This adhesive is a well-known and popular product in the market of epoxy adhesives. Its base is epoxy resin and hardener. Its properties are similar to those of metal welding. It says “cold welding” on the packaging. It has a number of unique characteristics.

In this review I will tell you about its features. I note that there is enough information about it on the Internet, since it is really in demand in everyday life.

Characteristics and instructions for use

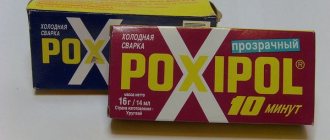

Poxypol glue is a two-component composition with a paste-like consistency. The ratio of proportions in the prepared mixture is 1:1. Available in two tubes marked “A” and “B”. This brand is presented in two types: “POXIPOL® 10 minutes transparent” in packages of 16g/14ml and 82g/70ml, also “POXIPOL® 10 minutes metallic” with a volume of 21g/14ml and 108g/70ml.

They have no difference in adhesive strength, the only difference is in applicability. It contains no solvents and is resistant to basic chemicals. For example: petroleum products, acid, solvent and others. Heat-resistant, operating temperature up to +120°C.

Moisture-resistant, the manufacturer guarantees hardening even in water. Apparently a marketing ploy. This property should not be taken literally. Since it will work after application to a dry and grease-free surface. Thanks to high adhesion and fast curing speed in 10 minutes. More is better.

In its finished form, the physical properties of poxypol do not change over time, and in tubes the storage is endless. You don't see this often. An excellent product for working on a vertical surface because it does not spread.

Effective in cold weather without additional heat and pressure. Again, I note that maximum strength is achieved only at room temperature. Therefore, mix the ingredients while in a warm place.

A deviation in one direction or another by 10 degrees does not have a significant effect.

The applied thickness does not matter. Hard and elastic in a repaired product. During operation, it can be subjected to significant loads.

Description and features

Poxipol is a two-component adhesive produced in two tubes. The first contains epoxy resin, and the second contains trimethylamine hardener. The latter is necessary so that the main component dries quickly. Poxipol is different in that when stored in tubes, the characteristics of the product do not change for decades. The features of this glue include the following:

- increased adhesion;

- the volume of glue after drying does not change (any amount can be applied);

- the duration of the complete drying period depends on the ambient temperature;

- glue is used for application to horizontal and vertical surfaces.

After hardening, the joint can be sanded, sanded, or threaded in this area. The characteristics of the glue do not change under such influence. There is no need to press the joints to harden. The glue dries completely within 24 hours, provided there is no vibration.

Blister packaging

There is an interesting point in using two-component poxypol. Included with the blister (not every one) is a self-cleaning tray for preparing the working composition. Made from a material that prevents components from sticking. Before using the tray, you must remove the applicator. To continue to use it, you only need to remove the hardened mixture. Which is prepared in equal proportions.

It is not recommended to change the dosage in any direction. Use within 10 minutes.

Maximum strength will be achieved after one day. At this time it is better to leave it completely alone. Adding fine steel shavings will provide even greater strength against impact and dynamic impact. The surface of the parts to be glued must be clean and dry. A smooth surface is treated with sandpaper of 180 grit or finer.

How to use it correctly

According to the instructions, before using the glue, the surface must be cleaned, removing dust, dirt and grease. For the latter, a soap solution or alcohol is used. After this, the surface is dried. It is recommended to sand metal parts with fine sandpaper. This will increase the strength of the connection. Having prepared the surface, you can begin mixing the glue. To do this, you need to squeeze out the required amount of epoxy resin and add hardener from the second tube in a similar volume.

Then, using the included spatula, mix both components until smooth.

Use the resulting glue to lubricate one of the surfaces. Next, the parts are pressed tightly against each other and held in this position for up to three minutes. If necessary, you can adjust the position of the fragments. This should be done within 5-10 minutes. The repaired product can be used 24 hours after restoration.

Application area

Instructions for use and technical characteristics of this glue are fully posted on the manufacturer’s website. It tells in detail in what areas it can be used and what properties it has.

So, it glues metal, plastic, and wooden products. Also porcelain tiles, porcelain, earthenware, marble, concrete. More rubber and glass. By the way, you can find out about other effective brands of adhesives for metal here https://kraskaguru.ru/klej/dlya-stroitelstva/po-metallu.html.

Cold welding poxipol is not used for food materials.

Perfect for home repairs in workshops, designing various kinds of crafts. Assembly, fastening, connection of furniture interior made of wood or metal. Particularly recommended for items experiencing fairly heavy loads. Remember this. Let's say - slats and crossbars for beds, crossbars for stools. Legs of tables, chairs, armchairs.

Repairing wooden or metal doors and windows, attaching hinges. Leaky tanks and water containers. Filling and repairing cracks in sinks, bathtubs, and toilets. Fastening the handles of hand-held equipment. Almost the entire list, from a heavy hammer to a light mop. Bonding marble and granite blocks.

For restoration of stucco, monuments made of concrete, plaster or marble. Fastening various accessories. For support in walls to hang heavy objects. In country gardening, installation of fasteners for hanging objects, tools and massive decorations.

Patching radiators made of non-ferrous alloys and fuel tanks on cars or motorcycles. Also other household items. Boat frames or car bodies. Strengthening and joining seams in vehicles. Restores threaded connections. Joining and repairing garden furniture from the main materials used.

Restoration of vases, flower pots, large porcelain items, fountains in gardening. Bonding of concrete pipes for drains or storm gutters. Plastic drainage systems. As you can see, the possibilities are great.

These conclusions have been studied, and the methods of applicability have been determined from laboratory findings.

Glue composition

The production of building materials is based on the use of a combination of special chemical compounds, which, when closely interacted, give the desired result. Epoxy adhesive "Poxipol" is made using a very sticky resin, which has a high level of adhesion and excellent elasticity.

The adhesive seam tolerates tensile and shrinkage loads well, so that even after many years the substance will not lose its original qualities. But the resin itself takes a very long time to harden, so special solvents are added to it, which evaporate after use, allowing the glue to harden in the shortest possible time.

The production is carried out on modern high-precision equipment, so quality control is at its best. Two-component adhesive "Poxipol" goes on sale in the form of a set of two tubes with liquids.

It is not difficult to guess that one bottle contains resin, and the other contains solvent. When you need to glue something, you just need to dilute the mixture in a one to one ratio. To do this, it is better to use any unnecessary container that you would not mind throwing away after work. You need to prepare small portions, since the life cycle of the mixture is quite limited.

Useful tips and safety precautions

When the glue dries, you can drill, sand, saw. To achieve improved joint quality when working with materials such as stainless steel, brass or other perfectly smooth surfaces, be sure to sand. After this, degrease, then apply the finished mixture.

It is not flammable, but will not withstand open fire. Not suitable for working with polyethylene, teflon, polypropylene. You cannot repair a gas pipeline at home. You can paint it to get the desired color. At the same time there will be protection from ultraviolet radiation.

If not used carefully, it can be removed from hands with any abrasive material. Then rinse well with warm water and regular soap. Because epoxy resin is very sticky. Do not swallow. Keep out of the reach of children and pets.

Approximate analogues

Analogues of poxypol glue are everything called “cold welding” and partially “liquid nails”. These are present in the brands “Bison”, “Zubr”, “Moment”, “Almaz”, ABRO. Moment Epoxylin 2 in 1, “Super Grip”, “Epoxy Exclusive”, “Epoxy Metal”, “Done Deal DD6580” and many others. There are a lot of options, fortunately the adhesive market is saturated. There are plenty to choose from.

Advantages and disadvantages of the product

The use of the adhesive composition Poxipol has a number of advantages:

· the seam formed during application retains its shape after hardening;

· interacts with any types of materials;

· does not damage plastic products;

· it is convenient to work with him;

· dries quickly - after an hour you can already use it;

· easy to use.

However, there are also disadvantages:

· the connection does not work effectively enough in conditions of increased vibration;

· analogues (copies of the product) have appeared on the market, which are noticeably worse in connection quality;

· may melt under high heat;

· the adhesive composition cannot be prepared in advance;

· the preparation is too small in volume, which creates certain difficulties when carrying out large-scale work.

Objective reviews

It is very popular among car enthusiasts. It was noted that the glued parts hold securely in all weather conditions. The reviews are enthusiastic, there are no shortcomings, with rare exceptions. High price. But the point is, he can glue things that others cannot. Therefore, at a critical moment it can help out a lot. Also durable, reliable, quick to set.

Not really suitable for plastic. One of the disadvantages is when it falls off from strongly expanding parts when heated. After all, it is known that advertising exaggerates the quality of a product. Therefore, before the main gluing, conduct a small trial experiment.

What are the differences?

There is an opinion among people that transparent glue is much better in operation than colored Poxipol. But this is nothing more than another myth. The composition of both models is absolutely identical, and the addition of dyes does not affect the properties in any way. So when choosing an option, you should not focus on the color of the mixture. This brand is truly one of the best today and rightly enjoys a high level of trust around the world. So there is no need to worry about its technical characteristics. They are time-tested and multimillion-dollar successful operations.

Cold welding

"Poxipol" based on epoxy resin has the consistency of plasticine. It consists of two components that are mixed together before use. This plastic mass is applied directly into the gap and does not require pressing. It hardens in just ten minutes and after 1 hour forms a tight connection, after which the part can be drilled, sawed, etc. But it is still recommended not to move the bonded surfaces for 24 hours until the chemical reaction between the two components is completed and complete polymerization.

Poxipol glue

is not afraid of atmospheric influences: temperature changes, water, freezing-unfreezing processes, UV radiation. The compound does not release any substances, so it can be used for gluing dishes. In general, this two-component composition is suitable for gluing metal, concrete, brick, wood, rubber, plastic, ceramics, and glass. Materials with a glossy or enameled surface are best roughened first with sandpaper to enhance adhesion, otherwise the adhesion may be short-lived.

Components of glue " Poxipol"

» Mix immediately before use in a 1:1 ratio.

There is transparent and gray glue POXIPOL 10 Min Metallic for metal products. The gray compound, known as “cold welding,” is intended for pipe parts, filling dents and rust gaps in automobile bodies, train cars, and for non-threaded joints and some utility flanges. To apply this material, simply clean the metal from paint and degrease the gluing area. The composition of POXIPOL 10 Min Metallic

allows the connected part to be subjected to mechanical stress or painting after an hour. Of course, such fastening of metal parts will be weaker than real welding, but if the part is not subjected to sharp impacts or falls, then it is quite capable of maintaining a tight seal, and is even suitable for gas pipelines, water supply, etc.

After applying the adhesive, there is 3 to 6 minutes left to adjust the position of the surfaces, after which the viscosity of the adhesive will not allow changing the position of the parts. The popularity of Poxipol glue is largely due to the ease of its use, which does not require special effort or skills.

"POXIPOL"

— “Acts” on a dry, clean surface without grease or oil.

"POXIPOL"

- For materials such as metals, ceramics, rubber, glass, concrete, fiber-reinforced concrete, wood, hard plastics (plastics), except polyethylene, polypropylene, Teflon (polytetrafluoroethylene). To achieve a better result, the surface should first be “sanded” (made rough).

After applying the prepared mass to the surfaces to be glued, the glue hardens, even under water. To improve bonding of “difficult” surfaces such as stainless steel, copper, bronze, galvanized steel, ceramic tiles, etc. It is recommended to first apply a thin layer of "contact" - toluene-free adhesive and allow it to dry for at least 30 minutes.

Poxipol, what is it?

A few years ago, a two-component composition, Poxipol, appeared, produced by a Uruguayan company, which in turn belongs to the parent company Acapol, located in Argentina. It's a bit far. Does it really make sense to transport glue from Latin America? However, if they carry it, it means it is special in some way. Perhaps at a price. But no, the price is quite human - in the range of 250-300 rubles for one package, which includes a total of 21 g of the two-component material Poxipol. The price of a package of 70 g is generally somewhat lower, but such options are rare.

By and large, cold welding Poxipol is the same epoxy resin with a hardener. It is distinguished from epoxy glue by the use of modifying substances and plasticizers. We open the cardboard packaging and see two bottles - one contains epoxy resin with plasticizers, the other contains a hardener. Depending on the packaging, the box may contain a plate made of a special material for mixing the two-component composition. The instructions for use indicate that the tubes contain:

- composition A is an epoxy, rheological modifier, filling agent;

- composition B - trimethylamine, filler, modifying additives.

Glue hardening time

By and large, the consumer is interested in how long the glue dries, what tensile strength and what temperature it can withstand. All this is indicated in the specifications. For example, it is written right on the packaging that the hardening time is ten minutes, although in fact the composition polymerizes and completely hardens in 24 hours, and trimethylamine ceases to emit harmful fumes only after 78 hours.

However, according to the results of publicly available tests, complete hardening of the composition occurs only after 48 hours. Trimethylamine in its pure form is a very toxic substance, it is especially dangerous in the form of fumes, about which not a word is written in the instructions. If so, let's first consider security measures.