Home / Burners for boilers

Back

Published: 06/22/2020

Reading time: 3 min

1

2425

The burner design ensures efficient operation of the boiler and complete combustion of fuel. As a rule, gas burners for domestic and industrial units are sold together with the boiler. This is the optimal solution, since the boiler manufacturer will not only professionally calculate, manufacture and install the burner, but also calibrate its operation.

Such a unit will be ready to work with the best factory settings. In the case when a burner is purchased and installed independently, some difficulties may arise that can disrupt the thermal balance and performance of the thermal energy source.

To prevent this from happening, the owner must carefully select it to match the dimensions of the firebox and the thermal power of the boiler.

- 1 Classification of burners

- 2 How does a gas burner work?

- 3 Operating principle of combination burners

- 4 Operation of household burners

Review of gas burners

When choosing a device, you should take into account its technical characteristics, type of fuel supply, compatibility with other devices and principle of operation.

Several types of burners are popular among consumers. Let's start the review with the modification of the KChM. Most often it is used in boilers converted from solid fuel analogues or LNG. The design is equipped with three nozzles and automation. The second popular type of gas burners is “Hearth”. The device is a pneumatic mechanism with automatic functionality. It has an increased level of security and stops working in the following cases:

- With a lack of traction.

- If the flame goes out.

- Due to a disruption in the natural gas supply.

“Hearth” has a fuel pressure controller, which makes it possible to optimize combustion, even if there are failures in the main system. These models are easy to maintain; soot does not accumulate in the convective compartment.

How to choose?

What you need to pay attention to when choosing a burner device for a boiler:

- productive power - noise level during operation (applies to supercharged models) - type of heating equipment for which the burner is purchased - type of fuel - pros and cons of this device - provide for possible malfunctions in the operation of the local gas supply line.

Taking these factors into account, you can choose the most suitable burner device for your boiler so that it operates as efficiently as possible without the burden of frequent preventative maintenance.

Burners with forced air supply and preliminary preparation of the gas-air mixture

Combination burner GBL-1,2 COMBI

Burners with forced air supply and preliminary preparation of the mixture are most widespread. The gas flow through these burners can be very small (fractions of a cubic meter per hour) and very large (5000 m3/h or more). In burners of this type, it is possible to ensure a predetermined quality of preparation of the mixture before it enters the embrasure or firebox. To speed up the mixing process, gas is most often supplied through a series of slits or holes, the axes of which are directed at an angle to the air flow. When gas jets are supplied into the air flow from the center to the periphery, the burners are called “with central gas supply”, when supplied from the periphery to.

In many burners, air is supplied to the point of mixing with gas in a swirling flow. The most common devices for twisting are: guide vanes with a constant or adjustable blade angle, snail-shaped burner body, tangential air supply to the cylindrical body. In burners for high-capacity boilers, tangential blade swirlers are also used. An increase in the degree of twist intensifies the processes of mixture formation and fuel combustion, but at the same time the burner resistance and energy consumption increase.

Depending on the design of the burner, the quality of mixing gas with air can be very different: in the mixing chamber, the preparation of the gas-air mixture can only begin, ending with the combustion process, or it can be completely prepared for combustion. The mixing chamber of the burner usually has a small volume, and the speed of the mixture leaving the mouth at a rated thermal power is 10-50 m/s.

Combined burners - oil-gas and dust-gas, as a rule, have a forced air supply. The fuel oil nozzle is located along the axis of the burner and, depending on the design adopted, during gas operation it is removed or moved away from the mouth to avoid overheating. To burn fuel oil, air is used, supplied through the same air guide devices that are used when operating on gas fuel.

Based on materials from the book “Combustion of gases in the furnaces of boilers and furnaces and maintenance of gas facilities of enterprises” Chepel V. M., Shur I. A. 1980

Burner design

Regardless of the types of burners, they consist of certain parts:

- burner head;

- element for fastening the burner to the cylinder;

- nozzle;

- gearbox with fuel supply adjustment;

- holders for placing dishes.

The burners can also additionally have wind protection, a piezoelectric element for comfortable ignition, a transport case and an adapter for attaching various types of cylinders.

The burner head has a plate-shaped appearance and is located above the nozzle. The mounting unit for connecting the cylinder to the burner is usually either mounted on the body of the gas burner, or is a separate element with a hose. When using a burner in winter, it is better to use a hose attachment; the burner is more stable and when cooking food, it is possible to warm the cylinder without stopping.

Injectors

Nozzles are made of brass or bronze. They have a cone-shaped hole, the diameter of which directly determines the power of the burner, which in turn is regulated by a gearbox with fuel supply control. In this case, a special handle is provided to adjust the feed. Utensil holders come with teeth, which is more convenient, and smooth ones.

A comment!

Such an additional element as wind protection is very convenient and is widely used not only against the wind, but also for the correct distribution of heat, as well as its reflection.

The piezoelectric element of the burner is usually a button, but in some cases it is combined with a gas supply. Transport cases are made of fabric, and most often hard plastic. The presence of mounting adapters when using gas burners makes it possible to use various cylinders.

Popular varieties

Now let's look at the most common models.

With soldering attachment

This device is intended for heating medium-sized parts, as well as for compact soldering. This occurs due to heating from the sting flame. Such a torch can easily be called a soldering iron without wires. The gas reservoir has a capacity of 8 milliliters. When filling with butane, the flame temperature is 1300 degrees, and the tip temperature is 450. The flame length can be adjusted within 4-6 centimeters. The diameter of the burner is 1.5 centimeters and the length is 13 centimeters.

The price of this model is approximately 400 rubles.

Advantages:

- easy refueling;

- presence of a nozzle for contact soldering;

- the refill is enough to seal several medium-sized parts;

- low price;

- compactness.

Disadvantages: there is no piezo ignition.

Micro burner

There is nothing in this device except a nozzle with a gas supply regulator and a tank with a filling valve. It does not have piezo ignition and is supplied unfilled. In this regard, you will have to additionally purchase a gas can (can be used for lighters). Such a burner is enough to heat heat shrink or solder two wires without a soldering iron. The weight of such a device is 43 grams, and the length is up to 20 centimeters.

The price of the equipment is 200 rubles. This is the cheapest device of this type.

The advantages are the following parameters:

- easy refueling;

- the lowest price.

Flaws:

- there is no piezo ignition;

- the gas station runs out quickly;

- the flame is small.

Mini soldering iron KVT XZ-1

This is a remarkable device from a brand that produces gas equipment. It has piezo ignition. The set includes: 4 soldering tips, a tip cleaning sponge, and a solder spool.

For contact soldering, the stated power of the soldering iron is 137 W. For a soldering iron weighing 120 grams and 21 centimeters long, this is a lot. Electric soldering irons have never even dreamed of such weight and size characteristics. This soldering iron is not positioned as a torch, but it can be used in this capacity - the flame comes out like a pencil.

The price of such equipment is 2300 rubles.

Disadvantages: high price.

Advantages:

- high thermal power;

- good case;

- there is a set of components;

- convenient for soldering;

- famous brand.

Iris Barcelona

This type of equipment is intended for repairing jewelry and electronic equipment, welding and soldering. Its flame is adjustable. You can refill with a regular gas cylinder, which is intended for lighters. The flame can reach a length of up to 3 centimeters, and the temperature can reach 1300 degrees. It can work for approximately 20 minutes. The length of the device is 20 centimeters.

Such a device costs 1,500 rubles.

Advantages:

- brand;

- presence of piezo ignition;

- small dimensions.

Disadvantages: the flame does not allow processing large and medium-sized parts.

Butane torch KVT X-220

Intended for repair and construction work. Looks stylish. The handle is corrugated and pleasant. The flame ignition system is piezoelectric. The capacity of the cylinder for highly purified butane is 22 millimeters. This volume of gas is enough for 110 minutes of continuous operation. The flame reaches a length of 3-8 centimeters, and its shape is adjustable from wedge-shaped sharp to soft with yellow tongues. The device is 14 centimeters long and weighs 226 grams.

Such a device costs approximately 1,600 rubles.

But the advantages are:

- comfortable handle;

- presence of piezo ignition;

- presence of a stand;

- is a good option for desktop work.

Flaws:

- You can’t get into a narrow place;

- large dimensions. Because of this, it will not fit in your pocket.

Application in construction and everyday life

Manual injection burners are used in the repair, construction and household sectors, where an open flame is needed to heat the material. Their versatility is confirmed by a wide range of applications:

- heating and soldering of metals;

- melting of bituminous materials for roof waterproofing;

- firing old paint;

- drying of reinforced concrete panels and casting molds;

- soldering and bending of pipeline systems;

- repair of cable lines;

- fire treatment of animal carcasses and much more.

This device is very easy to assemble and disassemble. Its design allows the use of different nozzles, so one device can be used for various gas-flame work.

Safety regulations

When working with a gas-air burner, you must strictly follow safety rules. First of all, you should carefully select a device, the type of which should correspond to its purpose. During operation, you need to use personal protective equipment and monitor the temperature of the case. In case of excessive overheating, it is better to take a short break.

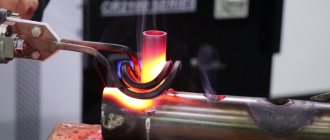

The picture shows how to check the gas burner before operation

Since gas-air technology involves the use of pressure vessels, they must also meet appropriate requirements. The process of preparing and filling propane cylinders is very similar to filling vessels with welding mixture, which can be read about in the article: filling with welding mixture: how it is done.

High-quality gas for flame processing can be purchased at. On this site you will receive professional service and technically correct refilling of propane cylinders.

Manufacturing parameters

Before assembling the burner, you should determine in advance the required parameters, the main ones of which are:

- Flame type – torch or vortex. The design of flameless burners is too complex to make at home. The torch flame affects a small area and is used for precision welding. Using a vortex, you can quickly heat large surface areas.

- Flame adjustment device. The regulator allows you to reduce sludge and increase flow depending on the material and processing method. A water valve can be used for control.

Main characteristics

If you want to purchase this equipment, then you need to know which parameters play the main role.

- Flame type. The flame may resemble a torch or be a swirl type. For spot soldering, a flame in the form of a torch is suitable. This will allow you to influence a small area of the product. But the vortex flame warms up a large surface area well.

- Flame adjustment. Some types of burners do not have a regulator at all. On the rest it is located in different places. The simpler the fire adjustment, the more convenient the work. The variety of positions of the regulator will allow you to process different materials and perform other operations in addition to soldering - metal tempering, heating and others.

Devices with disposable and stationary cylinders

The most convenient and compact device is a mini-gas burner, which is equipped with a disposable cylinder. It is good to use for soldering copper products in hard-to-reach places, and its low weight and compactness make the work more convenient. The fuel in such burners is gas mixtures, acetylene or propane. On the handle of the device there is a valve for adjusting the fire level.

Maximum connection quality can be achieved by using gas burners with stationary cylinders. With their help, you can process even the most refractory metals.

Air-gas injection burners

Burners of this type are called injection, since air is sucked into them (injected) due to the energy of gas jets emerging from one or more nozzles. With a single-nozzle burner, a stream of gas coming from a gas pipeline under pressure is ejected from the nozzle at high speed, as a result of which a vacuum is created in the mixer injector. Due to rarefaction, the surrounding air is sucked into the burner and, when moving along the mixer, mixes with the gas. The gas-air mixture passes through the throat of the mixer (narrow part), which levels out the flow of the mixture, and enters its expanding part - the diffuser, where the speed of the mixture decreases and the pressure increases. After the diffuser, the gas-air mixture enters either the confuser, where its speed increases to the calculated speed, and is supplied through the mouth to the combustion site, or into a manifold with fire holes. Coming out of these holes, the gas-air mixture burns in the form of small bluish-violet torches with an inner cone of greenish-blue color.

Injection burners are divided into medium-pressure burners, capable of injecting all the air necessary for complete combustion of the gas, and low-pressure burners, most often injecting only part of the air, which is called primary. The rest of the air - secondary - enters the combustion zone due to rarefaction in the firebox or due to convection in the atmosphere. Stable operation of medium-pressure burners without flame loss is possible only with the presence of a flame stabilizer. Low pressure burners can operate without special stabilizing devices.

A characteristic feature of the operation of injection burners is the dependence of the primary air consumption coefficient α primary on the vacuum (back pressure) in the furnace. At a constant position of the air damper, α first increases with increasing vacuum, and decreases with increasing back pressure. The greater the pressure of the injection gas, the less this dependence affects: the vacuum (back pressure) in the furnace has the greatest effect on the operation of low-pressure burners, the minimum - on the operation of medium-pressure burners at a pressure in front of the nozzle of more than 0.4-0.5 kgf/cm2.

Some designs of injection burners do not have a diffuser part (injection and mixing occur in a cylindrical mixer) and a control air damper.

Main advantages: no energy consumption for driving a fan to supply air, automatic maintenance of the calculated ratio of the quantities of gas and injected air within certain limits and their good mixing. Disadvantages: limited control range with an α value of about 1, high noise level when using medium and high pressure gas, dependence of injection capacity on the degree of vacuum in the furnace, difficulty in using heated air.

Burner flame

One of the indicators of proper burner operation is the color of the flame. Gas equipment is characterized by an even bluish flame without admixtures of other colors. The presence of yellow or red splashes indicates that the burner is not working well, which reduces the efficiency of the heating equipment.

First of all, this applies to injection burner devices, but sometimes it is also typical for fan burners. The flame may simply lack oxygen. Also, dust and other small debris can get in with the air, which will clog the device, reducing the efficiency of the boiler. All this directly affects the flame. If it hums, the burner is loud, or the fire has changed color, you need to adjust the correct operation of the device.

Types of burners

According to their design and functional differences, burner devices are divided into:

By purpose:

- for high power industrial equipment

- for household equipment.

By type of fuel used:

- devices for natural gas;

- devices for liquefied gas;

- universal devices.

By adjusting the flame:

- single-stage – capable of operating on/off;

- two-stage (as a variation - models with smooth modulation) - operate at full power, when the desired temperature is reached, the flame is reduced by half;

- modulating - boilers with a modulating burner are characterized by smooth adjustment of the flame power.

According to the principle of operation:

- injection/atmospheric. They operate by supplying air from the room. They are installed respectively in open combustion chambers. Also used for old-style boiler models.

- fan/supercharged. They work in isolated combustion chambers. Combustion air is supplied by a fan. According to their design features, they are divided into: - vortex (round-shaped nozzle holes) - direct-flow (shape of a narrow slot with a round/rectangular cross-section).

- diffuse-kenetic. Air enters two simultaneously: one is mixed with gas fuel, the second is added directly to the chamber during combustion.

Design examples

Understanding the designs of gas burners, we will take the path of increasing power, this will allow us to better understand the material. And from the very beginning we will get acquainted with such an important circumstance as supercharging.

Mini from a spray can

It is well known how a single-mode mini gas burner for tabletop operation, powered by a lighter refill can, works: these are 2 needles inserted into each other, pos. And in the figure:

Mini gas burner device powered by a spray can for refilling lighters

Pressurization - from an aquarium compressor. Since without the resistance of the sprayer under water it gives a noticeably pulsating flow, you need a receiver made of 5 liters of eggplant. Soda is not produced in these, so the receiver plug will need to be additionally sealed with raw rubber, silicone or just plasticine. If you take a compressor for an aquarium with a capacity of 600 liters or more, and the fuel is 100% isobutane (such cans are more expensive than regular ones), you can get a flame of over 1500 degrees.

The stumbling blocks when repeating this design are, firstly, adjusting the gas supply. There are no problems with air - its supply is set by the standard compressor regulator. But adjusting the gas by bending the hose is very rough, and the regulator from the dropper quickly breaks down, since it is also disposable. Secondly, pairing the burner with the can - in order for its valve to open, you need to press on the filling fitting

The first thing that will help solve the problem is the node shown in pos. B; they make it from the same pair of needles. First, you need to select a piece of tube for the sleeve that fits onto the canister fitting with a little effort, and then, also with a little effort, push it into the needle cannula; it may need to be drilled out a bit. But the sleeve should not hang either on the fitting or in the cannula separately.

Then we make a clip for the canister with an adjusting screw (pos. B), insert the canister, put the regulator on the fitting according to pos. B, and tighten the screw until the required gas supply is obtained. The adjustment is very precise, literally microscopic.

Soldering torches

The easiest way to make a soldering torch is approx. by 0.5-1 kW, if you have any gas valve available: oxygen series VK, from an old autogen (the acetylene barrel is plugged), etc. One of the design options for a soldering torch based on a gas valve is shown in Fig.

Simple gas torch for soldering

Its peculiarity is the minimum number of turned parts, and even those can be selected ready-made, and quite wide possibilities for adjusting the flame by moving the nozzle 11. The material of parts 7-12 is quite heat-resistant steel; in this case, the relatively inexpensive St45 is suitable, because the flame temperature, due to the complete lack of profiling of the gas channel and ejector windows (which do not exist as such), will not exceed 800-900 degrees. Also, due to the fact that this burner is single-circuit, it is quite voracious.

Dual-circuit

A double-circuit gas burner for soldering is much more economical and allows you to get a flame of up to 1200-1300 degrees. Examples of structures of this kind powered by a 5 liter cylinder are shown in Fig.

Double-circuit gas burners for soldering

Burner on the left – output approx. 1 kW, therefore it consists of only 3 parts, not counting the gas barrel and handle, so a separate valve for adjusting the flame is not required. If desired, you can make replaceable injector capsules for lower powers; Fuel consumption at low power will drop quite noticeably. The simplicity of the design in this case is achieved through the use of a scheme with incomplete separation of the air circuits: all the air is sucked in through the holes in the housing, but part of it is carried away by the burning gas jet through a hole with a diameter of 12 mm into the afterburner.

Incomplete separation of the air circuits does not allow reaching a power of more than 1.2-1.3 kW: Re in the combustion chamber jumps “above the roof”, which is why combustion begins with pops until it explodes, if you try to adjust the flame by applying gas. Therefore, without experience, it is better to set the injector in this burner to 0.3-0.4 mm.

A burner with complete separation of air circuits, the drawings of which are given on the right in the figure, develops power up to several kW. Therefore, its fittings require, in addition to the shut-off valve on the cylinder, a control valve. Together with a sliding primary ejector, it allows one to regulate the flame temperature within a fairly wide range, maintaining its minimum flow rate at a given power. In practice, having set the flame to the desired strength with the valve, move the primary ejector until a narrow blue jet (very hot) or a wide yellowish one (not so hot) comes out.

For forge and forge

The dual-circuit burner with complete separation of circuits is also suitable for forging work. For example, how to build a forge for the one just described in 10-15 minutes from scrap materials, see the video:

Video: gas forge in 10 minutes

A metalsmith's and forge's gas burner specifically for the forge can also be built according to a complete dual-circuit scheme, see next. video clip.

Video: DIY gas burner for the forge

And finally, a mini gas burner can also heat a small tabletop forge; how to make them together yourself, see:

Video: DIY mini-horn at home

For fine work

Here in Fig. Drawings of a gas burner with a built-in control valve for particularly precise and critical work are given. Its feature is a massive combustion chamber with cooling fins. Thanks to this, firstly, thermal deformation of burner parts is reduced. Secondly, random surges in gas and air supply have virtually no effect on the temperature in the combustion chamber. As a result, the installed flame remains very stable for a long time.

High-quality gas burner for particularly demanding work

High temperature

Finally, let's consider a burner designed to produce a flame of the highest possible temperature - using 100% isobutane without pressurization, this burner produces a flame with a temperature of more than 1500 degrees - it cuts sheet steel, melts any jewelry alloys in a mini-crucible and softens any silicate glass, except quartz. A good injector for this burner is made from a needle from an insulin syringe.

High temperature gas burner

Heating

If you are planning to once and for all transfer your old stove or boiler from wood-coal to gas, then you have no choice but to purchase a modulated pressurized burner, pos. 1 in Fig. Otherwise, any savings on homemade products will soon be eaten up by excessive fuel consumption.

Heating gas burners

In the case when heating requires a power of more than 12-15 kW and in addition there is a person ready and able to take on the duties of a stoker, regulating the gas supply in accordance with the outside temperature, a cheaper option would be a double-circuit atmospheric burner for the boiler, the design diagram of which is given in pos. . 2. The so-called. Saratov burners, pos. 3; They are produced in a wide range of capacities and have been successfully used in heating engineering for a long time.

If you need to stay on gas for some time, for example, until the end of the heating season, and then start reconstructing the heating system, or run, for example, a country or sauna stove on gas, then for this you can make a one-and-a-half-circuit gas burner with your own hands for ovens. A diagram of its structure and operation is given in pos. 4. An indispensable condition is that the furnace of the heating device must have a blower: if secondary air is allowed into the gap between the throat of the furnace and the burner body, fuel consumption will increase significantly. A drawing of a one-and-a-half-circuit gas burner for a furnace with a power of up to 10-12 kW is given in pos. 5; The oblong openings for primary air intake must be located outside!

Roofing

A gas burner for roofing work with modern built-up materials (roofing lamp) must be dual-mode: at half power the underlying surface is heated, and at full power the coating is fused after unrolling the roll. Delay is unacceptable here, so you cannot waste time readjusting the burner (which is only possible after it has cooled down).

The structure of an industrial roofing gas burner is shown on the left in Fig. It is dual-circuit with incomplete separation of circuits. In this case, such a solution is acceptable, because The burner operates at full power for approx. 20% of the process cycle time and is operated outdoors by trained personnel.

Gas burners for roofing work

The most complex component of a roofing lamp, which is unlikely to be repeated at home, is the power switching valve. However, it is possible to do without it at the cost of a slight increase in fuel consumption. If you are a generalist and do roofing work occasionally, then the decrease in profitability due to this will not be noticeable.

Technically, this solution can be implemented in a burner with connected pairs of air circuits, see on the right in Fig. The transition from mode to mode is carried out either by installing/removing the housing of the internal circuits, or simply by moving the lamp in height, because The operating mode of such a burner strongly depends on the exhaust back pressure. To warm up the underlying surface, the lamp is moved away from it, then a powerful wide stream of not excessively hot gases will come out of the nozzle. And for surfacing, the lamp is brought closer: a wide “pancake” of flame will spread across the roofing material.

Principle of operation

Portable mini-gas burners with piezo ignition can be of different designs. For some models, the cylinders may be disposable, while for others they can be removable, and still others even work with stationary ones. Many portable burners have piezo ignition to make starting a fire safe and easy. This device is mainly used for soldering copper pipes or other products made of not very refractory metal. During soldering, different solders are used - liquid or solid soldering acids.

During operation, the mixture contained therein is supplied from the cylinder: acetylene, propane or butane. The gas enters the nozzle and is ignited there. The flow of fire that has formed allows the part to be heated to the required temperature at which soldering will be possible.

A portable mini-torch with piezo ignition can be used for soldering wires, cables, pipes, copper, as well as for repairing electronics with various types of solders. It may also be useful for repairing some parts in the car (radiator and others).

But the scope of application of a device with piezo ignition is not limited to soldering of products. It can also be used in some plumbing work, during corrosion of products or during dismantling to warm up parts.

There are also some non-standard ways to use a portable device. If you like fishing, picnics or hunting, then this device may be useful to you in the field. It can be used to quickly heat up food or start a fire. Using this unit, you can quickly scorch game while hunting.

Application

The scope of use of this equipment is very wide. It can be useful for installing climate control systems, repairing cooling equipment, carrying out plumbing work and other operations. It is often necessary to use this device even when making jewelry. In these cases, one or another type of equipment may be required.

Gas burners are classified according to the following principles.

- According to the method of adjusting the flame - with a power regulator or piezo ignition.

- The nozzles are replaceable, rotating, and resemble a spear.

- According to the scope of application - equipment of a narrow focus and multifunctional.

How to use a propane torch

A propane gas torch will be simply necessary when carrying out roofing work, drying casting molds, removing old paint, crimping couplings, soldering copper pipes, etc. Before using the burner, two cylinders are purchased - with oxygen and propane - on which reduction gears are mounted. The latter provide optimal pressure.

When the reducers are connected to the gas burner using hoses, you can unscrew the valves and release the gas. Before igniting, the gases pass through an injector where they are mixed. The temperature of the emerging flame exceeds 2 thousand degrees.

To carry out work, first open the valve with flammable gas, then with oxygen. The mixture coming out of the nozzle must be set on fire. The pressure of the consumables is adjusted based on instrument readings or flame color. Afterwards, using a filler wire, a weld pool is formed, and the molten metal must be moved, forming a seam. When the work is completed, the filler wire is removed and the gas mixture is extinguished.

Design features of the gas burner

This element of the unit creates a stable flame; it is in the burner that the fuel entering the device is burned. Then the resulting heat moves upward, where there is a heat exchanger through which the coolant liquid moves. Combustion products and excess heat escape into the atmosphere in one way or another.

The gas burner has a simple design; it consists of several main components, including:

- Nozzle – used to release gas.

- Ignition system – designed to ignite gaseous fuel.

- A sensor that monitors the presence of a burning flame.

- Automation system – monitors temperature indicators.

This is how the design looks simplified.

Modern gas burners for heating boilers are devices that must meet a number of requirements:

Quiet operation. Is an important quality. Many consumers are familiar with Soviet-era instantaneous water heaters, in which the flame made a lot of noise. But modern models operate relatively quietly. Also, when choosing a device, you should pay attention to the ignition, since there should be no explosions or pops. The noise level is additionally affected by the design of the combustion chamber.

Long period of operation In older models of gas units, burners worked for a long time, since at that time the equipment was made to last. Nowadays such technologies are not used, so these elements installed in gas boilers break down quite often. In this case, experts recommend purchasing devices manufactured under well-known brands, for which they use high-quality components. You should not buy Chinese equipment of unknown manufacture and cheap domestically produced boilers, since they often have short-lived burners installed.

Complete combustion of gaseous fuel

This is an important requirement, since the burner must burn natural gas completely with minimal release of combustion products and other associated compounds, including carbon monoxide. The degree of combustion is also affected by other components

We should not forget about arranging high-quality gas removal - for this you need to make a chimney that has good draft.

The operating principle of a gas burner is simple:

- The unit detects the presence of a discrepancy between the temperature in the heating circuit and the indicators specified by the equipment users.

- After opening the gas valve, fuel enters the burner.

- At the same time, the ignition system is activated.

- Once the gas is ignited, a flame appears.

At the same time, the flame sensor starts working, which monitors its presence: if the fire suddenly goes out, the automation shuts off the fuel supply. Once the heating system reaches the required temperature, the gas supply stops.

In what cases is it necessary to adjust the burner flame?

An atmospheric gas burner for heating equipment often fails. It is equipped with models of both wall-mounted and floor-standing boilers. The injection burner of floor-standing equipment reduces its efficiency for various reasons:

- Burner power is too high. This happens when a high-power burner is purchased for small heating equipment. At the same time, there is not enough space for combustion, the air flow for such power is weak, which leads to the transition of the flame from blue to yellow, sooting of the combustion chamber and chimney.

- If the chimney is poorly cleaned, the boiler draft deteriorates. At the same time, waste combustion products are poorly removed, and the air flow is small. This worsens combustion and the flame turns yellow.

- A defect in the burner itself does not make it possible to correctly adjust the complete combustion of the fuel.

- Due to pressure changes in the gas supply system, well-regulated equipment can release large amounts of unexhausted gas into the chimney. Partially it settles with soot and soot. A large layer of soot reduces traction and increases fuel consumption.

- Starting heating equipment after repair.

- The presence of extraneous noise during operation of the boiler or gas burner.

- Changing the type of fuel.

You may be interested in learning about the operating principle of a double-circuit gas boiler >>>

Types of burner ignition

A modern instantaneous gas water heater is produced with automatic ignition and a manual pilot ignition system.

For economic reasons, manual ignition is unprofitable. The system consists of a piezoelectric element activated by pressing a button. Pressing a key produces a spark that ignites the igniter. The operation is simple, but the igniter constantly burns throughout the day, consuming gas. It is irrational to turn it off, since you will often have to re-ignite it when you need to consume hot water.

Auto-ignition occurs immediately after opening the hot water tap:

- The first operating principle of electronic ignition is based on batteries. The waiting igniter does not light. When the mixer tap is opened, the pressure in the water supply changes and the sensor gives a signal to the electronic unit to ignite. The energy from the batteries creates a spark. The flame lit on the igniter ignites the burner. Having done its job, the igniter turns off until the next start. Battery ignition does not require much energy. The battery charge lasts for a year.

- The second operating principle of auto-ignition is based on a hydrogen generator. The instantaneous gas water heater is equipped with a turbine instead of batteries. It is driven by the flow of water created in the water supply when the mixer tap is opened. The hydrogenerator produces a spark that ignites the igniter.

Gas water heaters with automatic ignition are beneficial due to lower gas consumption and ease of use.

1.2. Gas water heaters and their burners

A gas water heater is designed to instantly heat the required amount of water. Domestic instantaneous water heaters do not have a storage tank, since the water is heated through a coil using a gas burner (Fig. 10).

In previous versions of geysers and in modern budget models, the burner is ignited from a constantly burning pilot light, ignited by a match or a piezoelectric element. Newer models, which are offered by all geyser stores, use automatic electric ignition and electronic control of the outlet water temperature.

When choosing a geyser, you must first find out what function it will perform. It’s one thing if the column is needed only for taking water procedures or only for washing dishes in the kitchen, and quite another if it is needed to supply hot water to several water points at the same time. That is, first of all, you need to pay attention to the performance or power of the gas water heater, which are interconnected. Household gas water heaters are conventionally divided into 3 groups based on power:

power up to 19 kW, power up to 25 kW and power up to 32 kW. Therefore, according to the flow rate of water heated by the column at 25°C, or according to productivity, they are also divided into 3 groups: 10-11 l/min, 13-14 l/min and 15-17 l/min. Thus, based on the need for hot water, you need to choose a column based on power.

Rice. 10. Household gas water heater (view without lid)

The second thing you need to pay attention to when choosing a column is the ignition method, which should be reliable and convenient. If previously domestic gas water heaters were mainly ignited with a match, then modern gas water heaters have manual piezo ignition, which is triggered by pressing a button. But piezo ignition is not only inconvenient, since usually the column is in one place, for example, the basement, and the tap in another - in the bathroom, but it also leads to excessive gas consumption. After ignition, the igniter of the column remains burning and continues to burn even after using the water heater, which increases gas consumption by about a quarter. The new hot water heaters have automatic ignition when you open any hot water tap. The automatic ignition method is much better, since you do not need to run to the column, which in this case starts working immediately after opening the tap.

In turn, automatic ignition can be either from a built-in battery or from a hydraulic turbine generator. After closing the tap, the gas is turned off and the column is turned off. It should be noted that if the water pressure in the water supply system is below 0.035-0.045 MPa, then ignition from a turbogenerator will be impossible. While battery ignition and piezo ignition are possible already at a water pressure of 0.01-0.02 MPa. And if there is low water pressure in the house, then it is better to choose a gas water heater with ignition from built-in batteries.

The type of burner is another parameter for choosing a hot water column, which is also worth paying attention to. Possible options for burners: with constant power and adjustable, which, in turn, come with step and smooth adjustment, as well as with automatic adjustment (flame modulation).

In simple and affordable models, manufacturers install gas burners with constant power. When operating such equipment, the water temperature has to be adjusted manually, which is not very convenient. A column with a constant power burner will simply reduce the temperature of the heated water when the hot water flow increases, for example, when the water tap is opened to a larger amount or when another consumer is connected. But a water heater with an automatically controlled burner will maintain the required heating temperature when the volume of passing water changes. Of course, a gas water heater with an adjustable burner is more convenient in everyday life, but it is also, naturally, more expensive. Everyone knows and understands that in winter the temperature of the water entering the house and, therefore, at the inlet of the water column is lower, and in summer it is higher. The power regulator that can be equipped with these household units allows you to adjust the power of the gas water heater burner depending on the time of year. The digital display is another additional device that makes operating the burner more convenient. It can display various information, for example, water temperature, column operating mode, etc.

As can be seen from Fig. 11, all gas burners used in water heating columns have many small holes to separate the burned gas into separate small streams and ensure the flow of ambient air to them, since without this it is impossible to quickly burn a large amount of gas inside any column.

Rice. 11. Gas burners for domestic gas water heaters

After choosing a column based on power, type of burner and ignition, you need to pay close attention to its safety during operation. All geysers are usually equipped with the same protection circuit, which provides for operation in the event of the burner flame disappearing, the heat exchanger overheating, and also in the absence of the necessary draft in the chimney duct. If any of these malfunctions occurs, the gas supply is automatically stopped and the column is blocked. Resumption of operation of the water heater occurs only after detection and elimination of the identified defect.

The most important thing for a gas appliance is reliable and safe operation. Therefore, you need to buy a water heater from a well-known brand that has a wide network of service centers for preventive maintenance of the gas appliance during operation. In addition, the installation of a gas appliance, especially the connection to the gas pipeline, must be carried out by specialists from a licensed (certified) company with the preparation of all necessary documentation, otherwise if force majeure circumstances (fire) occur due to this gas appliance, the insurance company will not compensate for losses.

Gas oven thermostat

In order for the oven to work correctly and food to cook within the specified temperature range, a thermostat or thermostat is installed inside the cabinet. They can be mechanical, electromechanical, or electronic; to control a given mode, a rotary knob, button, or other, more complex and highly accurate devices are used. What is a thermostat in a household gas stove and how does it regulate the operating mode of the oven?

Gas stove thermostat diagram:

Diagram of a dilatometric oven thermostat: 1 - tubular rod; 2 - movable wedge; 3 - ball; 4 - pusher; 5 - spring-loaded valve; 6 - spring.

How does a gas oven thermostat work?

The operating principle of such a thermostat is very simple. The dilatometer, which records the temperature increase in the oven, heats up, causing the linear rod to expand. It activates a mechanism that ultimately acts on the spring-loaded valve. The stronger the heating inside the oven, the further the spring-loaded valve will move and close the gas supply hole. Accordingly, as the temperature decreases, the linear rod decreases and the system works in the reverse order, opening a larger hole for gas access and increasing the temperature inside the oven.

Gas oven thermostat

The maximum temperature inside the oven is limited by a switch knob installed on the front panel of the gas stove.

How to check if the thermostat is working

Having figured out what a thermostat or temperature controller is in a gas stove, you need to make sure that this device is working properly.

Significant errors in the instrument readings can ruin any culinary masterpiece. In one case, the food will simply burn, in the other, it will remain raw. To check the thermostat, it is best to invite a specialist who, using precision instruments, will identify any deviations in temperature readings, up to 1 °C. If this is not possible, and a difference of 3-5 °C is not of great importance, you can check it yourself:

- Turn on the oven at 150°C;

- Place a mechanical thermometer inside the oven, designed to measure temperatures in the appropriate temperature range;

- Leave the oven on for 20-25 minutes until the temperature reaches the desired level;

- After 20 minutes, check the temperature readings on the thermometer and thermostat. If the difference in indicators exceeds 5-10 °C, the temperature controller needs to be repaired.

Important: to repair a gas stove, you must invite a specialist, since the problem may not only be a damaged thermostat, but also noticeable heat loss due to a loose door

Features and history of creation

The first gas stove was invented back in the century before last, shortly after the general gasification in England. One of the gas factory workers named James Sharp was the first to think about using gas for cooking. It was he who, in 1825, designed the first analogue of a modern gas stove and installed it at home, significantly simplifying his life.

10 years later, factory production of such devices began, however, at first accidents often occurred, since people were not yet accustomed to the fact that gas must be handled very carefully

The period from 1837 to 1848 saw the evolution of the gas cooking appliance. The first models created by de Merle were not perfect enough. Afterwards they were improved by d'Elsner, who was an inventor. All these models still did not bear much resemblance to modern ones. But in 1857, the most advanced model of that time was invented by de Beauvoir, and it was this design that subsequently formed the basis for the creation of gas stoves for many years.

On the territory of Russia, stoves appeared only in the 30s of the last century, since mass gasification began after the revolution. However, the new devices were mainly used in apartments rather than private homes

Gas-powered units significantly saved housewives’ time, so they considered this feature a good compensation for the need for careful handling. Modern modified gas devices have a number of features

Among them there are both fairly new characteristics and those that were characteristic of all previous models.

- This unit only runs on gas. Therefore, it is necessary to either connect it to the general gas supply system, or supply fuel from a cylinder.

- A characteristic feature is the low cost of operation of this device. Even if you cook a lot, you won't have to pay a big utility bill because gas is cheap.

- A gas stove performs 3 main functions for cooking. It allows you to cook, fry and bake foods (if you have an oven).

- In most cases, the stove requires a hood, since sometimes the gas on which the device operates has a specific odor.

- A negative feature of the device is the need for extremely careful and attentive handling of it. Otherwise, there is a possibility of a gas leak, which could cause an explosion in the living space and tragic consequences.

- In the modern market of household appliances, gas stove models are presented in various embodiments.

Typology

The market offers a variety of gas cylinders for burners. The selection of a highly specialized or universal tool is determined by the requirements of the tasks:

- Activation time for one-time operations;

- The need to create a certain temperature;

- The amount of air involved in fuel combustion: diffusion, injection with full/partial mixing with air in front of the outlet;

- Control of the combustion process, temperature increase/decrease;

- Weight and dimensions of the complete device, grip;

- Volume and type of cylinders, connection method;

- Calorific value of the combustible mixture;

- The gas burner on the canister has piezo ignition and a clamp to keep the valve in working condition.

Tourist

The simplest device according to the requirements is a burner for cooking and heating a tent. The butane filler provides a temperature of 800–1000 C. There are 3 types of placement of the heating object:

- Installation directly on a cylinder with a wide base;

- Side connection;

- Removed via flexible hose.

Installation on a kerosene stove-type cylinder is compact, but the technical solution causes criticism:

- The load on the body is high;

- Instability of combustion, blowing out of fire by wind;

- Instability of the structure;

- Inadmissibility of installing wind protection;

- The case may overheat.

Important! Overheating of the cylinder body can lead to an explosion.

The stability of the structure allows installation on unprepared soil

Remote hose placement is fire safe. The fireplace can be protected with wind shields. The combustion intensity is adjusted using a gearbox.

Artificially pressurized lamp

Injection gas burners for a can with piezo ignition and additional air intake are suitable for melting, soldering with copper, refractory fluxes, and heat treatment. The variety of tools includes miniature ones for jewelers and decorators, solid ones for long-term use with high consumption of flammable substances.

Fundamental differences determine the caloric content of the fuel and the exit front of the pre-air-enriched mixture from the nozzle. A narrowed dagger torch is necessary for high-temperature soldering.

Expanded – replacement of the forge, hardening furnace.

The power of a gas blowtorch ranges from 1.5–3 kW. The conditional division into professional and amateur models is reflected in the cost. Filling the cylinder up to 0.5 liters with many hours of use.

Focused supply of thermal energy leads to fuel savings. The set includes several nozzles of different orientations and flame concentrations. Changing the nozzles turns the tool into a microcircuit soldering iron or micro-cutter.

Pencil-type burners have a built-in container that must be refilled from a standard cylinder. The hose extension will allow you to use a container from the retail chain.

Soldering iron

A gas soldering iron is less often equipped with a piezo ignition. The temperature balance is lower and the scope of application is narrower. But mastering technical skills is easier. In half of the cases, preliminary mixing of gaseous media is not provided.

The concentration of the torch core is not provided. Long-term heat treatment of large areas does not threaten the cylinder with overheating by the reflected heat flow due to the elongation of the gas supply tube and the dispersion of the flame.

Cutter

A gas torch is suitable as a substitute for a blowtorch if you expand and lengthen the torch. Soldering iron for refractory solders when focusing the core by installing a nozzle with a swirling flame.

Gas equipment

Fuel containers vary in configuration, size, filling volume, and composition of the combustible mixture. The main difference in the fastening method:

- Threaded, European standard - external thread, US standard - increased diameter.

- Collet.

- With internal valve.

- Pierceable.

Standardized thread is the preferred option. The burner or extension hose is screwed onto the neck. A fuel leak is unlikely. The connection is reliable.

The valve-type cartridge prevents gas loss. The connection with the burner or extension cord is made by forcefully pressing and then turning the lock until it stops.

Punctureable balloons are less common. The inconvenience is that before the cylinder is empty, disconnecting the burner is impossible without losing the contents.

Adapters allow you to universally use cylinders of any type and design for the purchased equipment. A pair of adapters will eliminate difficulties with selection and articulation.

How to achieve safety

To make a gas burner safe to operate and not waste fuel, the golden rule should be: no scaling or any changes to the prototype drawings at all!

Here the matter is in the so-called. Reynolds number Re, showing the relationship between flow speed, density, viscosity of the flowing medium and the characteristic size of the region in which it moves, for example. cross-sectional diameter of the pipe. From Re one can judge the presence of turbulence in the flow and its nature. If, for example, the pipe is not round and both of its characteristic sizes are greater than a certain critical value, then vortices of the 2nd and higher orders will appear. There may not be physically distinguished “pipe” walls, for example, in sea currents, but many of their “tricks” are explained precisely by the transition of Re through critical values.

Note: just in case, for reference, for gases the value of the Reynolds number at which laminar flow becomes turbulent is Re>2000 (in the SI system).

Not all homemade gas burners are accurately calculated according to the laws of gas dynamics. But, if you arbitrarily change the dimensions of the parts of a successful design, then the Re of fuel or sucked air may jump beyond the limits that it adhered to in the author’s product, and the burner will become, at best, smoky and voracious, and, quite possibly, dangerous.

Injector diameter

The determining parameter for the quality of a gas burner is the cross-sectional diameter of its fuel injector (gas nozzle, nozzle, nozzle - synonyms). For propane-butane burners at normal temperatures (1000-1300 degrees), it can be approximately taken as follows:

- For thermal power up to 100 W – 0.15-0.2 mm.

- For a power of 100-300 W - 0.25-0.35 mm.

- For a power of 300-500 W - 0.35-0.45 mm.

- For a power of 500-1000 W - 0.45-0.6 mm.

- For a power of 1-3 kW - 0.6-0.7 mm.

- For a power of 3-7 kW - 0.7-0.9 mm.

- For power 7-10 kW – 0.9-1.1 mm.

In high-temperature burners, the injectors are made narrower, 0.06-0.15 mm. An excellent material for the injector would be a piece of needle for a medical syringe or dropper; from them you can select a nozzle for any of the indicated diameters. Needles for inflating balls are worse; they are not heat resistant. They are used more like air ducts in supercharged microburners, see below. It is sealed into the injector cage (capsule) with hard solder or glued with heat-resistant glue (cold welding).

Power

Under no circumstances should you make a gas burner with a power exceeding 10 kW. Why? Let's say the burner efficiency is 95%; for an amateur design this is a very good indicator. If the burner power is 1 kW, then it will take 50 W to self-heat the burner. A 50 W soldering iron can get burned, but it does not threaten an accident. But if you make a 20 kW burner, then 1 kW will be superfluous; this is an iron or electric stove left unattended. The danger is aggravated by the fact that its manifestation, like Reynolds numbers, is threshold - either simply hot, or flares up, melts, explodes. Therefore, it is better not to look for drawings of a homemade burner for more than 7-8 kW.

Note: industrial gas burners are produced with a power of up to many MW, but this is achieved by precise profiling of the gas barrel, which is impossible at home; see one example below.

Armature

The third factor that determines the safety of the burner is the composition of its fittings and the procedure for using it. In general the scheme is as follows:

- Under no circumstances should the burner be extinguished using the control valve; the fuel supply is stopped using the valve on the cylinder;

- For burners with a power of up to 500-700 W and high-temperature ones (with a narrow injector, excluding the transition of Re gas flow beyond the critical value), powered by propane or isobutane from a cylinder up to 5 liters at an external temperature of up to 30 degrees, it is permissible to combine control and shut-off valves in one - standard on the cylinder;

- In burners with a power of more than 3 kW (with a wide injector), or powered from a cylinder of more than 5 liters, the probability of “overshooting” Re beyond 2000 is very high. Therefore, in such burners, between the shut-off and control valves, a reducer is required to maintain the pressure in the supply gas pipeline within certain limits.