Despite the large number of synthetic and polymer materials that have become widespread in modern industry and everyday life, the use of iron alloys is not inferior to the palm. The most critical parts, mechanisms, tools and other components are made of various grades and types of metal that have the necessary properties to solve the assigned tasks. Active searches for a complete replacement for metal alloys have not yet been successful, since the difference in the properties of the materials is too great. The development of metallurgy does not stop; new technologies and methods for producing high-strength and hard materials are emerging. At the same time, the old, traditional methods of metal smelting, worked out over centuries and studied in detail by many generations of metallurgists, have not been forgotten. Let's consider the design of a blast furnace - one of the oldest designs for the production of foundry cast iron, which is actively used to this day.

DIY blast furnace for home

The blast furnace is used in metallurgy for smelting cast iron and ferroalloys from a charge. It has high productivity, so recently, to heat a private home, many craftsmen have made such stoves on their own. These furnaces also have another name - shaft-type furnaces or long-burning furnaces.

Construction of a large blast furnace.

A do-it-yourself blast furnace operates on the same principle as its industrial version; it allows for the most efficient use of fuel, and its consumption is significantly reduced. Such a stove is the best solution for heating a house, cottage, garage, or greenhouse.

The main feature of a homemade blast furnace is that the process of fuel combustion in it is delayed for a long time.

This homemade blast furnace can operate on coal, wood and even sawdust. You can buy a long-burning stove in a store, but if you do everything yourself, the savings will be significant.

Story

The need to improve iron smelting technology arose a long time ago. Low-melting ores, located almost on the surface of the earth, did not have large volumes and were quickly consumed. The existing smelting technique was untenable and did not allow working with refractory ores. There was a need to improve existing equipment and technology. First of all, it was necessary to increase the size of the furnaces and significantly strengthen the pressurization mode.

The first mentions of structures similar to blast furnaces were found in China. They date back to the 4th century. In Europe, the appearance of blast furnaces dates back to the 15th century; before that, so-called cheese-blowing furnaces were used. The immediate predecessor of the blast furnace was the Catalan forge, which used technological techniques close to the blast furnace production method. Its distinctive features were:

- Continuous charge supply process;

- Use of powerful hydraulically driven air supply units.

14th century blast furnace

The volume of the Catalan forge was only 1 m³, which did not allow obtaining large volumes of products. In the 13th century, the Stutofen, an enlarged and improved version of the Catalan bugle, was created in the European principality of Styria. It was about 3.5 m in height and had two technological openings - the lower one for supplying air, the upper one for extracting kritsa (raw iron). Stukofen produced three types of semi-finished iron products:

- Steel;

- Malleable iron;

- Cast iron.

The difference between them was in the carbon content - most of it was in cast iron (more than 1.7%), in steel it was less than 1.7%, and in malleable iron the content was 0.04%. The high level of carbon content was assessed negatively, since cast iron cannot be forged, welded, and it is difficult to make weapons from it.

It is important! Initially, cast iron was classified as industrial waste because it could not be forged. Attitudes towards it changed only after the start of secondary smelting, which began to be done due to a shortage of fusible ores. Convertible iron obtained from cast iron was of higher quality, which served as an incentive to expand the conversion process.

Further expansion of capacity and improvement of technology gave rise to the emergence of the blaufen, which was already about 5–6 m high, capable of smelting cast iron and iron simultaneously. It was already practically a blast furnace, albeit a somewhat smaller, simplified design. A two-stage process was established, when the first stage was the production of cast iron, and the second was the smelting of iron from it under increased pressure.

The appearance of the first blast furnaces in Europe dates back to the end of the 15th century. Almost immediately, similar designs appeared in England, and in the USA the first blast furnaces were created much later - in 1619. The first blast furnace in Russia was built by A. A. Vinius at his manufactory in Tula. The process consisted of the following steps:

- Charcoal loading and pressurization.

- Placing pig iron in front of the mouth, melting, and draining the cast iron down.

- Loss of some carbon during passage near the tuyeres.

- Supply of the resulting iron to the nozzle, a powerful boost, during which the excess carbon burned out, and the soft iron settled at the bottom.

Iron was removed from the bottom of the forge and forged, removing liquid slag and compacting the pigs. With this method, the yield of finished iron was about 92% of the original weight of cast iron, and its quality significantly exceeded that of a critical product.

The fuel crisis became a serious problem. Charcoal was used to smelt the ore, which led to the destruction of forests. The problem grew to such an extent that metal was imported into England from Europe, and later from Russia, for 2 centuries. It turned out that the forest grows slower than it burns. Attempts to use coal have shown that it contains a large amount of sulfur, which significantly reduces the quality of the metal. Many experiments were carried out that were not successful.

This is interesting! The solution was found only in 1735 by the English metallurgist A. Derby II, who found a way to convert coal into coke. Since that time, the fuel problem was overcome, and the process received a new impetus for development.

The next revolutionary discovery was the heating of the air used for supercharging. It made it possible to significantly reduce coal consumption by up to 36%. There are special requirements for the grade and quality of metal in terms of manganese, silicon, and phosphorus content. The technology and design of furnaces were improved and supplemented, little by little coming to a modern look.

Homemade blast furnace

Scheme of a blast furnace for in-house production.

If you decide to make such a design with your own hands, then be prepared for the fact that there will be a lot of dirt and noise when performing the work, so it is best to do it outside.

The main secret of this design is the presence of a special restrictor for air access to coal or firewood. It allows a small amount of oxygen to pass through, which is enough to maintain smoldering of the loaded portion of fuel, while active combustion does not occur, so heat is released evenly over a long period of time.

In order to make this stove yourself, you will need the following supplies and tools:

- large barrel or pipe;

- two pieces of pipe;

- channel;

- tape measure, level, hammer, hacksaw;

- Sheet steel

- welding machine, electrodes;

- mortar and bricks for the foundation.

First you need to cut off the top of the barrel, this must be done carefully, as you will need it in the future. Instead of a barrel, you can use a large diameter pipe. To make the bottom for the pipe, it is better to weld a rectangular sheet of metal, it will give it greater stability.

A circle is cut out of the sheet, the diameter of which is slightly smaller than the diameter of the barrel, and a hole is made in it for another pipe. Weld a pipe with a diameter of 10 cm to a steel circle. Sections of the channel are welded to this circle from below; they serve to press down the fuel as it burns out.

To cover the barrel, take a sheet of metal or a previously cut off upper part and make a hole in it for the pipe. In order to add fuel, it is necessary to cut out the hatch and install a door. A door is made under it to remove the remains of the bookmark.

Receipt

The blast furnace is made of eight double sheets of wrought iron and a crucible.

| Ingredients | Process |

| Double Wrought Iron Sheet + Crucible |

Constructionedit

The height of a blast furnace determines the amount of ore, flux, and charcoal it can contain, and therefore the maximum amount of ore that can be smelted at one time. The small blast furnace is one block high and requires a minimum of 4 fire brick blocks and 12 wrought iron sheets. In size, the maximum blast furnace can be 5 blocks high, and requires 20 fire brick blocks and 60 wrought iron sheets:

| Furnace construction diagram |

| Layer 3 |

| Layer 2 |

| Layer 1 |

A minimum size blast furnace is constructed as follows:

Layer 3:

- Fire Bricks: In two blocks above the ground, create a “pipe”, surrounding the central air block on all four sides.

- Metal Sheets: Place wrought iron sheets or higher grade metal sheets on the sides of the chimney. Note: Sheets should not be placed on top or bottom.

Layer 1:

Crucible: Place the crucible on the ground under the center air block.

Layer 2:

Blast Furnace Block: Place the blast furnace block between the chimney and the crucible (⇧ Shift+RMB) under the central air block.

- Bellows: Place the Bellows on the side of the blast furnace block, making sure the side with the hole faces the blast furnace.

- Completion: Place the tuyere in the blast furnace.

- Expansion: Blast furnaces can increase the overall storage capacity by adding up to four additional layers to an existing structure. To extend a blast furnace, simply add an additional layer to the chimney.

Applicationedit

Used for smelting cast iron. To do this, you need a tuyere (put it in the blast furnace inventory). The smelting process is as follows:

Throw an equal amount of charcoal, flux and iron ore (Limonite, hematite or magnetite) into the structure from above. At the first level of the structure max. capacity is 4, and each subsequent level also increases the capacity by 4. The maximum (5) level structure has a capacity of 20.

Important: in the process of smelting ore, charcoal will be consumed, so it will have to be added periodically. You can add coal in advance, then it will be consumed as needed

The optimal quantity is 3 pieces (tested for level 1-3 structure).

- Light the main block of the blast furnace using an igniter or flint.

The texture of the block will change to “burning”. Working blast furnace - The blast furnace should be heated to a “bright white” temperature. To do this, you need to use furs (RMB on them).

Attention: if there is too little coal, the blast furnace will simply cool down and the whole process will have to start again! A shortage of 1 (2 if the oven is not fully loaded) units is acceptable. coal until the desired temperature is reached

- Upon reaching the required temperature and in the presence of a tuyere, the blast furnace will begin to pour molten pig iron into the crucible underneath, and the strength of the tuyere will be wasted (at the rate of 1 piece of ore = 1 unit of strength)

- You can remove cast iron from the crucible using clay molds

Foundation and chimney

Since the metal part of the structure will become very hot during operation, the stove must be installed on a foundation. Its weight is light, and it is not necessary to make a recess for the foundation; a simple slab is made, which can consist of a layer of brick covered with mortar.

To remove combustion products, it is necessary to make a chimney. You can take a pipe with a diameter of 15 cm or more. For it to work effectively, the straight part must be larger than the diameter of the barrel. It is better not to bend the chimney, and if this is necessary, then the bending angle should be more than 45 degrees.

As for the reflector, it can be installed or not installed. If there is a reflector, such a stove will work even more efficiently, since it allows you to redistribute heat flows.

Installation features

Such a stove can be lined with brick, but if it is located in a separate or utility room, then this is not necessary.

- The parts of the chimney must be connected in the direction opposite to the movement of smoke.

- No flammable objects should be placed near the stove; there should be free space around it.

- The chimney must be made collapsible so that it can be cleaned periodically.

- You can attach a pipeline to the barrel in the form of a loop through which the liquid will pass into the heating system. This way it will be possible to heat not just one room, but the whole house.

- To be able to regulate the heating intensity, a tap is installed in the system near the boiler, with which it will be possible to limit the flow of hot liquid.

Principle of operation

The operating principle of a blast furnace is as follows: ore charge with coke and limestone flux is loaded into the receiving chamber. In the lower part, periodic release of cast iron/ferroalloys and separately molten slag is carried out. Since the level of material in the blast furnace decreases during release, simultaneous loading of new batches of charge is required.

The operating process is constant, combustion is maintained with a controlled supply of oxygen, which ensures greater efficiency.

The design of the blast furnace ensures a continuous process of ore processing, the service life of the blast furnace is 100 years, major repairs are carried out every 3-12 years.

Who invented it?

This made it possible to significantly reduce coke consumption by more than a third and increase the efficiency of the furnace. Before this, the first blast furnaces were actually cheese-blowing furnaces, that is, unenriched and unheated air was blown into them.

The use of cowpers, that is, regenerative air heaters, made it possible not only to increase the efficiency of the blast furnace, but also to reduce or completely eliminate contamination, which was observed in case of technology violations. We can safely say that this invention made it possible to bring the process to perfection. Modern blast furnaces operate precisely on this principle, although their control today is automated and provides greater safety.

Air heaters

Air heaters have been built in blast furnaces since the invention of E. A. Cowper, that is, since 1857. Air heaters look like large towers located next to the blast furnace. From the blast furnace, through a pipe - a gas outlet - hot furnace gas enters the air heater, which in a special chamber inside the air heater mixes with the air entering through another pipe and burns. The resulting even hotter gas passes through the nozzle - a column made of bricks with a gap between them for the passage of gas. This gas heats the nozzle and is removed from the air heater through the third pipe. When the nozzle heats up to the required temperature, ordinary, unheated air is allowed into the air heater, which, passing through the nozzle, is heated to a temperature of over 1000 ° C and then goes into the blast furnace for smelting cast iron. At the same time, the nozzle is gradually cooled, and when it has cooled sufficiently, it is heated again by burning the blast furnace gas. From this it can be seen that the process of heating the air for the blast furnace is not continuous, and since the smelting of cast iron in the blast furnace is ongoing, several air heaters are built during it - while one of them works to heat the nozzle with top gas from the blast furnace, the other works to heat the air for the blast furnace with the nozzle.

Domain process

Modern furnaces for melting cast iron provide approximately 80% of the total amount of cast iron; from the casting sites it is immediately supplied to electric smelting or open-hearth shops, where ferrous metal is converted into steel with the required qualities.

Pig iron is produced from cast iron, which is then sent to manufacturers for casting in cupola furnaces. To drain slag and cast iron, special holes called tapholes are used. However, in modern furnaces, not separate, but one common tap hole is used, divided by a special heat-resistant plate into channels for supplying cast iron and slag.

How does a blast furnace work?

The blast furnace process is entirely dependent on the excess carbon in the furnace cavity; it consists of thermochemical reactions occurring inside when all components are loaded and heated.

The temperature in a blast furnace can be 200-250°C directly under the top and up to 1850-2000°C in the active zone - steam.

When hot air is supplied to the furnace and coke is ignited, the temperature in the blast furnace rises, the process of decomposition of the flux begins, as a result of which the carbon dioxide content increases.

When the column of material in the charge decreases, iron monoxide is reduced; in the lower part of the column, pure iron is reduced from FeO, flowing into the furnace.

As the iron drains, it actively contacts carbon dioxide, saturating the metal and giving it the required properties. The total carbon content of iron can be as low as 1.7%.

Bad cast iron

At high melting temperatures, ore iron quickly gets rid of the oxygen atoms that oxidize it and combines with carbon atoms (from coal). In the stukofen, iron was enriched with carbon before slag (other impurities) had time to separate from it. The slag was smelted when not only a lump of kritsa (iron with a small carbon content) had already formed in the furnace, but also molten cast iron (iron over-enriched in carbon).

The high carbon content made cast iron brittle and impossible to forge or weld. What could be done with such metal? And when smelting refractory ores, a lot of cast iron was produced, and it was mixed with liquid slag. At first this mixture was thrown away, but in the 14th century. They began to extract beads - homogeneous pieces of cast iron - from the crushed slag and cast rough products from it.

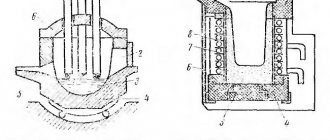

Blast furnace device

The design of a blast furnace is very complex; it is a large complex that includes the following elements:

- hot blast zone;

- melting zone (this includes the hearth and shoulders);

- steam, that is, the zone where FeO reduction occurs;

- a mine where Fe2O3 reduction occurs;

- fire pit with pre-heating of the material;

- loading of charge and coke;

- blast furnace gas;

- the area where the material column is located;

- outlets for slag and liquid iron;

- collection for waste gases.

Additional furnace elements

The operation of the oven requires the operation of auxiliary devices. Among them:

- air heaters; large tower-type elements are located next to the furnace; blast furnace gas enters them, which then burns; due to this, even hotter gas is formed, heating the air through a complex system; the latter - heated to a temperature of at least 1000 degrees - is used for smelting cast iron;

- blowers; compressed air is necessary for fuel combustion; air enters the furnace thanks to devices that generate a pressure of about 25 MPa;

- devices for lifting and filling the charge;

- gas purifiers for cleaning blast furnace gases;

- other auxiliary devices - for example, overhead cranes with which foundry yards are equipped.

Modern furnaces are equipped with automation systems. Computerization makes it possible to control and regulate the basic parameters associated with the functioning of the blast furnace. The level of raw material filling, gas pressure, blast temperature, etc. are under control.

How to make a blast furnace with your own hands?

Nuances

Cast iron production is a highly profitable business, but it is impossible to organize the production of ferrous metal without serious financial investments. Do-it-yourself blast furnace in “makeshift conditions” is simply not feasible, which is associated with many features:

- the extremely high cost of a blast furnace (only large plants can afford such expenses);

- the complexity of the design, despite the fact that a drawing of a blast furnace can be found in the public domain (above the diagram), it will not be possible to assemble a full-fledged unit for the production of cast iron;

- individuals and individual entrepreneurs cannot engage in the production of cast iron, simply no one will issue a license for this;

- deposits of raw materials for ferrous metallurgy are almost exhausted; there are no pellets or sinter on free sale.

Cost using the example of efficiency factor No. 7

Manufacturing blast furnaces is a resource-intensive and expensive process that cannot be put into production. Since blast furnaces are used exclusively in industry, their design and assembly are carried out for a specific metallurgical complex, which includes many objects and components of the internal infrastructure. This situation is observed not only in the Russian Federation, but also in other countries of the world that have their own metallurgy facilities.

The cost of manufacturing and installing a blast furnace is quite high, which is associated with the complexity of the work. An example is the large domain complex No. 7 called “Rossiyanka”, installed in 2011. Its cost was 43 billion rubles; the best engineers from Russia and foreign countries were involved in production.

The complex includes the following units:

- ore receiving device;

- inlet stations of the bunker overpass and the central hub;

- bunker overpass;

- compressor station (installed at the foundry yard);

- installation for injection of pulverized coal fuel;

- utilization thermal power plant;

- control center and administrative building;

- foundry yard;

- blast furnace;

- air heating blocks;

- pumping station.

The new complex ensures the production of more than 9,450 tons of cast iron per day, the useful volume of the furnace is 490 cubic meters, and the working volume is 3,650 cubic meters. The design of the blast furnace ensures waste-free and environmentally friendly production of cast iron; blast furnace gas for thermal power plants and slag used in road construction are obtained as by-products.

Memory

Participants in the construction of blast furnace No. 9 were awarded the badge of the same name.

In 1974, to mark the launch of the furnace, a commemorative medal was issued.

The construction of blast furnace No. 9 left a significant mark on the art of the USSR. Artists painted many canvases dedicated to both the blast furnace itself and the people who built it.

Paintings dedicated to blast furnace No. 9:

- Taleev A. M. The Ninth Heaven (1973);

- Sitnik P. F. Pit of the ninth blast furnace (1973);

- Gorodissky V. N. Birth of the Ninth (1974);

- Filonenko V.D. Construction of the ninth blast furnace (1974);

- Kozulin M. Ya. Construction of the ninth Krivoy Rog (1974);

- Fungus D.K. Installation of DP-9. Brigade of Honored Builder of the Ukrainian SSR A.P. Matvienko (1974);

- Gorbachenko V.S. Construction work at the ninth blast furnace; The ninth blast furnace is under construction;

- Shishko G. G. On the construction of DP-9 (1974);

- Tkach A. S. Romantics of the Ninth (1974);

- Kostenko A. O. On the Ninth; Morning at DP-9;