One of the most popular power tools, which is used with equal success in production and at home, is an electric drill.

The drill is a universal assistant. It’s not difficult to expand its capabilities; you just need to buy additional attachments, and there are a great many of them. Some allow you to drill into walls, others allow you to mix building mixtures, and others help you cut sheet material.

At the final stage of manufacturing various decorative products, an attachment for sanding wood is indispensable; with its help, you can create a perfectly smooth surface. In this case, you do not have to spend money on buying a full-fledged grinding machine.

Range of accessories

Electric drill attachments are replaceable tools for various purposes, which are driven by the drill motor. For fixation in the cartridge, each of them has a connecting pin. The right attachment will help you perform a whole range of jobs without the need to purchase expensive tools.

Among other things:

- removing traces of corrosion from the metal surface;

- removal of old paintwork;

- cleaning welds, removing burrs;

- milling of soft material;

- polishing of metal products, including those with complex geometry;

- grinding the inner surface of the holes;

- sanding the wood surface;

- polishing varnished products;

- polishing glass and grinding its edges;

- grinding and polishing various small parts.

The industry offers a wide range of ready-made accessories, so you can choose the right tool for any type of work. Some types of attachments can be used together, allowing you to turn your drill into a small, portable machine.

When choosing a nozzle, in addition to its purpose, you should pay attention to the manufacturer and country of production. Too often you can find cheap, low-quality tools, the use of which will not give the desired effect, and in some cases can cause serious injury.

Knife manufacturing options

A homemade knife can be made from a variety of metal parts that are no longer suitable for their intended use due to the fact that they have become unusable.

These may be the following items:

• worn motorcycle connecting rods are suitable for making a set of knives with different blade lengths; • wheel wrenches with one end broken off; • crutches used for laying rails; • circular saw blades with different thicknesses and diameters; • a hacksaw blade of a pendulum saw that is damaged.

If you have certain forging skills, you can make a knife from materials such as thick metal cable or a chain of household units. In this case, a chainsaw is an excellent option. Its chain has good strength and will make a knife similar to Damascus blades.

If the circular saw has a large disc diameter and minimal damage, then it may be enough for two homemade knives. The discs are made of very durable metal, since the saw was originally designed for long-term work with chains.

Drill attachments: is it worth buying?

Most often, an electric drill with attachments is used when there is no special tool, and its purchase is not justified. For example, you should not buy a grinder if you only need to sand a single workpiece. It is much more practical to buy a drill with a set of attachments and use it as a universal tool.

It should be noted that the choice of accessories for drills is very wide. They are not limited to simple grinding and polishing tools. If necessary, a drill can take on the role of a router, screwdriver, jigsaw, construction mixer, and even metal scissors.

Note! Plus, a drill with an attachment is an excellent option for processing workpieces in hard-to-reach places.

Among the disadvantages of this tool, we can only mention the low efficiency of an electric drill when working with some types of attachments; for example, it is much easier to grind a large area with a full-fledged grinder. However, given the affordable price of even the highest quality attachments, a set of basic ones should be in every home workshop.

Advantages of plucking devices

The main advantage of the products in question is the ability to quickly and easily obtain finished carcasses without feathers. Such devices do not have a negative effect on meat, so they can be used for any type of poultry.

There is no need to specifically buy a drill or screwdriver if you need to remove feathers from poultry. Any rotating mechanism, such as an electric motor, is suitable for such purposes. The disadvantage of using an electric motor is that it cannot be moved. This disadvantage is also an advantage, since during operation the plucked carcass can be held with both hands.

Stationary type of plucker with electric motor

Making a pinching device is not difficult. If such a task is set, then you need to start implementing it by ordering a certain number of nails. It is recommended to order fingers with a reserve so that during operation of the nozzle they can be replaced if necessary.

Types of nozzles

There are a huge number of accessories for drills. Some of them are designed for ease of drilling, others allow you to create large diameter holes, and others help with grinding and polishing. There are also highly specialized devices, for example, a cutter for a mini-drill for wood, which turns a hand tool into a mini-milling machine.

It is not always necessary to have a strictly vertical hole passing through the entire workpiece. There are times when it is necessary to drill at a precisely specified angle, and also several parallel holes. Here the drilling angle limiter will come to the aid of the master. Basically, these are lightweight structures that fit onto the drill and ensure its precise positioning.

Another useful accessory for an electric drill is a depth stop. The limiter is included in the basic package of delivery of almost any drill. The device is extremely simple - it is a metal rod that does not allow drilling deeper than the specified value.

Required tools and materials

Since there is no need to forge and harden the future blade, the entire tool can be found in a garage that is at least somewhat equipped. We will need:

- markers: black and silver;

- ruler, piece of paper and caliper;

- angle grinder (grinder);

- files with different grains;

- as well as sandpaper and masking tape;

- epoxy adhesive;

- grinding and drilling machines;

- container with water for cooling;

- hammer, core and vice.

Mechsaw knife.

Everything in this set is wonderful for one simple reason - any element can be replaced with something similar.

A drilling machine is, of course, cool, but an electric drill is enough. And so with any tool from the list. You will definitely need materials to make the handle, but more on that later.

For grinding and polishing

One of the most popular attachments are devices for grinding and polishing the surfaces of metal and wooden products. They differ markedly from each other in execution and purpose.

Plate

They are almost a complete analogue of the sanding pads that are used in electric sanders. The only difference is that instead of a connecting thread they have a pin that is clamped into the cartridge. Actually, if necessary, you can use the working part of a grinding machine for a drill, having first screwed a regular bolt into it.

The material from which this nozzle is made can be any. There are metal models, plastic ones, and rubber ones are often found. The latter accurately follow the contours of the workpiece, creating a perfectly flat surface. The cutting part of this attachment is sandpaper. It is sold in the form of ready-made discs that have a special coating that prevents slipping.

Cup

Cup-type attachments are used for roughing the workpiece. With their help, old paintwork is removed from wood, scale is removed from metal, and rust is removed. Structurally, it is a bowl-shaped body, inside of which hard bristles made of springy wire are laid. At the bottom of the cup there is a pin for fixing in the drill chuck.

Disc and fan

Disc nozzles have a structure similar to cup nozzles. The only difference is that the brush is not limited by the size of the body, but, on the contrary, comes out of it, forming a kind of prickly “sun”. The nozzle is convenient for processing large surfaces, but requires caution during operation - one ill-considered movement is enough to damage the product and possibly cause injury.

Fan nozzles have a similar design. Their working part is petals made of sandpaper on a fabric base. This attachment is convenient for working with aluminum parts and cleaning cast workpieces from slag.

Drum or cylindrical

Nozzles in the shape of a cylinder, on the outside of which an abrasive material (sandpaper) is fixed, are intended for processing the internal surfaces of cylindrical holes. Most often they are made of metal or rubber. By selecting the grain size of the skin with this device, you can process a wide variety of materials, from wood to metal and glass.

Polishing attachments

The final stage of product processing is its polishing. Polish parts that have been milled and varnished. This procedure is performed using special pastes that are applied to a soft moving surface. Felt, leather, foam rubber or fabric can be used as such. Structurally, this attachment is a disk made of soft material, in the center of which there is a pin for fastening in the cartridge.

How to make a knife from a mechanical saw with your own hands

The thickness of the mechanical saw is usually 2-2.5 mm, unless you find another option. This is quite enough to perform all knife tasks. They are light in the hand, hold an edge for a long time and are completely legal.

Just don't go wrong with the length. And in terms of other qualities, the knife will not fall under the article on edged weapons.

Handmade knife from mechanical saw.

Making a knife

This process can be divided into several stages. For a detailed and understandable description, we will do this:

- Of course, the first thing is a layout drawing. If you don’t have enough experience, don’t disdain this moment, it’s really important. Measure the “saw” workpiece itself, the model should not protrude beyond the edges, and do not forget about the shank and handle. All these points must be taken into account initially.

- Trace the sketch onto a piece of saw with a black marker. We clamp it in a vice and use an angle grinder to cut off a piece of the length we need. At the same stage, cut out the shank so that you don’t have to return to the vice and grinder again. After rough work, “remove” all burrs with a file.

- Particular attention is paid to future descents. This process is the most important and must be taken seriously. We take almost the “blade” and paint it over with a black marker, then use a caliper to mark it. We measure the slopes in accordance with the layout. Then carefully and, most importantly, symmetrically draw a strip along the blade using a caliper. A scratched line should appear on the black paint. We do the same on the other side. Be sure to outline the markings with a silver marker, preferably with aluminum powder.

- To remove triggers, it is best to use a special device; for more details, see the article: “How to make triggers on a knife.” It will be much faster and, most importantly, more accurate. And now about the marker with aluminum dust, when working on a grinding machine, the workpiece will heat up. A simple one will simply “burn out”, namely the one described above, on the contrary, it will begin to harden and will not fall off. Thanks to this little trick, the descents will be perfect. A belt on the grinder for making descents is not needed with very fine grain, P80 and P120 are enough. You can make it perfect later, but this is a draft version.

- Start making descents from the handle, after removing one side, do the same on the other. After making sure that everything is in order, you can walk around with a felt circle with paste. Then you should wrap the blade with masking tape several times - this both protects against cuts and prepares you for working with the handle.

- The handle will be made of wooden symmetrical overlays. We drill holes in the shank. We mark the block and divide it into exactly two parts. In accordance with the holes on the blade, we drill them on the linings. Then you need to cut along the handle, in accordance with the shank. Having marked everything out and tried it on, we begin to work on the shape of the handle; here, be guided only by your taste. Read more in the article: “How to make a handle for a knife.”

- When the parts are ready, you can connect them with rivets. The knife is almost ready, all that remains is to treat the handle in hot wax. If you don’t have it, you can use natural oils, latex-based compounds, silicone or special wood impregnations.

Homemade knife from a mechanical saw.

At the final stage, as an option, walk the handle on a felt circle, thereby removing excess oils. And wipe with a damp cloth. The blade is ready for use.

For curved cutting

There is an interesting device that allows you to turn a drill into a jigsaw. The device is fixed in a chuck and makes it possible to cut wood-based sheet material, plastic and even thin sheet metal. The cutting tool is a movable file.

This device is a useful thing in the household, but the nozzle has a fairly high price. If you need to make curved cuts frequently, you should consider purchasing an inexpensive jigsaw.

There are other similar devices. Drill attachments for drilling round holes in wood are very popular. They help overcome the drill size limitation typical for most models and drill a hole of any diameter.

For tightening screws

Perhaps this is the simplest and most popular attachment of all existing ones; in essence, it is a hardened bit with a cross for different sizes of screws. It is enough to clamp it into the chuck, and the electric drill can easily replace the screwdriver. The only condition for using the attachment is that the drill must have a speed regulator.

More complex devices are also available for sale that allow screws to be tightened at different angles. Separately, flexible devices with a cable in a sheath can be noted. With their help you can work in the most difficult to reach places.

Homemade drill accessories

Despite the fact that the industry offers a wide range of attachments, both in sets and individually, home craftsmen often make various accessories for the drill with their own hands. Such a desire can be caused by a number of reasons. Some people don’t have a suitable attachment at the right time, others are not satisfied with the quality of those that go on sale.

Drilling angle limiter

A very useful and very simple device is the angle limiter. Separately, it is worth noting that this attachment performs two functions at once. It provides a precise drill angle and limits the depth of the hole.

The main part of the nozzle is a clamp with a thickening in the upper part. The clamp is attached to the drill body. Two holes with a diameter of 6 mm are made in the thickening. A thrust bracket is bent from a wire of the same diameter at the required angle. A stop is attached to the bracket, allowing you to adjust the depth of the hole. It would be useful to make several replacement brackets with the most popular parameters.

For cutting round workpieces

The basis of many homemade products is a circle made of plywood or other sheet material. Most often it is cut using a jigsaw, but the same can be done using a drill. To do this, you just need to make a simple holder that works on the principle of a compass.

The device is a pin that is attached to the drill body with a clamp. The vertical stop moves along the pin and is fixed in the required position. The stop is held on the workpiece with its pointed end, and the rotating drill cuts out a circle. Instead of a drill, it is better to use a cylindrical cutter; with its help it is easy to make a high-quality cut without much effort.

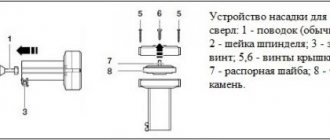

Adapter for miniature drills

The chuck of a conventional drill has restrictions on the maximum and minimum diameter of the drill, and often it is necessary to make a hole with a mini-drill with a diameter of up to 0.1 mm. A standard chuck cannot compress a small shank, but if you first clamp the drill into a collet chuck for an electric motor, and then fix it in the drill chuck, the problem will disappear.

Features of a saw blade

A power saw can be used to make a blade in almost any condition. Even if it has deteriorated and rusted, it will still be suitable for homemade work. The product has enough advantages:

- the knife will be made for yourself, so that it will be unique and will fit well in the hand;

- wide choice of material both in length and width of the butt;

- does not require hardening;

- it is possible to make several knives from one blade;

- such a blade will be in the price category of $100 and above, better than the “Chinese” one for $30-40.

This is true. Having spent not a lot of time, depending on experience, you literally get a product with good cutting properties for pennies. Don't overheat it during production and you'll get a great knife.