Wire rod is a type of rolled metal product, which is a round wire made from carbon steel grades St0, St1, St2 and St3, in accordance with GOST 380, or from non-ferrous metals or alloys of non-ferrous metals in accordance with the accepted specifications. Carbon steel wire rod is available in diameter 5.0; 5.5; 6.0; 6.3; 6.5; 7.0; 8.0 and 9.0 mm. In this case, deviations in diameter are allowed +/- 5%, and the ovality of the wire rod is allowed no more than 50% of its diameter. Wire rods made of non-ferrous metals (copper, aluminum) or their alloys (bronze, brass) are manufactured with a diameter of 1 to 16 mm. Wire with large diameters is made to order in limited quantities. Wire and wire rod are two words denoting the same material.

Wire rod production technology

Wire rod production is carried out on metal rolling machines using rolling and drawing methods. Initially, a square of carbon steel with a cross-section of 10x10 mm is launched into the shafts of the rolling machine. Several shafts installed in series compress the steel workpiece, giving it a circular cross-section of a given diameter. At the same time, during rolling and the impact of the shafts on the workpiece, it itself heats up due to the friction force. Upon completion of rolling, the wire of the required diameter is fed into the installation, which twists the wire rod into a ring. After twisting the ring, it is transferred by special automated mechanisms to the cooling zone.

Wire rod production technology: rolling and drawing

Although the wire rod is hot-rolled metal, I cool it in three ways:

- УО1 – accelerated single-stage cooling;

- УО2 – two-stage accelerated cooling;

- VO – natural air cooling.

Natural air cooling can be carried out both in the workshop on special pallets and outdoors at temperatures up to +10 degrees. In essence, in this way, a red-hot wire rod is obtained, which has good strength and at the same time bends easily. Wire made using accelerated cooling - УО1 and УО2, at the stage of its cooling is placed in special chambers, which are equipped with forced powerful hoods. As a result of rapid cooling, semi-hardened and tempered wire is obtained, relatively speaking.

Delivery and labeling

The finished wire rod is wound into coils weighing at least 160 kg. Typically, each coil is a continuous piece, which is marked according to the requirements of GOST 7566. A marking is attached to each coil, which indicates the manufacturer, wire rod diameter, grade and grade of steel, and heat number. However, it is allowed to wind two sections of wire rod into one coil - but only if one section does not exceed 10% of the mass of the coil. In this case, the manufacturer must guarantee the weldability of the products and put two marking labels - one for each segment.

According to the technical conditions TU 14-15-254-91, wire rod according to TU is manufactured in 4 classes:

class VK - high-quality wire rod;

class VD - wire rod with high deformation;

class KK-quality wire rod;

class PD - structural wire rod.

Characteristics of steel wire rod

In terms of strength, wire rod is classified into two classes: B - normal strength and B - increased strength. The strength of the wire is determined by the grade of steel used and the cooling method. For example, if steel grade St0 was used, then the mass fraction of carbon in it should not exceed 0.20%. That is, this wire will be more flexible than wire from St1.

According to the established GOST 380, the entire coil of wire rod must be twisted from a single core, and along the entire length of the wire there should be no deviations from the diameter by more than 5%. Also, there should be no scale, burrs or rolled out cracks along the entire length.

The influence of impurities on the quality of the finished product

In the manufacture of wire rod, different grades of steel can be used. The key requirement is the consistency of the chemical composition along the entire length of the product. It should also be taken into account that the presence of various additives can have a significant impact on the final properties of the product. In particular:

- Increasing the amount of nitrogen will give the material hardness, but make it more brittle;

- Excessive chromium content will negatively affect the heat treatment procedure;

- Phosphorus and sulfur are unable to distribute evenly in the metal and make the metal extremely brittle when heated;

- Carbon helps to increase the strength of steel, while increasing its ductility, elasticity and wear resistance;

- Silicon and manganese ensure steel melts uniformly, increasing its density, abrasion resistance and strength. Among other things, manganese is able to neutralize the harmful effects of sulfur. However, excessive concentrations of silicon oxides should not be allowed. They will negatively affect the ductility of the material.

Scope of application of steel wire rod

Most of all, steel wire rod is used for reinforcing monolithic concrete structures. For example, in the manufacture of reinforcement cages, stacked clamps square, round or with a rectangular shape are made directly from wire rod. With the help of reinforcement cages, monolithic columns, crossbars, belts, overhead lintels and strip foundations are reinforced. In addition to using wire rod in frames, it is also used in the manufacture of welded reinforcing mesh with a cell of 100x100 or 150x100 mm. Reinforcing mesh is used to reinforce monolithic planes, for example, concrete floors, interfloor slabs or screeds.

Unlike wire rod, reinforcement has higher strength, so it is the main element of concrete structures. You can read more about reinforcement, its types and characteristics in a special article: what is reinforcement; how to choose it; characteristics, bending and knitting of reinforcement.

Steel wire rod is also used when laying load-bearing walls or partitions made of brick, cauldron, cinder block, foam block or gas block. Depending on the specific stone used for masonry, steel wire is inserted into every 2 - 4 row of mortar, thereby increasing the overall strength of the masonry.

Steel wire is quite often used on its own as an installation material. For example, when installing wooden poles for power lines, first a concrete pile with a square cross-section - a stepson - is installed in the ground, and then a vertical wooden pole is tied to the concrete pile with wire rod. Quite often, wire rod is used to tie the Mauerlat to a concrete belt when constructing a gable roof.

Using wire rod when installing wooden poles

aluminum wire rod

Where is wire rod used?

Rolled wire is widely used in various fields of activity. With its help, large, heavy loads are packaged, reinforced frames are made, and used for reinforcing reinforced concrete structures. As for the characteristics of a popular product, it is copper, aluminum or steel wire rod with a diameter of 6-8 mm.

If you use rolled wire as a raw material, you can get nails, steel cables, electrodes, meshes and other products. As for price characteristics, the most affordable is wire rod with a diameter of 8 mm, which is explained by the peculiarities of the production process.

Aluminum wire

Aluminum wire rod is a continuous and round rod with a diameter of 1 to 16 mm. Aluminum wire is made in two different ways. In the first case, production is carried out by rolling a workpiece of a larger cross-section through rollers. In the second case, molten aluminum is used. Aluminum melted to a liquid state is fed into a crystallizer - a large rotating ring made of refractory metal and water-cooled. During the rotation of the crystallizer, molten aluminum takes the form of a rod, which immediately enters the line of rolling rollers, where the rod is formed into aluminum wire rod of a given diameter. Aluminum wire rod is manufactured in accordance with GOST 13843-78.

Responsible Cooling

After this comes the cooling stage of the wire rod. It can be natural (in this case, the wire rod receives the VO marking) and accelerated (UO marking).

Natural cooling produces a softer and more flexible wire rod (and then wire), while accelerated cooling produces a more rigid and elastic one. Industrial fan installations or water flows can speed up the cooling of the wire rod. With the first cooling method, the marking of the wire rod will indicate YO1, and with the second - YO2.

The rapidly cooled wire rod (intended for the production of wire in the future) is cleaned of scale, which should not be more than 18 kilograms per ton on the UO1 wire rod, and no more than 10 kg/t on the UO2 wire rod. Scale is removed either mechanically (then the wire rod is passed through a special descaling machine), or chemically, when the surface of the wire rod is etched with a solution of sulfuric acid with the addition of table salt, trisodium phosphate and other additives.

The chemical method gives a smoother surface, but it is also fraught with the acquisition of the so-called metal. "etching fragility". The mechanical method is safe in this regard, because - but it is less reliable and produces a rough surface.

Copper wire

Copper rod is produced by continuous casting of molten copper followed by rolling on the shafts of a rolling machine, in accordance with GOST 546-2001. Copper wire rod, depending on the copper grade used, is divided into three classes: A, B and C. Class A and B wire is made from M00k grade copper, while class C wire rod is made from M0k grade copper.

copper wire rod

The main application of copper wire rod is the manufacture of electrical wires and cables designed to withstand a greater load than aluminum wires can withstand. The resistivity of copper is one and a half times less than that of aluminum, and with a high load on the electrical network, the aluminum wire, especially at the point of twisting or connector, heats up more, which can lead to a break or short circuit. Copper wire, in turn, can withstand heavy loads.

Means and methods for testing finished wire

Mandatory check for copper rod:

- Tests according to State Standard 26877 for cross-sectional ovality.

- According to GOST 6507 for deviations from the declared sections. Tools – calipers for large gauges and micrometers (with graduations from 0.01 mm).

- Inspection. In case of minor defects, the surface is cleaned until it is brought to acceptable values.

- Determination of the chemical composition in accordance with GOSTs 31382, 9717, 13938, 27981. If the enterprise has a well-equipped chemical laboratory, it is allowed to study the chemical composition of copper in wire rod using other methods. Not in conflict with existing standards.

- According to GOST 7229 for determining resistance. Equipment – micrometer and high-precision scales.

- Conductivity and elongation test according to GOST 1497.

Tips for choosing when buying wire rod. Wire rod quality

As a rule, ordinary people, and even various construction companies, do not encounter the purchase of wire rod made of non-ferrous metals. Wire made of non-ferrous metals is mainly purchased by factories that manufacture electrical cables.

In most cases, when carrying out construction or installation work, it becomes necessary to buy steel wire rod. Steel wire rods are marked according to GOST 7566. Steel wire is sold in the form of coils consisting of 1 or 2 strands. If there is only 1 continuous strand in the coil, then all technical characteristics of the wire can be found out by the attached label. If there are 2 cores in a skein, then there must be 2 labels.

When purchasing steel wire rod, markings on the label are as follows:

Wire rod B-5.0 mm St3kp UO1 GOST 30136-94

This means that wire rod of normal strength, with a diameter of 5 mm, made of steel grade St3kp with one-stage accelerated cooling is twisted into a coil and the material complies with the specified GOST.

In addition to studying the information on the coil label, it is also worth making a visual inspection of the core for the presence of scale, cracks and burrs. In addition, it is worth paying attention to the overall color of the core. If the color of the core does not differ, it means that such steel wire will have different flexibility and strength in different parts of its length.

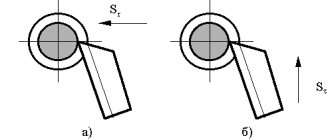

There is an old way of determining the flexibility of wire rod “by eye”. To do this, take a core and bend it into an arc. The free end goes around the main core, and the end begins to bend clockwise. A high-quality wire rod should bend around a rod equal to its diameter, that is, around itself 180 degrees. In this case, cracks or breaks should not form at the bend.

Individual characteristics of wire rod

In most cases, wire rod comes in round and oval sections. It can reach 10 mm in diameter, but the most popular are products with a cross section of 5-8 mm, made of steel. As for products made from copper and other non-ferrous metals, they have a small cross-section, rarely exceeding 1 mm. The finished wire rod is used as an independent product, and also becomes a raw material for the production of other long products.

All stages of the manufacturing process are subject to careful control, which ensures high quality of the finished product. Product parameters are checked against current standards. In particular, curvature, ovality and other deviations are measured.

Wire rod price. Wire rod weight.

The cost of wire rod is comparable to the cost of the material from which it is made. For example, steel wire rod can cost 20-30 rubles per kg, aluminum wire rod costs about 150 rubles per kilogram, copper wire - about 300 rubles per kilogram.

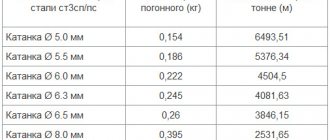

Wire rod weight: weight of one meter depending on the diameter and length of one ton depending on the diameter

The weight of the wire rod depends on its material and diameter. As an example, the table shows the weight of steel rod depending on the diameter. Copper wire has about the same weight. Aluminum wire is approximately three times lighter than steel and copper.