Tool alloy steel 9ХФ was produced back in the USSR. Unrivaled steel was used to make tools capable of cutting other alloys, and its quality was never questioned. Saws made from 9HF were used in logging sawmills. Now the production of this brand has been established in Ukraine and Russia, but the quality of modern alloys in many respects is inferior to those produced during the Soviet period.

Blades made of 9HF steel.

Dear please help me with steel grade

I ask the guru for help. Tell me, does anyone know what kind of steel Soviet circular saws for cross cutting were made from? I have one with a diameter of 50 cm. And how blades from it work. I'm new to the site, please don't jump straight into the search.

With a high probability 85xf. Quite a decent piece of steel. I made a couple of knives from the disk of an industrial circular saw (Disc without soldering). A modern brazed disk can be made from full G.

Nothing to add

I don’t know the brand, but I tried to bind it with y7. it turned out to be a good knife. good contrast. https://guns.allzip.org/topic/97/461298.html

I have one - 600 mm in diameter. It is marked 9ХМФ. I looked in reference books and it is used mainly for circuses. drank. They claim a hardness of 61, but after making the knife I feel like it’s less. I will heat the next blade.

quote: I have one - 600 mm in diameter. It is marked 9ХМФ. I looked in reference books and it is used mainly for circuses. drank. They claim a hardness of 61, but after making the knife I feel like it’s less. I will heat the next blade.

quote: and this is correct! Since hardening is 61 units (and the same on frame saws) only on the tooth using HDTV

Possibly! But provided that the saw was not in use, all the sides of the working saws are burnt, and if they sawed leafy wood or a pine tree, then such a thing is welded on it, you can barely pull it off with a grinder!

Although it may be 30xgsa

Source: guns.allzip.org

Wood saw blade steel grade

How to choose a circular saw blade? Where is the best place to sharpen a circular saw blade?

A circular saw is a universal tool that works with various materials - from wood to plastic and sandwich panels. However, in order for the cut to be even and without jagged edges, a well-chosen circular saw blade . Note that there is no universal disk suitable for materials, because each product solves its own problems. Today, do not save money by buying products from an unknown brand - this is dangerous at first.

Technical information for tool steel circular saws

Circular saws for wood

A circular saw is a rotating cutting tool in the shape of a circular blade with many cutting teeth around its perimeter, which is designed for mechanical cutting of wood and wood-based materials.

The circular saw is made of alloy tool steel, with heat treatment, leveling, calibration, setting and sharpening.

- Material: The circular saw is made of 75Cr1 . (DIN 1.2003); (ČSN 19418)

heat treatment: The circular saw is hardened to 44-48 HRc for body thickness up to 3 mm and to 42-46 HRc for body thickness over 3 mm.

- leveling: When leveling the circular saw, deviations from the flatness of the surface are eliminated, i.e. so that the axial (face) runout of the circular saw does not exceed:

- values 0.2 mm for circular saws with a diameter of up to 200 mm

- values 0.4 mm for circular saws with a diameter of up to 500 mm

- values 0.6 mm for circular saws with a diameter of up to 800 mm

- values 0.8 mm for circular saws with a diameter of over 800 mm

The run-out of the circular saw blade changes in the clamped state near the mounting hole, and it is necessary to pay attention to the quality of the clamping flanges, which must be at least 5x√D of the saw blade.

calibration: By properly adjusting the preload, the strength of the saw blades is increased, which allows for higher feed rates and thus improved cutting accuracy and cut surface quality. During manufacturing, circular saw blades are calibrated for a cutting speed of 60 m/sec for smaller thicknesses and 80 m/sec for thicker circular saw blades. The corresponding speeds for which the saw is calibrated are indicated on the circular saw.

routing: The amount of routing (on one side) is usually 1/4 of the thickness of the disk body. Only the upper third of the tooth is moved apart. The layout must be symmetrical, otherwise the circular saw begins to deviate towards a larger layout. The layout is always done before sharpening; after sharpening it is only controlled and corrected if necessary. If you use too small a setting, the circular saw overheats, loses strength and moves to the side. If the setting is too large, losses arise from too wide a cut, higher energy consumption and increased roughness of the cut surface. For soft wood we choose a larger layout than for hard wood. For longitudinal cutting, we choose a larger layout than for cross cutting. For wet wood we choose a larger layout than for dry wood. For a frozen tree, we choose a smaller wiring than for an unfrozen tree. If the machine is in poor condition, we choose a larger wiring.

- A99 60L 9V (white)

- A96 60L 9V (gray)

The most common reasons for short sharpening times:

- Overheating of the cutting inserts: manifested by a change in the color of the tips of the cutting inserts, which occurs due to overheating of the material during sharpening. Overheating can occur due to too much pressure (removal of too much material) from the grinding wheel onto the surface being sharpened, from using a grinding wheel that is too hard, a grinding wheel that is too fine in grit, improperly holding the tool, or intense sharpening without cooling.

Types of saw blades

What remains for our client to do? Saw blades are divided into two types:

- Solid ones are created from solid metal and are distinguished by sharply ground teeth. They are popular due to their affordable cost, restoration ability, in other words, re-sharpening. On the other hand, solid products wear out faster.

- Carbide blades for hand-held circular saws are more reliable and durable because they are equipped with sharpened cobalt or tungsten carbide tips on the teeth. With the use of carbide materials, products are more durable and reliable, however, if the discs become dull, it will be difficult to return them.

Scope of use and main characteristics

Small and medium-sized circular saws in terms of cutting depth belong to the class of hand-held equipment that has sufficient maneuverability and convenience. At the same time, such saws have little power, and therefore they do not differ in the highest productivity. Saws with a large cutting depth are considered more professional equipment, which is why they are used in small enterprises and woodworking shops.

The second main indicator is the power of the unit inside the saw design

. It is for this reason that the parameter determines the performance of the product. In 3rd place in terms of main characteristics is the disk rotation speed. You need to saw hard materials with equipment that has a higher value than this popular rumor.

The shape of the teeth is important!

When choosing a saw blade, you should look at the design features of the products, the placement of the teeth, and their shape:

- straight similar teeth are suitable for cutting chipboard, wood, plywood or aluminum;

- alternating alternating teeth are used for cutting wood of soft and hard texture or plywood, also for cross cutting;

- A circular saw blade with trapezoidal teeth is used when working with chipboard, soft non-ferrous metals, and plastic. Thanks to the special shape of the teeth, the material does not split, and the cutting itself is carried out in two steps - first a preliminary cut is made, then the edges are trimmed;

- the teeth have a positive or negative slope: the 1st is needed when sawing workpieces with thick walls, the 2nd - with thin walls;

- their rare teeth with deep cavities provide a good longitudinal cut of wood, in this case the sawdust is simply removed;

- Small, closely spaced teeth allow cross cutting of materials. The most convenient among these types is a circular saw blade, which has a special protrusion at the back. Due to the use of this design, the cut is made quickly and moderately.

Before choosing one or another drive, you need to ask yourself a few questions.

RECOMMENDED CUTTING CONDITIONS ON BAND SAW EQUIPMENT

| Workpiece material | Material designation | Cutting speed, m/min | Cooling | ||||

| DIN | GOST | Special | Bi-metal | Emulsion | Oil | ||

| Yes | No | ||||||

| Structural steels | St 35-St 42 | St 35-55 | 40-55 | 60-80 | 1:10 | X | |

| St 50-St 70 | 30-45 | 50-70 | 1:20 | X | |||

| Hardenable steels | C10-C15 | 45-65 | 60-90 | 1:10 | X | ||

| 14NiCr14 | 30-40 | 40-50 | 1:10 | X | |||

| 21 NiCrMo 2 | 30-45 | 45-55 | 1:10 | X | |||

| 16MnCr5 | 30-45 | 50-65 | 1:10 | X | |||

| Nitrided steels | 34 CrAI 6 | 20-35 | 1:20 | X | |||

| 34 CrAI Ni 7 | 20-35 | 1:20 | X | ||||

| Chrome steels | C 35-C 45 | 35-55 | 55-75 | 1:20 | X | ||

| 41 Cr4 | 40X | 25-35 | 40-60 | 1:20 | X | ||

| 40Mn4 | 40G | 35-45 | 50-65 | 1:20 | X | ||

| 42 CrMo 4 | 40 XM | 30-40 | 35-50 | 1:20 | X | ||

| 36 NiCr 6 | 40 HN | 30-40 | 50-60 | 1:20 | X | ||

| 24NiCr14 | 25-35 | 40-60 | 1:20 | X | |||

| Bearing steels | 100 Cr 6 | 25-35 | 50-65 | 1:30 | X | ||

| 105 Cr4 | ШХ 15 | 25-35 | 50-65 | 1:30 | X | ||

| 100 CrMo 6 | 20-30 | 40-50 | 1:30 | X | |||

| Spring steels | 65Si7 | 65 G | 30-40 | -100 | 1:30 | X | |

| 50 CrV 4 | 50HFA | 30-40 | 40-60 | 1:30 | X | ||

| High carbon tool steels | C80W1 | U8A | 25-35 | 40-55 | 1:30 | X | |

| C125W1 | 20-30 | 35-45 | 1:30 | X | |||

| C 105 W 2 | U10A | 25-35 | 40-50 | 1:30 | X | ||

| Alloyed | 105 Cr 5 | 30-40 | 50-60 | 1:30 | X | ||

| x210Cr12 | X12 | 20-35 | X | ||||

| x 40 CrMoV 51 | 4Х5МФС | 20-30 | 30-40 | 1:30 | X | ||

| x210CrW12 | HVG | 20-30 | X | ||||

| x 165 CrMoV 12 | XM12 | 20-35 | 1:30 | X | |||

| 56 NiCrMoV 7 | 5ХНМ | 25-3 | 20-40 | 1:30 | X | ||

| 100 CrMo 5 | 20-30 | 35-45 | 1:30 | X | |||

| x 32 CrMoV 33 | 20-30 | 30-45 | 1:20 | ||||

| High speed steels | S 6-5-2 | R6M5 | 25-40 | 1:30 | X | ||

| S 6-5-2-5 | R6M5K5 | 25-40 | 1:30 | X | |||

| S 18-0-1 | P18 | 25-40 | 1:30 | X | |||

| S 18-1-2-10 | Р18К10 | 25-40 | 1:30 | X | |||

| Valve steels | x 45 CrSi 93 | 30-40 | 1:20 | X | |||

| x45CrNiW189 | 30-40 | 1:20 | X | ||||

| High temperature steels | CrNi 2520 | 25-40 | 1:10 | X | |||

| x 20 CrMoV 211 | 25-40 | 1:10 | X | ||||

| x5NiCrTi2615 | 25-40 | 1:10 | X | ||||

| Heat-resistant steels | x 10 CrAI 7 | 20-30 | 1:10 | X | |||

| x15CrNiSi25/20 | 20-30 | 1:10 | X | ||||

| x 10 CrSi 6 | 20-30 | 1:10 | X | ||||

| Stainless and Scale-resistant steels | x 5 CrNi 189 | 25-35 | 1:10 | X | |||

| x 10CrNiMoT1810 | 25-35 | 1:10 | X | ||||

| x 10 Cr 13 | 12Х13 | 25-35 | |||||

Circular saw tanto.Production process and end.

Circular saw knife

.On the saw there was a mark made in our country and GOST numbers. GOST steel grade

9xf

, and this.

You should choose a saw blade for a circular saw taking into account the type of cut - you will prefer it to be transverse or longitudinal. Even today, the materials you intend to cut also play an important role - wood, plastic, chipboard, non-ferrous metals, pipes... Let us note one thing - any series of discs is designed directly for specific work.

The quality of the blade directly affects the cutting efficiency. A good canvas is created by laser cutting, while balancing is done on a computer. Each disc is sanded separately. A high-quality blade will reflect sanding tool marks when illuminated. If the blade is rough and looks roughly processed, the saw blade for a circular saw will not work efficiently and will soon become dull.

The main reasons for premature failure of the belt web.

- Chipping (knockout) of teeth

- The saw pitch is too small.

- Saw pitch too large.

- The workpieces are not securely fastened.

- Saw speed is too low, resulting in excessive penetration.

- Feed pressure is too high, causing the saw to cut into the material too much.

- Weak saw tension causes it to slip.

- Slipping (stopping) of the saw under load, leading to excessive penetration of the saw into the material.

- The saw cleaning brush is missing, does not work, or is worn out.

- Cracks in tooth cavities.

- Difficult movement of the saw in the guides and pulleys due to contamination of the pulleys or reduced clearance in the guides.

- The gap between the guides is too large.

- The guides are too far from the workpiece.

- The side guides clamp the saw in the tooth gullet area.

- Weak side guides cause the saw to tilt

- Incorrect saw tension.

- Cracks on the back of the saw.

- Wear of the upper support bearing in the guides

- High supply pressure.

- Wear of side guides.

- The blade is pressed against the pulley collar.

- Beating (vibration) of the saw

- Crooked weld.

- The saw pitch is too much.

- Missing teeth (broken).

- Supply pressure too low or high.

- Premature dulling of teeth.

- The saw speed is too high for the material.

- Saw pitch too small or too large

- The saw blade is not parallel to the feed direction.

- Defects on the side guides.

- The guides are poorly secured or worn.

- Non-perpendicular cut.

- The saw blade is not parallel to the feed direction.

- Large gap in guides.

- The table surface is not perpendicular to the saw.

- The vice is not perpendicular to the saw.

- Low saw tension.

- The side guides are poorly secured.

Taking into account the diameter

Any saw

has its own dimensions, if the equipment for it must be selected taking into account this parameter.

The diameter of the disks is important, because if the diameters are different, this will lead to losses. So, the cutting depth depends on the outer diameter. Experts say that the sawing depth above the workpiece can be small: here the cut will be better, the heating will be reduced, and the load on the engine will be small. It is important that the disk is tightly fixed to the mounting pin.

How to sharpen?

Just like any other tool, the saw needs timely care. The most crucial moment is sharpening the circular saw blades. Experts note that the carbide tooth wears out along the main top edge; if powerful workpieces are sawed, then the side edges also wear out rapidly. The saw should not be allowed to become too dull, because it will be the least productive, and it is not a fact that it is possible to sharpen the discs.

Proper sharpening involves simultaneously ensuring the proper sharpness of the cutting edge. If you sharpen them along one frontal plane, then the number of sharpenings will be less. Many owners of similar tools are interested in how to sharpen a circular saw blade. This depends on the material of the teeth. Sharpening in most cases is carried out on a wheel made of CBN, also called greenish carbide, otherwise based on diamond wheels. CBN wheels are specifically used for sharpening saws made of high-speed steel, and diamond wheels are used for sharpening cutters made of hard alloys. To sharpen quickly, but have less impact on the degree of wear, it is worth choosing diamond wheels with a larger grain size.

For sharpening, machines that have different functionality are also used. The most complex and expensive methods for models provide automatic sharpening. When sharpening, the teeth should be spaced apart: if this is done incorrectly, then at the time of cutting there will be a burning smell, extraneous noise, and the material itself will move jerkily, which is not very comfortable.

The condition of the disks should be constantly monitored, because their wear will increase the load on the mechanisms and at some point lead to complete wear. Thanks to constant sharpening, of course, you can extend the life of the equipment, improve productivity and reduce the time for the cutting process. If after sharpening the cut remains sloppy and the material moves unevenly, it means that you should pay more than just attention to the location of the teeth.

How to choose saw blades? This is easy to do if you follow a few rules:

- Find out the diameter of the mounting hole and the outer diameter of the blade on the label - you must meet the requirements of the features of your saw.

- Pay attention to the thickness of the disc: thin ones provide a good and clean cut and are used when working with valuable types of wood, while thick ones are specifically used for preliminary cutting of materials.

- The disk will indicate what the maximum permissible speed is. A low speed will allow you to develop a higher cutting speed, but will lead to deformation of the disk and a poor saw.

- Evaluate the quality of the saw blade: if it is not bad, then the cutting plane will be smooth, without roughness or imperfections.

B – pay attention to safety and choose saw blades that are designed for a specific type of saw. And additionally think about where to sharpen the circular disk

saws, if you can’t do this at home.

Source: xl-info.ru

Frame saw steel grade

Why did Russia fall in love with machetes, khukri, parangs or bolos?

After all, in Rus' there was a very good, in no way inferior to cutting and piercing edged weapon - the cleaver. And as a type of cutlasses - short and light broadswords. How to make a cleaver? Cleaver - Broadsword is not only an excellent bladed weapon, but a full-fledged assistant in any campaign - it is razor-sharp and strong, like a short sword, reliable and durable if made of the right steel, for example, 9HF Soviet-hardened steel.

The need for a cleaver-broadsword for a survivalist-autonomous taiga dweller is obvious, so it is unnecessary to list the areas of its application. Separately, it can be noted that the broadsword presented in the video is not a bladed weapon, according to the legislation of the Russian Federation for a separate feature - its “yoke” from the axis of the blade is higher than 15 mm. Testing sharpening in the field revealed all the unique properties of the steel from which the broadsword is made.

Soviet steel grade 9HF is worthy of special consideration.

Modern steel of this brand cannot be compared with the steel of the Soviet period. Moreover, since 9HF steel was used to cut other steels, its quality life was unprecedented during the Soviet period. It was used not only for cutting other steels. Yes, 9KF steel could not be welded. But the quality, temperature and plastic properties of this steel made it an optimal choice for use on sawmills during logging. Why?

One detail is important here. Namely, the design of sawmills, which led to the fact that there was no better steel to use in them than 9HF steel. So, the design of the R-63 sawmill was specific (it remains this way to this day))), complex, timeless, but not very easy to maintain. If one of the cutting saws broke down, it was necessary to reconfigure the entire saw scale again, which led to downtime of the sawmill, and given that logging in the USSR was carried out mainly by prisoners in the zones, such downtime did not contribute to the career growth of its bosses. And delivering new saw blades to the wilds was problematic.

| In this regard, there is an interesting fact: in some places the R-63 was tuned, paradoxically, by prisoner musicians. The 9xf blades were all industrial grade, the grip in the frame was the same, but the tension gap had a slight play. According to GOST, everything turned out fine, and the service life of the canvases was very decent. But still, sometimes incidents occurred due to the imperfection of the human spirit of the saw set. So, the prisoners, not having the opportunity to sharpen steel blades with high quality, quickly receive them from manufacturing plants, despite the fact that the plan had to be EXCEEDED, came up with the idea of using blades made of 9HF steel, which holds an edge perfectly and is incredibly flexible and durable, and for grips insert razors that allow you to tune the frame with a kind of tuning fork: they achieved the same sound of the saw blades in the frame, the frame was started, the service life of the threading was enormous - all the blades were tensioned equally - there was no overload of tension on some blades, and a lack of it on others. The service life of 9HF steel on wood is enormous. |

R-63 sawmills became a thing of the past as soon as the famous Soviet-made 9HF blades ceased to be produced. Modern ones, declared as saws made from 9HF, do not have nearly the same properties as the old steel: their composition is not the same, the hardening is not the same, and, accordingly, the characteristics are not the same. In some villages and abandoned sawmills, grandfathers still have either whole canvases or fragments of Soviet-made canvases. Craftsmen, knowing the amazing qualities of that steel, collect them as best they can and where they can - in villages and abandoned areas. Here are its characteristics:

This kind of 9HF steel from the Soviet period can be recommended to any taiga autonomous worker for making a cleaver or knife, since with fantastic flexibility, it has amazing hardness, holds the sharpening of the cutting edge for up to six months (unless, of course, you cut stones and sand) and does not lose their properties in the low temperature conditions of the Arctic region, the Far North, Siberia and the Far East.

Greetings to everyone! Please tell me a normal knife will be made from such a saw?

maybe the comrade is thinking about a katana?

I made it from something similar. The owner of the knife likes it. My impressions are mixed. It rusts and dulls faster than you expect. (I didn’t do chemical oxidation, but in vain). But, on the plus side, even a dull one (it practically doesn’t cut office paper) chews wood with a bang. That's just my opinion based on experience, nothing more.

I made one from a saw like this at one time. A little soft.

Needs to be reheated. All woodworking tools are not heated too hard, but the steel is good.

9хф with a high probability of 45-49 HRC

quote: will a saw like this make a normal knife?

If you call me, I’ll throw in my 5 kopecks: in the photo - a saw for a frame saw, hardness and steel have already been indicated above

9ХФ, 45-49 HRC. Well, now the main ambush: this saw has already worked quite a bit, and has been used up for a long time, so it will be very difficult to squeeze even 45 units out of it. only for retraining, and this is dancing with tambourines. I made 4 knives from this saw, none of them are even suitable for peeling potatoes.

I carried this saw for a hardness tester. Showed 44 units, and not a single more. I made a machete out of it. But, really, the guy hasn’t been able to pick it up for three months now, so there’s no response yet. And one friend made a couple of knives from such a saw, and at the same time he cut the cuts with a file. For example, I don’t understand such softness for a knife.

Isn't it cemented by any chance? (then it makes sense to sharpen on one side to work with the carbon layer)

zone hardening will save the father of Russian democracy

there is no need to cement, the composition of the steel is normal

quote: Originally posted by steppehunter: Is it by any chance not cemented?

Maybe U7A or 6FKh, the steel is not very good, and the fabric is thin, judging by the photo.

quote: Originally posted by nik ol: Most likely 9хф or 6хф.

quote: Originally posted by Shyr3000: this saw has already worked hard and has been used up quite a bit, so it will be very difficult to squeeze even 45 units out of it. only for re-hardening

quote: Originally posted by Nikolaich72:

If you don’t mind, can I insert one of your photos into my topic? I didn’t take a photo of my saws right away, but now they’re all cut up.

Classification of saw blades

Depending on the design features, the equipment is divided into 2 types:

Monolithic . The entire disc is made of tool steel. Its main advantages include low cost , the possibility of self-sharpening and maintainability - a large margin of safety.

Carbide . The base is made of tool steel, and the teeth are made of hard alloys with the addition of tungsten carbide. The main advantages are high saw edge hardness , clean cuts and long intervals between sharpenings .

Carbide-tipped discs allow you to perform woodworking with maximum speed and productivity , but they have a serious drawback - maintenance requires special tools and above-average skills.

What kind of disks are there?

In production and everyday life, different types of disks are used. They differ from each other not so much in the material of production, the position of the teeth, but also in the scope of use. Our client can of course divide the products exhibited on the financial market into 4 types:

Models used when working with brick, tile, granite and hard materials. The cutting edge of such products is often diamond-tipped, which allows you to quickly handle any material of any density. There are products on the market for wet cutting and dry cutting. The main feature of dry saw blades is the presence of cooling holes and a segmented edge. When using a saw with such a blade, it is imperative to take breaks so that the attachment cools down. Wet saw blades have no teeth and are soldered all over the edge. The diamond layer can reach 5.5 mm in height. Such equipment is used in the professional field for long-term use. Cooling occurs due to the supplied water.

myth type of product is used when working with lumber or other solid wood. As a rule, they also differ, however, in the operations they perform. There are discs of this type for quick cutting of wood. They differ from others in the small number of teeth, which are produced by a rough cut. There are also products in the field for clean cutting, on the edges of which there are many small teeth for longitudinal cutting with large teeth. If the cut is meant to be made across the workpiece, then use a disk with small teeth. Universal products are considered to have both small and large teeth on the edges. They will help you do

any woodworking without changing the disc.

This model is used to perform work with metal, including pipes, profiles, fittings, etc. These metal saw blades differ in the type of material that they will process. If a disk is used in a saw design without liquid cooling, then there will be slots in its body, which will replenish the pumped temperature.

This equipment is used when working on plastic, fiberglass or metal-plastic. The teeth on such products have a negative sharpening angle, so careful cutting is performed even on small parts. Some equipment of this type is used as a disc on laminate, chipboard or fiberboard.

During work, sharp equipment must be used. Otherwise warped and dull discs become a prerequisite for jamming in the product, and, accordingly, blocking the motor.

Important Features

So that readers do not get lost in the wilds of the modern market for accessories for circular saws, we have prepared 5 main criteria that will help you make your choice. Let's consider them in order of importance.

External diameter

The outer or outer diameter of the disk should not exceed the dimensions of the circular saw casing, otherwise it will not be possible to install it in the seat. Increasing the parameter leads to an increase in the depth of cut. The characteristics vary from 65 to 500 mm.

Landing diameter

Landing, or internal diameter - the size of the hole in the center of the equipment. Determines whether the saw blade will fit on the spindle. The most popular sizes: 16 , 20 , 22 , 30 and 32 mm. But the full range is much wider - from 11 to 50 mm.

Manufacturers may install pins on the saw seat for additional fixation . In this case, you need to choose a disk with appropriate holes .

Number of teeth

As the number of teeth increases the processing speed decreases , but the cleanliness of the cut improves . And vice versa: the fewer teeth, the faster the work goes , but the cut becomes less and less accurate . The characteristic has its own classification, presented in the table:

| Number of teeth, pcs | ||

| 1 | Big | 80-90 |

| 2 | Average | 40-80 |

| 3 | Small | 10-40 |

Tooth sharpening angle

Sharpening inclination is the angle of deviation of the cutting edge of the tooth from the radius of the saw blade. The picture clearly shows how a characteristic can influence the work process. The angles are:

Standard : 5-15 °. Universal sharpening. Suitable for all types of cuts.

Positive : 15-20 °. Ideal for rip sawing due to its gripping effect.

Negative : from to - 5 °. Used for cross cutting, does not form chips.

Disc thickness

The standard parameter is 3.2 mm. The thinner the disk, the more it heats up and the faster it fails. The large thickness guarantees a long service life of the equipment, but slows down the work. In this case, the excess consumption of material increases due to the wide cut.

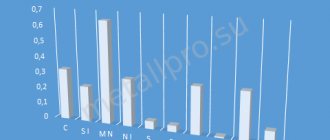

Chemical composition

In accordance with GOST 5950-2000, 9HF includes:

- Carbon (C) – 0.9% (increases hardness).

- Manganese (Mn) – 0.3-0.6% (increases strength).

- Chromium (Cr) – 0.4-0.7% (protects against corrosion).

- Molybdenum (Mo) – 0.2% (makes it possible to harden the material to high HRC values, increases density).

- Vanadium (V) – 0.15-0.3% (gives elasticity, protects against corrosion).

- Nickel (Ni) – 0.4% (adds toughness).

- Silicon (Si) – 0.4% (increases strength, acts as a deoxidizer and degasser to remove oxygen when melting metal).

Other impurities are present in small quantities.

Details of the composition in the table:

Chemical composition of 9HF.

Marking

As you can see in the picture, the disc markings can tell you about many technical characteristics. But there is a dependence that should not be neglected: the shape of the teeth directly affects the ability to work with a specific material.

The classification developed by representatives of the GASS divides discs into the following categories based on tooth shape :

GK and GS:p alternately beveled . Suitable for processing all types of wood and “clean” chipboards , without plywood and plastic coatings.

GM : direct . They can only cope with cutting soft wood.

GT : trapezoidal . They are useful in cases where you need to cut MDF or chipboard with lamination.

GR : conical . Cuts multi-layer coatings with double lamination.

GA : trapezoidal and straight . Same features as GT .

laser markings to high-quality saw blades . If the parameters are “written” with ordinary paint , it means that we are looking at an economy-class product that will quickly become unusable.

Popular manufacturers

The modern market is full of offers from manufacturers. But there are companies that are time-tested. It is their products that are preferred by owners of circular saws. A short list of popular brands is as follows:

CMT . The company appeared in Italy back in 1962 . Production was moved to China, and only the head office remained in Europe.

"Makita" . The year the company was founded was 1915 . Much time has passed since then, but Japanese products are still popular all over the world.

"Bosch" . This name has long been a symbol of unsurpassed quality. Saw blades under the Bosh brand are welcome guests in every home workshop.

"Attack" . The organization appeared in 1998 in Russia. It can rightfully be called the oldest supplier of consumables on the domestic market.

Metabo . The name comes from the German name for a hand drill. The assembly of the first products began in Germany after 1924 .

Dewalt . The company's victorious march around the planet started in the USA . Since 1922 , the brand has produced accessories for power tools.

Advanced technologies are not easy to understand. Tooling manufacturers are constantly improving their production. We invite you to watch a video that will help you make the right choice and learn a lot of useful information:

Source: bydom.ru