DIY heating register

Today we will tell you how to make a heating register with your own hands, as they say, from what is on the farm, because this is what usually happens. We will talk about how to make a drawing of the future design and how to connect the registers to the heating. You can calculate the length of the sections and their number based on an existing pipe of a certain cross-section, or make a calculation for purchasing a new rental. If the production of heating registers is supported by the desire to save money, hiring an experienced welder is out of the question. Yes, and there is nothing complicated there. You will soon see this for yourself.

Serpentine registers (S-shaped)

Such registers have become quite popular. The design of these devices is quite simple: there are several sections that are connected by arcs, the diameter of which is close to the sectional ones. Due to this, the hydraulic pressure inside the device is significantly reduced. As a result, the register becomes a single unit, the entire surface of which is working, which significantly increases the efficiency of such devices.

Such heating registers made of smooth pipes usually contain a large amount of carbon. In addition, registers made of other materials can be found on the market: cast iron, alloy or stainless steel.

Combined instruments

Any device can be supplemented with a heating element, this way a combined heating device is obtained. It may not be associated with the system, and can be used separately.

If this is an isolated register with heating only from the heating element, then an expansion tank must be installed in its upper part. Its capacity should not be less than 10% of the capacity of the heating device. For steel registers, closed tanks should be installed.

Such steel structures are a great help in very cold times, when the heating capabilities of the boiler become limited. This option is very practical during the off-season, when it is not advisable to use the network at full capacity. After all, the room at this time only needs a little warming up.

Heat dissipation of registers

The heat transfer of registers made of steel pipes is the transfer of heat energy between the battery and the environment. Heating devices made from smooth pipes are less economically profitable.

The heat output of one meter of these structures is approximately 550 W, for a diameter from 3.2 to 21.9 cm. Welding installation work is recommended to be carried out so that mutual heating of the elements does not occur.

Under such conditions, the heat transfer rate becomes higher. If the register is assembled correctly, it becomes a reliable and durable steel heating device. Optimizing the heat transfer of a steel pipeline is decided at the design stage of its structure. To do this, use the following methods.

- Change of infrared radiation in the direction of increase. This can be done using paint.

- Ribs are installed, which also increases the required design performance.

But, there are cases when these indicators need to be reduced. Such actions are required by sections of the pipeline that pass outside residential premises. In these situations, the line is thermally insulated.

Calculations are carried out in this way: Q = K*F*dT. In this formula, Q denotes the thermal transfer coefficient, K is the thermal conductivity of steel materials, and F shows the length of the pipe taken for calculations. dT in this formula is the sum of the initial and residual temperatures, taking into account the room temperature.

Advantages and disadvantages of heating radiators

The designation dT is also called temperature difference. You can find out by adding the temperature at the outlet of the boiler equipment with the numbers at its input. The resulting readings are multiplied by 0.5 or divided by two. The room temperature is subtracted from this value.

If the steel heating pipeline is in insulating material, then the resulting number should be multiplied by the efficiency of the insulating material. It shows the percentage of thermal energy of the heating system released during the flow of the coolant.

If you want to design a system competently, then you should not select steel pipe assortment by eye. Correct calculations in this case not only make it possible to reduce the cost of construction work, but also to install a heating system that will work effectively for a long time.

Installation of steel registers

Installation of steel pipe registers is carried out in two ways. The first is threaded connections, and the second is through welding. In this matter, solutions are selected based on the total weight of the structure, its dimensions and characteristics.

The process itself is similar to the work when connecting radiators. The difference lies only in the geometric volumes of the structure. If there is a question of connecting the heating device to gravity networks, then the required slope standards must be observed.

The register must be tilted towards the movement of the coolant. For a pipeline with natural circulation, the described standards are not required.

The rules that are used for the correct connection of structures made of steel pipes are as follows:

- Minimum distances from windows and walls should be maintained. This distance is 20 cm. These indentations are needed for ease of repair maintenance.

- When using threaded connections to connect the device, it is recommended to use only gaskets made of paronite, or flax, which is used in plumbing work.

- Each steel appliance must be painted after installation. Otherwise, rust can form on its surface very quickly. At the same time, the thermal conductivity index is slightly reduced, but its maintenance-free service life is extended.

- All installation work should not be planned for the heating season. After a trial check and comparison of the calculated power of the device, it may be necessary to promptly make changes to the design.

Steel radiators. Why NOT use when replacing heating radiators with steel pipes.

Among the installation features, two mounting options can be distinguished. The first is by hanging the device on the wall, and the second is by mounting it on racks. The decision in this situation depends on the weight and dimensions of the device and the type of walls.

The combined version of fastening the structure has become very popular. To do this, first prepare the racks, and then attach them to the walls.

This method is suitable even for very heavy heating devices and guarantees a high level of safety. We must not forget about air vents; they complement every heating device. The collected air is released from the line through the air vent.

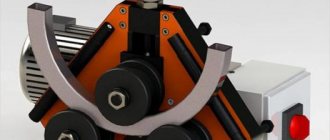

Sectional registers made of smooth pipes

Sectional registers are in very good demand among owners of private houses. Such devices consist of pipes that are interconnected and closed with plugs. The energy carrier passes through the top pipe, enters the next one, and ultimately ends up in the discharge line. To increase heat transfer, they try to make transitions between sections as close to the edge as possible. Interpipe plugs can be elliptical or flat. The inlet pipe can be made with a flange, thread or welding. The design of sectional registers includes a threaded fitting, to which a special vent is attached to remove air from the system. Pipes for sections can have different diameters (from 25 mm to 40 cm), so choosing the appropriate option is not difficult. Transition pipes usually have a smaller diameter. In addition, one of the most important operating conditions for such installations is the pressure in the system not exceeding 1 MPa.

Design features

Essentially, a register is one or more pipes connected to each other in parallel

Here it is important to create conditions so that the coolant flows sequentially from one pipe to another, releasing heat into the room. Therefore, two types of registers are made

Sectional

Several parallel pipes, the ends of which are closed with plugs. Jumpers are installed between them, through which the coolant flows from one section to another. It moves from top to bottom, that is, it enters the upper pipe and comes out of the lower one.

Important! The jumpers are installed in a checkerboard pattern. If between the first and second sections the jumper is installed on the left, then between the second and third - on the right

The diameter of the jumpers is much smaller than the diameter of the sections. For example, if the diameter of the main register element is 80 mm, then the jumpers are 32-40 mm.

Serpentine, their drawing

This is the same design, only the sections are connected to each other by double 90° bends of the same diameter as the main pipes, and a continuous pipe structure of one large diameter along the entire length is obtained. The heat transfer of this type of register is much higher than that of the previous version.

Photo 1. Drawing of a coil-type register, which is a continuous pipe structure of the same diameter along the entire length.

The advantages of the design include the low hydraulic pressure of the coolant inside the device, which allows a sufficiently large volume of hot water to pass through it.

Reference! The coil can be installed either horizontally or vertically.

Location options

Heating registers, depending on placement options, can be divided into two groups: portable and stationary. Portable systems are quite mobile, and they can be moved absolutely freely - if only there was power. And such systems are usually powered by electricity. Inside portable registers there are usually heating elements of different power, which provide heating of the energy carrier. Such units can be used both in the house and in the garage, at the dacha, at a construction site, etc. Stationary registers are demanding in terms of their location. Firstly, they require permanent mounting, and secondly, they need to be connected to a boiler, which will ensure heating of the coolant and its circulation through the system.

Reduced heat transfer.

In order to save energy, it becomes important to reduce the heat transfer of pipes in those sections of communications that are not used for their intended purpose, for example, when moving from one building to another or in an unheated room.

There are many options for using thermal insulation materials for this. Manufacturers offer a fairly wide range to choose from, ranging from cheap fiberglass to more expensive types of polystyrene foam. You can purchase pipes with insulating elements already built into them.

To summarize, we conclude that the use of such calculations helps to significantly save money and avoid many technical obstacles when designing water and heat supply systems.

Actually, you are a desperate person if you decide to undertake such an event. The heat transfer of a pipe, of course, can be calculated and there are a great many works on the theoretical calculation of the heat transfer of various pipes.

Let's start with the fact that if you decided to heat your house with your own hands, then you are a stubborn and purposeful person. Accordingly, a heating project has already been drawn up, pipes have been selected: either metal-plastic heating pipes or steel heating pipes. Heating radiators have also already been looked at in the store.

But, before acquiring all this, that is, at the design stage, it is necessary to make a conditional relative calculation. After all, the heat transfer of heating pipes, calculated in the project, is the key to warm winters for your family. There is no room for error here.

Methods for calculating heat transfer from heating pipes

Why is the emphasis usually placed on calculating the heat transfer of heating pipes? The fact is that for commercially manufactured heating radiators, all these calculations have been made and are given in the instructions for use of the products. Based on them, you can easily calculate the required number of radiators depending on the parameters of your home: volume, coolant temperature, etc.

Tables.

This is the quintessence of all the necessary parameters collected in one place. Today the Internet contains a great many tables and reference books for online calculations of heat transfer from pipes. In them you will learn what is the heat transfer of a steel pipe or cast iron pipe, the heat transfer of a polymer or copper pipe.

All that is needed when using these tables is to know the initial parameters of your pipe: material, wall thickness, internal diameter, etc. And, accordingly, enter into the search the query “Table of heat transfer coefficients of pipes.”

This section on determining the heat transfer of pipes also includes the use of manual reference books on heat transfer of materials. Although they are becoming more and more difficult to find, all information has migrated to the Internet.

Formulas.

The heat transfer of a steel pipe is calculated according to the formula

Qtr=1.163*Str*k*(Twater - Air)*(1-efficiency of pipe insulation), W where Str is the surface area of the pipe, and k is the heat transfer coefficient from water to air.

The heat transfer of a metal-plastic pipe is calculated using a different formula.

Where is the temperature on the inner surface of the pipeline, °C; t

c is the temperature on the outer surface of the pipeline, °C;

Q—

heat flow, W;

l

—pipe length, m;

t

—coolant temperature, °C;

t

inc—air temperature, °C;

a n is the external heat transfer coefficient, W/m 2 K; d

n - outer diameter of the pipe, mm;

l—thermal conductivity coefficient, W/m K; d

in

-

internal diameter of the pipe, mm; a int - internal heat transfer coefficient, W/m 2 K;

You understand perfectly well that calculating the thermal conductivity of heating pipes is a relative value. The formulas include the average parameters of certain indicators, which may, and do, differ from those that actually exist.

For example, as a result of the experiments, it was found that the heat transfer of a polypropylene pipe located horizontally is slightly lower than that of steel pipes of the same internal diameter, by 7-8%. It is internal, since polymer pipes have a slightly thicker wall thickness.

Many factors influence the final figures obtained in tables and formulas, which is why the footnote “approximate heat transfer” is always included. After all, the formulas do not take into account, for example, heat loss through the building envelope made of different materials. There are corresponding tables of amendments for this purpose.

However, by using one of the methods for determining the heat output of heating pipes, you will have a general idea of what kind of heating pipes and radiators you need for your home.

Good luck to you, builders of your warm present and future.

Material of manufacture

If you make a selection depending on the material of manufacture, then the registers can be classified into the following categories:

- Steel;

- Aluminum;

- Cast iron.

Which heating registers are best to choose? Steel registers became the most common. Their connection to the heating system is carried out by threading or welding. Such devices have good heat transfer and reasonable cost. Aluminum registers are much lighter than steel registers. In addition, they are resistant to corrosion, are made without connecting seams and have good heat dissipation. The main disadvantage of such devices is their very high price. Read also: “What types of heating registers are there – selection, calculation, characteristics.” Registers made of cast iron are connected to the heating system using a flange connection. They are quite easy to install and inexpensive. The disadvantages of cast iron products include low inertia, which significantly reduces the heating time of the registers.

Calculation of the number of ribs

Heating registers must be calculated before purchasing them. The diameter of the pipes is very important: experts believe that pipes with a cross-sectional diameter in the range from 3 cm to 8 cm are suitable for a private house. This decision is determined by the fact that a conventional heating boiler is not capable of producing a larger amount of heat, so too large surfaces will not warm up completely . When making calculations, you need to pay attention to the length of one register rib and the heat transfer per meter of this length. For example, a meter-long pipe with a 6-centimeter cross-section can heat one square meter of area. When calculating the required number of edges, the result must be rounded up. The calculation of the number of heating registers must also take into account the characteristics of the building. For example, if a building has a large number of windows and doors, or if the walls are thin and poorly insulated, then the number of registers can be increased by 20-50%.

Heating register installation

Installing heating registers usually does not require the help of a qualified specialist, but carrying out the operation yourself requires careful preparation. The most important thing is to ensure a reliable connection between the registers and the pipeline. The connection must be able to withstand a load of 10 MPa. When welding, it is very important to maintain good quality. For clarity, you can look at the photo, which shows a diagram of connecting heating registers.

It is best to place registers along the walls. A prerequisite for installing heating devices is maintaining a constant slope, which for registers is 0.05% of its length. In addition, registers should be installed closer to the floor surface.

The efficiency of the device will depend on a large number of factors. For example, a reduced main pipe diameter will increase resistance to the energy carrier, which will affect performance. The most commonly used systems are with the following parameters:

- pipe diameter: 25-160 mm;

- sectional adapters: from 30 mm;

- distance between main pipes: from 50 mm;

- maximum pressure: 10 MPa;

- material: steel.

Operating rules

There are no special requirements for the operation of registers compared to radiators:

They must be securely mounted on legs or strong brackets.

Any heating devices with water should not freeze.

If corrosion occurs, the damaged areas should be cleaned, covered with an anti-corrosion primer and painted in several layers.

Registers must not serve as a support for any loads.

It is necessary to ensure that the heating system does not become airy - this impairs its performance.

Advantages of heating registers

Heating registers have a number of advantages:

- possibility of using an individual drawing;

- The coolant can be not only water, but also heated steam;

- connecting the heating register to the system is extremely simple;

- excellent for heating large buildings because they have very good heat transfer;

- They're pretty cheap.

A homemade heating register is shown in the video: Conclusion Registers have already become good competitors to conventional heating radiators. Do-it-yourself heating registers allow you to save a lot, and these designs can work even in rooms with an aggressive environment.

Conclusions and useful video on the topic

You can learn about the sequence of manufacturing a heating register from a profile pipe and the secrets of welding from the video:

Homemade heating equipment continues to be actively made and used in rural areas or in private industries for heating office technical premises. But many refuse to use such irrational structures, especially where metering and monitoring devices for coolant consumption are being introduced.

Would you like to tell us how you assembled a register for your garage or cottage with your own hands? Do you have information that could be useful for DIYers? Please write comments in the block below, share useful information and photos on the topic of the article, and ask questions.