Recently, corrugated sheeting has become a very popular material; it is increasingly used in construction. With its help, outbuildings, garages are erected, roofs are covered, areas are fenced... The scope of application of profiled sheets is very wide. And this is not surprising, because this material has many advantages - it is strong while being light, durable and, very importantly, plastic (profiled sheets bend quite easily). But not everyone knows how to easily bend corrugated sheets. Let's talk about this.

Methods that allow you to bend corrugated sheets

The simplest and most affordable way to get bent corrugated sheets is to use a hammer. The work in this case is simple and does not take much time. However, you should be extremely careful, because if you use the hammer incorrectly, there is a high probability of getting a poor-quality bend.

When changing the material, in order to avoid mistakes, you should understand the structure and properties of the corrugated sheet. The possibility of bending and using one or another method depends on these properties. Corrugated sheets are made of hot-dip galvanized steel, sometimes coated with polymer. The rigidity of the material is ensured by profiling, which is standard in length - 12 and 6 meters, and in thickness can reach up to one and a half millimeters.

As for the waves, they are low and high and completely different in shape - sinusoidal, trapezoidal, rounded. Any of these types can be bent if necessary. And there are several ways to do this. Bending devices are usually differentiated into five types depending on the drive:

- Devices with pneumatics. They work using pneumatic cylinders

- Machine tools equipped with electromechanics are stationary mechanisms that are equipped with drive systems, electric motors and gearboxes

- Mechanical ones operate from the energy of the flywheel

- Machines with hydraulic installations operate on hydraulic principles

- Manual – require the muscular strength of workers, easy to transport

Bent profiled sheet

The main trend in the development of the construction industry at the present stage is the wider use of products based on metal profile sheets with different thicknesses and sizes. This popularity of this material is due to its high strength, excellent ductility and long service life.

Profiled sheets have proven themselves to be durable and practical materials.

The use of corrugated sheets became especially widespread after the advent of the latest anti-corrosion technologies, which increased the durability of the metal several times. At the same time, the requirements for both the complexity of bending a metal structure and its quality are growing endlessly.

The previously common method, when corrugated sheets were bent with a hammer, has long gone into history, since it is simply impossible to bend a sheet with the proper bending quality in this way.

Before moving on to solving the question of how to bend a profiled sheet, let us briefly dwell on the purpose, the basis of the area of application and some of the nuances of installing corrugated sheets.

Self-production of sheet bending machine

One of the main trends in modern construction is the use of products made from corrugated sheets. The high popularity of this building material is due to its long service life, high ductility and strength.

Corrugated sheeting has high ductility and strength, as well as a long service life.

It began to be used most widely after anti-corrosion technologies became available in industry, increasing the durability of this material several times. Both straight and bent sheets of corrugated sheets are used. But not everyone knows how to bend corrugated sheets correctly.

Scope of application of corrugated sheets

Corrugated sheet fastening diagram.

The oldest tool for changing the shape of a sheet of profiled flooring is a hammer. The work is extremely simple to complete; difficulties can only arise with the quality of the resulting bend - sometimes it is almost impossible to achieve a certain angle. In such cases, it is advisable to create a special device so that the corrugated sheet changes its shape.

In order to know how to change corrugated sheeting, how to bend it, you need to understand the structure and properties of this material. Thus, the basis for the profiled sheet is hot-dip galvanized steel. In some cases, a polymer coating is applied to the sheets. In order to increase the degree of rigidity of the sheet, it is profiled or given a wave-like shape. The length of each profile is standard - 12 and 6 m. The thickness, in turn, can vary - within 0.4-1.5 millimeters.

The waves of the sheet can be low or high, and can be made in a sine-shaped, trapezoidal or rounded shape. Depending on the purpose, profile width and shape of the corrugation, different types of sheets are distinguished.

Corrugated sheets have a wide range of applications. It can become either a decorative element for walls or fences, or the basis for fences, formwork, load-bearing structures, etc. Most often, corrugated sheets are used in low-rise and private construction, for the construction of summer houses and cottages, kiosks, gas stations and shops.

If there is a need to independently produce corrugated sheets, you should take care of special equipment - a guillotine, an unwinding machine, a control unit and a profiling machine. A standard line is capable of producing about 70 linear meters per hour.

This volume will be sufficient to meet the needs of a standard construction site.

Types of sheet bending devices

Table of types of corrugated sheets.

An economically advantageous alternative to purchasing bent corrugated sheeting is to make it yourself. Sheet bending is easy to do at home. Its design may vary depending on the purpose. So, if the expected bending length does not exceed 250 mm, the base of the device can not be fixed with a workbench, but simply clamped in a vice. It is worth considering that the degree of elasticity of the metal does not allow the sheet to be bent at an angle greater than 90°. In such cases, it is advisable to use metal spacers.

Some machines can be designed on the principle of a conventional press. They often consist of dies, punches and a bed. Such devices require extensive operating experience and can only be used in industrial production, as they can be hazardous.

With certain skills, you can create a walk-through (broaching) sheet bending machine. By changing the location of the rolls, the bending radius of the material can be varied. It can be designed either manually or equipped with an electronic drive. Factory multifunctional sheet bending machines have recently appeared on sale. The cost of such a unit usually exceeds $2000, which is why homemade sheet benders are so popular.

Production of sheet bending machine

Table of technical characteristics of corrugated sheets.

A homemade device is capable of performing more than a thousand work cycles without reconfiguration or repair. The estimated bending angle of the deck is about 120°.

Materials required to create a sheet bending machine:

- channel (support beam);

- cheek;

- wooden pillow;

- handle;

- clamp;

- bracket;

- screws;

- pressure beam;

- traverses.

When creating such a device, it is preferable to use standard structural steel, which does not bend under the influence of gravity. Some designs involve replacing a traverse of a similar size with a channel. It is advisable to use wedge-shaped side shelves of the channel. This will significantly reduce the diagram.

Corrugated sheet installation diagram.

One of the mandatory aspects is milling the pressing surface. If the surface is poorly processed, there is a high probability of pot-bellied folds appearing.

When creating the device, you should focus on the dimensions of the frame. So, the larger it is (up to 450 cm), the greater functionality it can have. For example, elongated structures will become available for production. To perform the most standard work, a bed size of 200 cm is sufficient.

If desired, you can equip the manual sheet bending machine with any additional functions. For example, it is convenient if a cutting device is attached to it.

This option may increase the overall cost of the machine, but is cost-effective due to the fact that production speed will be increased.

Corrugated sheet bending technology

Diagram of a machine for bending corrugated sheets.

To create a transversely bent profile, bend the sheet at an angle of 90° to its profile direction. In such cases, a distinction is made between single and double bending. Cross bending can replace a large number of parts with seals and seam joints.

To create arches, corrugated sheeting should be bent into a smooth arc. It is worth considering that the rounding in this case can be convex or concave. Arched profiles are used to create galleries, canopies and curved roof surfaces.

In order to bend corrugated sheets using a specialized device, no qualifications or special knowledge are required. It is worth considering that for small-scale production you can use a manual sheet bender; for mass production it is advisable to use an industrial unit.

The most widely used is the rotary design of a sheet bending machine with a bending beam. The bending angle for a manual sheet bender varies within 180°. Such characteristics are quite sufficient for the manufacture of the most common types of corrugated sheets.

If you need to deform a small amount of corrugated sheeting, you can do this without the use of additional devices. So, for this you will need a corner and an ordinary straight board. You should first outline the line along which bending will be done. Marks can be made using a marker. Next, the metal corner should be laid on a flat surface and corrugated sheeting should be laid on top.

Based on this line, the board should be laid. You should press the board with your foot and press on the edge of the corrugated sheet. The pressure should not be applied too much, but in such a way that the metal flows. All subsequent operations should be performed sequentially, relying on the ribs of the corrugated sheet.

In the event that slight heaving of the material is observed on the ribs, you can knock a little in this place with a hammer through a block or an ordinary mallet.

Source: https://masterprofnastila.ru/kreplenie/kak-sognut-profnastil.html

Production

Arc-shaped corrugated sheeting is manufactured using special technology and modern technology. Equipment for the production of arched corrugated sheets must have high levels of geometric accuracy, in particular roller shafts and guillotine shears.

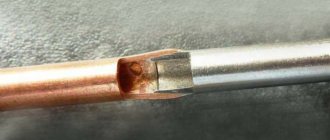

Bent corrugated sheet

The material arrives at the plant in a roll, after which the alloy galvanized steel is unwound using a special lifting mechanism - a production crane. It should be noted that the automatic line for this type of activity is quite large in size, because a bent span is produced immediately (a piece of processed steel, with parameters from 500*1250 mm to 1000*2500 mm).

Processing begins as soon as the steel hits the rolling table. It moves the material along a further path, unbending and centering it, this ensures precision processing and high strength of the corrugated sheet. The most important stage is the creation of corrugation; for this purpose, rolling machines with high efficiency rates are used. The arched load-bearing corrugated sheeting should have high rigidity, but at the same time, the corrugations should not be too large, because this has a negative impact on flexibility. Manufacturers have found a way out by combining the shapes of the recesses. For arched material, special shafts are developed that have several edges. After cold rolling, depressions of the desired shape are formed on the steel sheets.

Photo - hangar without a frame made of corrugated sheets

After this, guillotine shears cut the sheet and it is transferred to the painting workshop. Processing a bent sheet is not fundamentally different from painting the usual straight flooring. The method of high-current electrolysis is used.

Video: production of arched corrugated sheets

Features of bending processes

Naturally, the thinner the metal, the easier it is to bend. Longitudinal bending is mainly carried out in places where “local” bending of a small part of the sheet is necessary - for example, when turning a fence 90 degrees or at another angle. In such cases, it is recommended to select the bend zone at the bottom of the wave (at the point of close contact with the base).

Transverse bending is more difficult in that during the process it will be necessary to deform (“break”) the strength “framework” of the wave. In this case, the process of bending along metal layers is accompanied by expansion in one zone and narrowing in the opposite part. This inevitably leads to uneven deformations, crushing or other damage to the wave. In other words, when the corrugated sheet is bent transversely, the “marketable” appearance is often lost and the integrity of the protective coating is compromised.

Self-tapping screws with press washer for steel roofing materials

To tighten the screws, you will need a hand-held power tool. You can only get by with a drill with reverse and adjustable speed, but fasten the sheets with a screwdriver, since only they have the ability to adjust the torque and pressure on the screw. Based on their type, they are divided into cordless and corded drills. There is one, but quite practical piece of advice. Use network devices on the lower rows and with a low roof. To ensure greater mobility on high and steep slopes, it is better to use a cordless screwdriver complete with a holster. In addition to it, it is advisable to purchase a pouch for self-tapping screws, which is attached to the installer’s belt. Often roofing material has to be cut along contours, for example, in areas of valleys or dormer windows. For this purpose, you should use a jigsaw or electromechanical (notching) scissors. You can also use ordinary metal scissors, but with them you can only cut the corrugated sheet sheet lengthwise, since the high waves (stiffening ribs) do not allow you to cut the sheet crosswise. The use of an angle grinder is not recommended due to damage to the polymer layer, but is not completely excluded in practice.

How to protect the cut?

The use of the mentioned tools will allow minimizing the area with damaged polymer. However, the integrity of the protective coating of the corrugated sheet will be damaged if cut or cut by any of the listed methods.

Under the influence of humidity, an unprotected cut can oxidize and begin to rust. Treating the edges with a special anti-corrosion compound will prevent destruction from negative environmental influences and extend the service life of the material.

After applying the moisture-resistant preparation and curing according to the instructions, the cut areas must be coated with high-quality factory paint of the appropriate tone and texture, which can be included with the packaging of the profiled sheets.

If the dye is not available, you can purchase a spray can with a coating of the desired color. You will have to tinker a little, but the damaged material will again acquire an aesthetic appearance.

When arranging the roof, you can disguise the painted cut areas by using additional elements in the form of ridges and end strips.

Method 3. Cutting corrugated sheets with an electric jigsaw

A jigsaw is used for corrugated sheeting, the corrugation height of which starts from 25 mm and is combined with a short length. Cutting with an electric jigsaw is done across or along the sheet, however, it is necessary to firmly press the profiled sheet so that it does not rattle.

Cutting should be done at high speed using a fine-toothed saw blade designed specifically for metal. In case of high speed, a reciprocating mode of operation with a longitudinal inclination of the saw is recommended.

The advantages of cutting corrugated sheets with a jigsaw are the low cost of work.

The disadvantages of cutting corrugated sheets with a jigsaw are the inconvenience of cross-cutting corrugated sheets with corrugations of 25 mm or more, the practical impossibility of cutting thin strips, severe burning of the edges of the metal sheet and protective polymer coating, and loud noise during operation.

We create a corner of a fence from corrugated sheets with our own hands: methods and rules for carrying out work

Owners of private houses have always sought to protect their territory from prying eyes with a fence.

With its help, you could not only organize your personal space, but also partially protect your property from theft. The simplest, most affordable and at the same time quite aesthetically pleasing fence is a corrugated fence.

This building material has shown itself very well both in the form of a roof and in the form of a fence. It is strong, durable and lightweight.

Corrugated fence corner

The most important and “thin” place of any fence is the corner. From there begins measurement and construction. A fence made of corrugated sheets is no exception.

But here, during construction, a number of difficulties arise, since in most cases those who want to build this structure with their own hands are faced with the problem of creating an aesthetic and durable angle and rotation.

This must be done both for aesthetic purposes and for safety reasons (the edges of the corrugated sheeting are very sharp). Let's look at how to create a fence rotation angle correctly and at the same time spend a minimum of time and effort.

Sheet folding methods

The craftsmen have developed several options for creating a fence corner from corrugated sheets. Some of the most optimal ones, which create a minimum of damage to the protective coating, are:

- using a homemade sheet bender;

- simple screwing on the larger side, bending the smaller side and fastening it;

- using a pipe;

- using a 40 angle and a roller with a 45 degree bevel.

Homemade sheet bender

This device is made of wood (or from thick chipboard strips). To assemble it, you will need four boards longer than a sheet of corrugated board.

Three of them are connected using internal door hinges. Transverse through grooves are made in the central board along the edges for bolts. Similar holes are made in the fourth.

To bend a sheet of corrugated sheets with your own hands, you need to do the following steps:

- measure the distance that needs to be bent inward;

- Mark with a soft pencil and draw a straight line;

- lay the sheet on the board, which is located in the middle, and secure it with a second one so that the marked fold point falls on the edge;

- lift the desired board and bring the angle to 90 degrees.

If all measurements are made correctly, the corrugated sheet will fit well into place. This will give the fence a complete look. In the photo you can see the results of the work done.

Screwing and bending with a mallet

The simplest method is to screw the sheet to the stand from the side where the area is larger, and bend the edge. In this case, you need to use a mallet (wooden hammer). The blows must be applied lightly so as not to damage the protective coating. After the final bending of the corner, you can screw the smaller side.

Using a pipe

Everything here is as simple as in the previous version. To carry out the procedure you need:

- screw the sheet to the stand;

- take a small piece of pipe and wrap it with electrical tape;

- gradually bend the sheet with upward and downward movements;

- screw the edge.

The pipe is wrapped with electrical tape so as not to damage the coating. This will extend the service life and aesthetic properties of the profiled sheet. Instead of a pipe, you can use cylindrical pieces of wood.

Angle and roller

To bend the corner of the corrugated sheet when installing the fence, you can use a 40-gauge metal corner and a roller, which is ground at 45°. The procedure is carried out as follows:

- The profile is placed on the ground so that the inner side faces up. In this case, it is recommended to put rubber nozzles on the ribs so as not to damage the sheet.

- A sheet is placed on top and, using a roller, passed along the canvas to the marked place.

With each pass, increase the rotation angle by 10-20°. After completing the procedure, the sheet can be safely attached to the fence.

Arrangement of the corner

In most cases, so that no structural elements of a corrugated sheet fence are visible, various decorative elements are used on the yard side. These can be either figurines or plants. The last option is most often used. But what to plant in the corner of the fence? There are several options here:

- Large bush. It will effectively hide all the pipes and frame in the corner.

- In the case of a high fence, you can plant small trees with a lush crown.

Decorative coniferous species perform well here. At the same time, they will decorate the corner throughout the year. An example of this option is in the photo.

What to remember

When carrying out work on bending corrugated sheets to create an angle on the fence, you need to remember about the protective coating. It is quite fragile, and if it is damaged, the sheet will simply begin to rust.

The sheets must be screwed with special self-tapping screws with rubber linings. If rivets are used, then such protection may be absent, since these elements cannot be scrolled.

comments: 0 Write a comment

Read other articles from this section

Dimensions of profiled sheets depending on marking and purpose

Depending on the type of profile and its parameters, there are three main categories of profiled sheets: wall corrugated sheets, which are marked with the marking “C”, load-bearing sheets with the marking “H” and universal metal profiles, which are marked with the letters “NS”.

- Wall corrugated sheeting is the most suitable material for creating fences and barriers, the characteristic difference of which is the small height of the corrugation. Sheets marked “C” are used in structures that do not involve large loads, so the main area of application is small fences, wall partitions and frames for temporary buildings. The material can be used several times, and thanks to the low profile (corrugation), the calculated amount of material is always less than for other brands of corrugated sheeting. The most popular models are corrugated sheets marked C8, C10, C21 and MP20

- Corrugated sheeting marked “H” is the most durable material, which is made from thick sheets of galvanized steel. The profile height starts from 44 mm, due to which the rigidity of the sheet is significantly increased compared to similar sized models of other brands. The material is very durable, so it can be used both for installing fences and for installing formwork or ceilings. Common models of load-bearing corrugated sheeting - H60, H75, H114

- Universal corrugated sheeting “NS” has a profile height of 20 mm. Additional strength is provided by stiffening ribs, which allow the use of corrugated sheets to create hangars, garages, sheds or roofs, and can also be used to create fencing structures. Common brands are profiled sheets NS35, C44

Basic principles

Metal bending is carried out using various methods. Welding is often used, but temperature exposure can change the shape and properties of the finished product. This reduces performance properties and manufacturing accuracy.

Since when bending metal, the outer layers of the metal stretch, and the inner ones begin to compress, it is necessary to bend part of the rolled metal relative to another by a given angle. The angle can be found using calculations.

The product is deformed to those values that are within the specified limits. They depend on the following parameters:

- Thickness of the metal sheet;

- How much is the bending angle?

- How durable is the material;

- Speed and time of the procedure.

The permissible deformation indicator will depend on them. The next step is to select the type of bending.

What is ondulin?

Ondulin is a modern roofing material that visually resembles slate due to the wavy surface topography. The ondulin sheet used for roofing consists of cellulose fiber, pressed under high pressure, impregnated with purified bitumen with hardeners and coloring pigments.

This coating was invented in France and was used as a temporary coating to repair numerous roofs damaged during the war. Ondulin, or as it is called in Russia, Euro-slate, has the following advantages:

- A light weight . The weight of the material is quite light, the weight of one sheet is less than 4 kg. As a result, ondulin is lighter than corrugated sheets, soft tiles or metal tiles, as well as other heavier roofing coverings.

- High breaking capacity . Due to the random arrangement of cellulose fibers, even the highest loads cannot lead to rupture of the sheet.

- High noise insulation ability . If we compare ondulin and metal tiles, we can note its undeniable advantage - sound insulation ability, which effectively dampens the sounds of rain, wind, and hail.

- Easy to install . Ondulin sheets are very light, so lifting them onto the roof and doing the work of laying the covering is quite possible with your own hands in the shortest possible time.

Note! Laying ondulin can only be done if the roof slope is at least 10 degrees. And then, with such a low slope, it is recommended that in order to cover the roof with this material, it is necessary to install a continuous sheathing and organize high-quality waterproofing.

- Promotion

- SALE

13%

Selecting a grade of profiled sheet

Corrugated sheeting is marked according to sheet strength and purpose. The model range starts with sheet C-8 and ends, as a rule, with H-158 and higher; the brand may also contain additional indices indicating, for example, the profile shape or wave pitch. In the European classification there are analogues of the domestic sheet under designations starting with T or RAN. The choice of a specific profile depends on the planned roof structure, while the general rule is that the lower the grade, the greater the roof slope angle should be: for C-8 - C-25 it should be at least 15 °, for more durable classes - from 6 ° . The slope is designed to reduce the weight load from precipitation, primarily snow. The same parameter is influenced by the depth of the profile, its shape and the repetition period of the corrugations (pattern).

Bending Options

We have already mentioned that you can bend corrugated sheets across by hammering the material (by the way, there is an option to purchase already bent sheets). But this method is not always suitable. It is much more profitable to use special sheet bending machines; you can make them yourself.

A sheet bender for corrugated sheets can have different devices, which depend on the purpose of the curved sheet. For example, if the expected bend does not exceed 2.5 cm, you can not fix the base of the sheet bender with the workbench, but use a regular clamp with a vice. Don't forget that due to the elasticity of the metal, you won't be able to bend it more than 90 degrees. It is better to use metal spacers.

Many machines are similar to a conventional press. Their design includes dies, punches and beds. However, most often such devices are used for industrial production, because it requires enormous experience and skill to work on such machines, and they are also very dangerous.

Machine for the production of corrugated sheets

Certain skills will help in creating a pass-through (broaching) sheet bender. In this case, you can change the location of the rolls and thereby achieve different bending radii. Such a device can be manual or electronic.

Recently, ready-made sheet-bending machines can be found on sale. However, their price is quite high, and in some cases exceeds $2,000. In this regard, homemade sheet benders are especially popular and in demand.

What are the advantages of all types of galvanized corrugated sheets?

- Light weight and easy installation. The sheets are easy to transport, lift onto the roof and work with them. No effort required, no special skills required. You can handle it on your own.

- Resistance to weather conditions, temperature changes, high humidity and corrosion. Fire resistance and environmental safety, durability (service life up to 50 years).

- Minimal maintenance after installation - repairs to individual areas are rarely required. Aesthetics and a large selection of colors according to the RAL catalog, affordable price.

At Skyprofile, you can quickly select a galvanized profiled sheet with any parameters. You can calculate the quantity and cost of material online using calculators. You can pick up your order at any of our 25 stores in different cities of Belarus.

vote

Article rating