In households, a machine for bending profile pipes is not used so often that it is necessary to buy expensive factory-made equipment.

If such a need arises, a simple pipe bender can be made privately, having previously decided on what type of this structure is suitable for completing the task.

- Machine version with rotary platform

What types of pipe benders are there?

Benders for profile and round pipes are usually divided into several types according to the principle of operation:

- Manual or mechanical. In such designs, the user himself sets the desired bending angle, and then rolls the pipe through rollers to give it shape. The advantages of pipe benders include low cost and compactness.

The disadvantage of manual profile pipe benders can be considered low accuracy - Hydraulic. A comparison of pipe benders shows that such models are more advanced because they work faster, are capable of bending steel workpieces with walls up to 4 mm, and at the same time they are quite easy to use. The operating principle of the hydraulic drive is the same as that of a car jack.

Hydraulic profile pipe benders are compact and large-sized for stationary use - Electrical. Models are equipped with a gearbox or hydraulics, but in any case they come into action when the electric drive is started. The user is not required to exert any effort to bend the profile pipe.

Electric pipe benders can handle workpieces of almost any diameter, but are expensive

For private needs, manual and hydraulic pipe benders are most often chosen. They have an optimal price-performance ratio.

How to choose a pipe bender for a profile pipe

When purchasing a pipe bender for your home or workshop, you need to pay attention to several parameters. Among them are the purpose of the tool and its functionality.

Operating principle

Profile pipe benders come in three-roller and angular types. The former are most often used in production; they allow you to bend the pipe evenly along its entire length with maximum precision and accuracy. Tools of the second type help to perform bending in a specific area; usually they are chosen for personal purposes.

Functionality

Some models of pipe benders work only with profile or round pipes, others are equipped with replaceable segments and are suitable for workpieces of all types. Universal bending machines are more convenient. With their help, you can give the desired shape to round and square pipes, as well as metal strips and reinforcement rods.

Tool dimensions

Manual pipe benders are usually compact; some hydraulically driven models can also be considered mobile. But electrical equipment requires installation in a specific location on a rigid base and is large in size and weight. When choosing a pipe bender for a profile pipe, you need to think in advance whether you will have to transport the tool from place to place, and how convenient it will be to do this.

How to make a profile bending machine with your own hands?

Not every novice craftsman is able to purchase a ready-made factory-type machine for bending metal pipes, since this is quite expensive equipment.

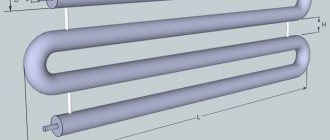

Drawing of a bending machine.

As an alternative, you can try to make a manual machine yourself, following the following instructions:

- Place gears, bearings, rings connected with a key on the pressure shaft. Turn out the cages for bearings and rollers according to a previously prepared drawing of such a shaft. Also for the unit it is necessary to make three shafts, one of which is suspended on springs, and the other two are installed on the sides.

- Drill holes in the rings to create grooves and threads, and then make a shelf using a channel with pre-arranged holes and threads required when installing the pressure shaft.

- After preparation has been completed, the machine structure is assembled using a welding machine and bolted connections. First, install the frame, which simultaneously serves as the legs of the pipe bender.

- Next, hang the shelf on springs with a pressure shaft fixed on it, after which you should install the side support shafts on a homemade pipe bender. Don't forget to attach a handle to one shaft.

- Finally, you need to install a jack on the machine and it is ready to go.

Rating of the best hydraulic pipe benders for profile pipes

Hydraulic manual benders for profile pipes are in particular demand. Their prices are usually reasonable, and such machines are easier to handle than mechanical equipment. It is necessary to apply less force to form a bend.

APV-9 Professional

The Russian pipe bender is suitable for performing work both in the home workshop and on the road. The universal model supports three types of bending and interacts with both round and profile pipes. The device is equipped with thermally hardened prefabricated rollers, which allow you to independently set the dimensions of the groove; the elements are made of high-strength steel.

The hydraulic jack of the pipe bender has a lifting capacity of 10 tons and copes with workpieces of increased hardness. Allows you to work with both large and small pipes.

The average cost of a profile pipe bender APV-9 is 30,000 rubles

Metal Master APV-200

The compact but powerful hydraulic machine is capable of bending profile pipes with a maximum diameter of 60/40/2. The tool rollers are thermally hardened and have a high safety margin. There are a total of two clamping elements and one leading upper element. Thanks to the bearings, the rollers rotate easily, the side rollers can move in a horizontal plane, which provides a wide bending radius.

Important! The machine for profile pipes can be installed in a workshop, or you can take it with you to sites. The equipment fits easily into the trunk.

The average cost of a hydraulic pipe bender APV-200 starts from 69,000 rubles

Metal Master TGA 40

The hydraulic profile pipe bender allows you to deform square and round pipes, as well as bend reinforcement and steel strips. Suitable also for the manufacture of railings, greenhouse elements and decorative parts. Suitable for both home and industrial use, the machine is used in construction, mechanical engineering and instrument making.

Demonstrates high resistance to operational loads. It is quite easy to operate, the workpiece is fed manually, and the hydraulic clamp ensures fast and accurate deformation. Suitable for processing profile pipes with a diameter of up to 40 mm.

You can buy a TGA 40 hydraulic machine from 20,000 rubles

Top 5 best manual pipe benders for profile pipes

Hand tools for bending profiles can be either mechanical or hydraulic. But both types of models are easy to use, moderate in cost and reliable.

Stalex HTR-40

A universal pipe bender for steel profiles with adjustable rollers allows you to roll workpieces with a diameter of 15-40 mm and a wall thickness of 1.5 mm. The bending radius can be changed quickly and easily during the process. The manual machine is equipped with hydraulics with a lifting capacity of 2 tons, there are return springs that bring the pressure roller back to the upper position without effort on the part of the user.

A compact and powerful pipe bender is suitable for making railings, canopies, canopies and other structures that use profile pipes. Since the machine is operated manually, it can be used anywhere, regardless of the availability of electricity.

You can buy a pipe bender HTR-40 from 16,000 rubles

Proma KO-200

The machine is designed for cold bending of steel rods, profile pipes and metal strips; it works with medium-hard materials. Equipped with a wide base for greater stability, it can also be mounted on a workbench using four holes. It is lightweight and small in size, making it easy to transport. Suitable for processing square and round pipes, the maximum bending angle is 200°.

You can buy a Proma profile pipe bender from 13,000 rubles

Stalex TR-60

A manual pipe bender with an extended working lever allows you to easily give the desired bend to metal workpieces with minimal force. The body is equipped with a ruler to control the deformation radius; the machine works with square and round pipes of 15-38 mm. Made of powder coated steel, suitable for stationary and tabletop installation.

Important! The disadvantage of the model can be considered the lack of rollers for working with profile pipes in the kit. However, they can be purchased separately.

The average price of Stalex TR-60 starts from 16,000 rubles

Blacksmith MTB10-40

A manual pipe bender without an electric drive or hydraulics, however, is simple and reliable. The machine is equipped with three rollers - between them you need to clamp the workpiece and turn the handle to accurately bend the pipe. The angle is adjusted using the upper roller; it is pressed harder or weaker.

The effort required from the user is minimal; the budget machine is very functional and easy to use. The only negative is that in the absence of experience, controlling the flexion angle may cause difficulties.

The average cost of MTB10-40 starts from 14,000 rubles

Smart & Solid BendMax-300

The manual profile bender is designed to work with 50/30/2 mm pipes. The machine is made of durable steel with a two-layer zinc coating and is reliably protected from corrosion. Among the advantages are reliability, high-quality assembly and ease of operation. The tool can be used both at home and in small workshops.

You can purchase a bender for profile pipes BendMax-300 from 18,000 rubles

Required design elements

The operating diagram of a pipe bender is very simple

To make a pipe bender with your own hands, you can use drawings of various designs. Their choice is determined mainly by what materials you have. Most often they opt for front-type pipe benders, the design of which includes:

- three rollers (shafts), which must be metal;

- drive chain;

- axes of rotation;

- a mechanism that will set in motion all elements of the device;

- metal profiles from which the frame of the device will be made.

Very often, a machine for bending profile pipes is made with rollers made of wood or polyurethane. When choosing such materials, you should take into account the strength characteristics of the pipes that will be subject to bending. If you neglect this requirement, then the working elements of the homemade device may simply not withstand the load and collapse.

Drawing of a pipe bender: the sectional view shows the mounting structure of the pressure roller

To understand how to bend a profile pipe on a homemade device, it is important to understand the technology used for this process. As a rule, pipe benders use the rolling or rolling principle, which minimizes the risk of kinking and damage to the pipe.

To make a bend on a profile pipe using such a device, it must be inserted between the rollers of the pipe bender and turn the handle. The use of such a simple bending device allows you to obtain bends on a profile pipe that fully comply with the specified parameters.

Pipe bender using a jack

To make a simple machine for bending profile pipes, you will need the following structural elements:

- ordinary jack;

- metal profiles and shelf necessary for making the frame;

- springs with high strength;

- shafts in the amount of 3 pieces;

- drive chain;

- a number of other structural elements.

When using such a device, the operation of which can be seen in one of the videos below, the pipe is laid on two side rollers, and a third one is lowered on top of it, creating the required force. To give the pipe the necessary bend, you need to rotate the handle that drives the chain and, accordingly, the equipment shafts.

Option with inverted jack

Rating of pipe benders for round pipes

In production, repairs and decorative work, it is necessary to bend not only profiles, but also round blanks. Several models of manual pipe benders are in demand.

Rothenberger Minibend

The mobile hand-held pipe bender weighs only 420 g and is suitable for bending round pipes at an angle of up to 180°. Works with copper, aluminum and brass workpieces, and copes with thin-walled steel. Supports pipe diameters of 6-10 mm. Among the disadvantages, users note only a small range of applications.

Advice! The pipe bender is best suited for repairing refrigeration units and for plumbing work.

The average cost of a Rothenberger pipe bender starts from 2,700 rubles

YATO

A very budget-friendly Chinese manual pipe bender is designed to work with workpieces with a diameter of up to 20 mm. Equipped with a measuring scale for setting the bend angle and a lock for stopping the tool at the right time. It is not suitable for deforming large and high-strength pipes, but it copes well with basic household tasks.

You can buy a YATO pipe bender for only 700 rubles

Force 653180

A manual pipe bender with a long handle is designed to change the geometry of pipes with a thickness of 6-20 mm. Made from a metal alloy, it is highly durable and interacts even with steel. Performs bending up to 180°. The design of the equipment is simple, the instrument can be easily transported.

The price of the Force pipe bender starts from 1200 rubles

Brands, brands, manufacturers

From the rich variety of foreign and Russian manufacturers, the following companies can be distinguished, based on customer reviews:

- Manual pipe benders: “Stalex” (main production is in Europe), “Smart&solid” (St. Petersburg).

Pipe bender Smart&Solid BendMax-200. Photo ForgingPRO

- Hydraulic pipe benders: “Stels” (Russian brand, production concentrated in China), “Renza” (for thick pipes, China).

Hydraulic pipe bender Stalex HB-60 Premium. Photo VseInstruments.ru

- Electromechanical pipe benders: “Blacksmith” (a popular Chinese manufacturer of equipment for cold forging in Russia).

Rating of the best electric pipe benders

Electrically driven pipe benders for regular and profile pipes are of particular interest. To work with them, you do not need to put in any effort; automation is responsible for the entire process of deforming the workpieces. But the cost of such machines is very high; they are usually purchased for production purposes.

3RE-30 Junior

An electromechanical machine with two drive rollers guarantees high bending accuracy for 30 mm round pipes and profile workpieces. Equipped with a remote hand-held control panel, it operates in horizontal and vertical positions. Does not require specialized commissioning before use.

You can purchase an electric pipe bender 3RE-30 Junior from 160,000 rubles

Tor HHW-G76

The Russian machine for round and profile pipes with a maximum diameter of 80 mm is equipped with a 2 kW motor. Control is carried out through a manual or foot drive; the pressure roller is adjusted manually. After setting the desired angle and placing the workpiece, all that remains is to put the device into operation. To increase the bending angle, reverse rolling is provided. The machine carefully deforms profile pipes without flattening or breaking them.

You can buy a pipe bending machine HHW-G76 from 79,000 rubles

BMK-55U

The three-roll production pipe bender handles workpieces up to 80 mm in one pass. Works with steel, chrome-plated, nickel-plated pipes and does not even damage the polymer or paint coating. Due to two screw clamping systems, it ensures high bending accuracy, and control is carried out through a remote control panel.

The cost of the BMK-55U machine starts from 515,000 rubles