As a good alternative to barrier structures built from brick and stone using traditional technology, modern builders and landscape designers propose using fences made of gabions - three-dimensional mesh structures, the inside of which can be filled with various materials. Traditionally, gabions are made of mesh and stone, but their filler can also be broken bricks or tiles, glass bottles, wood cuts, etc.

Gabion fencing with stone filling

By choosing different materials to fill gabions, you can give them various decorative characteristics, which is what modern landscape designers use successfully. However, exceptional decorativeness is not the only advantage of gabions, which, due to their large mass, can withstand extreme snow and wind loads and are not subject to deformation over time, even when installed on unstable ground. It is also important that installing a fence made of stones placed in nets, when comparing such a process with the construction of structures made of stone and brick using traditional technology, is more economically profitable. This benefit is explained by the fact that when installed, gabions do not require serious deepening, the creation of a massive foundation and the use of concrete mortar to connect the stones used to each other.

What are gabions

Gabions are containers made of galvanized metal mesh of various shapes, filled with stone. Originally, gabions were one of the elements of the defensive system; with their help, redoubts were erected. In peacetime, these structures are used to strengthen coastlines, slopes, in the construction of artificial embankments, and also as retaining walls.

The private use of gabions is much wider - they are used not only for fixing the soil, but also in landscape design, for the manufacture of garden sculptures and various small forms, as well as in the construction of fences.

For the manufacture of containers, a strong mesh is used, woven from galvanized wire, with a protective zinc layer thickness of 250-280 g/m², rod thickness 2-6 mm.

This wire is resistant to corrosion, withstands both the load from the stone and external natural influences, maintaining its shape.

Less commonly, containers are formed from a mesh with a protective polymer coating, although in this case the frame can be not only the characteristic gray, but also other colors. As for the shape, it depends on the scope of application - sculptures can be anything, but functional structures are mostly rectangular.

As a rule, gabions are filled with rubble stone; these can be of various types:

- granite;

- sandstone;

- quartzite;

- river gravel.

The main condition is that the stone fraction must be 30-40% larger than the mesh cell to prevent the filler from falling out. The decorative effect of gabions largely depends on the filler - it can be multi-colored in the total mass or from several layers of different colors. Massive “cobblestones” look good in massive structures made of mesh with a large mesh, and if we are talking about flower beds, flowerpots and stands, then a small mesh and a corresponding stone are more suitable.

Unlike most materials traditionally used in the construction of fences, gabions do not require a foundation or waterproofing. Direct contact with the ground is not critical for them and their properties do not deteriorate over time - due to permeability, precipitation simply passes through the gabion and is absorbed into the ground.

It is important that gabions do not require special care; if desired, they can simply be refreshed using a high-pressure washer.

Coupled with strength, durability, versatility and decorativeness, unpretentiousness has earned such stone fences great popularity among private owners.

Configurations of bulk fences

The configuration of the bulk fence primarily depends on the area of the site. However, the wishes and financial capabilities of its owners also play a significant role.

The sizes of sections, their height and thickness can be very different. Bulk fragments, in accordance with the design idea, represent a completely blank wall or are installed separately, at a certain distance from each other.

Quite interesting fences are obtained by using non-standard mesh structures, for example, cylindrical in shape. They can act as the main sections of a fence or imitate posts between rectangular panels.

If desired, the fence can be supplemented with built-in niches, benches and other decorative elements.

In some cases, pergon sections are successfully combined with inserts made of metal, artistic forging, polycarbonate or wood.

About the European picket fence

Recently, there has been a slight decline in interest in standard blind barriers - increasingly, self-builders prefer partially permeable structures. Apparently this is also associated with an increase in demand for metal picket fences, otherwise known as Euro picket fences, used to fill the spans between posts. Visually, this material resembles the usual wooden picket fence, but is made of galvanized steel sheet, in which stiffeners are formed. The polymer coating protects the zinc layer from washing out and increases the decorative effect of the metal picket fence.

Despite the many advantages of natural wood, it requires not only initial preparation, but also the renewal of the protective and decorative layer over time. For those who are attracted by the appearance of a picket fence, but do not want to regularly spend time, effort and money on renovating wood, a Euro picket fence is the best option.

Do-it-yourself fence made of gabions and euro-fence for the soul

Selshio FORUMHOUSE Member

My wife and I spent a long time choosing which fence to build on our property - we wanted it to be both beautiful and inexpensive. The plot is 43x39 m, and it is expensive for us to build it with a brick foundation and the like. Once I was at one of my work sites and saw a man with a fence made of gabions with a wooden picket fence. I liked it, started studying the issue on the forum, and it turned out that the topic is not new and relatively common. As a result, we began to study the issue in more detail.

The result of monitoring and estimation was the following construct:

- Gabion pillars – 350×350×2000 mm.

- Gabion lintels – 150×500 mm.

- Mesh (galvanized, hot-dip galvanized after welding) – 50×50×4 mm, in cards 0.45×1.95 m.

- Fasteners (knitting wire staples, 2 mm) – 10 kg (1 kg = 1000 pieces).

- Filler – river gravel, fraction 40-70 mm, 30 m³.

- Filling the spans with a checkerboard Euro picket fence.

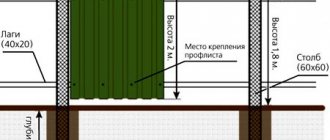

- Supports for pillars and logs - tubing pipe (pump and compressor) 76 mm, wall thickness 6 mm, used, from oil.

- The logs between the pillars are 40×20×1.5 mm.

The choice of pipe is explained by several reasons - oil as an anti-corrosion coating, a thick wall will resist rotting for a long time, cost.

Tools and materials

To build a gabion fence you will need consumables. Basic set includes:

- staples with which the parts of the gabions will be connected (you can also take a simple spiral wire);

- geotextile material;

- steel pins that secure the structure in the ground;

- steel braces for screeding opposite walls.

You can’t do without additional tools that will help ensure safety and speed of work:

- mittens;

- hammer;

- level;

- pliers;

- mount;

- shovel.

To make a fence from gabions you will need a level.

Particular attention is paid to the choice of mesh and stone for the filler.

Frame

Selshio considered concreting the pillars inappropriate - why make a “float” that could be squeezed out by frost heaving. And considering that the groundwater level is below 6 m and the soil is loam, you don’t have to worry too much about heaving. Therefore, I made do with drilling holes 150 × 1000 mm, inserted a pipe into the hole, hammered it with a sledgehammer about another 0.5 m deep and sprinkled it with crushed limestone, fraction 20-40 mm, with layer-by-layer tamping.

After installing the pillars, I began assembling gabions - frames without a bottom and a cover, under the pillars instead of a bottom there is crushed stone bedding, under the crossbars there is just soil. I specially did a test backfill in the winter - nothing sank, why spend money on geotextiles or other base. He connected the cards together with staples using a special handicraft tool. The pillars are reinforced with ties (2 mm) - at intervals of 20 cm in a square post, a diamond shape is formed from the ties. There are mesh diaphragms in the crossbars every 60 cm.

I bent the “antennae” and hooked it onto the rod of the adjacent card, and additionally secured it with staples every 20-30 cm. I attached the lintels to the posts in the same way, with staples.

Since the lintels are 0.7 m longer than the cards, I added overlapping mesh overlays and connected them with staples.

I welded the logs after installing the posts and crossbars - if you don’t touch the galvanization, it won’t deteriorate.

Preparation and installation

At the first stage of preparation, a place is selected where the gabion fence will be installed. The surface must be cleaned, cleared of debris and leveled as much as possible. We should not forget about the roots of plants, including trees.

Then measurements and calculations are made of the amount of material that will be used to construct the structure. The main thing you need to purchase is mesh and filler.

Accurate marking is carried out using a thin string or fishing line. This will create a delineation of the entire perimeter of the future fence.

At the second stage, the top fertile layer of soil is removed, as well as a trench of a certain size is dug.

To prevent grass from growing under the fence, it is better to line the bottom of the trench with geotextiles.

At the final stage, the pillars are installed, with the help of which the fence will be attached. To do this, you need to dig several holes. The distance between pits should not be less than 2 m.

The pillars are placed in the pits so that their third part fits in. For example, if you plan to build a structure 2 m high, then the pole should be higher than 3 m, and it should be placed 120 cm into the ground.

Next, the supports are filled with cement mortar. It will take 48 hours for the solution to completely harden and fix the pillars well.

A prerequisite is a strictly vertical position of the pillar; for this, a plumb line or level is used when erecting it.

Beginning of installation - installation of the mesh structure. First of all, all parts of the future fence are measured and cut out. Then the tension is carried out on the poles, which is fixed with zinc fasteners.

To obtain the desired tightness of connecting the parts, tie clamps are used. Having completed the fastening work, we proceed to treat the mesh with an anti-corrosion substance to prevent the appearance of rust in the places where the wire was cut.

Only after finishing tensioning the fasteners and processing the mesh, do we begin filling the structure.

Each stone that is placed into the structure is carefully selected to achieve a harmonious appearance. This is an important process, because the type of gabion fence depends on the placement of stones.

Ready-made gabion fence

The stones are laid tightly layer by layer. To build a wide structure, wide stones are placed near the walls, and sand or crushed stone is poured into the middle.

Once the stones are poured, a mesh of the required size is installed on top.

If you have basic builder skills, you can make such a fence yourself. The most important thing is correct calculations and strict adherence to the instructions for the manufacture and construction of the structure.

In fact, it’s not that difficult; there are step-by-step instructions online on how to make a fence from gabions, which will make the task much easier.