Copper rod is a product of the metallurgical industry, which is widely used in many industries (metallurgy, production of fittings, production of parts and machine tools). The main difference between copper rods is their constant cross-sectional diameter and chemical homogeneity of the material (only small inclusions of other metals besides copper are allowed).

How does GOST regulate a copper rod? What formula is used to determine the weight of a copper rod? And what do government regulations say regarding storage and transportation? Below we will find out in detail the answers to these questions.

Physical properties and applications

As the name suggests, the main chemical from which the rod is made is copper. In their natural form and during smelting, some other elements are included in the composition (iron, carbon, tungsten and some others), but the content of these substances in most cases is very small (usually less than 0.1%).

Copper has low chemical activity and is resistant to corrosion, so rods are usually used in everyday life and in industry as a semi-finished material from which various parts are made.

One of the main areas of application of copper rods is the manufacture of shut-off valves for water and gas supply systems - after all, copper does not rust during short contact with water, which allows the use of such valves for a long time.

Copper is easy to drill, bend, stamp and weld, so rods are often used to make various parts for the needs of mechanical engineering and shipbuilding - valves, washers, bolts, shafts, hexagons, and so on.

They are also often used to make various food-grade installations, since when used correctly, copper rods are an environmentally friendly material.

Using copper rods (circles)

Copper circles are often used in the heating sector, air conditioning, roofing, and water supply. Due to its high corrosion resistance, reliability and quality, the sale of copper circles is a widely demanded service.

The good electrical conductivity of copper rod determines its popularity in electrical engineering and instrument making, as well as in the energy sector - for the manufacture of certain housing elements, advanced conductors, and conductive structures.

Bushings, copper nails, rivets, nuts, bolts, washers, valves, gears, shafts, etc. are made from a copper circle (rod). It is also in demand in the production of taps for water and gas supply systems, because absolutely safe for humans.

Supplier: LLC RTG "MetPromStar"

GOST standards

The production of copper rods is regulated by state standards GOST. In post-Soviet Russia, the 1535 standard was initially in force, but in 2006 a number of corrections and changes were made to it, which came into force in 2008 and are still in effect (the new standard became known as 1535-2006). According to Gosstandart officials, politicians do not plan to change the state standard regarding copper rods in the near future.

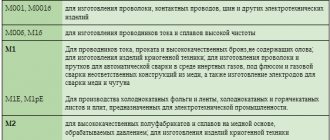

In accordance with GOST 1535-2006, copper rods can be produced from high quality copper, which correspond to the grades M1r, M1, M2, M3, M1f, M3r and M2r. These brands differ slightly from each other, and the minimum concentration of copper in them should be 99.5%. Elements such as silver, iron, nickel, antimony, tin, arsenic, sulfur and others are allowed as small inclusions. For each rod, three cutting methods are allowed - square, circle and hexagon. Also note that in practice, in most cases, rods are made square and round, and hexagons are gradually falling out of use. The following technologies are used for the production of copper rods:

- Cold rolling allows you to obtain round and square products.

- Hot forming - usually used to make square and hexagonal bars.

In addition to technical indicators of shape and composition, a copper rod may have some other specifications - manufacturing accuracy, accuracy of circle curvature, ductility, tensile strength, dimensionality, quality of electric charge transmission, and others. All these parameters must be taken into account by the manufacturer. Finished copper rods according to GOST should not have any external defects. If a flaw was discovered during production, then it must be cut off in order to comply with GOST standards.

The surface must not be heavily contaminated to prevent the controller or purchaser from inspecting the material or testing it for compliance with government regulations. Small traces and defects associated with storage and operation are completely acceptable - this does not contradict GOST standards.

To carry out control activities, a person must select a test rod blindly, and the quantity depends on the size of the batch (usually 2-3% of the rods are subject to control testing, but not less than 2 pieces).

When performing an inspection, the operator must check many parameters - ovality, diameter, elongation, chemical composition. For checking, a ruler, tape measure, square + auxiliary devices for special testing (assessment of electrical resistance, checking the chemical composition, etc.) are used.

Copper circle M1

Calibrated rod made of the highest quality copper. The number “1” indicates the chemical purity of the alloy or the content of impurities, i.e. the alloy contains 99.9% pure copper and only 0.1% impurities of other metals. This brand has excellent corrosion resistance, high ductility, conductivity, both electrical and thermal.

According to the state of the original raw materials, M1 copper circle is divided into hard, soft and pressed. To improve the useful properties of products, an alloying method is used or technological processing of the metal is performed.

Weight of copper rods depending on cross-section diameter

In the most general case, the mass of any object with a homogeneous structure is calculated using the following formula: M = P x S x A, where each letter is deciphered as follows:

- A is the length (usually measured in linear meters).

- S - cross-sectional area (depends on the shape of the product, measured in square meters).

- P - physical density (is a constant value and depends on each specific substance).

Pay attention to the variable P - for copper the physical density will be 8890 kilograms divided by cubic meter. Also pay attention to the variable S - the cross-sectional area of an object depends on its shape, and for round and square rods the cross-sectional area will be measured using the following formulas:

- The cross-sectional area of a square rod will be measured using the formula: S = dx d. In this case, the variable d is the cross-sectional diameter of its cross-section (that is, the distance between two adjacent corner points of the square).

- The cross-sectional area of a round rod will be measured using a slightly more complex formula: S = (Pi xdxd)/4. In this case, d is the diameter of the section, and Pi is a constant that is approximately equal to 3.14.

Using this knowledge, we will draw up a final equation for the dependence of the mass of the rod on its length:

- For square: M = P x S x A = 8890 xdxdx A.

- For round: M = P x S x A = 8890 x (Pi xdxd)/4 = 6979 xdxdx A.

Mass table

The weight table for a copper rod 1 linear meter long will look like this:

| Section diameter | Approximate mass of a round rod 1 meter long (that is, parameter A is equal to unity) | Approximate mass of a square rod 1 meter long (that is, parameter A is equal to unity) |

| 5 millimeters | 0.15 kg | 0.2 kg |

| 6 millimeters | 0.22 kg | 0.28 kg |

| 7 millimeters | 0.3 kg | 0.39 kg |

| 8 millimeters | 0.39 kg | 0.5 kg |

| 9 millimeters | 0.5 kg | 0.64 kg |

| 10 millimeters | 0.62 kg | 0.79 kg |

| 15 millimeters | 1.39 kg | 1.77 kg |

| 20 millimeters | 2.47 kg | 3.14 kg |

| 25 millimeters | 3.85 kg | 4.9 kg |

| 30 millimeters | 5.55 kg | 7.07 kg |

Using this table is very simple - if you need to find out the mass of a rod of any length, then in this case you need to multiply the corresponding number from the table by the length in meters. Consider this simple example: you have a round copper bar 15 meters long with a cross-sectional diameter of 7 millimeters - in this case, its mass will be 0.3 x 15 = 4.5 kg.

Copper density value

The density of this metal, which can be viewed in a special table, has a value equal to 8.93 * 103 kg/m3. Also in the table you can see another characteristic of copper, no less important than density: its specific gravity, which is also 8.93, but measured in grams per cm3. As you can see, for copper the value of this parameter coincides with the density value, but do not think that this is typical for all metals.

The density of this, and any other metal, measured in kg/m3, directly affects the mass of products made from this material. But to determine the mass of a future product made of copper or its alloys, for example, brass, it is more convenient to use the value of their specific gravity rather than density.

Storage and transportation

In addition to technical regulations, the state standard GOST contains a number of requirements that relate to the storage and transportation of copper rods. However, please note that small quantities of rods are allowed to be transported in any form. In the case of large and medium-sized parties, the legislation puts forward fairly strict and unambiguous requirements. Let's consider the basic requirements regarding the storage and transportation of copper rods:

- Copper rods should be stored in dry, ventilated areas where there are no toxic reagents that may react with copper during short-term or long-term storage. When there is excess humidity, water often evaporates - this can cause a chemical reaction between the copper and water, leading to rusting. Chemically active reagents also pose a danger to copper, since this metal reacts quite actively with many substances, which can also lead to damage or deformation.

- The optimal way to store it is in special compartments and on shelves, where nothing will press on top. However, please note: you can place any solid objects on top of the bars, but you need to take into account the load standards (otherwise the copper will begin to bend).

- If the diameter is 18 mm or less, then it is recommended to fasten the copper rod into medium-sized coils for transportation (weighing up to 140 kilograms). In 3-5 places you need to tighten the rods with a special hard wire throughout the bundle for reliable fixation. Larger ones (from 18 to 35 millimeters) should be combined into small bundles (2-3 pieces each) - they also need to be tied at the end for reliable fixation. Finally, it is recommended to place the coils on wooden pallets.

- There is also a universal way of packing rods of any diameter for transportation - in large large bundles weighing 450-550 kilograms, which are recommended to be placed on a wooden pallet. This packaging method is very convenient - it allows you to evenly distribute the weight throughout the entire volume, which will make copper products resistant to deformation, and such bundles can not only be transported, but also stored in a warehouse.

- Fragile and thin products of small diameter (less than 10 millimeters) for transportation are recommended to be laid in one or several layers - after which they should be packaged in synthetic materials to prevent squeezing and deformation. After this, the packages with bundles need to be tied with a special wire at different ends to securely fix the package. For transportation, packaged packages are recommended to be placed on pallets.

Specific Gravity Calculation

Today, many methods and algorithms have been developed for measuring and calculating not only density, but also specific gravity, which make it possible to determine this important parameter even without the help of tables. Knowing the specific gravity, which differs between different alloys of copper and pure metal, as well as the density value, you can effectively select materials for the production of parts with given parameters. It is very important to carry out such measures at the design stage of devices in which it is planned to use parts made of copper and its alloys.

Specific gravity, the value of which (as well as density) can be seen in the table, is the ratio of the weight of a product made either from metal or from any other homogeneous material to its volume. This relationship is expressed by the formula γ = P/V, where the letter γ denotes specific gravity.

Specific gravity and density, which are inherently different characteristics of a metal, should not be confused, although they have the same meaning for copper.

Knowing the specific gravity of copper and using the formula for calculating this value γ = P/V, you can determine the mass of a copper billet having a different cross-section. To do this, it is necessary to multiply the specific gravity value for copper and the volume of the workpiece in question, which is not particularly difficult to determine by calculation.

Units of specific gravity

Different units are used to express the specific gravity of copper in different measurement systems.

- In the GHS system, this parameter is measured in 1 dyne/cm3.

- The SI system uses a unit of measurement of 1 n/m3.

- The MKSS system uses a unit of measurement of 1 kg/m3.

If you are faced with different units of measurement for this parameter of copper or its alloys, then it is not difficult to convert them into each other. To do this, you can use a simple conversion formula, which looks like this: 0.1 dyne/cm3 = 1 n/m3 = 0.102 kg/m3.

Copper ore before processing