Cable weight is the most important characteristic of a power line, taken into account when carrying out electrical installation work. Expressed in kilograms per kilometer of conductor, it depends on the material from which the conductors are made, their number, and cross-sectional area. Also, this calculation sometimes takes into account such characteristics of cable products as the thickness and material of the insulating layer of its conductive cores and outer sheath.

Cable calculator for calculating weight and length

VVG and VVGng

| Number of cores, nominal cross-section, mm2 | Core cross-sectional shape | Cable outer diameter, mm | Cable weight, kg/km |

| 1x1.5 | cool* RE* | 5,4 | 43 |

| 1x2.5 | 5,8 | 55 | |

| 1x4 | 6,6 | 78 | |

| 1x6 | 7,1 | 100 | |

| 1x10 | 7,9 | 143 | |

| 1x16 | 9,5 | 215 | |

| 1x25 | 11 | 316 | |

| 1x35 | 13 | 418 | |

| 1x50 | 13,5 | 554 | |

| 1x70 | R.M. | 16,5 | 797 |

| 1x95 | 19 | 1086 | |

| 1x120 | 20,7 | 1345 | |

| 1x150 | 22,6 | 1668 | |

| 1x185 | 24,8 | 2014 | |

| 1x240 | 27,6 | 2535 | |

| 2x2.5 | cool RE | 9,8 | 120 |

| 2x4 | 11,5 | 168 | |

| 2x6 | 12,5 | 212 | |

| 2x10 | 14,1 | 302 | |

| 2x16 | 16 | 425 | |

| 2x25 | 19,4 | 646 | |

| 3x2.5 | cool RE | 10,3 | 154 |

| 3x4 | 12,2 | 221 | |

| 3x6 | 13,2 | 285 | |

| 3x10 | 15 | 414 | |

| 3x16 | 16,9 | 594 | |

| 3x25 | 20,6 | 909 | |

| 3x35 | cool* SE* | 20,6 | 1216 |

| 3x50 | 23,8 | 1640 | |

| 3x70 | S.M. | 27,8 | 2325 |

| 3x95 | 31,5 | 3102 | |

| 3x120 | 34,5 | 3920 | |

| 3x150 | 37,2 | 4666 | |

| 3x185 | 41,6 | 5839 | |

| 3x2.5+1x1.5 | cool RE/RE | 11,2 | 181 |

| 3x4+1x2.5 | 12,8 | 256 | |

| 3x6+1x4 | 14,4 | 342 | |

| 3x10+1x6 | 16,4 | 492 | |

| 3x16+1x10 | 19 | 712 | |

| 3x25+1x16 | 22,7 | 1087 | |

| 3x35+1x16 | SE/RE* | 22,5 | 1410 |

| 3x50+1x25 | SE/RE* | 26,2 | 1937 |

| 3x70+1x35 | SM/SE* | 31 | 2786 |

| 3x95+1x50 | SM/SE* | 35,9 | 3756 |

| 3x120+1x70 | SM/SM | 39,7 | 4634 |

| 3x150+1x70 | SM/SM | 43 | 5677 |

| 4x2.5 | cool RE | 11,2 | 191 |

| 4x4 | 13,3 | 278 | |

| 4x6 | 14,4 | 361 | |

| 4x10 | 16,4 | 531 | |

| 4x16 | 19 | 768 | |

| 4x25 | 22,7 | 1178 | |

| 4x35 | cool* SE* | 25,4 | 1596 |

| 4x50 | 28,2 | 2370 | |

| 4x70 | S.M. | 31,7 | 3052 |

| 4x95 | 36,6 | 4184 | |

| 4x120 | 39,7 | 5127 |

AVVG and AVVGng

| Number of cores, nominal cross-section, mm2 | Core cross-sectional shape | Cable outer diameter, mm | Cable weight, kg/km |

| 1x2.5 | cool* RE* | 5,8 | 40 |

| 1x4 | 6,7 | 55 | |

| 1x6 | 7,2 | 64 | |

| 1x10 | 7,9 | 82 | |

| 1x16 | 9,5 | 120 | |

| 1x25 | 11 | 163 | |

| 1x35 | 12 | 201 | |

| 1x50 | 13,5 | 260 | |

| 1x70 | 15 | 334 | |

| 1x95 | 19 | 493 | |

| 1x120 | 20,7 | 586 | |

| 1x150 | R.M. | 22,6 | 710 |

| 1x185 | 24,8 | 678 | |

| 1x240 | 27,6 | 1056 | |

| 2x2.5 | cool RE | 9,8 | 89 |

| 2x4 | 11,6 | 119 | |

| 2x6 | 12,6 | 141 | |

| 2x10 | 14,2 | 181 | |

| 2x16 | 15,8 | 228 | |

| 2x25 | 19,3 | 338 | |

| 3x2.5 | cool RE | 10,3 | 107 |

| 3x4 | 12,2 | 148 | |

| 3x6 | 13,2 | 178 | |

| 3x10 | 15 | 233 | |

| 3x16 | 17 | 305 | |

| 3x25 | 20,7 | 456 | |

| 3x35 | cool* SE* | 20,1 | 563 |

| 3x50 | 22,9 | 734 | |

| 3x70 | 26 | 966 | |

| 3x95 | 29,4 | 1258 | |

| 3x120 | 31,8 | 1507 | |

| 3x150 | 35 | 1829 | |

| 3x185 | 38,4 | 2224 | |

| 3x240 | 43,3 | 2834 | |

| 3x4+1x2.5 | cool* RE/RE* | 12,9 | 168 |

| 3x6+1x4 | 14,5 | 211 | |

| 3x10+1x6 | 16,5 | 275 | |

| 3x16+1x10 | 17,5 | 355 | |

| 3x25+1x16 | 21,3 | 527 | |

| 3x35+1x16 | cool* SE/RE* | 22,1 | 642 |

| 3x50+1x25 | 25,8 | 875 | |

| 3x70+1x35 | 28,7 | 1119 | |

| 3x95+1x50 | 32,6 | 1461 | |

| 3x120+1x70 | 36 | 1806 | |

| 3x150+1x50 | 38,3 | 2037 | |

| 3x150+1x70 | 38,7 | 2102 | |

| 3x185+1x50 | 41,8 | 2430 | |

| 3x185+1x95 | 42,6 | 2585 | |

| 3x240+1x120 | SE/SE* | 48,1 | 3326 |

| 4x2.5 | cool RE | 11,2 | 129 |

| 4x4 | 13,3 | 180 | |

| 4x6 | 14,5 | 219 | |

| 4x10 | 16,5 | 290 | |

| 4x16 | 19 | 400 | |

| 4x25 | 22,8 | 574 | |

| 4x35 | cool* SE* | 22,6 | 719 |

| 4x50 | 26,1 | 964 | |

| 4x70 | 29,2 | 1240 | |

| 4x95 | 33,1 | 1623 | |

| 4x120 | 36,4 | 1981 | |

| 4x150 | 39,6 | 2370 | |

| 4x185 | 43,4 | 2888 | |

| 4x240 | 49,2 | 3734 |

AVBVng and VBVng

| Number of cores, nominal cross-section, mm2 | Core cross-sectional shape | Cable outer diameter, mm | Cable weight, kg/km |

| 3x25 | coolant (RE) | 35,8 | 1494 |

| 3x35 | cool* SE* | 34,7 | 1671 |

| 3x50 | 36,6 | 1881 | |

| 3x70 | 39,3 | 2270 | |

| 3x95 | 42,6 | 2608 | |

| 3x120 | 45 | 2947 | |

| 3x150 | 47,3 | 3312 | |

| 3x25 | coolant (RE) | 35,8 | 1734 |

| 3x35 | cool* SE* | 34,8 | 2270 |

| 3x50 | 36,7 | 2750 | |

| 3x70 | S.M. | 41,1 | 3660 |

Why you need to know the weight of the cable:

An online cable weight calculator is necessary to calculate the load on cable-supporting structures, calculate the weight of future equipment or cable drum, and also select the appropriate type of transport for delivery.

It is simply impossible to constantly remember the characteristics of all types of cables, brand sizes and manufacturers, and using reference books to calculate weight is inconvenient.

Now you can forget about searching for information in a variety of paper publications and specifications. The online service “Calculation of cable weight” will instantly provide information about how many kilograms the brand of cable you have chosen weighs.

ASB, ASBG, ASBl, ASB2l, TsASB, TsASBG, TsASBL, TsASB2l

| Voltage, U (Uo/U) kV | Number of cores, nominal cross-section, mm2 | Core cross-sectional shape | Cable outer diameter, mm | Cable weight, kg/km |

| 1 (1/1) | 3×35 | cool* SE* | 28,2 | 1805 |

| 3×50 | 30,3 | 2091 | ||

| 3×70 | 33,1 | 2522 | ||

| 3×95 | 36,1 | 3026 | ||

| 3×120 | 39,3 | 3578 | ||

| 3×150 | 41,7 | 4177 | ||

| 3×185 | 45,2 | 4898 | ||

| 3×240 | 49,5 | 5895 | ||

| 3×35+1×16 | cool* SE/RE* | 30,1 | 2053 | |

| 3×50+1×25 | 32,8 | 2483 | ||

| 3×70+1×35 | 35,8 | 2985 | ||

| 3×95+1×50 | 39,3 | 3608 | ||

| 3×120+1×70 | 42,8 | 4273 | ||

| 3×150+1×70 | 45 | 4900 | ||

| 3×150+1×50 | 44,2 | 4757 | ||

| 3×185+1×50 | 47,6 | 5496 | ||

| 4×35 | cool* SE* | 31,6 | 2221 | |

| 4×50 | 34,1 | 2589 | ||

| 4×70 | 37,4 | 3129 | ||

| 4×95 | 41,3 | 3919 | ||

| 4×120 | 45,1 | 4648 | ||

| 4×150 | 48 | 5311 | ||

| 4×185 | 52,2 | 6306 | ||

| 4×240 | 57,1 | 7590 | ||

| 6 (6/6) | 3×35 | cool* SE* | 34,6 | 2575 |

| 3×50 | 36,4 | 2915 | ||

| 3×70 | 39,3 | 3395 | ||

| 3×95 | 42,3 | 3940 | ||

| 3×120 | 44,8 | 4459 | ||

| 3×150 | 47,2 | 5096 | ||

| 3×185 | 50,2 | 5813 | ||

| 3×240 | 54,4 | 6873 | ||

| 10 (10/10) | 3×35 | cool* SE* | 38,6 | 3150 |

| 3×50 | 40,5 | 3455 | ||

| 3×70 | 43,3 | 4018 | ||

| 3×95 | 46,3 | 4599 | ||

| 3×120 | 48,8 | 5153 | ||

| 3×150 | 51,2 | 5850 | ||

| 3×185 | 54,2 | 6597 | ||

| 3×240 | 58,2 | 7602 |

AVBbShv and AVBbShng

| Number of cores, nominal cross-section, mm2 | Core cross-sectional shape | Cable outer diameter, mm | Cable weight, kg/km |

| 1x50 | cool* RE* | 16,6 | 481 |

| 1x70 | 19,2 | 626 | |

| 1x95 | 22,2 | 821 | |

| 1x120 | 24,3 | 998 | |

| 1x150 | R.M. | 24,6 | 1030 |

| 1x185 | 26,6 | 1195 | |

| 1x240 | 31,7 | 1591 | |

| 1x300 | 33,9 | 1778 | |

| 1x400 | 37,5 | 2248 | |

| 1x500 | 40,6 | 2642 | |

| 1x625 | 44,3 | 3145 | |

| 1x800 | 53 | 4100 | |

| 2x4 | cool* RE* | 15,2 | 390 |

| 2x6 | 16,3 | 439 | |

| 2x10 | 17,8 | 526 | |

| 2x16 | 19,4 | 615 | |

| 2x25 | 22,6 | 669 | |

| 2x35 | 24,9 | 812 | |

| 2x50 | 27,9 | 989 | |

| 3x2.5 | cool RE | 14 | 329 |

| 3x4 | 16 | 420 | |

| 3x6 | 19,1 | 510 | |

| 3x10 | 20,9 | 594 | |

| 3x16 | 21,5 | 598 | |

| 3x25 | 25,2 | 807 | |

| 3x35 | cool* SE* | 24,2 | 881 |

| 3x50 | 27,4 | 1120 | |

| 3x70 | 30,1 | 1372 | |

| 3x95 | 33,5 | 1714 | |

| 3x120 | 36 | 2000 | |

| 3x150 | 39,2 | 2370 | |

| 3x185 | 42,6 | 2816 | |

| 3x240 | 47,9 | 3545 | |

| 3x4+1x2.5 | cool RE/RE | 15 | 362 |

| 3x6+1x4 | 20,4 | 563 | |

| 3x10+1x6 | 22,3 | 668 | |

| 3x16+1x10 | 22 | 655 | |

| 3x25+1x16 | 25,9 | 887 | |

| 3x35+1x16 | coolant* SE/RE | 26,7 | 1016 |

| 3x50+1x25 | 29,9 | 1276 | |

| 3x70+1x35 | 32,9 | 1564 | |

| 3x95+1x50 | 37,2 | 2000 | |

| 3x120+1x70 | 40,1 | 2358 | |

| 3x150+1x50 | 42,5 | 2624 | |

| 3x150+1x70 | 42,9 | 2696 | |

| 3x185+1x50 | 46,3 | 3114 | |

| 3x185+1x95 | 47,2 | 3282 | |

| 3x240+1x120 | SE/SE* | 52,3 | 4061 |

| 4x2.5 | cool RE | 15 | 362 |

| 4x4 | 17,1 | 472 | |

| 4x6 | 20,4 | 569 | |

| 4x10 | 22,3 | 681 | |

| 4x16 | 23,2 | 702 | |

| 4x25 | 27,3 | 959 | |

| 4x35 | cool* SE* | 27,1 | 1100 |

| 4x50 | 30,3 | 1372 | |

| 4x70 | 33,3 | 1694 | |

| 4x95 | 37,6 | 2172 | |

| 4x120 | 40,5 | 2542 | |

| 4x150 | 43,7 | 2979 | |

| 4x185 | 48 | 3600 | |

| 4x240 | 53,3 | 4487 |

AVBbShv

| Number of cores, nominal cross-section, mm2 | Core cross-sectional shape | Cable outer diameter, mm | Cable weight, kg/km |

| 1x240+2x1 | round multi-wire round stranded | 31,7 | 1591 |

| 1x300+2x1 | 33,9 | 1778 | |

| 1x400+2x1 | 37,4 | 2248 | |

| 1x500+2x1 | 40,6 | 2642 | |

| 1x625+2x1 | 44,3 | 3145 | |

| 1x800+2x1 | 53 | 4100 |

How to distinguish a cable with two twisted pairs from 4x.

Any copper cable for transmitting electrical signals has information

with brief characteristics. In my case it was “KSSPV 2x2x0.52”.

KSSPV -

This is

a symmetrical communication

cable

with polyethylene insulation

and

a polyB

inyl

chloride sheath.

2x2 – number of pairs and copper cores

in one cable

.

In my case, this means that the wire has two twisted pairs, each of which consists of two intertwined copper strands.

EVBV, EVBVng, EVBVk, EVBVkng, EPvBV, EPvBVng

| Voltage, U (Uo/U) kV | Number of cores, nominal cross-section, mm2 | Core cross-sectional shape | Cable outer diameter, mm | Cable weight, kg/km |

| 1,2 | 3x16/10 | cool* RE* | 23,1 | 1321 |

| 3x25/10 | 26,8 | 1797 | ||

| 3x35/110 | R.M. | 28,9 | 2178 | |

| 3x50/10 | 32,2 | 2754 | ||

| 3x70/10 | 40,8 | 4346 | ||

| 3x95/10 | 44,6 | 5201 | ||

| 3x120/10 | 47,8 | 6105 | ||

| 6 | 3x16/10 | cool* RE* | 35,3 | 2320 |

| 3x25/10 | 37,7 | 2766 | ||

| 3x35/10 | R.M. | 39,8 | 3196 | |

| 3x50/10 | 42,2 | 3752 | ||

| 3x70/10 | 50,9 | 5585 | ||

| 3x95/10 | 53,8 | 6404 | ||

| 3x120/10 | 57 | 7431 |

Table of copper weight in KG cables - “VTOR-DNEPR - Reception of recyclable materials”

21.12.14 22:47

Calculation example

If the cable has a sheath (lead or aluminum), then using the formula below you can calculate its weight in 1 linear meter of cable:

m (gram) = p x 3.14 × 100 (cm) x (R2 (cm) - r2 (cm))

p - metal density (lead - 11.3; aluminum - 2.9) R - outer radius of the shell (cm)

r - internal radius of the shell (cm)

Example 1: Cable ААШв 4×120. Four aluminum conductors with a cross section of 120 sq. mm. 4 × 0.324 g = 1.296 kg per 1 linear. m

and aluminum shell 2.9 × 3.14 × 100 x (22 - 1.852) = 526 g.

Example 2: MCSB cable 4×4 × 1.2. Four copper quads with a diameter of 1.2 mm. 4 × 4 x 0.010 = 0.160 kg per 1 linear. m

and lead sheath 11.3 × 3.14 × 100 x (1.32 - 1.182) = 1056 g.

copper density = 8.9

aluminum density = 2.7

For example: Weight of copper in 1 km of cable VVG 3x1.5 = 3*1.5*8.9 = 40.05 kg per 1 km.

Cable name Copper weight, kg/km

| Cable KG 1 x 2.5 | 22,25 |

| Cable KG 1 x 4 | 35,60 |

| Cable KG 1 x 6 | 53,40 |

| Cable KG 1 x 10 | 89,00 |

| Cable KG 1 x 16 | 142,40 |

| Cable KG 1 x 25 | 222,50 |

| Cable KG 1 x 35 | 311,50 |

| Cable KG 1 x 50 | 445,00 |

| Cable KG 1 x 70 | 623,00 |

| Cable KG 1 x 95 | 845,50 |

| Cable KG 1 x 120 | 1 068,00 |

| Cable KG 1 x 150 | 1 335,00 |

| Cable KG 1 x 185 | 1 646,50 |

| Cable KG 1 x 240 | 2 136,00 |

| Cable KG 1 x 300 | 2 670,00 |

| Cable KG 1 x 400 | 3 560,00 |

| Cable KG 2 x 0.75 | 13,35 |

| Cable KG 2 x 1.0 | 17,80 |

| Cable KG 2 x 1.5 | 26,70 |

| Cable KG 2 x 2.5 | 44,50 |

| Cable KG 2 x 4 | 71,20 |

| Cable KG 2 x 6 | 106,80 |

| Cable KG 2 x 10 | 178,00 |

| Cable KG 2 x 16 | 284,80 |

| Cable KG 2 x 25 | 445,00 |

| Cable KG 2 x 35 | 623,00 |

| Cable KG 2 x 50 | 890,00 |

| Cable KG 2 x 70 | 1 246,00 |

| Cable KG 2 x 95 | 1 691,00 |

| Cable KG 2 x 120 | 2 136,00 |

| Cable KG 2 x 150 | 2 670,00 |

| Cable KG 3 x 0.75 | 20,03 |

| Cable KG 3 x 1.0 | 26,70 |

| Cable KG 3 x 1.5 | 40,05 |

| Cable KG 3 x 2.5 | 66,75 |

| Cable KG 3 x 4 | 106,80 |

| Cable KG 3 x 6 | 160,20 |

| Cable KG 3 x 10 | 267,00 |

| Cable KG 3 x 16 | 427,20 |

| Cable KG 3 x 25 | 667,50 |

| Cable KG 3 x 35 | 934,50 |

| Cable KG 3 x 50 | 1 335,00 |

| Cable KG 3 x 70 | 1 869,00 |

| Cable KG 3 x 95 | 2 536,50 |

| Cable KG 3 x 120 | 3 204,00 |

| Cable KG 3 x 150 | 4 005,00 |

| Cable KG 4 x 1.0 | 35,60 |

| Cable KG 4 x 1.5 | 53,40 |

| Cable KG 4 x 2.5 | 89,00 |

| Cable KG 4 x 4 | 142,40 |

| Cable KG 4 x 6 | 213,60 |

| Cable KG 4 x 10 | 356,00 |

| Cable KG 4 x 16 | 569,60 |

| Cable KG 4 x 25 | 890,00 |

| Cable KG 4 x 35 | 1 246,00 |

| Cable KG 4 x 50 | 1 780,00 |

| Cable KG 4 x 70 | 2 492,00 |

| Cable KG 4 x 95 | 3 382,00 |

| Cable KG 4 x 120 | 4 272,00 |

| Cable KG 4 x 150 | 5 340,00 |

| Cable KG 5 x 1.0 | 44,50 |

| Cable KG 5 x 1.5 | 66,75 |

| Cable KG 5 x 2.5 | 111,25 |

| Cable KG 5 x 4 | 178,00 |

| Cable KG 5 x 6 | 267,00 |

| Cable KG 5 x 10 | 445,00 |

| Cable KG 5 x 16 | 712,00 |

| Cable KG 5 x 25 | 1 112,50 |

| Cable KG 5 x 35 | 1 557,50 |

| Cable KG 5 x 50 | 2 225,00 |

| Cable KG 5 x 70 | 3 115,00 |

| Cable KG 5 x 95 | 4 227,50 |

| Cable KG 5 x 120 | 5 340,00 |

| Cable KG 2 x 0.75 + 1 x 0.75 | 20,03 |

| Cable KG 2 x 1 + 1 x 1 | 26,70 |

| Cable KG 2 x 1.5 + 1 x 1.5 | 40,05 |

| Cable KG 2 x 2.5 + 1 x 1.5 | 57,85 |

| Cable KG 2 x 4 + 1 x 2.5 | 93,45 |

| Cable KG 2 x 6 + 1 x 4 | 142,40 |

| Cable KG 2 x 10 + 1 x 6 | 231,40 |

| Cable KG 2 x 16 + 1 x 6 | 338,20 |

| Cable KG 2 x 25 + 1 x 10 | 534,00 |

| Cable KG 2 x 35 + 1 x 10 | 712,00 |

| Cable KG 2 x 50 + 1 x 16 | 1 032,40 |

| Cable KG 2 x 70 + 1 x 25 | 1 468,50 |

| Cable KG 2 x 70 + 1 x 35 | 1 557,50 |

| Cable KG 2 x 95 + 1 x 35 | 2 002,50 |

| Cable KG 2 x 120 + 1 x 35 | 2 447,50 |

| Cable KG 2 x 150 + 1 x 50 | 3 115,00 |

| Cable KG 3 x 2.5 + 1 x 1.5 | 80,10 |

| Cable KG 3 x 4 + 1 x 2.5 | 129,05 |

| Cable KG 3 x 6 + 1 x 4 | 195,80 |

| Cable KG 3 x 10 + 1 x 6 | 320,40 |

| Cable KG 3 x 16 + 1 x 6 | 480,60 |

| Cable KG 3 x 25 + 1 x 10 | 756,50 |

| Cable KG 3 x 35 + 1 x 10 | 1 023,50 |

| Cable KG 3 x 50 + 1 x 16 | 1 477,40 |

| Cable KG 3 x 70 + 1 x 25 | 2 091,50 |

| Cable KG 3 x 95 + 1 x 35 | 2 848,00 |

| Cable KG 3 x 120 + 1 x 35 | 3 515,50 |

| Cable KG 3 x 150 + 1 x 50 | 4 450,00 |

vtor-dnepr.com.ua

APvVG and APvVGng

| Number of cores, nominal cross-section, mm2 | Core cross-sectional shape | Cable outer diameter, mm | Cable weight, kg/km |

| 3x2.5 | cool RE | 12,8 | 173 |

| 3x4 | 13,9 | 203 | |

| 3x6 | 14,9 | 236 | |

| 3x10 | 16,6 | 296 | |

| 3x16 | 19 | 395 | |

| 3x25 | 22,4 | 538 | |

| 3x35 | cool* SE* | 21,7 | 624 |

| 3x50 | 24,5 | 800 | |

| 3x70 | 27,6 | 1033 | |

| 3x95 | 30,6 | 1306 | |

| 3x120 | 33,5 | 1579 | |

| 3x150 | 37,1 | 1924 | |

| 3x185 | 40,9 | 2346 | |

| 3x240 | 45,8 | 2967 | |

| 3x4+1x2.5 | cool RE/RE | 14,8 | 228 |

| 3x6+1x4 | 16 | 268 | |

| 3x10+1x6 | 17,9 | 338 | |

| 3x16+1x10 | 20,6 | 453 | |

| 3x25+1x16 | 23,9 | 632 | |

| 3x35+1x16 | cool* SE/RE* | 24,4 | 734 |

| 3x50+1x25 | 27,5 | 933 | |

| 3x70+1x35 | 30,6 | 1194 | |

| 3x95+1x50 | 34,5 | 1546 | |

| 3x120+1x70 | SE/SE* | 37,7 | 1885 |

| 3x150+1x50 | SE/RE* | 39,6 | 2119 |

| 3x150+1x70 | SE/SE* | 40,3 | 2186 |

| 3x185+1x50 | SE/RE* | 43 | 2531 |

| 3x185+1x95 | SE/SE* | 44,8 | 2730 |

| 4x2.5 | cool RE | 13,7 | 196 |

| 4x4 | 14,8 | 234 | |

| 4x6 | 16 | 274 | |

| 4x10 | 17,9 | 350 | |

| 4x16 | 20,6 | 471 | |

| 4x25 | 24,7 | 675 | |

| 4x35 | cool* SE* | 25,3 | 808 |

| 4x50 | 28,2 | 1012 | |

| 4x70 | 31,5 | 1310 | |

| 4x95 | 35,4 | 1700 | |

| 4x120 | 38,4 | 2050 | |

| 4x150 | 41,7 | 2454 | |

| 4x185 | 46,1 | 3037 |

Density of copper and its specific gravity - units of measurement, examples of weight calculation

The density of copper (pure), the surface of which has a reddish tint and a pinkish tint at the fracture, is high.

Accordingly, this metal also has a significant specific gravity. Due to its unique properties, primarily excellent electrical and thermal conductivity, copper is actively used for the production of elements of electronic and electrical systems, as well as products for other purposes. In addition to pure copper, its minerals are also of great importance for many industries. Despite the fact that there are more than 170 types of such minerals in nature, only 17 of them have found active use.

Copper is widely used in manufacturing

Copper density value

The density of this metal, which can be viewed in a special table, has a value equal to 8.93 * 103 kg/m3. Also in the table you can see another characteristic of copper, no less important than density: its specific gravity, which is also 8.93, but measured in grams per cm3. As you can see, for copper the value of this parameter coincides with the density value, but do not think that this is typical for all metals.

The density of this, and any other metal, measured in kg/m3, directly affects the mass of products made from this material. But to determine the mass of a future product made of copper or its alloys, for example, brass, it is more convenient to use the value of their specific gravity rather than density.

Specific Gravity Calculation

Today, many methods and algorithms have been developed for measuring and calculating not only density, but also specific gravity, which make it possible to determine this important parameter even without the help of tables. Knowing the specific gravity, which differs between different alloys of copper and pure metal, as well as the density value, you can effectively select materials for the production of parts with given parameters. It is very important to carry out such measures at the design stage of devices in which it is planned to use parts made of copper and its alloys.

APvBbShv and APvBbShng

| Number of cores, nominal cross-section, mm2 | Core cross-sectional shape | Cable outer diameter, mm | Cable weight, kg/km |

| 3x4 | cool RE | 16,7 | 400 |

| 3x6 | 17,8 | 449 | |

| 3x10 | 19,5 | 526 | |

| 3x16 | 21,5 | 635 | |

| 3x25 | 25,2 | 847 | |

| 3x35 | cool* SE* | 24,2 | 900 |

| 3x50 | 27 | 1112 | |

| 3x70 | 30,1 | 1387 | |

| 3x95 | 33 | 1700 | |

| 3x120 | 36,3 | 2046 | |

| 3x150 | 39,5 | 2404 | |

| 3x185 | 43,4 | 2877 | |

| 3x240 | 48,3 | 3557 | |

| 3x4+1x2.5 | cool RE/RE | 17,7 | 440 |

| 3x6+1x4 | 18,9 | 497 | |

| 3x10+1x6 | 20,8 | 585 | |

| 3x16+1x10 | 23 | 714 | |

| 3x25+1x16 | 26,4 | 936 | |

| 3x35+1x16 | cool* SE/RE* | 26,9 | 1045 |

| 3x50+1x25 | 30 | 1285 | |

| 3x70+1x35 | 33,1 | 1588 | |

| 3x95+1x50 | 37 | 1959 | |

| 3x120+1x70 | SE/SE* | 40,1 | 2385 |

| 3x150+1x50 | SE/RE* | 42,1 | 2646 |

| 3x150+1x70 | SE/SE* | 42,7 | 2722 |

| 3x185+1x50 | SE/RE* | 45,4 | 3103 |

| 3x185+1x95 | SE/SE* | 47 | 3325 |

| 4x4 | cool RE | 17,7 | 445 |

| 4x6 | 18,9 | 503 | |

| 4x10 | 20,8 | 598 | |

| 4x16 | 23 | 732 | |

| 4x25 | 27,1 | 990 | |

| 4x35 | cool* SE* | 27,7 | 1130 |

| 4x50 | 30,7 | 1374 | |

| 4x70 | 33,9 | 1715 | |

| 4x95 | 37,9 | 2158 | |

| 4x120 | 40,8 | 2547 | |

| 4x150 | 44,1 | 2996 | |

| 4x185 | 48,6 | 3637 |

Marking and designation

Most often, when purchasing a conductor, a welder encounters the following designations:

- KOG – specially flexible cable;

- KRPT – rubber-sheathed and insulated cable, portable type, heavy;

- KG – flexible cable.

It is the latter type that is the most popular when carrying out welding work. You should also pay attention to the letter values:

- KG-HL welding cable is used in conditions of low ambient temperatures (down to -60°C);

- KG-T – tropical, intended for use at high temperatures (up to +55°C);

- KNG – non-combustible insulation.

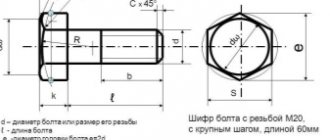

Additional information in the marking - in the form of numbers - shows the number of cores and cable cross-section diameter . Each variety has its own distinctive features.

[ads-pc-2][ads-mob-2]

AAShv, AAShng, TSAAShv, TSAAShng

| Voltage, U (Uo/U) kV | Number of cores, nominal cross-section, mm2 | Core cross-sectional shape | Cable outer diameter, mm | Cable weight, kg/km |

| 1 (1/1) | 3×35 | cool* SE* | 22,6 | 772 |

| 3×50 | 24,6 | 938 | ||

| 3×70 | 27,9 | 1224 | ||

| 3×95 | 30,8 | 1525 | ||

| 3×120 | 34 | 1860 | ||

| 3×150 | 36,8 | 2224 | ||

| 3×185 | 40,3 | 2679 | ||

| 3×240 | 44,6 | 3316 | ||

| 3×35+1×16 | cool* SE/RE* | 24,5 | 881 | |

| 3×50+1×25 | 27,2 | 1117 | ||

| 3×70+1×35 | 30,6 | 1423 | ||

| 3×95+1×50 | 34 | 1789 | ||

| 3×120+1×70 | 38 | 2238 | ||

| 3×150+1×70 | 40,1 | 2544 | ||

| 4×35 | cool* SE* | 26,4 | 1017 | |

| 4×50 | 29 | 1250 | ||

| 4×70 | 32,1 | 1571 | ||

| 4×95 | 36,4 | 2038 | ||

| 4×120 | 40,2 | 2487 | ||

| 4×150 | 43,1 | 2903 | ||

| 4×185 | 47,9 | 3591 | ||

| 4×240 | 52,9 | 4464 | ||

| 6 (6/6) | 3×35 | cool* SE* | 29,4 | 1200 |

| 3×50 | 31,3 | 1390 | ||

| 3×70 | 34,1 | 1675 | ||

| 3×95 | 37,4 | 2062 | ||

| 3×120 | 40 | 2386 | ||

| 3×150 | 42,3 | 2727 | ||

| 3×185 | 45,3 | 3189 | ||

| 3×240 | 50,1 | 4021 | ||

| 10 (10/10) | 3×35 | cool* SE* | 33,3 | 1475 |

| 3×50 | 35,6 | 1704 | ||

| 3×70 | 38,4 | 2032 | ||

| 3×95 | 41,4 | 2410 | ||

| 3×120 | 43,9 | 2757 | ||

| 3×150 | 46,8 | 3246 | ||

| 3×185 | 50 | 3756 | ||

| 3×240 | 54 | 4462 |

Cable channel

Cable channels are electrical installation boxes used for laying lines of different voltage levels and purposes (from high-voltage power lines to cable communication channels). Depending on the material of manufacture, they can be metal or plastic.

The boxes are laid both on horizontal (floor, ceiling) and vertical (walls) surfaces. To protect the wiring placed in them from environmental influences, the channels are covered with special covers.

AABl, AABlG, AAB2l, AAB2lShv, AABnlG, TsAABL, TsAABLG, TsAAB2l, TsAABnlG

| Voltage, U (Uo/U) kV | Number of cores, nominal cross-section, mm2 | Core cross-sectional shape | Cable outer diameter, mm | Cable weight, kg/km |

| 1 (1/1) | 3×35 | cool* SE* | 28,2 | 1330 |

| 3×50 | 30,3 | 1543 | ||

| 3×70 | 33,1 | 1870 | ||

| 3×95 | 36,1 | 2235 | ||

| 3×120 | 39,2 | 2632 | ||

| 3×150 | 41,7 | 3045 | ||

| 3×185 | 45,2 | 3586 | ||

| 3×240 | 49,4 | 4314 | ||

| 3×35+1×16 | cool* SE/RE* | 30,1 | 1483 | |

| 3×50+1×25 | 32,9 | 1784 | ||

| 3×70+1×35 | 35,8 | 2128 | ||

| 3×95+1×50 | 39,2 | 2569 | ||

| 3×120+1×70 | 42,8 | 3059 | ||

| 3×150+1×70 | 45 | 3447 | ||

| 4×35 | cool* SE* | 31,6 | 1627 | |

| 4×50 | 34,2 | 1899 | ||

| 4×70 | 37,4 | 2290 | ||

| 4×95 | 41,2 | 2809 | ||

| 4×120 | 45 | 3338 | ||

| 4×150 | 48 | 3839 | ||

| 4×185 | 52,3 | 4577 | ||

| 4×240 | 57,3 | 5553 | ||

| 6 (6/6) | 3×35 | cool* SE* | 34,6 | 1879 |

| 3×50 | 36,6 | 2111 | ||

| 3×70 | 39,3 | 2456 | ||

| 3×95 | 42,3 | 2874 | ||

| 3×120 | 44,8 | 3250 | ||

| 3×150 | 47,2 | 3666 | ||

| 3×185 | 50,2 | 4193 | ||

| 3×240 | 54,5 | 5073 | ||

| 10 (10/10) | 3×35 | cool* SE* | 38,5 | 2238 |

| 3×50 | 40,4 | 2477 | ||

| 3×70 | 43,3 | 2864 | ||

| 3×95 | 46,2 | 3306 | ||

| 3×120 | 48,7 | 3705 | ||

| 3×150 | 51,2 | 4230 | ||

| 3×185 | 54,4 | 4805 | ||

| 3×240 | 58,4 | 5594 |

Welding cable design

The basis is conductive copper core , consisting of a large number of wires of small diameter (about 0.2 mm). The number of wires can vary and range from 1 to 5. Welders use wires with one core.

The insulation is a rubber shell made of natural (RTI-1) or butadiene (RTI-2) rubber.

Between the two layers there is a special film made of synthetic material, which prevents the two layers from sticking together.

In some cases, the protective film is replaced with talc or other special powder.

You should know! The cores are also in a rubber sheath : RShT-2 or RShT-2HL.

The first option implies that the wire should be used in regions with a temperate climate, the second option can be used in low temperature conditions (not lower than -60°C). You can clearly study the KG cable for a welding machine in the presented figure.

PvBbShv and PvBbShng

| Number of cores, nominal cross-section, mm2 | Core cross-sectional shape | Cable outer diameter, mm | Cable weight, kg/km |

| 3×4 | cool RE | 16,7 | 471 |

| 3×6 | 17,7 | 554 | |

| 3×10 | 19,5 | 708 | |

| 3×16 | 21,4 | 924 | |

| 3x25 | 25,1 | 1301 | |

| 3x35 | cool* SE* | 24,2 | 1532 |

| 3x50 | 27 | 2075 | |

| 3x70 | S.M. | 31,9 | 2865 |

| 3x95 | 35,6 | 3606 | |

| 3x120 | 38,6 | 4473 | |

| 3×4+1×2,5 | cool RE/RE | 17,6 | 503 |

| 3×6+1×4 | 18,8 | 626 | |

| 3×10+1×6 | 20,7 | 803 | |

| 3×16+1×10 | 23 | 1125 | |

| 3×25+1×16 | 26,3 | 1425 | |

| 3×35+1×16 | cool* SE/RE* | 25,8 | 1739 |

| 3×50+1×25 | 28,3 | 2237 | |

| 4×4 | cool RE | 17,6 | 540 |

| 4×6 | 18,8 | 644 | |

| 4×10 | 20,7 | 840 | |

| 4×16 | 23 | 1117 | |

| 4x25 | 27 | 1618 | |

| 4x35 | cool* SE* | 27,7 | 1952 |

| 4x50 | 29,3 | 2471 | |

| 4x70 | S.M. | 32,6 | 3339 |

| 4x95 | 36,3 | 4362 | |

| 4x120 | 39,5 | 5369 |

Welding cable requirements

The welding cable must have high flexibility, strength, as well as moisture and oil resistance. These parameters are common and basic for conductors of various types. In addition, the following important requirements apply:

- welding work can be performed in different environmental conditions, so the wire must be resistant to shock, rupture and aggressive chemical environments ;

- in most cases, the cord is stored wrapped, so it must withstand repeated winding and unwinding, and also be resistant to bending ;

- possibility of use at different temperatures and their fluctuations;

- UV resistance ;

- resistance to mold formations .

There are also requirements regarding design features, which will be analyzed in the next section.

PvBVng

| Number of cores, nominal cross-section, mm2 | Core cross-sectional shape | Cable outer diameter, mm | Cable weight, kg/km |

| 3x10 | RE | 22,9 | 1050 |

| 3x16 | 24,9 | 1310 | |

| 3x25 | R.M. | 29,9 | 1820 |

| 3x35 | 32,4 | 2180 | |

| 3x50 | 36 | 2780 | |

| 3x70 | 39,5 | 3570 | |

| 3x95 | 45,4 | 4690 | |

| 3x120 | 49,2 | 5600 | |

| 4x10 | RE | 24,5 | 1220 |

| 3x16+1x10 | RE/RE | 26,7 | 1490 |

| 3x25+1x16 | RM/RE | 31,4 | 2060 |

| 3x35+1x16 | 33,2 | 2390 | |

| 3x50+1x25 | RM/RM | 37,8 | 3140 |

| 3x70+1x35 | 42,6 | 4130 | |

| 3x95+1x50 | 47,9 | 5280 | |

| 3x120+1x70 | 51,9 | 6420 |

GOST cable

The choice of brand of cable products by cross-section, material, and installation method is regulated by such regulatory documents as:

- GOST R 50571.5.52-2011;

- GOST 31947-2012;

- GOST 10348-80;

- GOST 7399-97;

- PEU-7.

The requirements of these documents need to be known not only to specialists involved in electrical installation work, but also to simple home craftsmen who independently install wiring in their houses and apartments.

PvVG and PvVGng

| Number of cores, nominal cross-section, mm2 | Core cross-sectional shape | Cable outer diameter, mm | Cable weight, kg/km |

| 3x2.5 | cool RE | 12,8 | 215 |

| 3x4 | 13,8 | 275 | |

| 3x6 | 14,9 | 343 | |

| 3x10 | 16,6 | 479 | |

| 3x16 | 19 | 684 | |

| 3x25 | 22,3 | 992 | |

| 3x35 | cool* SE* | 21,8 | 1254 |

| 3x50 | 24,5 | 1652 | |

| 3x70 | S.M. | 29,5 | 2379 |

| 3x95 | 32,7 | 3148 | |

| 3x120 | 36,1 | 4005 | |

| 3x4+1x2.5 | cool RE/RE | 14,8 | 292 |

| 3x6+1x4 | 15,9 | 399 | |

| 3x10+1x6 | 17,9 | 556 | |

| 3x16+1x10 | 20,5 | 864 | |

| 3x25+1x16 | 23,8 | 1120 | |

| 3x35+1x16 | cool* SE/RE* | 22,9 | 1420 |

| 3x50+1x25 | 25,8 | 1906 | |

| 4x2.5 | cool* RE* | 13,6 | 237 |

| 4x4 | 14,8 | 329 | |

| 4x6 | 15,9 | 417 | |

| 4x10 | 17,9 | 593 | |

| 4x16 | 20,5 | 856 | |

| 4x25 | 24,6 | 1302 | |

| 4x35 | 24,2 | 1640 | |

| 4x50 | 26,8 | 2125 |

Advantages

Aluminum wiring is characterized by high electrical resistivity. This resistance is equal to 0.0271 Ohm x sq.mm/m. Taking this fact into account, the latest editions of the PUE note that in an apartment or house you can only use aluminum wiring whose cross-section exceeds 16 square meters. millimeters.

Ultimately, it turns out that to ensure the required level of throughput, you need to use a cable with a large cross-section. In other words, you need to install wiring that is thick. If we compare copper wiring, it has an electrical resistivity that is equal to 0.0175 Ohm x sq. mm/m.

The last fact can be called very bad for connection points. The fact is that when aluminum is heated, its shape and ductility change. Of course, the wire expands. After the load has disappeared and the cable has cooled, it takes on its usual shape. However, after repeated repetition of such processes, the contact between the ends of the electrical wires weakens.

Aluminum is also highly brittle. It increases greatly after it overheats. As for the service life, for aluminum wiring it is 25 years. After this, you need to install a different type of wiring.

SB, SBl, SB2l, SBG, SB2lG, TsSB, TsSBl, TsSB2l, TsSBG

| Voltage, U (Uo/U) kV | Number of cores, nominal cross-section, mm2 | Core cross-sectional shape | Cable outer diameter, mm | Cable weight, kg/km |

| 1 (1/1) | 3×35 | cool* SE* | 28,3 | 2438 |

| 3x50 | 30,3 | 2945 | ||

| 3x70 | S.M. | 34,9 | 4005 | |

| 3x95 | 38,3 | 5086 | ||

| 3x120 | 41,6 | 6133 | ||

| 3x150 | 44 | 7500 | ||

| 3x50+1x25 | SE/RE* | 32,4 | 3389 | |

| 3x70+1x35 | SM/SE* | 37,6 | 4693 | |

| 3x95+1x50 | SM/SE* | 41,7 | 6001 | |

| 3x120+1x70 | SM/SM | 46,3 | 7384 | |

| 3x150+1x70 | SM/SM | 48 | 8346 | |

| 6 (6/6) | 3×35 | cool* SE* | 34,6 | 3212 |

| 3x50 | 36,6 | 3779 | ||

| 3x70 | S.M. | 41,2 | 4963 | |

| 3x95 | 44,5 | 6057 | ||

| 3x120 | 47,1 | 7064 | ||

| 3x150 | 49,4 | 8274 | ||

| 10 (10/10) | 3×35 | cool* SE* | 38,6 | 3782 |

| 3x50 | 40,5 | 4309 | ||

| 3x70 | S.M. | 45,1 | 5547 | |

| 3x95 | 48,5 | 6732 | ||

| 3x120 | 51,1 | 7774 | ||

| 3x150 | 53,3 | 9057 |

Cable calculator

Removal and dismantling of scrap metal

We are members of the Chamber of Commerce and Industry

Our prices are the most honest

On this page you can find out the approximate amount of copper or aluminum contained in the cable. To do this, you need to know the number of cores, their cross-sectional area or diameter, as well as the length of the cable.

Please note...calculations obtained as a result of entering data into the table are for informational purposes only and may differ significantly from the final value. This calculator provides theoretical data, which usually differs from actual data.

This may happen for the following reasons:

1. You entered incorrect cable data (number of cores, cross-section or cable length)

2. In cable production there are certain tolerances for underestimating the cross-section of the cores. Many unscrupulous manufacturers often abuse this in order to reduce cable production costs. As a rule, cables with large cross-sections differ from theory by 5-10%. There are some manufacturers selling cable or wire with a cross-section of 0.5-2.5 mm2 with a copper content reduced by 20-30%.

3. The price of copper or aluminum in the cable used in this table is taken from the price table for large cross-section power cable.

Cable weight calculator #1

Determining the approximate cost of a cable for scrap metal based on its technical parameters (cable brand, cross-section and number of cores)

- 1Cut a small piece of cable as shown in the picture

- 2Using a caliper, measure the diameter of one core and enter the value in “mm” (millimeters) in the line “Conductor thickness”

- 3Count the number of individual cores in the “bundle” and enter the value in the “Number of cores” line

- 4Indicate the cable length in meters in the “Enter cable length” line (the more accurately you specify this parameter, the more accurately we can calculate the metal content)

All calculations on this site are not a public offer

Cable weight calculator #2

Determining the approximate price of a cable based on the percentage of metal content in the cable

- 1Weigh a piece of cable on a high-precision scale and enter the value in window No. 1

- 2Remove the insulation from the cable, freeing it from the PVC sheath and armor.

- 3Weigh pure metal (in this case aluminum) and enter the value in window No. 2

- 4In window No. 3, enter the approximate amount of uncleaned cable in kilograms

- 4So we get the approximate amount that you will receive after handing over the cable.

All calculations on this site are not a public offer

www.metallolom-lom-spb.ru