A centering drill, which belongs to the category of cutting tools, is designed to make centering holes before drilling in ferrous and non-ferrous metals, as well as ceramic, wood and other materials with a certain degree of hardness. In addition, it is used when drilling fasteners that cannot be unscrewed with a screwdriver. Such drills of different diameters are used in industrial, agricultural, construction and household enterprises in the manufacture of products for various purposes, carrying out repair work and creating crafts with your own hands. The combined drill, which is essentially a tool, must comply with the dimensions and requirements specified in Russian GOST 10902-77, 14034-74 and 14952−75, foreign analogues DIN 333 and ISO 866:2016. The tool is classified as one that is used by professionals. Centering holes are made using jigs (lathe, centering, drilling) and using hand tools (hammer, drill).

Primary requirements

Drills that are designed to produce centering holes are made from. According to the requirements of the regulatory document, this material must provide the following hardness parameters for the working part of the tool with a diameter:

- less than 3.15 mm – 63–65 HRC;

- more than 3.15 mm – 63–66 HRC.

A separate category of centering drills, the manufacturing material of which contains cobalt (5%) and vanadium (3%), must have a hardness that is at least one unit higher than the above parameters.

The diameter of centering type drills may have deviations, the limit values of which are also specified in the regulatory document:

- for tools with a diameter over 5 mm – +0.15 mm;

- 2.5–5 mm – +0.12 mm;

- 0.8–2.5 mm – +0.1 mm;

- up to 0.8 mm – +0.05 mm.

Geometric dimensions of center drills

The regulatory document also lists the requirements for the condition of the surface of drills belonging to the centering type: there should be no cracks, nicks, tarnished colors or rough spots on it. It is accepted that tarnish colors may be present in the area of the grooves - where the grinding wheel exits.

The standard also specifies criteria for failure of the centering tool, which for drills with a diameter of up to 3.15 mm occurs in the event of their breakage, and for a tool with a diameter of over 4 mm - in the event of wear of its rear surface by the amount specified in the relevant tables.

The difference in the width of the feathers must be within the following limits for drills with a diameter of:

- up to 3.15 mm - no more than seven hundredths of a millimeter;

- more than 3.15 mm – no more than one tenth of a mm.

Tips for choosing

The choice of center drill will depend on the size of the hole to be made

The weight of the workpiece, which is fixed in the metalworking machine, is also taken into account. Standard sizes depending on the weight of the workpiece are regulated by GOST - the greater the mass of the part, the larger the drill diameter required

Each drill diameter has 2 design options, so its type is selected depending on the requirements for the roughness of the hole walls.

The combined centering drill is selected according to the requirements for the type of holes specified in the design drawings. To determine the quality of a tool, there are a number of items by which it must be checked.

Compliance with Rockwell hardness standards. The centering drill data is indicated in its technical specifications. A high-quality tool has an indicator of at least 63-66 HRC. Exceeding these standards leads to the fact that the drill will be fragile and short-lived. Low standards will cause the tool to become dull very quickly.

The drill corresponds to the declared diameter. You can check this with a micrometer. The elongated working blade of the drill is subject to measurement - and if its diameter exceeds the permissible error standards, it will not be possible to obtain a hole of a given size using this tool.

Determine the integrity of the product

This is especially important for its cutting part, as well as for the cone-shaped crown. There should be no cracks or gouges on the tool where the working surfaces are.

During operation, the drilling tool gradually changes the angle of the cutting inserts. This leads to a decrease in cutting speed and excessive heating of the drill. Over time, any drill requires sharpening, which must be done while maintaining the angle of inclination of the cutting part.

Quality control

Drills for making centering holes are professional tools. It is for this reason that they take full responsibility for monitoring their technical characteristics. The most important stage of quality control of centering equipment is checking its functionality. It is produced on special samples, which are made of steel 45 and on the HB scale have a hardness in the range of 187-207 units.

During the test, the performance of the tool that is being tested is compared with how a sample behaves under exactly the same conditions, the accuracy and rigidity parameters of which are precisely known.

After testing in metal processing, the center drill should not have any chipping areas on its cutting part. People who have tested the tool evaluate whether it is suitable for further processing. The means used for such control are a magnifying glass (loupe) and a measuring device necessary to compare the parameters of the instrument being tested with the value indicated in the drawing. GOST 8.051−81 when checking geometric parameters allows for the following errors:

- For angular values, a deviation of 35% from the specified tolerance is permissible.

- For linear geometric parameters and the relative position of equipment surfaces, a deviation of 25% from the tolerance indicated in the drawing is permissible.

Recommendations for the use of measuring instruments, as well as the rules for conducting hardness tests, are specified in GOST 9013−59. Such drills are also checked for surface roughness. To do this, they are compared with a reference sample. The requirements for the roughness value are set out in GOST 9378−75.

When checking the centering tool, as well as during machining, a cooling lubricant must be used. It is a 5% aqueous emulsol solution. Scheduled tests, which are carried out on 5 (or more) instruments, are carried out with the following frequency:

- Once every three years, the average time to failure is checked.

- Twice a year a check is carried out to ensure trouble-free operation.

Tricks at work

If it was not possible to remove the pin fragment with an extractor, then it was removed using a tap. To do this, I drilled out the hole drilled along the axis of the stud a little more and restored the thread with a tap. If the diameter of the hole drilled along the axis of the stud was chosen correctly, then when the tap passes, the remnants of the threaded part of the old stud are chipped and removed. The main thing is to correctly calculate the diameter of the hole. This is easy to do if you know the diameter and pitch of the thread. So, for example, for a thread M8×1.5 mm, you need to subtract the pitch value from the diameter of the thread (8 - 1.5 = 6.5 mm) and reduce it by another 0.5...0 .6 mm. That is, the drill should have a diameter of approximately 6 mm so that when drilling it does not affect the ridges and valleys of the thread on the stud piece and leaves a minimum of metal that the tap can easily crumble and remove. We could go on and on about various examples of “inappropriate” use of a center drill – there are many of them. My advice to home craftsmen: get this useful tool in your workshop and you won’t regret it. It is not so difficult to purchase such drills in specialized tool stores and on the market; they are on sale quite often.

Features of different types of drill sharpening

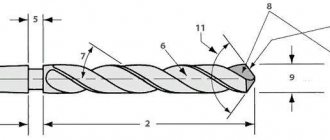

The correctness of the chosen method depends on an accurate assessment of the wear of individual elements. The ones that suffer the most wear are:

- back or front surface;

- jumper;

- set angles;

- chamfered.

Depending on the degree of wear of one of the parameters or several simultaneously, a type of sharpening is selected that can eliminate these shortcomings.

To achieve a high-quality drilling result, it is necessary to correctly select the diameter of the drill and the shape of the cutting edge. To maintain it in working condition and give it the required shape, you should choose the right method (type) of sharpening.

The types used are designated by accepted abbreviations and are divided into the following categories:

- NP - involves consistent grinding of the transverse edge. This allows you to reduce its length, thereby reducing the magnitude of external loads and increasing the period of normal operation of the drill.

- NPL - this type involves processing the transverse edge and ribbon. Which leads to a decrease in the transverse size of the ribbon. This processing helps to obtain the required clearance angle. This reduces the friction force of the cutting edge on the metal surface;

- DP - belongs to the category of double sharpening. Correct application allows you to get one transverse and four additional cutting edges.

- DPL - this processing of metal drills involves sequential sharpening of the ribbon. As a result, better conditions are created for heat removal, reliability and durability are increased.

All types of processing are aimed at creating optimal conditions during drilling. Descriptions of the rules and characteristics of sharpening are established by the relevant standards. All parameters for sharpening a drill for metal are summarized in a single table. It shows the geometry of the cutting edge shapes used for various cutting conditions. The listed types of sharpening allow for high-quality restoration of the parameters of the cutting part of a tool with a diameter of up to 100 mm.

When applying the listed methods, it is very important to take into account the parameters of the metal from which the tool is made. This is necessary for the correct selection of a sharpening tool (grinding wheel)

For example, for high-quality restoration of drills made of high-speed steel, experts advise using an electrocorundum grinding wheel. If the drill is made of carbide materials, it is advisable to process it with a diamond-coated wheel. The operation of restoring parameters leads to significant heating of the part, especially its cutting edge. Therefore, this process must be carried out in stages using coolant.

Particular attention should be paid to restoring the basic parameters of the drill in a home workshop. It is necessary to ensure high quality of the following indicators:

- the same length of edges and ribbon (measurement can be made with an existing measuring tool);

- sharpness of both edges (check is carried out visually);

- values of both angles (front and back).

To simplify the latter task, many craftsmen make their own templates that provide the required sharpening angle. Exact observance of these parameters and correct pointing of the jumper significantly increases the service life of the drill.

However, there are certain types of drills, the specifics of which significantly complicate the sharpening process. Problems with sharpening a twist or step drill are associated with the complex geometry of their design. Therefore, sharpening of such tools is carried out on special machines using developed equipment.

Sharpening step drills for metal is particularly difficult. Such sharpening can only be carried out using special tools and extensive experience. However, it should be noted that the majority of such tools cannot be re-sharpened at all.

Neither method is applicable to diamond-coated drills or other hard bits.

Alignment methods

Centering for drilling holes avoids the following problems:

- Using a ruler. A simple method used in the manufacture of low-critical parts due to low accuracy. Positioning of holes is carried out using a ruler, feeler gauges and axial gauges.

- Radial-axial method. Centering using dial indicators. The method is relevant when working with large couplings and is used in many modern industries.

- Reverse indicator method. Centering involves taking measurements at two points. The result is simultaneous control of angular and parallel displacement.

- Centering by laser. Carrying out work using laser beams, indicator blocks and a calculation module.

Laser alignment is most widespread due to its high speed, accuracy and simplicity.

Rice. No. 5 Set of devices for laser alignment

Main parameters, technical characteristics by type

It is important for anyone who is choosing a centering drill to read its detailed description, because this is a very precise tool used by professionals. General standards for centering drills can be found in GOST 14952-75, which indicates their marking rules, standard sizes, as well as requirements for drills

General standards for centering drills can be found in GOST 14952-75, which specifies their marking rules, standard sizes, and requirements for drills.

Center drill type

There are four main types of this type of drill:

- Type A - for creating centering holes in which the cone angle is 60°, and there is no safety cone.

- Type B - for creating centering holes in which the cone angle is 60°, and also has a safety cone with an angle of 120°.

- Type C - for creating centering holes in which the cone angle is 75°, and there is no safety cone.

- Type R – for creating centering holes with an arc-shaped surface.

The centering drill, according to GOST 14952-75, must have a working diameter of 0.5 - 10 millimeters. In all the above four types, there are two design options, the choice of which depends on the required roughness of the hole walls.

Technical specifications

Centering drills for metal, in addition to their type (A, B, C, R) and the diameter of the working part, differ in a number of parameters (they are described in the same GOST 14952-75). Their design can be one-sided or two-sided. They are usually made from materials such as alloy steel, carbon steel, high speed steel or alloy. The length ranges from 21 to 108 millimeters, the seat diameter is from 3.15 to 31.5 mm, the length of the working part of such a drill is from 1.0 to 9.2 millimeters, and the hardness of the working part varies from 63 to 66 HRC.

Selecting a center drill

Note that when choosing a centering drill, you must pay attention to the diameter. There is one significant difference with “regular” drills.

The diameter of a conventional drill is determined by the thickness of its shank, and in the case of a centering drill, it is determined by the thickness of the cutting part of the drill.

Popular manufacturers

The distribution network presents centering drills from the best domestic and foreign manufacturers.

Among Russian companies, quality products are produced by Sestroretsk Instrumental. The product range is produced in strict accordance with current domestic GOST standards. Their service life depends on operating conditions and is at least 130 operations without re-sharpening. Foreign analogues are manufactured with markings that differ from domestic ones, according to current foreign standards. Their correspondences can be found on the Internet and in the accompanying documentation. Among manufacturers, centering tools from DeWALT (USA), Werko, Robert Bosch GmbH (Germany), YG-1 (South Korea) and some manufacturers from China are especially popular. In the latter case, it is necessary to study customer reviews so as not to buy goods from unscrupulous manufacturers.

The video describes in detail the purpose and design of centering drills:

We ask those who have worked with such cutting tools to share their experience in the comments to the text, tell us what equipment they used, what nuances of the operation and the sharpening process exist.

Marking and metal from which the center drill is made

Centering drills are also marked according to GOST 14952-75. As mentioned above, they have a letter in their designation (A, B, C or R).

A centering drill according to GOST 14952-75 is marked “A” and “B” if it is intended to create a hole at an angle of 60 degrees. The difference here is the presence of a safety cone (letter “B”) or its absence (letter “A”). The marking “C” is used for drills that make holes at an angle of 75 degrees (there is no safety cone), and the letter R is used for drills that make holes with arc-shaped walls.

For example, consider a centering drill with a diameter of 1.0 mm.

If the drill is type “A” and made in the first version, then it will be marked 2317-0101 GOST 14952-75, and if in the second version, then 2317-0001 GOST 14952-75. Here “2317” denotes the specific design characteristics of the drill necessary for its operation, and 0101 is the serial number of the standard size according to factory tables.

Instruments belonging to group “B” are marked differently (in particular, if they are made in the first version, then as “2317-0113”, and if in the second - “2317-00-12”). Type "C" drills are designated as "2317-0124" (in the first version) and as "2317-0022" (in the second version), and group R as "2317-0027". And let us remind you once again that this is all true if the drill diameter is 1 mm.

GOST 14952 75 also assumes that such tools will be made of R6M5 tool steel, its foreign analogue HSS or R9 high-speed steel. However, the steel grade may not be indicated in the marking of centering drills.

We choose metal drills depending on their type and purpose

When choosing a drill for metal, the master, first of all, looks at its appearance.

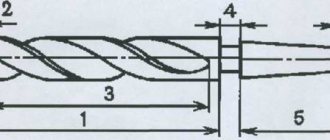

Twist drills

The most popular type. These simple, cheap drills are designed to make blind and through holes of certain diameters. The working part is a cylindrical rod with two cutting edges. The grooves serve to remove chips.

Photo No. 1: twist drills for metal

Cone drills

The working parts are shaped like cones. In everyday life, such metal drills are rarely used. They are best suited for special machines and two-handed drills. They are used to make holes with diameters from 6 to 60 mm.

Photo No. 2: cone drill for metal

How to choose a step drill for metal

Tapered metal step drills are best suited for making holes in thin sheets. These tools look like this.

Photo No. 3: step drill for metal

As you can see, when making holes of different diameters in thin sheet metal, the tool does not need to be changed.

Center drills for metal

Centering drills for metal are designed for making centering holes in workpieces. They are necessary for fixing products on various special machines.

Photo No. 4: centering drills for metal

Left hand drills

Left hand metal drill bits are specifically designed for drilling out bolts and screws with broken heads. This cannot be done using ordinary drills. The bolt or screw will turn.

Photo No. 5: left-handed metal drill

Core drills for metal

Core drills or annular cutters are used to quickly drill large diameter holes (from 15 to 100 mm) in metal workpieces. The operating principle of such tools is based on core milling. It uses 4–12 times less energy than using conventional drills.

Photo No. 6: core drills for metal

These drills are designed for installation on drilling, milling and turning machines. For manual work, use special tools with QuickIN Plus type clamps.

Feather prefabricated drills

Spade drills are excellent for machining cast iron, structural steel and hard forgings. These tools are used to make shaped and stepped holes of large diameters. Feather prefabricated drills consist of holders to which pentagonal cutting inserts of various sizes are attached. They have special grooves to remove chips.

Photo No. 7: prefabricated feather drills with plates

Carbide drills

Carbide drills are made using particularly durable materials. There are the following types of such instruments.

- Monolithic.

- Welded.

- With special plates.

Photo No. 8: carbide drills with inserts

Such tools are purchased for processing workpieces made of heat-resistant steels and titanium alloys. Next, we’ll tell you how to choose a high-quality twist drill for metal.

Factory and home use of CA

Centering drills are in demand in many branches of human activity. They are used in factories involved in such areas as mechanical engineering, the production of high-precision equipment and tools, and furniture manufacturing. They are installed in private workshops, on the territory of workshops of small enterprises, and at service stations. The use of CS allows you to obtain an accurate perpendicular hole without bevels, with the help of which parts of complex structures will be fastened.

In addition, drills are often used by ordinary people in everyday life when they want to do some simple work. For example, with the help of such a tool it is easy to make a hole in damaged furniture, which can later be used to repair the product. Another example: CA can be used for drilling printed circuit boards - the drill will enter this surface exactly at an angle of 90 degrees, which will ensure high quality and precision processing. In everyday life, compact small drills are usually used, and the drill must be compatible with them (check this detail with the store salesperson).

Recommendations for choosing a center drill

There are no universal centering drills. A centering drill must be selected based on a number of factors.

Let's list them:

- Firstly, you need to take into account the material with which you will be working, as well as the diameter and length of the working part, drill material, taper and type of centering hole.

- Secondly, if you plan to center the part before drilling it, the centering drill should be selected smaller in diameter than the size of the hole after final drilling. And vice versa, if you need to drill out a tightly stuck screw that cannot be removed with a screwdriver, then the drill must be selected with a diameter similar (or larger) to the screw that needs to be drilled.

- Many people use center drills to drill holes for threads. In this case, you need to select the diameter of the drill so that it is smaller than the diameter of the thread. Otherwise, it simply won’t be possible to cut it.

- It is also necessary to take into account the requirements for the roughness of the hole walls, since centering drills are available in two types.

Drill selection parameters according to GOST

Having looked at the GOST for a self-centering drill, it becomes obvious that you need to pay attention to a number of characteristics, such as:

- Appearance. It's simple: the instrument should never have scratches, dents or any externally noticeable mechanical defects.

- Accuracy. We look carefully at this indicator, because it determines what the tolerances for deviations in the diameter of the drilled holes will be. For example, if the diameter of the working area of the centering drill is less than 8 millimeters, then the deviation should not be higher than 0.05 millimeters.

- Hardness. If this parameter is deviated, the drill will not last long. If it is low, then the drill will not be resistant enough during operation, and if it is too high, then the drill will be fragile. The hardness should be between 63 and 66 HRC, according to the Rockwell hardness scale.

- Length. This parameter is responsible for the performance of the drill. It must be selected based on the length of the workpiece.