Steel is one of the most common materials in modern production. In its composition, it consists of iron and carbon, and to give the material special additional qualities, additional impurities are added, the proportions of which vary depending on the final purpose. St3 steel is becoming increasingly widespread. It is used in the manufacture of a fairly wide range of designs, but most people know it as a material for making pipes for heat supply systems. As part of this material, we will look at the features and characteristics of steel 3.

Main details

St3 steel is currently one of the most in demand due to its operational features. It is most widespread in the industry of manufacturing pipes for heating systems, as well as many other items for everyday use.

Galvanized circle made of steel St3

In most cases, St3 steel is classified as ordinary quality carbon steel.

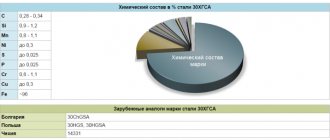

Chemical composition of steel St3

The area of use and functionality of each type of steel is determined by its chemical composition, since it determines the specific properties of the material, as well as the potential difficulties of heat treatment.

Due to its chemical composition, this type of steel is the most widespread on the market, and many construction works cannot be imagined without its use. The main chemical properties in this case can be identified as follows:

- Iron concentration is 97%, carbon concentration ranges from 0.14 to 0.22%. The hardness of the structure, as well as some of the physical properties, is determined precisely by the carbon content in the material.

- A small amount of alloying elements, namely chromium and nickel. Their concentration does not exceed 0.3%. Copper is added to this brand in the same percentage.

The main requirement for the production of this type of steel is the organization of a strict system for controlling the concentration of harmful impurities, which means phosphorus and sulfur. Excessive amounts of nitrogen should also be avoided.

St3 grade steel is a mandatory material for the construction and construction of above-ground and underground communications, production of transport, as well as various machine tools.

The most important element in the manufacture of st3 is deoxidation, which means the removal of oxygen from the molten raw material, on which the mechanical and physical properties of the alloy will directly depend.

Depending on deoxidation, st3 is divided into the following categories:

- Calm. Aluminum, silicon and manganese are used for deoxidation.

- Boiling. Only manganese is used for deoxidation.

- Semi-calm. Use of aluminum and manganese for deoxidation.

The properties of the ST3 steel alloy are presented in table form.

| Surface hardness | 131 MPa | ||

| Temporary resistance | 360-570 MPa | ||

| Yield strength | 235-245 MPa | ||

| Relative extension | 33% | ||

| Relative narrowing | 59% | ||

| Forging temperature range | 750-1300 degrees | ||

| Unlimited weldability by any possible method | |||

Is it possible to harden stainless steel

Hardening refers to the heat treatment of metal, during which intense heating is first carried out, and then sudden cooling in a liquid. During this technological procedure, the ductility and elasticity of the product decreases, but its strength increases. How to properly harden stainless steel items at home?

Types of hardening

Humanity has been using hardening technology for many centuries. Agricultural tools and bladed weapons were hardened already in the Middle Ages.

Hardening of stainless steel was thought about in the era of the industrial breakthrough, when steel alloys with anti-corrosion properties were needed.

It was then that a new method of hardening steel was developed, which made it possible to impart unique chemical and physical properties to the materials.

Stainless steel has a needle-like internal structure called martensite, which makes these alloys highly durable and highly resistant to embrittlement. When heat treating such steel, the viscosity coefficient increases, which expands the scope of their application.

Process Features

When hardening steel, continuous monitoring is required for:

How does the steel hardening process take place?

- uniform heating of the edge and middle of the product;

- the appearance of blue and black spots on the surface of the stainless steel, they indicate strong and uneven heating;

- maintaining temperature indicators;

- uniform cooling in liquid.

As such a liquid, ordinary water or machine oil is most often used. The color change during metal hardening is controlled using a special color scheme.

How to harden steel at home?

Rural residents often resort to self-hardening of metal, thus increasing the service life of household items: plow shares, carpentry and plumbing tools, hunting knives, axes. It is more difficult for a city dweller to process stainless steel - a special workshop is required.

Required Tools

In order to harden steel at home, you need to arm yourself with:

- Pliers with an extended handle;

- Hammers of different sizes;

- Files for subsequent processing;

- Electric oven;

- Gas burner;

- Blowtorch.

To create a cooling environment, you will need any container of appropriate size.

Hardening methods

Stainless steel can be hardened in different ways. First of all, the product heats up well. For this use:

- Burner;

- Electric oven;

- Blowtorch;

- A fire on coals.

The last option will be the best; the fire will be able to provide a much higher temperature.

The most commonly used cooling medium is:

When cooling with oil, the part is dipped into it twice with a short interval of a couple of seconds. The first dive takes 3-4 seconds, and the second - 5-6 seconds. Immediately after this procedure, the steel is immersed in water until it cools completely.

In the second cooling method, the part is immersed in wax several times. If the stainless steel no longer penetrates into the liquid medium, the cooling process is considered complete. Simply clean the surface with turpentine.

How to choose a temperature mode?

The choice of temperature mode plays a big role when hardening steel. Overheating is fraught with loss of inherent strength; this occurs due to a quantitative decrease in carbon in the metal structure.

In some cases, after completion of the stainless steel hardening process, residual stresses appear; they are removed through further mechanical processing.

This problem can be prevented if the product being hardened is cooled in stages, with a measured decrease in temperature conditions.

This step-by-step hardening technique is used in the manufacture of parts with very high strength values.

How to gradually lower the temperature of the cooling medium? To do this, prepare several containers with different liquids: saline solution, alkaline solution, mineral oil, synthetic oil. This method allows you to completely eliminate internal stress, which negatively affects the useful properties of steel. A small disadvantage of the technique is the high cost of implementation.

Master class on hardening a kitchen knife

After hardening, the knife gains strength and elasticity. The procedure does not require a lot of time.

Take:

- Gas burner or electric oven.

- Wax for cooling.

- Turpentine.

- Ticks.

Step by step process:

- Remove the handle from the product.

- Place the blade in the stove compartment. When using a burner, the chamber is made by hand using refractory bricks.

- Turn on the stove (burner). Heat the knife until it acquires a rich red hue. If possible, control the heating by checking the color you purchase against the color chart.

- Soak the stainless steel until it turns bright red and remove from the compartment.

- Immediately immerse the metal in the prepared sealing wax for a couple of seconds. Pull it out. Repeat the procedure many times until the part no longer fits into the sealing wax.

- Clean the stainless steel with turpentine to remove wax residues.

Master class on hardening an ax

Sometimes the manufacturer violates the technology of heat treatment of steel, and the ax turns out to be very soft, quickly begins to dull and form dents, or brittle, then the blade becomes covered with cracks and loses color. The situation can be corrected.

Take:

- Electric oven;

- Wire circle;

- Water;

- Machine oil;

- 2 containers for water and oil.

Step by step process:

- Blunt the cutting edge to 0.1 cm.

- Heat the ax blade to 750-760°C.

- To determine the heating temperature, apply a magnet to the stainless steel; it is not attracted to stainless steel at 768°C.

- Cool slowly to 550°C.

- The cooling procedure takes up to 10 hours. No special cooler is required; just leave the ax in the switched off oven.

- Clean the stainless steel from scale using a wire wheel.

- Heat the blade to 800-830°C until a rich fiery red hue.

- Cool first in water (30°C), lowering for 3-4 seconds. Move the stainless steel quickly in the container, this will help avoid the formation of a steam cushion.

- Cool in machine oil.

- Preheat oven to 300°C. Keep the part in it for an hour.

- Cool outdoors.

On a note

After removing the hot steel from the furnace (burner), it will be elastic and soft, so there is a high probability of damage. To avoid unpleasant consequences, you need to immerse it in a cooling medium smoothly and carefully.

When choosing steel products, pay attention to foreign manufacturers; in their tools, the percentage of stainless metal content exceeds Russian GOST standards.

Long and strong heating of the metal makes the hardening process deeper, resulting in a hard and elastic blade. After this, it will be less strong and gradually lose its cutting qualities.

Annealing modes of carbon steels

The same stainless steel should not be hardened many times: the metal begins to tire and wastes the necessary qualities.

Hardening steel for the first time is a responsible undertaking that requires continuous monitoring. When heated, the product is removed every 3-4 seconds, this allows you to strictly observe the color of the metal. In case of overheating, the steel takes on a white tint; in case of underheating, it becomes dark blue.

To harden stainless steel at home, you must arm yourself with a gas burner, an electric oven, a blowtorch, or light a fire.

In addition, the process cannot be carried out without a coolant (water, sealing wax or machine oil). You will need long-handled pliers and special gloves.

Self-hardening of stainless steel requires constant monitoring of color changes in the material.

on the topic: The hardness of stainless steel and a little about descents

Annealing, hardening and heat treatment of stainless steel

The heating, holding and cooling operations of stainless steel fundamentally affect its structure. After such treatment, the chemical composition remains unchanged, but the stainless steel radically changes its properties. A distinction is made between strengthening and softening heat treatment. Reducing the strength of stainless steel is necessary when the workpiece is to be cut.

Heating

Deep, uniform heating transforms the structure. Heating is carried out directly, gradually or in steps. The heating time depends on the method (furnace, flame or high-frequency electric), on the mass of the metal and the physical properties of the stainless steel type (heat capacity, thermal conductivity). The heating rate is determined by the type of workpiece, the chemical composition of the steel and the temperature range.

Excerpt

The reached temperature ensures the completion of structural transformations. It is important to calculate the optimal time, otherwise the steel will be freed from carbon and scale will form. At high heating temperatures, the holding time should be minimal.

Cooling

Cooling in water exceeds 300 °C per second, but with a furnace it is only 20−30 °C per hour. Cooling occurs faster in air than in an oven. These processes increase the hardness, strength, wear resistance or improve the machinability of the material.

Provider

Are you interested in heat treatment of stainless steel? We offer heat treatment of stainless steel from the supplier Evek GmbH with delivery to any city. Full compliance with modern quality standards. The supplier Evek GmbH offers heat treatment of stainless steel, the price is optimal in this segment of rolled metal.

Buy, favorable price

The supplier Evek GmbH offers heat treatment of stainless steel, the price is determined by the technological features of production without including additional costs.

The company's website displays information about the latest product arrivals. Today you can buy stainless steel at the best price. We have the best price-quality ratio.

In the rare metals segment, Evek GmbH is a profitable supplier.

Physical properties

Currently, the scope of use of St3 steel is constantly expanding. Already now, the basis for a huge number of workpieces is precisely this type of steel. This is largely due to mechanical properties, among which are:

- Yield strength;

- Temporary resistance;

- Relative extension;

- Impact strength.

- Tensile strength.

At the same time, the following most important technical characteristics are also highlighted:

- Hardness 131 MPa.

- Heterogeneous density;

- No restrictions on weldability;

- No tendency to temper brittleness.

It is these technical characteristics that determine the active use of St3 steel in the construction industry.

Hardening steel st3 at home

How to harden a knife at home?

This question arises for many home craftsmen. Metal hardening is a type of heat treatment that allows you to deform and change the state of a substance. This method of improving the properties of weapons has been used since ancient times. For example, in the Middle Ages, hardening was used to increase the strength and hardness of various objects: from ordinary knives to axes and sickles. Thanks to the development of technology, this heat treatment is now available not only at industrial enterprises where there is special equipment, but also at home. We will talk about this in detail in this article.

Decoding the brand

The specifics of decoding any grade of metal are determined by the relevant regulatory documents, as well as GOSTs. For example, according to GOST 380, the following types of metal are available: steel St3SP, St3PS and St3KP.

Indexes are mandatory for any marking. This is an important note for the preparation of any documentation and descriptions in this type of activity.

When deciphering a brand, the following principle should be used:

- St is a formal designation used to indicate the common quality of carbon steel.

- 3 – digital value showing the conventional number of the alloy grade. According to current accepted numbering rules, stamps from 0 to 6 can exist.

- G is a symbol that is not used in all markings. Indicates the presence of manganese impurities.

- Sp is the degree of deoxidation of the material. The most important parameter of steel grade. The additional designation “ps” means “semi-calm”, and “kp” means “boiling”.

It is worth noting that this particular approach to deciphering markings began to be used relatively recently after the introduction of new standards. Before this, other approaches were used to create steel markings, which were additionally divided into various groups.

Structure of steel after quenching and tempering

Steel in its usual form is a fairly soft and malleable metal.

Some grades do not require special strength (these are the so-called ordinary quality steels, produced in accordance with the requirements of GOST 380): the indicators obtained after smelting are quite sufficient, for example, for sewer manholes or protective gratings.

But there are categories of steels - structural and instrumental - for which the initial strength indicators are not enough. They must be subjected to heat treatment. Its main type is hardening.

Microstructure of steel 45 after annealing and hardening

Hardening and tempering of steel. Colors of heat and tarnish

You may have heard these terms more than once when talking about forged knives, and steels in general. It's time to figure out what they mean.

Hardening, in its essence, is heating the finished product to a certain temperature, followed by cooling at a certain speed, and tempering is additional heating following hardening to lower temperatures with a different cooling mode; exactly which one depends on the grade of steel. The speed is regulated by the so-called. “quenching medium” - a liquid in which the blade is cooled at a certain speed: machine oil, saline solutions, air flow, etc. For example, oil cools at a rate approximately 6 times slower than circulating water.

To get to specific numbers, you need to understand why these two processes are needed at all.

Features of processing steel with mechanical tools

One of the most important aspects of drawing up the correct technological process for processing parts made from ST3 is the choice of cutting modes and the choice of the right tool.

For turning and milling, a cutting tool is used, which is made of hard alloys VK8, T5K10. Taps and dies can also be used, which are made from P18 and P6M5. When cutting threads by hand, it is recommended to use castor oil, which will greatly simplify the process.

Depending on the type of processing, as well as the available technical parameters of the machine equipment, a specific choice of processing speed is made.

Proper cooling (holiday)

In order to achieve the necessary properties of the metal, you need to responsibly choose the cooling medium in which this process will take place.

The list of cooling media that are suitable for our business is as follows:

- One medium with liquid. Cold water is best. The body is placed inside and remains there until it cools completely.

- Two environments with different liquids. As in the first case, water is placed in the first medium, and the product is sent there first. After initial cooling, it is placed in oil or saline solution.

- Next comes standard jet cooling. There is nothing complicated or special here: the product is simply placed under running cold water until cooled. Perfect for cases when it is necessary to heat a separate element of the entire product.

- A special staged cooling method that uses several different temperature conditions.

Correct temperature

Before starting the process of hardening steel at home, it is necessary to understand the temperature regime, which must be observed to achieve a high-quality result. The product must be uniformly heated to a temperature of about 700−850 degrees Celsius, and then quickly released to 400−500 using one of the methods described above.

Use of St3 steel

Deoxidation is a key factor for this grade of steel. Depending on it, specific possible operating conditions and processing features of a given metal are determined. The chemical and physical properties of the metal will deteriorate as the total amount of oxygen increases.

Steel can also be classified depending on its silicon content:

- Boiling. Silicon level not less than 0.05%.

- Semi-calm. Silicon levels range from 0.05% to 0.15%.

- Calm. Silicon level is above 0.15%.

During the production of boiling steel, additional gas saturation occurs. However, such steel is classified as non-deoxidized, and therefore is less valued.

The quiet variety of steel has the highest final cost. This is explained by the fact that it is this type of steel that undergoes the most thorough purification from oxygen to ensure the greatest hardness and strength. As a result, this metal is most resistant to negative environmental influences.

Angles made of steel St3

The quiet version of this steel is used to create rolled sheets, railway elements, suspended structures, fittings, and pipelines.

At the same time, the semi-quiet variety of steel contains about 1% oxygen. It is characterized by less hardness and ductility than the calm variety, but has also become quite widespread. It is necessary for the production of pipes with different diameters and wall thicknesses, hexagons, angles and squares of load-bearing structures, as well as sheet metal.

Foreign analogues of markm steel 3sp

| USA | A284Gr.D, A57036, A573Gr.58, A611Gr.C, GradeC, K01804, K02001, K02301, K02502, K02601, K02701, K02702, M1017 |

| Germany | 1.0038, 1.0116, DC03, Fe360B, Fe360D1, RSt37-2, RSt37-3, S235J0, S235J2G3, S235JR, S235JRG2, St37-2, St37-3, St37-3G |

| Japan | SS330, SS34, SS400 |

| France | E24-2, E24-2NE, E24-3, E24-4, S235J0, S235J2G3, S235J2G4, S235JRG2 |

| England | 1449-2723CR, 1449-3723CR, 3723HR, 40B, 40C, 40D, 4360-40B, 4360-40D, 4449-250, 722M24, Fe360BFU, Fe360D1FF, HFS3, HFS4, HFW3, HFW4, S235J2G 3, S235JR, S235JRG2 |

| European Union | Fe37-3FN, Fe37-3FU, Fe37B1FN, Fe37B1FU, Fe37B3FN, Fe37B3FU, S235, S235J0, S235J2G3, S235JR, S235JRG2 |

| Italy | Fe360B, Fe360BFN, Fe360C, Fe360CFN, Fe360D, Fe360DFF, Fe37-2, S235J0, S235J2G3, S235J2G4, S235JRG2 |

| Belgium | FE360BFN, FE360BFU, FED1FF |

| Spain | AE235BFN, AE235BFU, AE235D, Fe360BFN, Fe360BFU, Fe360D1FF, S235J2G3, S235JRG2 |

| China | Q235, Q235A, Q235A-B, Q235A-Z, Q235B, Q235B-Z, Q235C |

| Sweden | 1312, 1313 |

| Bulgaria | BSt3ps, BSt3sp, Ew-08AA, S235J2G3, S235JRG2, WSt3ps, WSt3sp |

| Hungary | Fe235BFN, Fe235D, S235J2G3, S235JRG2 |

| Poland | St3S, St3SX, St3V, St3W |

| Romania | OL37.1, OL37.2, OL37.4 |

| Czech | 11375, 11378 |

| Finland | FORM300H, RACOLD03F, RACOLD215S |

| Austria | RSt360B |

Features of ST3 production

All chemical and physical properties of the finished material will be determined by the components that are included in the composition, and therefore largely depend on the technologies used in the production of the alloy.

The basis of the steel alloy is ferrite, which is a component of iron-carbon alloys. At its core, this element is a solid solution of carbon and alloying components. This alloy is also infused with carbon to increase its strength.

Phosphorus, sulfur and their derivatives are considered harmful impurities, since they impair the ductility of the alloy and also increase its brittleness when exposed to cold.

Advantages and disadvantages of ST3 steel

The main strengths of this steel grade are:

- Excellent weldability under any heat treatment.

- Possibility of obtaining a large variation in mechanical properties.

- Low cost with a large number of operating options.

- Possibility of hardening using high-frequency current.

- No tendency to temper brittleness.

The main disadvantage, which is inherent in all such carbon analogues, is the increased susceptibility to corrosion. Other disadvantages include the impossibility of using the alloy in northern climates, as well as increased fragility due to its coarse or medium-grained structure.

The demand for boiling alloys is explained by their high availability, since they have the lowest price, and their structure is easiest to further process. Thus, if it is necessary to use active heat treatment, this variety will be the most suitable, although it is worth considering its reduced performance characteristics due to high oxygen levels.

Incomplete hardening of steels

Quenching at temperatures lying between A1 and A3 (incomplete quenching) retains in the structure of hypoeutectoid steels, along with martensite, part of the ferrite, which reduces the hardness in the quenched state and worsens the mechanical properties after tempering. This is understandable, since the hardness of ferrite is 80HRC, and the hardness of martensite depends on the carbon content and can be more than 60HRC. Therefore, these steels are usually heated to temperatures 30–50 °C above A3 (full hardening). In theory, incomplete hardening of steels is not permissible and is considered a defect. In practice, in some cases, incomplete quenching can be used to avoid quenching cracks. Very often this concerns hardening with high frequency currents. With such hardening, it is necessary to take into account its feasibility: type of production, annual program, type of product responsibility, economic justification. For hypereutectoid steels, quenching at temperatures above A1 but below Acm produces excess cementite in the structure, which increases the hardness and wear resistance of the steel. Heating above the temperature Acm leads to a decrease in hardness due to the dissolution of excess cementite and an increase in retained austenite. In this case, the austenite grain grows, which also negatively affects the mechanical characteristics of the steel.

Thus, the optimal quenching for hypoeutectoid steels is quenching from a temperature 30–50 °C above A3, and for hypereutectoid steels – at 30–50 °C above A1.

The cooling rate also affects the hardening result. The optimal cooling medium is one that quickly cools the part in the temperature range of minimum stability of supercooled austenite (in the range of the nose of the c-curve) and slowly in the temperature range of martensitic transformation.

Cooling stages during hardening

The most common quenching media are water of various temperatures, polymer solutions, alcohol solutions, oil, molten salts. When hardening in these environments, several cooling stages are distinguished:

— film cooling, when a “steam jacket” is formed on the surface of the steel;

- nucleate boiling, which occurs with the complete destruction of this steam jacket;

— convective heat transfer.

More details about the cooling stages during quenching can be found in the article “Characteristics of quenching oils”

In addition to liquid quenching media, cooling in a gas flow of different pressures is used. It can be nitrogen (N2), helium (He) and even air. Such quenching media are often used in vacuum heat treatment. Here it is necessary to take into account the fact of the possibility of obtaining a martensitic structure - the hardenability of steel in a certain environment, i.e. the chemical composition of the steel on which the position of the c-curve depends.