There are several ways to connect various objects and materials, but the simplest and most effective method is adhesive fixation. To use a glue gun, you need to know the general operating rules. The principle of operation is simple - the device heats up a polymer rod, which becomes plastic under the influence of temperature. Using a gun, the adhesive mass is applied to the desired area. Then the gluing itself is done.

How to use

Thermal guns are used at large furniture manufacturing enterprises, where they are used to install finishing elements on cabinets, upholstery of sofas, and armchairs. They are used in construction and the production of decorative items. When purchasing for home use, the list of operations increases. Hobbies, children's crafts, interior decoration, minor repairs are the area of application for a glue gun. You need to know the rules for using the device at home. Additional information will make the gun more effective where it can be used, and put it aside where it is inappropriate.

How to charge

Manufacturers have tried to make the operation of the device simple. The design of the pistol allows it to be loaded without additional devices, disassembly, or other operations. The simplest charge is the first one. The rod inlet and nozzle are clean. There are no traces of past work, signs of physical impact, or damage. For work, take the glue of the required brand. When purchasing, you need to know the characteristics of the rod. Products include the following types:

- Transparent. Universal rods with low melting point.

- Black. Designed for sealing joints, like sealant. They have a high melting point.

- Colored. The polymer is painted over the entire mass and the glue on the parts is not visible. Widely used in handicrafts.

- Decorative. They are used when the glue itself becomes a finishing element. May contain glitter, mother-of-pearl, and fibers.

- High temperature. Special types of glue for fixing elements that are subject to increased loads.

When purchasing, pay attention to the diameter of the rod. The most popular brands have values of 7 and 11 mm. However, products of other standards are also available for sale, for example, 8, 12 mm. The rod size specified in the instructions cannot be replaced.

As a rule, charging the glue gun itself is not difficult. The rod is inserted into the hole in the back of the device until it stops. In some models, it is necessary to advance it by repeatedly pressing the trigger until it rests on the heating chamber. Guns with a temperature indicator are convenient. A glowing diode indicates that the device continues to heat up. When the indicator goes out, you can start working.

Warm-up rules

The melting point is indicated on the packaging with the rods. If you purchased a low-power gun, then not every type of glue will work. There are models designed to work with low-temperature rods that melt at 105 °C. It is not recommended to insert consumables with a higher melting point into them. Even if the glue begins to soften, the work will be very difficult and long. Excessive pressure on the mechanical parts of the gun may cause them to break.

Main manufacturers

On the market of glue gun manufacturers, a unique rating of brands that you can trust has formed. Which one to give preference is the user's choice. Sometimes purchasing an unnamed model is justified if you need a tool for a certain period of time. If it breaks, you don’t mind throwing it away later. But among such “masterpieces” of Chinese consumer goods there is also a great marriage.

Dremel

A reputable North American brand, famous for its high-speed grinding machines, which came to be called Dremel. Thermal guns under this brand are reliable and fully worth the money spent on them. A switch is built into the handle, and a special stand is created in the front part. The nozzle is replaceable. It is convenient to work with such a gun, and it will last a long time. Dremel users, one and all, note the ergonomic handle of the unit and its lightness. But original glue sticks are not cheap.

Steinel

German scrupulousness, full compliance of the stated characteristics with the actual ones. Such a pistol, purchased for home crafts or repairs, will not let you down. Designed for a 220 V household network. There are models with temperature control, as well as battery-powered ones. By the way, autonomous Steinel pistols are considered one of the best: they contain electronic temperature controllers and an automatic shutdown unit.

Bosch

The products of the Bosch concern are known and respected far beyond the borders of Germany. Household and professional tools under this brand are reliable, trouble-free equipment. The products use high-quality components. Solutions are offered for amateurs and professionals. The pistol fits comfortably in the hand and is equipped with an electronic stabilizer.

The brand of the same name produces glue sticks of consistent quality. There are mains guns and compact battery guns.

Hobby and pro

Mid-class models for universal use are produced. The gun is equipped with a switch and has good ergonomics. One of the obvious advantages of the pistol is its low price (700 rubles). Provision is made for blocking the leakage of adhesive mass.

UHU

Another average one. You shouldn’t expect super quality from products under this brand, but the heat guns will live up to your hopes. They are classified as low-temperature (110 degrees), suitable for household purposes and handicrafts.

MasterHand

Cheap and cheerful - this is how the products of this manufacturer can be characterized. Not Bosch, but suitable for home crafts. There are no additional functions, including a power supply switch. There is no regulator either. One of the simplest and most inexpensive pistols, this is where its advantages end.

Stavr

Russian manufacturer. It produces pistols with good ergonomics, a replaceable nozzle and a convenient rocker key. Among the undoubted advantages is fast heating (about a minute). There is no control over the temperature regime for melting the glue.

Defort

Glue guns with conflicting reviews. Judging by the complete case and spare attachments (2 pieces), this is a tool for professionals. The slightly curved handle leaves a pleasant impression. But the price (up to 2 thousand) and the design of the suitcase are not particularly encouraging.

Kolner

A brand with mixed Russian-Chinese roots. The manufacturer provided a switch and lighting for the work area, and equipped the gun with a long power cable. And the price of the product is not too bad. In its price range, Kolner crushes its competitors with a set of additional functions; they almost never have a backlight or toggle switch. Not to mention the removable and spare nozzle.

Safety instructions for use

The device operates on mains power, and electric current always poses a health hazard. A gun is, first and foremost, a heating device. Temperatures can reach up to 200 °C. Glue is also an energy-intensive substance. It cannot cool down instantly. In case of contact with skin, burns are inevitable. When performing certain operations where contact with heated polymer is possible, it is necessary to wear gloves, ensuring the safety of your hands.

Lifehack. During a break, between individual operations, the glue gun is left on the stand with the nozzle down, under which you can put a piece of paper, a piece of fabric, which after work can be thrown away with the remaining glue. The working surface of the stand will remain clean. The glue will not get on the floor or table.

During operation, do not reach into the body with metal objects to remove glue or correct the position of the rod. Do not touch the nozzle during operation. The very same safety precautions when working with glue are not regulated, with the exception of the heating period. When cooled, it is completely harmless, therefore it is allowed for the manufacture of interior elements and children's toys.

What can be glued with a hot glue gun?

A hot gun is an excellent alternative to PVA glue, stationery glue, carpentry glue, and even instant glue. It glues reliably, allows you to assemble the structure quickly and, if necessary, correct defects. In addition to convenience and practicality, the use of a heat gun differs favorably from other methods in the absence of harmful evaporation and the resistance of the adhesive layer to water.

The device can be used to connect the following types of surfaces:

- Wooden.

- Metal.

- Ceramic.

- Leather.

- Textile.

- Plastic.

- Paper ones.

- Cardboard ones.

- Stone.

- MDF.

- Chipboard.

An extensive list of materials makes it possible to implement the most daring solutions for arranging the home interior, handmade items, and crafts for children. You can glue small elements such as rhinestones, glitter, beads to any base.

The strength of the glue will not be enough if you need to fix a surface that will be used intensively. For example, the toes of sneakers that have come off. You can try to glue it on urgently if you can’t go to a workshop or buy new ones. But such shoe repairs will not last long.

A hot gun is not suitable for gluing high-traffic surfaces Source pixabay.com

Using the tool on gypsum, concrete, and cement surfaces is not very effective. If necessary, it should be primed or painted. Then gluing will be more effective.

Problems and their solutions

Over time, some parts wear out. Most often this is the plastic from which the trigger, the advance mechanism and the o-rings in the feed coupling are made. Being in close proximity to the heating chamber, over time they lose elasticity, crack, and crumble. You can replace them yourself by cutting new seals from silicone or heat-resistant rubber. Then the glue under the pressure of the rod will again come out through the nozzles, and not through the resulting gaps or cracks into the gun body.

The nozzles need to be cleaned regularly. If the glue cannot be removed in a cold state, then the device is heated and excess polymer is removed using rags, thick paper, or cardboard. The device is inexpensive, so repairing it with replacement parts is unprofitable. The most vulnerable parts of the device are the trigger and the rod feed mechanism. During operation, the hot glue in the gun is quite mobile, so you should not press too hard on the trigger. You can damage it, or create excessive pressure in the heating chamber, which will lead to accelerated wear of the seals.

Additional features

When choosing a gun, you should pay attention to how the feed mechanism is made. It can be carousel or slider. The first type is more difficult to use, because it does not require pressing the trigger, but turning it, which can be inconvenient. Different types of rods may differ in melting temperature. To solve this problem, it is better to purchase a gun that has a built-in regulator. It makes it possible to preset the required operating mode. If you need mobility when making crafts, then you can get a battery-powered gun. It can function without a central power supply.

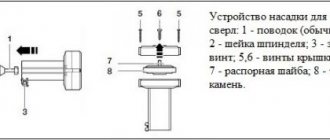

How to change the color of the rod correctly

Often during operation it becomes necessary to replace the rod. For example, to change the color of glue for decorative finishing. To do this, turn on the device. After heating, carefully remove the rod. Insert the desired one. After the time recommended to achieve the required temperature has been maintained, the remnants of the old rod are squeezed out of the nozzle until new glue appears. It is advisable to refill with a rod of a similar brand. Then the operating mode will remain the same, and there will be no noticeable difference in texture on the finished product. You can change not only the color of the glue. You can install a rod with filler to create an original design.

Direct operation of the glue gun

In fact, the rod does not contain adhesives. Adhesive qualities appear only when heated. It is a waterproof polymer that, in its liquid state, can adhere to almost any surface. This is achieved with the help of a pistol. The inserted rod is brought to the melting temperature in the heating chamber and extruded through the nozzle onto the part. The mode depends on the power of the device and the brand of glue.

Preparation time for low temperature rods is about 2 minutes. Then the glue is applied to the surface. The second part is pressed and held in this position until it sets. The time may increase if a significant amount of glue is used. If it is a small drop, then a few seconds are enough. If several grams are applied, then the structure needs to be kept for up to 2 minutes. Complete cooling and set of operational characteristics occurs in approximately 5 minutes.

Price categories

Prices for pistols, like any instrument, vary widely. There are simple ones, for 600 and even 400 rubles, and there are supermodels for 2.5 thousand. In the lower range there are unpretentious products with a minimal set of options. The exception is the Kolner with a long cable, a replaceable nozzle and a switch key on the handle.

The cheapest Dremel will cost 800 rubles, and it does not have any additional functions. Convenient, productive models of self-powered pistols (built-in lithium-ion battery) Bosch or Steinel cost 2400-2500 rubles. For comparison: a Bosch network high-temperature gun costs 2.1 thousand rubles.

Units costing more than 5 thousand are considered professional. If you need a pistol one-time, you can find a model for 300-400 rubles, a “one-day” one, since among similar products the mean time between failures is low. They are not even repaired, they are simply replaced with new ones.