Installation of a household pipeline involves the need to connect sections of pipes into a system of the desired configuration. A large number of different fittings have been developed for this purpose. Their choice depends on the pipeline material, its location and purpose. One of the convenient and simple types of pipeline installation is to fasten sections with collet fittings. They do not require special tools or skills, are available for self-installation, and are reliable.

What is a fitting and collet

You may be interested in:Hydraulic fracturing: types, calculation and technological process

In order to understand the principle by which collet fittings work, you should understand what a collet and a fitting are. The design of the first is ideal for use when connecting cylindrical parts. This is a metal bushing. There are special cuts on its side. They form springy petals. Thanks to the latter, the collet presses on the inner walls of the pipe. Its outer surface is pressed against the walls of the cartridge fitting.

You might be interested in: Flow production is... Concept, definition, methods of organization and technological process

Push-in connections that work according to the principle described above are also called clamp connections. But if we consider a fitting, then this term hides a connecting element. It is used to create pipeline systems for various purposes. Fittings of this design are used to solve various types of problems. This should include:

- creation of corner connections in pipeline systems;

- connection of pipes of different and identical diameters;

- connection of pipes with equipment and various plumbing devices, among the first should be highlighted: meters, filters, screens, pumps.

You may be interested in: Tuymazinskoye oil field: description and characteristics

Push-in connections are highly reliable. This is ensured by a collet that presses on the inner walls. The external fastening nut is also responsible for this. If you create a pipeline using such a connection, then among its properties will be:

- durability;

- reliability;

- tightness.

Briefly about the collet clamp

Along with all of the above installation methods, collet fittings occupy a special place, largely due to their unique features and technical characteristics. These features allow you to assemble a water supply system on your own in a short time, without resorting to the help of specialists and without spending a lot of financial resources.

What is a collet clamp - everything is simple and quite interesting at the same time. In ordinary language, this is a separate cell among the whole variety of connecting devices. This tool is special due to the unique technology through which the pipes are connected. The mechanism is based on a collet, which is used to connect elements that have a cylindrical shape (in our case it is a pipe, but it can be anything). The collet is based on a spring mechanism, thanks to which pressure is exerted on the pipe walls from the inside, and with the help of a fitting, the pipe is very tightly fixed to another section of the water supply.

Classification of collet clamps and types of pipes

Push-in connections can be divided into three categories depending on their purpose:

- for structures made of semi-solid materials;

- for pipes made of hard materials;

- for soft plastic systems.

This classification allows you to select clamps for connecting pipes of different types. Such connections can be made on products made of hard metal, polypropylene, softer metal-plastic and HDPE.

Push-in connection of pipes allows you to select elements for different types of systems. This connection can be used even by a non-professional.

Instructions for use

When selecting clamps for installing piping systems, the diameter of the pipes should be taken into account. This indicator for fittings must correspond to the transverse size of the pipeline; the tightness of the connection and reliability will depend on this. In order to determine the number of elements and where a straight fitting will be used and where an angular one will be used, you need to prepare a drawing of the pipeline system. Once you have it in hand, you will be able to understand how the sections of the future system will be located.

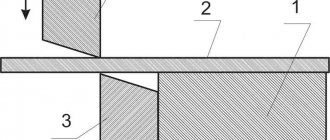

At the next stage, you can start cutting the rolled pipe into sections of the required length. A clamp should be selected for each pipeline joint. The installation for which the fittings will be used is carried out in a certain sequence. In the first step, the collet should be placed inside the pipeline. A special nut is screwed onto the outer part of the connecting element. The collet will begin to act in a certain way. The pipe from the inside will expand with its inner part, while the outside can be compressed with a nut. The same steps should be performed with the other pipe used in the joint being formed.

You may be interested in:Preparation of oil for refining: the main process, methods and technologies

The push-in connection for plastic pipes has a strong impact on the pipeline elements, so it must be used carefully. If the fastening nut is overtightened, you may experience the pipe simply bursting. Therefore, when using clamps that will be installed on plastic products, the force should be adjusted. This especially applies to HDPE pipes. The force should be measured when tightening the fastening nut.

Reusability

Quick-release collet connections are also good because, unlike welded connections and fittings, they can be used repeatedly. This distinguishes this technique from the one that involves connecting plastic pipes using heat. This important quality of the clamps allows you to simplify the pipeline repair process. The push-in quick-release connection allows you to reuse the fittings multiple times, so you can easily replace individual sections without dismantling the entire system.

However, such clamps also have disadvantages. The most significant is the fact that connecting elements weaken over time. This can cause leaks in systems. It will not be difficult to fix this problem; to do this, you need to tighten the collet fitting. Due to this lack of clamps, they must be placed in places where quick access to the system is provided. Fitting elements cannot be used inside walls or other building structures. Fittings are tightened to improve tightness approximately once a year.

Advantages and disadvantages of collet clamp for pipes

The use of collet-based clamps has gained popularity not so long ago. But now many specialists and professionals widely use this product for various jobs. Unlike a conventional fitting, such a connector has many advantages.

Advantages of a collet connection:

- Affordable price;

- Wide choose;

- Easy installation;

- Durability;

- Connection strength;

- Can be used several times.

The collet itself is inexpensive. In addition, its installation does not require special expensive devices or materials. At the same time, work on replacing the device will also not be very expensive.

There is a wide selection of collets in different sizes on the market. In this case, the product can be purchased at any hardware store or market. Collets are available for various pipes and diameters, so choosing the right product will not be difficult.

To install such fittings you do not need special tools. Anyone can learn to work with a collet in a minimum amount of time. And if installed correctly, the connection will last a long time. At the same time, the collet connection is quite reliable and sealed.

The cause of collet failure may be mechanical impact or rusty pipes.

Unlike other connectors, the collet can be used several times. This simplifies pipeline repair work. This way you can only notice a section of the pipeline without dismantling the entire system.

Among the shortcomings of the products, a gradual weakening of the connection is noted. As a result, the pipeline begins to leak. But dealing with this problem is quite simple. You just need to tighten the collet.

But this disadvantage requires that such a connection be installed in an accessible place. You cannot install hidden pipes and hide communications. Lifting work is usually performed once a year.

Additional information about the features of connecting pipeline elements

The collet connection of metal pipes is reliable. It can be used in conjunction with pressure and non-pressure pipelines. The joining can be done in such a way that metal and plastic pipes are connected into a common system. To do this, the ends of the elements that are to be connected should be cut off. The cut should be smooth and perpendicular. A coupling is applied to the joint.

The central part of the fitting should be located at the connection point. Markers should be placed on the pipes with a marker to indicate the position of the coupling. The ends of the pipes and the coupling are treated with silicone grease. The first pipe is inserted into the coupling. The second pipe is aligned along the axis with the first, and the coupling is pushed onto it. When putting on the coupling, you should follow the mark.

Installation

Installation of collet connections is the simplest possible. Classic threaded fittings rival in ease of installation, but you must seal the connection yourself (using tape or flax tow). Moreover, this will need to be done again each time if you need to disassemble the unit. In the case of a collet fitting, there is no such need.

To work you will need:

- scissors for plastic pipes or a hacksaw for metal;

- calibrator with bevel remover;

- wrench or wrench.

Let's look at the installation of a collet connection using the example of a metal-plastic pipe. The scheme of work is as follows:

- cut off the pipe;

- align the circle by putting the pipe on the calibrator and turning it;

- remove the internal chamfer (necessary to ensure that an uneven cut does not damage the o-rings on the fitting);

- disassemble the fitting by removing the nut and collet ring;

- put the nut and ring on the pipe in the order described;

- Pull the pipe onto the fitting until it stops;

- move the collet into place;

- tighten the nut.

Note! The hex nut should be tightened using wrenches, but do not tighten it all the way. As soon as a characteristic metallic sound appears, you should stop. If you do not rely on sound, then 1-1.5 free threads on the fitting should serve as a guide.

Characteristics of a push-in fitting

The push-in fitting has an external thread with an external hexagon. The nominal passage is 6 mm. The sealing threaded connection is coated. The assembly position can be any. The design operates on a reciprocating principle. The operating pressure range varies from 0.95 to 6 bar. The operating pressure, depending on the temperature, ranges from 0.95 to 14 bar.

There is one note regarding the work environment. It lies in the fact that working with lubricant is possible. The material has one drawback: it has low corrosion resistance. The base is alloyed stainless steel. The body material is brass with nickel plated. The ambient temperature during operation can vary from - 10 to + 80 ˚С.

Description of the collet connection of the cylinder

The push-in connection of a gas cylinder is sometimes also called a fitting or rod connection. People call it dichlorvos. Such cylinders are intended for special mobile kitchens. This connection allows you to use the cylinder in burners, but you should additionally purchase an adapter, which is sometimes included.

A collet cylinder has thinner walls than a threaded cylinder and is sometimes used at the connection to the torch, which can cause installation problems. As practice shows, the fuel in dichlorvos cylinders is of low quality.

Types of elements for metal-plastic

The collet connection of metal-plastic pipes can be represented by three types. The use of such products is effective in conjunction with various heating and water supply systems. The former can be water and steam. The connection of pipelines can also be carried out in systems for technological purposes, irrigation structures, etc.

Where there is a metal-plastic pipeline, there is a need to use special collet elements. They can be presented:

- corners;

- straight collets;

- tees.

Angles are designed to connect parts of a structure at right angles. The fitting can have an internal or external purpose. A straight collet is designed to connect two pieces in a sequential manner. Three products can be connected using a collet-type tee, which will go in series and at right angles.

Why choose collet fittings

Collet parts for connection are selected for several reasons. The first is the presence of o-rings in the housing with a fitting. With their help, high sealing of the connection is ensured. The material used in the fittings is of high quality. Installation is accessible even to a beginner.

The design includes a split crimp ring. With its help, the clamping is carried out smoothly, and the structure is not deformed. There is no electrical conductivity, because the collet-type fitting has a special dielectric gasket.

The nuances of using socket pipe connections

The socket connection is distinguished by its simplicity. So the end of one pipe has a larger size, where the necessary element is inserted. To seal the connection, various types of seals are used.

Types of socket connections:

- Without O-ring;

- With O-ring;

- By welding.

The first option is characterized by maximum simplicity. To begin with, the materials are measured and prepared (sawed off, sanded). Then the prepared pipe is inserted into the socket. The gap is sealed with a sealant. Compaction occurs due to oiled hemp or flax. The material is pushed deeper. And the nearest distance is treated with silicone sealant.

When using an O-ring, the required tightness is ensured by this rubber element. The ring is clamped between the walls of the pipe and the socket. In this case, it is important to monitor the alignment of the centers.

The use of welding is only possible with special equipment. This is how a mechanical or manual welding machine is used. The installation process is quite simple: the elements are heated and connected.

Affordability, durability and reliability

Push-in fittings are chosen for several reasons. One of them is low cost. This parameter consists of the price of the clamps, as well as the cost of their installation. To perform the work, the use of expensive equipment and special tools is not required. A rather important factor is also the possibility of replacing connecting elements, if necessary. These works will not be associated with serious financial costs.

Buying such fittings of almost any diameter today is not particularly difficult. On the modern market you can find clamps of any size. They are intended for pipes made of different materials. You can quickly learn how to qualitatively connect elements using clamps.

The connection created is durable under normal operating conditions. The pipeline has been in service for decades. Only high mechanical loads and corrosion processes can damage it. The advantage of collet clamps is also their reliability, as well as exceptional tightness.

Source

Results

Based on all of the above, we can conclude that collet clamps (or collet fittings) have become an excellent alternative for quick, and at the same time high-quality, installation of plumbing in any house or apartment. The pricing policy of the manufacturers of these parts is based on a surprisingly good price-quality ratio, and this material can be purchased at any specialized place.

An undoubted advantage is the fact that the use of collet clamps for pipes is available to anyone who can hold a wrench in their hands. In addition, you do not need a specialized, complex and expensive tool to install a water supply system, and there is no need for any professional skills and knowledge.

Although the fact that this pipe joining tool is very convenient and reliable, the loosening of the pipe clamp that you will have to deal with over time places some limitations on the use of collet clamps. There are situations when the water supply is laid in such a way that it is not possible to provide permanent access to the joints. In this case, this installation method is not suitable, but otherwise, at the moment it is difficult to find any better solution.