The petrol cutter is designed for fast and productive cutting of hard materials. This tool is successfully used where conventional cutting devices - circular, chain or circular saws - cannot cope. The first gas cutters appeared in the 50s of the last century. Currently, they are in service with rescue and fire services and are widely used in construction, incl. on the road, as well as in production and at home.

- 2 Design and principle of operation of a gas cutter

- 3 Choosing a gas cutter: main points

- 4 Intensity of use

- 5 Properties of the working material

- 6 Cutting method

- 7 Ergonomics

- 8 Safety requirements

- 9 Features of choosing a gas cutting tool

- 10 Working with a gas cutter, video

Advantages of gas cutters

The main advantages of this type of cutting tool are mobility and autonomy. Petrol cutters can work indoors and on construction sites where there is no electricity. Being a hand tool, they allow you to cut in hard-to-reach places.

With the purchase of a gas cutter, there is no need to purchase a whole arsenal of cutting machines. After all, this equipment is multifunctional and allows you to solve a wide variety of industrial and household tasks. Thus, gas cutters are used for cutting concrete, asphalt, brick or stone masonry, metal structures, plastics and composite materials. With their help, dismantling work, gating, cutting openings in walls and ceilings, etc. are performed. In addition, these units are successfully used in gardening, as well as in the construction of private houses and auxiliary buildings.

The petrol cutter is a rather massive and heavy tool. Therefore, when choosing a particular model, you should take into account its ergonomics, as well as the ratio of power, weight and vibration level.

Design and principle of operation of a gas cutter

The main component of a gas cutting tool is an engine, mainly a 2-stroke engine, which runs on a fuel mixture of oil and gasoline. The unit is mounted on a housing equipped with special handles and controls. The functional part of the gas cutter is the drive, on which a cutting disc with a diameter of 300-400 mm, protected by a casing, is installed. The transmission of torque from the engine to the drive is carried out via a belt.

The main feature of modern gas cutters is the presence of a multi-stage dust protection system. It prevents contamination of the carburetor, cylinder-piston group and bearings. In addition, dry cutting uses water cooling of the disc. It effectively neutralizes the main flow of dust and prevents a number of negative consequences of overheating, in particular, premature wear of the cutting element and destruction of its structure, and also reduces the load on the engine.

When working with a gas cutter, it is necessary to maintain a right angle between the cutting disc and the surface being processed. This reduces the load on the drive and prevents slippage from the cutting line and damage to the cutting edge. The maximum insertion depth of the disk for various models is in the range of 10-30 cm. When cutting dry materials, you should not use a gas cutter for more than 30-50 seconds - within 15-20 seconds after making the cut, it is necessary to ensure free rotation of the disk.

Powerful models weighing more than 15 kg are equipped with transport trolleys with a remote control system or special legs, which allow the tool to be firmly fixed when cutting.

Design

HUSQVARNA K750 cutter diagram

1 – Front handle; 2 – Water supply tap; 3 – Warning sticker; 4 – Air filter cover; 5 – Cylinder cover; 6 – Choke; 7 – Throttle trigger locking lever; 8 – Gas trigger; 9 – Starting gas clamp; 10 – Stop contact; 11 – OilGuard shutdown function (K750 OilGuard); 12 – Starter handle; 13 – Starter; 14 – Muffler; 15 – Fuel tank; 16 – Decompression valve; 17 – Cutting disc shield; 18 – Adjustment knob for protection; 19 – Belt shield; 20 – Water connection with filter; 21 – Cutting lever; 22 – Data plate; 23 – Belt tensioner; 24 – Cutting unit; 25 – Cutting disc; 26 – Universal key;

Petrol cutter Husqvarna k750

Choosing a gas cutter: main points

To ensure that the gas cutter does not disappoint its owner during operation, before purchasing a particular model, you need to study its individual characteristics:

- design features;

- functionality;

- power;

- weight;

- cutting depth;

- features of the filtration system;

- start time;

- ergonomics;

- ease of maintenance.

You should choose a power cutter based on conditions such as intensity of use, scope and method of application, as well as user requests for ergonomics and safety requirements at work. All this deserves separate consideration, since its effectiveness and ease of use directly depend on the correct choice of tool.

Maintenance

Below are some general routine maintenance instructions. If you have any further questions, please contact your dealer.

Maintenance instructions

Daily

- Check the safe operation of the throttle handle parts (throttle handle and starting throttle lock).

- Check the drive belt tension.

- Check the condition of the blade and drive wheel.

- Check the condition of the blade guard.

- Check the starter and starter cord and clean the outside of the starter air intake.

- Check the tightness of the nuts and bolts and tighten if necessary.

- Check the operation of the stop contact.

Weekly

- Check, clean or replace the plastic filter.

- Check the handles and vibration dampers to ensure they are not damaged.

- Clean the spark plug. Check the gap 0.5 mm.

- Inspect the starter and return spring. Clean the intercostal space on the flywheel.

- Clean the cylinder cooling fins.

- Check that the muffler is firmly attached and not damaged.

- Check the idle speed setting and adjust if necessary.

Intensity of use

Currently, professional and household models are available on the market, the main differences between which are working life, design and functionality. Regarding the first, household gas cutters are designed for approximately 25 hours of operation per month. They have low power and are suitable for small volumes of work. A professional tool has a wider range of applications, and its working life is about 8 hours of continuous operation.

Properties of working material

Global manufacturers produce three categories of gas cutters: concrete, metal and universal. The concrete cutting tool has a power of 4.2 kW and provides approximately 4700 rpm. Such high characteristics are necessary to ensure that the cutting disc does not get stuck in the material being processed during operation. Petrol cutters for metal have a power of up to 4.2 kW, and their engine provides a lower number of revolutions, sufficient for cutting metal with relatively little resistance. A universal gas-powered tool can work with any material, because... has high power and rpm.

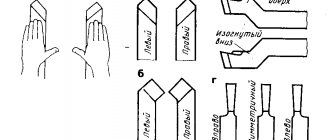

Note the adjustable cutting wheel angle and guide carriage

Usually the cutting wheel is located in the center of the gas cutter, which provides the best balance. However, it is possible to move the disk to the extreme left position. This can provide a more comfortable experience.

Purchasing a guide trolley will provide more convenient work with the tool. The device is intended for gas cutters that have a lot of weight and power. The trolley allows you to adjust the depth of the painting. The fuel consumption of a gas cutter is around 1 l/h. The tank has a volume from half to 1.3 liters.

Cutting method

You can cut hard materials using the “dry” or “wet” method. The first does not involve the use of water cooling - such gas cutters are suitable for performing small amounts of work in easily accessible areas. The advantage of wet cutting is that it solves the problem of dust during work, but this method is not applicable to solving all production problems.

A water-cooled tool costs significantly more than a “dry” one and is more difficult to repair and maintain.

Ergonomics

When selecting a tool, you should remember that the less it weighs, the easier it is to work with, but the less power and efficiency it will have. It is best to buy a medium-weight petrol cutter with a streamlined body - such a model will provide good maneuverability, and therefore work productivity. Special attention should be paid to the design of the handles. The best option is two handles, the distance between which should be as comfortable as possible for the operator, made of soft, non-slip material. You should also make sure that the design of the tool provides high-quality damping of vibrations that occur during cutting.

Security requirements

To avoid injury during operation, gas cutters are equipped with cast protective casings made of hard metal alloys with high impact resistance. In addition, global manufacturers use a system for blocking the disk when it gets stuck in the material being processed, and also supply the manufactured tools with belt and casing tensioning devices.

When working with a gas cutter, it is recommended to use protective gloves, glasses and headphones, and when dry cutting - respiratory protection.

Pay attention to the quality of cleaning filters

The gas cutter equipment must include at least a two-level air dust cleaning system. The external filter provides rough and preliminary cleaning of the air from larger particles, and the second filter removes remaining contaminants. Also prevents fuel backflow.

Opening the filter cover should not require much effort. Pay attention to how well the cutting parts and the engine are protected from dust and moisture.

To prevent injury from sparks and dust, gas cutters are equipped with protective covers. Make sure they are made using durable and reliable materials. For greater efficiency and ease of operation, it is necessary to check the belt tension, as well as the presence of the saw blade guard.

The most expensive models are those equipped with a hydraulic drive, which increases power with the same weight. There is also a reduction in smoke and noise.

Features of choosing a petrol cutting tool

In addition to conventional gas cutters - for metal, concrete and universal - specialized models are also produced. If you need a tool with an increased cutting depth, you should buy a wall chaser. Units for working with metal beams or rails are called rail cutters - they are equipped with devices for fixing the tool. Maximum ease of use is provided by a tool with an adjustable cutting angle. These gas cutters allow you to work in confined spaces – near walls or other obstacles.

Advanced models, which, of course, cost much more than conventional ones, are equipped with a hydraulic drive. The power of such a tool is several times higher than that of standard models, since hydraulics allow it to be increased without increasing the total weight. In addition, the hydraulic drive reduces noise and dust emissions - these gas cutters are perfect for working in enclosed spaces.

When choosing a gas cutting tool and consumables for it, it is necessary to ensure that the parameters of a particular model correspond to the characteristics of the material being processed, as well as the intensity and complexity of the work performed.

In conclusion, we note that you should buy tools from well-known brands with a complete set and reliable quality guarantees. It will be much easier to obtain the spare parts and materials necessary for repair and maintenance for such a gas cutter, and in operation it will be truly reliable and efficient.

Find out everything about the engine

When choosing a gas cutter, the first thing you need to know is whether the torque and power correspond to the weight of the engine. An important step will be to find out about the quality of the internal elements. It is also worth paying attention to the electronic ignition system and semi-automatic beam valve, whether they are available in the model you choose. It is worth noting that a high-quality engine has a “summer-winter” switch. And do not forget to pay attention to the amount of gases that are released during operation.