Characteristics

The presence of carbon in the composition provides good hardness (53–56 Hrc on the Rockwell scale). Chrome maintains corrosion resistance at an appropriate level. Thanks to this alloying element, the products are almost not subject to oxidation, and their beautiful appearance is maintained throughout their entire service life.

Due to its properties, steel can work indoors in contact with a large group of products and semi-finished food products, as well as with some carbonates, acetates and hydroxides.

Advantages and disadvantages

In addition to the fact that X30Cr13 steel is perfectly processed, it has the following positive properties:

- corrosion resistance;

- high hardness;

- easy sharpening;

- wear resistance;

- low tendency to temper brittleness;

- acceptable cost.

The negative point is that the material is difficult to weld.

Corrosion resistance

As already noted, X30Cr13 has high corrosion resistance. It is achieved due to the fact that in the search for a formula, the creators managed to achieve a balanced ratio of chromium and carbon. Corrosive properties manifest themselves in environments with moderate aggression, where there are no compounds such as chlorides; these can be organic acids, soaps, and detergents. Optimal corrosion resistance of the alloy can be achieved by hardening and polishing the surface.

This is what corrosion looks like on a product made of X30Cr13 steel..

A stable layer of chromium oxide forms on the surface of the steel, which prevents chemical reactions with the bulk of the material. This oxide layer is extremely thin, it is passive (corrosion resistant), tenacious (adheres well to the mass) and self-healing (reforms when cracked or damaged).

Properties

Stainless steels are often rightly associated with corrosion resistance, and the German alloy 1.4028 is no exception. Considering their physical and mechanical characteristics, experts are unanimous in the opinion that they are in many ways superior to similar materials.

Mechanical

Stable values of properties, including yield strength, tensile strength, ductility, hardness, and impact strength are determined by the chemical composition of the alloy.

General mechanical properties of X30Cr13(1.4028) in heat treated state:

- tensile strength (R m) - from 800 to 1000 MPa;

- yield strength (R e) – more than 600 MPa;

- HRC Hardness – from 45 to 51;

- HV hardness – from 450 to 550;

- elastic modulus (E) – 215 GPa.

The ranges of tensile strength, yield strength and hardness are largely determined by different heat treatment conditions.

Physical

Since the alloy is a martensitic stainless steel, it has a four-center crystal system. Due to the presence of carbon, it is hardened by heat treatment.

The alloy is magnetic and has relatively high ductility and toughness, which makes molding easier. It can be moderately strengthened by cold working. After annealing, the yield strength can reach 275 MPa.

Higher carbon content increases strength and hardness, but reduces ductility and toughness. They exhibit moderate corrosion resistance and poor weldability.

Forging

When processing by forging, gradual heating is required to a temperature of 800 °C; to accelerate, the temperature can be increased to 1050 °C - 1100 °C. Then you need to forge in the range of 1100 °C - 800 °C, slowly cool in a furnace in dry ash.

Welding

It is not advisable to weld the alloy, but if such an action cannot be avoided, it is important to follow the necessary safety measures . In particular, when welding, the workpiece must be preheated to a temperature of 300 - 400 °C, and then hardened in order to restore plasticity in the welding zone.

Treatment

The processing of stainless steel of this grade has a direct connection with hardness. The process is no different from processing other carbon steels of the same hardness.

Heat treatment

To improve the technical and operational parameters of finished products, heat treatment of the alloy is performed. Thanks to this, the hardness and strength of the material increases. For steel grade 30KhGSA, the following thermal treatment schemes are used. Hardening is used to change the characteristics of the surface layer. Annealing is carried out at a heating mode of up to 880 degrees, subsequent tempering is carried out in oil. This minimizes the risk of structural and surface deformations.

Any hardening involves rearrangement of the microcrystalline lattice. During processing, internal stresses often appear; in the future, they can cause the appearance of structural cracks. To prevent undesirable consequences, tempering is performed at a temperature of 540 degrees. Forging helps improve the quality of metal. Before processing begins, the workpiece is heated to 1240 degrees. Cooling is carried out in an aquatic environment or in the open air, depending on the dimensions of the product.

Chemical composition of steel

The letter X in the name of the X30Cr13 brand means that the steel is alloyed, the number 30 is the percentage of carbon content. Its amount is close to 0.3%. The remaining symbols indicate the presence of chromium. It's about 13% here.

Carbon is the main component that provides hardness and rigidity. It must be present in all types of steel. The chemical element chromium is a grayish-white metal with a shiny, hard surface. It provides the steel with the ability to harden. Thanks to this chemical element, wear resistance and anti-corrosion properties are significantly increased.

Table 1 shows the chemical composition of X30Cr13 steel.

Table 1

| WITH | Cr | Mn | Si | Ni | P | S |

| 0,26-0,35% | 12-14% | 1% | 1% | 0,6% | 0,4% | 0,3% |

Other alloys from the category Alloy structural steel

Alloy grade GOSTKhim. compound

| 10G2 | GOST 4543 - 71 | Fefrom 97%Mn1.2-1.6%Si0.17-0.3%C0.07-0.1%… |

| 10Х2М | GOST 5520 - 79 | Fefrom 95.3%Cr2-2.5%Mo0.6-0.8%Mn0.4-0.7%Si0.17-0.3%C0.08-0.1%… |

| 12G2 | GOST 1542 - 71 | Fefrom 97.3%Mn1.2-1.6%Si0.17-0.3%C0.08-0.1%… |

| 12Х2Н4А | GOST 4543 - 71 | Fefrom 93.5%Ni3.25-3.6%Cr1.25-1.6%Mn0.3-0.6%Si0.17-0.3%C0.09-0.1%… |

| 12X2NVFA | GOST 11268 - 76 | Fefrom 93.4%Cr1.9-2.4%W1-1.4%Ni0.8-1.2%Mn0.3-0.7%V0.18-0.2%Si0.17-0.3%C0.09-0.1%… |

| 12Х2НВФМА | GOST 11268 - 76 | Fefrom 92.4%Cr1.9-2.4%Ni1.2-1.6%W1-1.4%Mn0.6-0.9%Mo0.35-0.4%V0.18-0.2%Si0.17-0.3%C0.09-0.1%… |

| 12Х2НМ1FA | GOST 11268 - 76 | Fefrom 93.2%Cr1.9-2.4%Ni1.2-1.6%Mo0.7-1%Mn0.6-0.9%V0.18-0.2%Si0.17-0.3%C0.09-0.1%… |

| 12X2NMFA | GOST 11268 - 76 | Fefrom 94.4%Cr1.9-2.4%Ni0.8-1.2%Mo0.35-0.4%Mn0.3-0.7%V0.18-0.2%Si0.17-0.3%C0.09-0.1%… |

| 12ХН | GOST 10702 - 78 | Fefrom 97.1%Ni0.8-0.8%Cr0.4-0.7%Mn0.3-0.6%Si0.17-0.3%C0.09-0.1%… |

| 12ХН2 | GOST 4543 - 71 | Fefrom 95.5%Ni1.5-1.9%Cr0.6-0.9%Mn0.3-0.9%Si0.17-0.3%C0.09-0.1%… |

| 12ХН2А | GOST 4543 - 71 | Fefrom 96.2%Ni1.5-1.9%Cr0.6-0.9%Mn0.3-0.6%Si0.17-0.3%C0.09-0.1%… |

| 12ХН3А | GOST 4543 - 71 | Fefrom 94.7%Ni2.75-3.1%Cr0.6-0.9%Mn0.3-0.6%Si0.17-0.3%C0.09-0.1%… |

| 14Х2ГМР | ChMTU 1-645 - 69 | Fefrom 95.4%Cr1.3-1.7%Si0.9-1.2%Mo0.4-0.5%Mn0.17-0.3%C0.1-0.16%… |

| 14Х2Н3МА | GOST 4543 - 71, the latest version does not contain the material | Fefrom 93.8%Ni2.75-3.1%Cr1.5-1.75%Mn0.3-0.6%Mo0.2-0.3%Si0.17-0.3%C0.12-0.1%… |

| 14ХГН | GOST 4543 - 71 | Fefrom 96%Cr0.8-1.1%Ni0.8-1.1%Mn0.7-1%Si0.17-0.3%C0.13-0.1%… |

| 15G | GOST 4543 - 71 | Fefrom 97.5%Mn0.7-1%Si0.17-0.3%C0.12-0.19%… |

| 15N2M | GOST 4543 - 71 | Fefrom 96%Ni1.5-1.9%Mn0.4-0.7%Mo0.2-0.3%Si0.17-0.3%C0.1-0.18%… |

| 15X | GOST 4543 - 71 | Fefrom 97.2%Cr0.7-1%Mn0.4-0.7%Si0.17-0.3%C0.12-0.1%… |

| 15ХА | GOST 4543 - 71 | Fefrom 97.3%Cr0.7-1%Mn0.4-0.7%Si0.17-0.3%C0.12-0.1%… |

| 15KhGN2TA | GOST 4543 - 71 | Fefrom 95.4%Ni1.4-1.8%Cr0.7-1%Mn0.7-1%Si0.17-0.3%C0.13-0.1%Ti0.03-0.09%… |

| 15ХГНМ | GOST 10702 - 78 | Fefrom 96.5%Mn0.7-1.1%Cr0.4-0.7%Ni0.4-0.7%Si0.17-0.3%Mo0.15-0.2%C0.13-0.18%… |

| 15HF | GOST 4543 - 71 | Fefrom 97%Cr0.8-1.1%Mn0.4-0.7%Si0.17-0.3%C0.12-0.18%V0.06-0.1%… |

| 16G2 | GOST 1542 - 71 | Fefrom 96.4%Mn2-2.4%Si0.17-0.3%C0.12-0.2%… |

| 16ХСН | GOST 10702 - 78 | Fefrom 96%Cr0.8-1.1%Ni0.6-0.9%Si0.6-0.9%Mn0.3-0.6%C0.13-0.2%… |

| 18Х2Н4ВА | GOST 4543 - 71 | Fefrom 91.5%Ni4-4.4%Cr1.35-1.6%W0.8-1.2%Mn0.25-0.5%Si0.17-0.3%C0.14-0.2%… |

| 18Х2Н4МА | GOST 4543 - 71 | Fefrom 92.2%Ni4-4.4%Cr1.35-1.6%Mo0.3-0.4%Mn0.25-0.5%Si0.17-0.3%C0.14-0.2%… |

| 18ХГ | GOST 4543 - 71 | Fefrom 96.4%Cr0.9-1.2%Mn0.9-1.2%Si0.17-0.3%C0.15-0.2%… |

| 18ХГТ | GOST 4543 - 71 | Fefrom 96.3%Cr1-1.3%Mn0.8-1.1%Si0.17-0.3%C0.17-0.2%Ti0.03-0.09%… |

| 19Х2NVFA | GOST 11268 - 76 | Fefrom 93.3%Cr1.9-2.4%W1-1.4%Ni0.8-1.2%Mn0.3-0.7%V0.18-0.2%Si0.17-0.3%C0.16-0.2%… |

| 19X2NMFA | GOST 11268 - 76 | Fefrom 94.3%Cr1.9-2.4%Ni0.8-1.2%Mo0.35-0.4%Mn0.3-0.7%V0.18-0.2%Si0.17-0.3%C0.16-0.2%… |

| 19ХГН | GOST 10702 - 78 | Fefrom 95.8%Cr0.8-1.1%Ni0.8-1.1%Mn0.7-1%Si0.17-0.3%C0.16-0.2%… |

| 20G | GOST 4543 - 71 | Fefrom 97.5%Mn0.7-1%Si0.17-0.3%C0.17-0.2%… |

| 20G2 | GOST 10702 - 78 | Fefrom 97.1%Mn1.3-1.6%C0.18-0.2%Si0.17-0.3%… |

| 20N2M | GOST 4543 - 71 | Fefrom 95.9%Ni1.5-1.9%Mn0.4-0.7%Mo0.2-0.3%Si0.17-0.3%C0.17-0.2%… |

| 20X | GOST 4543 - 71 | Fefrom 97.1%Cr0.7-1%Mn0.5-0.8%Si0.17-0.3%C0.12-0.18%… |

| 20Х12Н12Г6 | GOST 9124 - 85 | Fefrom 66.2%Cr10-13%Ni10-13%Mn6-7%C0.15-0.2%… |

| 20Х14 | GOST 10543 - 98 | Fefrom 82.1%Cr13-15%C0.16-0.2%… |

| 20Х17Н3М | GOST 10543 - 98 | Fefrom 75.6%Cr16-18%Ni2-3%Mo1.2-1.7%C0.18-0.2%… |

| 20Х2Н4А | GOST 4543 - 71 | Fefrom 93.4%Ni3.25-3.6%Cr1.25-1.6%Mn0.3-0.6%Si0.17-0.3%C0.17-0.2%… |

| 20ХГНМ | GOST 4543 - 71 | Fefrom 96.4%Mn0.7-1.1%Cr0.4-0.7%Ni0.4-0.7%C0.18-0.2%Si0.17-0.3%Mo0.15-0.2%… |

| 20ХГНР | GOST 4543 - 71 | Fefrom 95.9%Ni0.8-1.1%Cr0.7-1.1%Mn0.7-1%Si0.17-0.3%C0.16-0.2%B0.001-0.005%… |

| 20HGNTR | GOST 4543 - 71 | Fefrom 96.5%Mn0.8-1.1%Cr0.4-0.7%Ni0.4-0.7%C0.18-0.2%Si0.17-0.3%Ti0.03-0.09%B0.001-0.005%… |

| 20ХГР | GOST 4543 - 71 | Fefrom 96.7%Cr0.75-1%Mn0.7-1.1%C0.18-0.2%Si0.17-0.3%B0.001-0.005%… |

| 20ХГСА | GOST 4543 - 71 | Fefrom 95.8%Si0.9-1.2%Cr0.8-1.1%Mn0.8-1.1%C0.17-0.2%… |

| 20ХМ | GOST 4543 - 71 | Fefrom 96.8%Cr0.8-1.1%Mn0.4-0.7%Si0.17-0.3%C0.15-0.2%Mo0.15-0.2%… |

| 20ХН | GOST 4543 - 71 | Fefrom 96.3%Ni1-1.4%Cr0.45-0.7%Mn0.4-0.7%Si0.17-0.3%C0.17-0.2%… |

| 20ХН2М | GOST 4543 - 71 | Fefrom 95.5%Ni1.6-2%Mn0.4-0.7%Cr0.4-0.6%Mo0.2-0.3%Si0.17-0.3%C0.15-0.2%… |

| 20ХН3А | GOST 4543 - 71 | Fefrom 94.6%Ni2.75-3.1%Cr0.6-0.9%Mn0.3-0.6%Si0.17-0.3%C0.17-0.2%… |

| 20ХН4FA | GOST 4543 - 71 | Fefrom 93.3%Ni3.75-4.1%Cr0.7-1.1%Mn0.25-0.5%Si0.17-0.3%C0.17-0.2%V0.1-0.18%… |

| 20ХНР | GOST 4543 - 71 | Fefrom 96%Ni0.8-1.1%Cr0.7-1.1%Mn0.6-0.9%Si0.17-0.3%C0.16-0.2%B0.001-0.005%… |

| 20HF | GOST 10702 - 78, the latest version does not contain the material | Fefrom 96.8%Cr0.8-1.1%Mn0.5-0.8%C0.17-0.2%V0.1-0.2%… |

| 21Х2NVFA | GOST 11268 - 76 | Fefrom 93.3%Cr1.9-2.4%W1-1.4%Ni0.8-1.2%Mn0.3-0.7%C0.19-0.2%V0.18-0.2%Si0.17-0.3%… |

| 21X2NMFA | GOST 11268 - 76 | Fefrom 94.3%Cr1.9-2.4%Ni0.8-1.2%Mo0.35-0.4%Mn0.3-0.7%C0.19-0.2%V0.18-0.2%Si0.17-0.3%… |

| 23Х2NVFA | GOST 11268 - 76 | Fefrom 93.3%Cr1.9-2.4%W1-1.4%Ni0.8-1.2%Mn0.3-0.7%C0.19-0.2%V0.18-0.2%Si0.17-0.3%… |

| 23X2NMFA | GOST 11268 - 76 | Fefrom 94.3%Cr1.9-2.4%Ni0.8-1.2%Mo0.35-0.4%Mn0.3-0.7%C0.19-0.2%V0.18-0.2%Si0.17-0.3%… |

| 25G | GOST 4543 - 71 | Fefrom 97.4%Mn0.7-1%C0.22-0.3%Si0.17-0.3%… |

| 25Х2ГНТА | TU 14-1-195 - 72 | Fefrom 94.7%Cr1.3-1.7%Ni0.9-1.3%Mn0.8-1.1%C0.22-0.2%Si0.2-0.5%Ti0.06-0.1%… |

| 25Х2Н4ВА | GOST 4543 - 71 | Fefrom 91.5%Ni4-4.4%Cr1.35-1.6%W0.8-1.2%Mn0.25-0.5%C0.21-0.2%Si0.17-0.3%… |

| 25Х2Н4МА | GOST 4543 - 71 | Fefrom 92.3%Ni4-4.4%Cr1.35-1.6%Mo0.3-0.4%Mn0.25-0.5%C0.21-0.2%Si0.17-0.3%… |

| 25ХГМ | GOST 4543 - 71 | Fefrom 96.1%Cr0.9-1.2%Mn0.9-1.2%C0.23-0.2%Mo0.2-0.3%Si0.17-0.3%… |

| 25ХГНМТ | GOST 4543 - 71 | Fefrom 96%Ni0.8-1.1%Mn0.5-0.8%Cr0.4-0.6%Mo0.4-0.5%C0.23-0.2%Si0.17-0.3%Ti0.04-0.09%… |

| 25ХГСА | GOST 4543 - 71 | Fefrom 95.7%Si0.9-1.2%Cr0.8-1.1%Mn0.8-1.1%C0.22-0.28%… |

| 25ХГТ | GOST 4543 - 71 | Fefrom 96.3%Cr1-1.3%Mn0.8-1.1%C0.22-0.29%Si0.17-0.3%Ti0.03-0.09%… |

| 27ХГР | GOST 4543 - 71 | Fefrom 96.7%Cr0.7-1%Mn0.7-1%C0.25-0.3%Si0.17-0.3%B0.001-0.005%… |

| 30G | GOST 4543 - 71 | Fefrom 97.4%Mn0.7-1%C0.27-0.3%Si0.17-0.3%… |

| 30G2 | GOST 4543 - 71 | Fefrom 96.6%Mn1.4-1.8%C0.26-0.3%Si0.17-0.3%… |

| 30X | GOST 4543 - 71 | Fefrom 96.8%Cr0.8-1.1%Mn0.5-0.8%C0.24-0.3%Si0.17-0.3%… |

| 30Х10Г10Т | GOST 10543 - 98 | Fefrom 74.4%Cr10-12%Mn10-12%C0.25-0.3%Ti0.15-0.3%… |

| 30Х3МФ | GOST 4543 - 71 | Fefrom 95%Cr2.3-2.7%Mn0.3-0.6%C0.27-0.3%Mo0.2-0.3%Si0.17-0.3%V0.06-0.12%… |

| 30Х5 | GOST 10543 - 98 | Fefrom 92%Cr4-6%Mn0.4-0.7%C0.27-0.3%Si0.2-0.5%… |

| 30ХГС | GOST 4543 - 71 | Fefrom 95.6%Si0.9-1.2%Cr0.8-1.1%Mn0.8-1.1%C0.28-0.3%… |

| 30ХГСА | GOST 4543 - 71 | Fefrom 95.7%Si0.9-1.2%Cr0.8-1.1%Mn0.8-1.1%C0.28-0.3%… |

| 30ХГСН2А | GOST 4543 - 71 | Fefrom 93.9%Ni1.4-1.8%Mn1-1.3%Cr0.9-1.2%Si0.9-1.2%C0.27-0.3%… |

| 30ХГСНМА | GOST 21729 - 76 | Fefrom 93.7%Ni1.4-1.8%Mn1-1.3%Cr0.9-1.2%Si0.9-1.2%Mo0.3-0.45%C0.27-0.34%… |

| 30ХГТ | GOST 4543 - 71 | Fefrom 96.2%Cr1-1.3%Mn0.8-1.1%C0.24-0.3%Si0.17-0.3%Ti0.03-0.09%… |

| 30ХН2ВА | GOST 4543 - 71 | Fefrom 95.2%Ni1.25-1.6%Cr0.6-0.9%W0.5-0.8%Mn0.3-0.6%C0.27-0.3%Si0.17-0.3%… |

| 30HN2VFA | GOST 4543 - 71 | Fefrom 92.6%Ni2-2.4%Cr0.6-0.9%W0.5-0.8%Mn0.3-0.6%C0.27-0.3%Si0.17-0.3%V0.1-1.8%… |

| 30ХН2МА | GOST 4543 - 71 | Fefrom 95.7%Ni1.25-1.6%Cr0.6-0.9%Mn0.3-0.6%C0.27-0.3%Mo0.2-0.3%Si0.17-0.3%… |

| 30ХН2МФА | GOST 4543 - 71 | Fefrom 94.7%Ni2-2.4%Cr0.6-0.9%Mn0.3-0.6%C0.27-0.3%Mo0.2-0.3%Si0.17-0.3%V0.1-0.18%… |

| 30ХН3А | GOST 4543 - 71 | Fefrom 94.5%Ni2.75-3.1%Cr0.6-0.9%Mn0.3-0.6%C0.27-0.3%Si0.17-0.3%… |

| 30HN3M2FA | TU 108.1028 - 81 | Fefrom 92.5%Ni3-3.5%Cr1.2-1.7%Mo0.4-0.65%C0.26-0.3%Mn0.25-0.5%V0.1-0.2%… |

| 30HPA | GOST 4543 - 71 | Fefrom 96.6%Cr1-1.3%Mn0.5-0.8%C0.27-0.3%Si0.17-0.3%B0.001-0.005%… |

| 33ХС | GOST 4543 - 71 | Fefrom 95.4%Cr1.3-1.6%Si1-1.4%Mn0.3-0.6%C0.29-0.3%… |

| 34ХН1М | TU 24-1-12-179 - 75 | Fefrom 94.7%Cr1.3-1.7%Ni1.3-1.7%Mn0.5-0.8%C0.3-0.4%Mo0.2-0.3%Si0.17-0.3%… |

| 34ХН1МА | TU 108-1028 - 81 | Fefrom 94.7%Cr1.3-1.7%Ni1.3-1.7%Mn0.5-0.8%C0.3-0.4%Mo0.2-0.3%Si0.17-0.3%… |

| 34ХН3М | TU 24-1-12-179 - 75 | Fefrom 93.7%Ni2.75-3.2%Cr0.7-1.1%Mn0.5-0.8%C0.3-0.4%Mo0.25-0.4%Si0.17-0.3%… |

| 34ХН3МА | TU 108-1028 - 81 | Fefrom 93.2%Ni2.75-3.7%Cr0.7-1.1%Mn0.5-0.8%C0.3-0.4%Mo0.25-0.4%Si0.17-0.3%… |

| 35G | GOST 4543 - 71 | Fefrom 97.3%Mn0.7-1%C0.32-0.4%Si0.17-0.3%… |

| 35G2 | GOST 4543 - 71 | Fefrom 96.6%Mn1.4-1.8%C0.31-0.3%Si0.17-0.3%… |

| 35X | GOST 4543 - 71 | Fefrom 96.7%Cr0.8-1.1%Mn0.5-0.8%C0.31-0.39%Si0.17-0.3%… |

| 35ХГ2 | GOST 4543 - 71, the latest version does not contain the material | Fefrom 96%Mn1.6-1.9%Cr0.4-0.7%C0.32-0.4%Si0.17-0.3%… |

| 35ХГН2 | Fefrom 95.9%Ni1-1.5%Cr0.7-1%Mn0.5-0.8%C0.32-0.4%Si0.17-0.3%… | |

| 35ХГСА | GOST 4543 - 71 | Fefrom 95.1%Cr1.1-1.4%Si1.1-1.4%Mn0.8-1.1%C0.32-0.39%… |

| 35HGF | GOST 4543 - 71, the latest version does not contain the material | Fefrom 96.7%Cr1-1.3%Mn0.95-1.2%C0.31-0.3%Si0.17-0.3%V0.06-0.12%… |

| 35ХН1М2FA | TU 108.1028 - 81 | Fefrom 93.9%Cr1.3-1.7%Ni1.3-1.7%Mn0.5-0.8%Mo0.4-0.6%C0.32-0.4%V0.1-0.2%… |

| 36G2S | GOST R 51245 - 99 | Fefrom 96.3%Mn1.5-1.8%Si0.4-0.7%C0.32-0.4%… |

| 36Х2Н2МФА | GOST 4543 - 71 | Fefrom 94.5%Cr1.3-1.7%Ni1.3-1.7%C0.33-0.4%Mo0.3-0.4%Mn0.25-0.5%Si0.17-0.3%V0.1-0.18%… |

| 38Х2Н2ВА | GOST 4543 - 71 | Fefrom 94.3%Cr1.3-1.7%Ni1.3-1.7%W0.5-0.8%C0.33-0.4%Mn0.25-0.5%Si0.17-0.3%… |

| 38Х2Н2МА | GOST 4543 - 71 | Fefrom 94.8%Cr1.3-1.7%Ni1.3-1.7%C0.33-0.4%Mn0.25-0.5%Mo0.2-0.3%Si0.17-0.3%… |

| 38Х2Н3М | OST 24,959.11 | Fefrom 93.3%Ni2.75-3.2%Cr1-1.5%Mn0.5-0.8%C0.35-0.4%Mo0.3-0.4%Si0.17-0.3%… |

| 38Х2НМ | TU 24,11,01,073 - 86 | Fefrom 94.9%Cr1.8-2.3%Ni0.6-0.9%Mn0.5-0.8%C0.32-0.4%Mo0.2-0.3%Si0.17-0.3%… |

| 38Х2НМФ | TU 24,11,01,073 - 86 | Fefrom 94.8%Cr1.8-2.3%Ni0.6-0.9%Mn0.5-0.8%C0.32-0.4%Mo0.2-0.3%Si0.17-0.3%V0.08-0.1%… |

| 38Х2У | GOST 4543 - 71, the latest version does not contain the material | Fefrom 96%Cr1.5-1.8%Al0.5-0.8%C0.35-0.4%Mn0.2-0.5%Si0.2-0.4%… |

| 38ХА | GOST 4543 - 71 | Fefrom 96.8%Cr0.8-1.1%Mn0.5-0.8%C0.35-0.4%Si0.17-0.3%… |

| 38ХВ | GOST 4543 - 71 | Fefrom 95.9%Cr0.9-1.3%W0.5-0.8%Mn0.35-0.6%C0.35-0.4%Si0.17-0.3%… |

| 38ХГМ | GOST 4543 - 71 | Fefrom 96.4%Cr0.8-1.1%Mn0.6-0.9%C0.34-0.4%Si0.17-0.3%Mo0.15-0.2%… |

| 38ХГН | GOST 4543 - 71 | Fefrom 96%Mn0.8-1.1%Ni0.7-1%Cr0.5-0.8%C0.35-0.4%Si0.17-0.3%… |

| 38ХГНМ | GOST 10702 - 78 | Fefrom 96.6%Mn0.5-0.8%Ni0.4-0.7%Cr0.4-0.6%C0.37-0.4%Si0.17-0.3%Mo0.15-0.2%… |

| 38ХМ | GOST 4543 - 71 | Fefrom 96.4%Cr0.9-1.3%Mn0.35-0.6%C0.35-0.4%Mo0.2-0.3%Si0.17-0.3%… |

| 38ХМА | GOST 4543 - 71 | Fefrom 96.5%Cr0.9-1.3%Mn0.35-0.6%C0.35-0.4%Mo0.2-0.3%Si0.17-0.3%… |

| 38ХН3ВА | GOST 4543 - 71 | Fefrom 93.3%Ni2.75-3.2%Cr0.8-1.2%W0.5-0.8%C0.33-0.4%Mn0.25-0.5%Si0.17-0.3%… |

| 38ХН3МА | GOST 4543 - 71 | Fefrom 93.8%Ni2.75-3.2%Cr0.8-1.2%C0.33-0.4%Mn0.25-0.5%Mo0.2-0.3%Si0.17-0.3%… |

| 38ХН3МФА | GOST 4543 - 71 | Fefrom 92.9%Ni3-3.5%Cr1.2-1.5%Mo0.35-0.4%C0.33-0.4%Mn0.25-0.5%Si0.17-0.3%V0.1-0.18%… |

| 38ХС | GOST 4543 - 71 | Fefrom 95.3%Cr1.3-1.6%Si1-1.4%C0.34-0.4%Mn0.3-0.6%… |

| 40G | GOST 4543 - 71 | Fefrom 97.3%Mn0.7-1%C0.32-0.4%Si0.17-0.3%… |

| 40G2 | GOST 4543 - 71 | Fefrom 96.5%Mn1.4-1.8%C0.36-0.4%Si0.17-0.3%… |

| 40GR | GOST 4543 - 71 | Fefrom 97.3%Mn0.7-1%C0.37-0.4%Si0.17-0.3%B0.001-0.005%… |

| 40X | GOST 4543 - 71 | Fefrom 96.7%Cr0.8-1.1%Mn0.5-0.8%C0.36-0.44%Si0.17-0.3%… |

| 40Х2Г2М | GOST 10543 - 98 | Fefrom 92.6%Cr1.8-2.3%Mn1.8-2.3%Mo0.8-1.2%Si0.4-0.7%C0.35-0.4%… |

| 40Х2Н2ВА | GOST 4543 - 71 | Fefrom 94.2%Ni1.35-1.7%Cr1.25-1.6%W0.6-0.9%C0.35-0.4%Mn0.3-0.6%Si0.17-0.3%… |

| 40Х2Н2МА | GOST 4543 - 71 | Fefrom 94.8%Ni1.35-1.7%Cr1.25-1.6%C0.35-0.4%Mn0.3-0.6%Mo0.2-0.3%Si0.17-0.3%… |

| 40Х3Г2МФ | GOST 10543 - 98 | Fefrom 92.1%Cr3.3-3.8%Mn1.3-1.8%Si0.4-0.7%C0.35-0.4%Mo0.3-0.5%V0.1-0.2%… |

| 40ХГНМ | GOST 4543 - 71 | Fefrom 95.9%Ni0.7-1.1%Cr0.6-0.9%Mn0.5-0.8%C0.37-0.4%Si0.17-0.3%Mo0.15-0.2%… |

| 40HGTR | GOST 4543 - 71 | Fefrom 96.4%Cr0.8-1.1%Mn0.8-1%C0.38-0.4%Si0.17-0.3%Ti0.03-0.09%B0.001-0.005%… |

| 40HMFA | GOST 4543 - 71 | Fefrom 96.4%Cr0.8-1.1%Mn0.4-0.7%C0.37-0.4%Mo0.2-0.3%Si0.17-0.3%V0.1-0.18%… |

| 40ХН | GOST 4543 - 71 | Fefrom 96%Ni1-1.4%Mn0.5-0.8%Cr0.45-0.7%C0.36-0.4%Si0.17-0.3%… |

| 40ХН2МА | GOST 4543 - 71 | Fefrom 95.5%Ni1.25-1.6%Cr0.6-0.9%Mn0.5-0.8%C0.37-0.4%Si0.17-0.3%Mo0.15-0.2%… |

| 40ХС | GOST 4543 - 71 | Fefrom 95.1%Cr1.3-1.6%Si1.2-1.6%C0.37-0.4%Mn0.3-0.6%… |

| 40HFA | GOST 4543 - 71 | Fefrom 96.6%Cr0.8-1.1%Mn0.5-0.8%C0.37-0.4%Si0.17-0.3%V0.1-0.18%… |

| 45G | GOST 4543 - 71 | Fefrom 97.2%Mn0.7-1%C0.42-0.5%Si0.17-0.3%… |

| 45G2 | GOST 4543 - 71 | Fefrom 96.4%Mn1.4-1.8%C0.41-0.49%Si0.17-0.3%… |

| 45X | GOST 4543 - 71 | Fefrom 96.7%Cr0.8-1.1%Mn0.5-0.8%C0.41-0.4%Si0.17-0.3%… |

| 45Х4В3ГФ | GOST 10543 - 98 | Fefrom 88.6%Cr3.6-4.6%W2.5-3%Mn0.8-1.2%Si0.7-1%C0.4-0.5%V0.2-0.4%… |

| 45ХН | GOST 4543 - 71 | Fefrom 96%Ni1-1.4%Mn0.5-0.8%Cr0.45-0.7%C0.41-0.4%Si0.17-0.3%… |

| 45ХН2МФА | GOST 4543 - 71 | Fefrom 94.7%Ni1.3-1.8%Cr0.8-1.1%Mn0.5-0.8%C0.42-0.5%Mo0.2-0.3%Si0.17-0.3%V0.1-0.18%… |

| 47GT | GOST 4543 - 71 | Fefrom 97%Mn0.9-1.2%C0.44-0.5%Si0.1-0.22%Ti0.06-0.1%… |

| 50G | GOST 4543 - 71 | Fefrom 97.2%Mn0.7-1%C0.48-0.5%Si0.17-0.3%… |

| 50G2 | GOST 4543 - 71 | Fefrom 96.4%Mn1.4-1.8%C0.46-0.5%Si0.17-0.3%… |

| 50X | GOST 4543 - 71 | Fefrom 96.6%Cr0.8-1.1%Mn0.5-0.8%C0.46-0.5%Si0.17-0.3%… |

| 50Х3В10Ф | GOST 10543 - 98 | Fefrom 82.4%W9-10.5%Cr2.6-3.6%Mn0.8-1.2%C0.45-0.5%Si0.4-0.7%V0.3-0.5%… |

| 50X6FMS | GOST 10543 - 98 | Fefrom 88.7%Cr5.5-6.5%Mo1.2-1.6%Si0.8-1.2%C0.45-0.5%V0.35-0.5%Mn0.3-0.6%… |

| 50ХН | GOST 4543 - 71 | Fefrom 95.9%Ni1-1.4%Mn0.5-0.8%Cr0.45-0.7%C0.45-0.5%Si0.17-0.3%… |

| 50ХНМ | GOST 10543 - 98 | Fefrom 95.3%Ni1.4-1.8%Cr0.5-0.8%Mn0.5-0.8%C0.5-0.6%Mo0.15-0.3%… |

| G13A | GOST 10543 - 98 | Fefrom 82.6%Mn12.5-14.5%C1-1.2%… |

| Х6Ф1 | GOST 15891 - 70 | Fefrom 88.8%Cr5.5-7%C1.4-1.7%V0.8-1.2%… |

Analogs

Steel is used for the manufacture of measuring instruments, machine parts and apparatus. European manufacturers use steel in the production of cutting tools. Knives made from this grade of steel usually have a low price, but do not hold an edge well, but practically do not chip , and also have good resistance to impact loads.

Steel is also used in the production of shafts, oil seals, bolts, springs, piston rods, machine parts, injection molds, knives and tools used in the food and household industries in the form of connecting rods. The profile range is wire or cold-rolled metal plate with a hardness of 45 to 51 HRC.

3H13 is a group of stainless martensitic steels. Steel is included in the list of corresponding analogues (0H13, 1H13, 2H13 and 4H13). It does not contain nickel, the chromium content here is on average 13%. Due to the high carbon content in the chemical composition, higher strength properties are obtained.

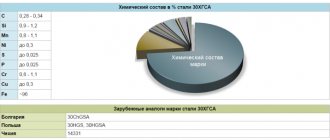

The closest imported analogues are in Table 2.

table 2

Analogues of steel X30Cr13

Application

Billets made of steel 30KhGSA are processed in accordance with cold stamping technology. This method makes it possible to produce earrings, rods, traverses, shafts, levers, sprockets, as well as cylinders and couplings. They are elements of low strength, so they are used in industrial units and lightly loaded mechanisms.

In general, the scope of application of such steel includes several areas.

- Construction. In this area, elements operated under variable loads have become widespread. Their resistance to oxidation is determined by the fact that these fasteners can only be used with special protection for the device.

- Aircraft manufacturing. In this industry, the alloy is in demand as a consumable for the production of flanges, shafts and other elements. However, it is prohibited to use 30KhGSA in the manufacture of critical parts.

- Mechanical engineering. The alloy has found its application in the manufacture and production of elements operating under conditions of variable or constant loads.

Reviews

Users note that X30Cr13 steel is quite an ordinary steel for kitchen knives with stable characteristics. If you carefully select a tool for sharpening blades and carry out sharpening taking into account the subtleties, knives can serve for a long time and not become dull. The excellent sharpness and durability of the cutting edge is noticeable to the eye.

The inertness of the alloy does not allow it to enter into a chemical reaction with aggressive media (acidic and alkaline), so it does not harm human health.

As a rule, people who want to purchase high-quality knives for kitchen work are more oriented towards the opinions and advice of those who draw their conclusions based on impressions of factory sharpening, which, as a rule, is not always successful. But with the correct and competent selection of abrasive means for dressing and good working technique, you can achieve tremendous success in sharpening.

Reviews allow us to conclude that knives made from X30Cr13 are quite suitable for everyday work. Hardness and strength allow them to be used intensively for various purposes, while the excellent appearance of the blades is maintained over a long service life.

Knives deserve respect and a place of honor in the kitchen. This is the consensus of many users of 1.4028 (X30Cr13) alloy products.

Application

The above characteristics make it possible to use the alloy in various industrial sectors:

- In construction, it is used to make fasteners that are subject to alternating bends.

- Even modern aircraft manufacturers use the alloy as a material for the manufacture of consumables: flanges, shafts and others.

- In mechanical engineering, high-quality products are produced that operate under constant variable loads.

The cost depends on the quality and dimensions of the scrap, as well as on the planned supply volumes.