during welding. Spraying is carried out under the influence of electromagnetic forces that are formed between a live wire and ferrimagnetic powder poured into a special hopper. The wire or rod is fed into the welding zone through this hopper.

There are the following main types of electrode coatings:

- acid ore . They contain oxides of manganese and iron, silica and a lot of ferromanganese. To create a protective environment, organic substances are included in the composition - starch, wood flour, cellulose and others;

- rutile _ They are becoming increasingly popular thanks to the development of technologies for the extraction of rutile minerals. Its main component is titanium dioxide (TiO2). In addition to rutile, coatings also contain other elements: potassium and magnesium carbonates, ferromanganese, silica;

- calcium fluoride . The composition includes calcium and magnesium carbonates, ferroalloys and fluorspar;

- organic . The composition contains mainly organic compounds. Most often, oxycellulose is used with the addition of slag-forming materials, deoxidizers and alloying additives.

Video description

Explanation of electrode designations.

Below we will talk about the classification of electrode elements, their purpose and properties.

The purpose of the metal rod is to fuse the material being welded to a specific place where the workpiece is joined. The main part of the electrode serves to conduct current through itself. The end of the consumable melts under the influence of the elevated temperature of the welding arc. At the moment of melting of the end of the electrode, a complete product is formed together with the molten structure.

What does a consumable electrode consist of?

The welding electrode has a simple structure. Its main component is the rod; a special coating is made on the outside. The end that melts and comes into contact with the material being welded is made without coating.

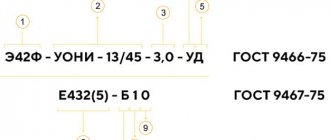

Labeling rules

A specific scheme is used to mark all types of existing electrodes. According to its construction, the first digit determines the type of electrode, the next position informs about the brand of the product, and it is followed by the diameter designation.

The fourth in this scheme is the code that determines the purpose, and the fifth is the thickness of the coating. The sixth is a code that characterizes the welding seam or metal deposit. Below you can read information about the coating of the rod. The eighth position provides information about the spatial location of the electrode during welding, and the ninth - about the voltage and type of current.

For a better understanding, it is worth considering a specific example:

The first four characters “E46A” carry information about the type of electrode rod. It deciphers like this:

- E – intended for electric arc welding;

- 46 – unit of arc rupture resistance according to GOST 9467-75 standards;

- A – improved rod class.

The next index “U” in the marking means that the electrode can be used in work with alloy and low-carbon steel. “D2” is assigned to the second group of products based on coating thickness.

The marking in the denominator 432(5) is a parameter of the weld joint that forms the weld. “B” is the main type of electrode coating. The position of the electrode during work corresponds to the value “1”. Current mode “0” is the reverse polarity of direct current.

Below is a table about the meaning of metal rod coating markings:

| Coverage type | Marking according to GOST 9466-75 | International ISO marking | Marking according to the old GOST 9467-60 |

| sour | A | A | P (acid ore) |

| basic | B | B | F (calcium fluoride) |

| rutile | R | R | T (rutile (titanium)) |

| cellulose | C | C | O (organic) |

| mixed types of coating | |||

| acid rutile | AR | AR | |

| rutile-basic | RB | R.C. | |

| mixed other | P | S | |

| rutile with iron powder | RJ | R.R. | |

Rating of foreign and Russian manufacturers of coated consumables

Now let's talk about choosing the highest quality electrodes. Let's start with manufacturers - world and domestic leaders. The criteria for their evaluation may be the breadth of the product line and production volumes, the presence of these manufacturers in professional reviews dedicated to welding, reviews of experts and craftsmen, and, finally, the types of electrodes for welding and the quality of the products themselves.

Letter marking.

First the world leaders:

ESAB

This Swedish company is more than a hundred years old, it holds a real championship in the quality, advancement and variety of its products. Swedish products are loved by both home craftsmen and in industry: their wide range offers options for every taste, as they say.

Kobe Steel

The Japanese have been working in this area for a long time and very seriously. They immediately identified a specific niche for themselves - oil and gas production enterprises. So Kobe Steel and oil workers around the world have a long and deep mutual love.

Klockner & Co SE

These are the Germans. The most popular foreign company in Russia producing welding consumables and other related products. In fact, the main specialization of the company is the production of a wide variety of steel alloys, so all their types of welding electrodes are only related products from Klocker & Co SE.

And now the Russians

Craftsmen and experts praise the consumables of this plant the most – both in terms of the breadth of the line and the quality. Despite the fact that the main consumers of this plant are large machine-building plants, they produce excellent products for ordinary buyers.

One of the oldest domestic production facilities, located in St. Petersburg. You can safely take consumables from St. Petersburg “electrodes”, the quality will not let you down.

NPO "Spetselektrod"

Plant in the Rostov region, in Volgodonsk. Reviews about their products vary, but most of them are positive. In any case, this is a production with quality standards, correct labeling, a good line and, most importantly, an inexpensive price. Try it.

NPP "Welding Eurasia"

How does a welding electrode work?

They offer the widest product line in Russia and are aggressive in promoting their products. NPP is a research and production enterprise. Apparently, the company unites several factories and produces electrodes under common brands. Reviews are also different, but most are positive or neutral. So you can take their consumables. And try, of course.

If we analyze numerous forums of professional and home welders regarding the quality of certain consumables, then the main complaint about the quality of electrodes, if any, is sticking. Based on this, we ask the question: can the best Swedish electrodes in the world stick?

We answer: of course they can. If they are stored incorrectly or if they are used to cook on surfaces other than those for which they are intended. Therefore, we advise you to approach the choice of electrode manufacturer with feeling, sense and without emotions. The main thing is precise procedures and standards.

Drying and calcination of electrodes

During transportation or storage, the electrodes may become damp. In this case, preliminary drying is needed, or even better, calcination. This is a very important procedure, which ultimately has a positive effect on arc ignition.

You should not frequently resort to calcining the electrodes, since repeated heating can damage the coating of the rod. It is advisable to undergo the procedure only the number of electrodes required for the current work. Or there should be very few of them left.

Piercing is also practical because it raises the temperature of the electrodes immediately before work. This is important, for example, for welding pipes or when working with thick workpieces. Preheating makes it possible to obtain tight joints during “pressure welding”. But keep in mind that gradual heating is important. With a sharp change in temperature, the formation of limescale cannot be ruled out.

Calcination is associated with the deadlines and duration of storage of the electrodes. According to generally accepted standards, the maximum shelf life of domestic products is five years. In practice, electrodes can be stored slightly longer without losing their characteristics.