Product Features

The threading head has a number of advantages (compared to round dies).

These include: 1. Automatic spreading of combs on the head. 2. Quick removal of the head without backscrewing. 3. Increased productivity. 4. High surface cleanliness and precision of work.

The heads are more durable than dies and allow you to precisely adjust thread sizes and, if necessary, cut them in 2 passes.

The heads offered also differ:

• collapsible design; • high landing accuracy; • perfect centering of pipes using long guides.

Equipment used

Even in the recent past, special units were used for pointing shafts, other parts, and thread cutting; various parameters were obtained using semi-automatic machines; the quality of work gradually became higher, as additional equipment was developed to simplify the process. Today there are many methods for performing the process:

- Screw-cutting lathes have been developed for the production of internal and external threads of various profiles;

- Drilling machines are designed to work with taps, dies, knurling, dies, thread-cutting heads, and milling.

A conditional division of equipment has been accepted according to the following criteria:

- type of tool arrangement;

- the workpiece or tool remains motionless during cutting;

- degree of use of automation and manual labor;

- type of tool used.

Tools for cold heading and thread rolling machines

For small diameter wire drawing, as well as applications requiring excellent wire surface quality, there is nothing better than drawing using diamond dies equipped with a single crystal of natural or synthetic origin, offered by the Taiwan Hardware Alliance.

Diamond die is a wire drawing equipment tool used for drawing soft copper, aluminum, stainless steel, tungsten and copper coated steel wire. The principle of drawing processing is to gradually reduce the diameter of the wire from the entrance to the diamond die to the exit from it (as shown in the figure below).

We recommend reading: Size of units in Udmurtia for pensioners of labor veterans

Advantage:

- High wear resistance and durability of the calibrating zone.

- Excellent surface quality of the finished product.

- Low coefficient of friction.

Application: Diamond

Send a file with your details and indicate what to invoice for.

PRELIMINARY APPLICATION FOR A MACHINE PASSPORT

Send a request, in the response we will indicate availability, price and other important information.

Response time usually takes from 20 minutes to 3 hours.

FEEDBACK

Send us your question and we will respond to your email within the next few hours.

We will be glad to hear any of your questions. We also look forward to your complaints, encouragement and suggestions.

CONTACTS

We are waiting for your call from Monday to Saturday from 09-00 to 20-00

And email and applications from the site around the clock!

More details on the "Contacts" page

Thread rolling with rollers

Our company carries out orders for thread rolling on automatic thread rolling machines, both individual and mass production.

Thread rolling is the most productive, widely versatile and accurate method of forming threaded connections on parts, characterized by the widest range of technological capabilities when it is necessary to produce threads of various diameters, accuracy and lengths. When thread rolling, two rollers are used, depending on the complexity of the part - three, on specialized thread rolling machines.

The most widely used method of rolling threaded surfaces with rollers is rolling with radial feed of one of the rollers, since the simplest equipment and tools are used, with the highest productivity. Most often, this process is carried out according to the following scheme: on a knife, with a pair of rotating rollers, with radial feed of one of them.

For rolling threads with rollers, 2- or 3-roller semi-automatic thread rolling machines are used. Semi-automatic profile rolling machines are universal units and are used for cold rolling on parts of precise trapezoidal, metric and any other types of threads, worm gears, lead screw profiles, fine-module helical wheels, corrugations, as well as for calibrating and straightening spherical and cylindrical bodies of rotation. The process of rolling the required profile on the cylindrical surfaces of rotating bodies is carried out by rolling the profile, made on special cylindrical rollers, on the surface of the workpiece, with the rotation of both rollers and translational radial movement of one or both rollers with the necessary certain force transmitted by a hydraulic feed drive (method of rolling with radial roller feed). The workpiece, a body of rotation, installed between the knurling rollers on a knife support - table, or in the rotating centers of a specialized device, receives translational rotational motion as a result of the friction force that arises during the interaction of the knurling rollers with the workpiece and increases as the roller profiles deepen into the body of the workpiece and the appearance on the workpiece of a profile negative in relation to the profile made on rollers.

The price for thread rolling varies depending on the complexity of the job.

To calculate the cost of work, you need to provide us with a technical specification - a drawing or sample of a part. We, in turn, guarantee reasonable prices and positive results.

By offering our customers adequate prices for the work that interests you, we look forward to long-term and mutually beneficial cooperation.

You can send technical specifications for the types of work you are interested in by email:

Email official mailbox

Our organization guarantees high-quality and fast execution of orders, on time, and an individual approach to each client.

We invite all interested parties to cooperate.

If you have any questions, call and our specialists will help you solve your problems.

Operating principle, purpose, advantages

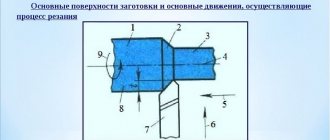

Thread cutting is considered an inseparable operation of metalworking production. Thread cutting is typical for CNC lathes, screw cutting and turning units, and thread processing units. Drilling machines can also cope with the thread-cutting mode using the drilling method.

Thread rolling units are installations used for rolling threaded and screw planes on workpieces - bodies of rotation made from ferrous and non-ferrous metals, as well as their mixtures. These alloys give the installation high-strength characteristics and increased service life. The equipment is easy to maintain, which allows rolling threads using three methods:

- Radial roller feed. Designed for cultivating small-length helical planes.

- Tangential feed of the part. It is characterized by an improved feed technology than radial feed of the workpiece, since it is carried out tangentially to the circle in a given area.

- Method of axial approach of a blank. Designed for processing long-length screw connections.

The most famous and popular thread rolling method is considered to be a variation when the rollers are fed radially. This is due to the elementary nature of the tools. The rolling procedure on thread rolling machines occurs through two movable rollers, but radial feed is possible only on one of the shafts.

It is worth noting that in the radial tool feeding method only cylindrical rollers are used, which comply with GOST 9539 standards.

All these methods are actively used in various areas of production. The operating principle of a thread rolling machine is based on changing the surface of a part and creating a shape using special tools. The formed profile is performed by pressing a certain load into the plane of the part, depending on the equipment. This is how the production of self-tapping screws, screws, and rivets is carried out.

The main positive aspects of the thread rolling device are:

- absence of chips, which increases the usefulness of the device;

- favorable economic indicator in the purchase of expensive consumables;

- increased wear resistance and service life of treated surfaces;

- integrity of the threaded connection of the workpiece;

- high performance of building elements.

These advantageous characteristics of roller rolling technology have led to their widespread use in large-scale production.

Three roller thread rolling machine

Description and features of the unit

The hydraulic thread rolling machine is in demand in the industrial sector. Its area of application is the processing of rounded surfaces, such as hairpins. As a result of the impact, various threaded planes are created. If we go deeper into a particular case, we use a thread rolling machine for pipes. Processing (knurling) differs favorably from cutting, since the part has high-quality characteristics and processes the metal economically.

DJY Thread Rolling Machine

Hydraulic thread rolling systems of the JDY production series have working shafts with one mobile spindle head. They are used for thread rolling and profiles on solid blanks. The knurling pressure in devices of this series varies in the range of 4-40 tons. If the consumer needs a greater load on the product being processed, then upon request the manufacturer will review the maximum possible rolling parameters.

The supporting bed of the JDY thread rolling machine is designed using the finite component method. By combining a cast and welded form, the maximum possible rigidity is achieved, but at the same time the work area is free for the equipment operator.

The running spindle assembly of a metalworking machine moves along roller bearings. The installation is intended for rolling a threaded connection using the radial method, sometimes called the mortise version. The length of the working rollers is characterized by exceeding the length of the created thread by a small distance. Such equipment operates in several modes: with flat dies, operation without retracting the threading head on the stop, adjustment, semi- and automatic modes.

The technical characteristics of some models of JDY CNC machines are summarized in the table:

| Equipment series | JDY-50 | JDY-30A | JDY-3T |

| Outer thread diameter, mm | 6-80 | 8-40 | 2-12 |

| Threaded connection pitch, mm (per inch) | 1-6 | 0,5 – 2,5 | 0,4 – 1,5 |

| Knurling frequency, rpm | 10-38 | 250-500 | 40 |

| Permissible cross-section of rolling dies: internal external, mm | 180 54 | 80 25,4 | 90 50,4 |

| Number of self-tapping screws and similar materials produced, pcs/min | 4-30 | 4-30 | 24-40 |

| Spindle motor | 10 HP | 2HP | 1HP |

| Machine weight, kg | 2700 | 520 | 280 |

| Device parameters | 1800x1500x1300 | 1150x920x1360 | 800x600x750 |

The complete technical data sheet for the models of thread rolling machines under consideration can be found on the Internet.

To watch online, click on the video ⤵

We cut threads on wooden cuttings / Business on cuttings / Original thread-cutting machine Read more

Double-spindle machine with automatic change and threading head TM20 1209. Stainless steel processing Read more

Industrial magnetic threading machine PromotechPRO 112T More details

Thread-cutting chuck for TV4 lathe More details

Threading machine MZK 95. More details

FDB Maschinen DM 45 LV drilling milling thread-cutting machine for metal FDB DM 45 LV machine Read more

FLOTT SB 18 PLUS DRILLING THREADING MACHINE More details

Threading machine Rothenberger Ropower R50 More details

Thread-cutting manipulator - video of work Read more

Threading machine from a conventional drilling machine. More details

Flott SB 25 Plus Drilling and tapping machine More details

Thread-cutting machine MZK-95M for cutting metric threads Read more

FLOTT TB 13 PLUS German DRILLING THREADING MACHINE More details

A simple threading machine with reverse. Do it yourself. Drawings. Vertical threading machine. Home made. More details

CNC thread cutting machine for plastic casing pipes Read more

Flott SB 40 NC Plus Drilling and tapping machine. The most accurate drilling machine. More details

Operation of the threading head. More details

PIPE THREADING MACHINE 20215 RIDGID 1233 220 VOLT Read more

Threading machine with workbench on wheels More details

Threading machine

Thread cutting machines are structurally complex mechanisms equipped with an electric drive and ensuring high productivity and reliability. The main types of work performed on this equipment include threading, nipple cutting, deburring and grooving. Such machines are used in the construction industry, repair shops, in small-scale and full-scale production. Despite the fact that thread cutting machines are easy to operate and reconfigure, they provide impeccable thread quality and high cutting speed. The machines are available on a mobile platform and in a desktop version.

The design of the smallest thread tapping machine is based on the concept of compactness and mobility. Such designs are equipped with a universal threading head, and they work in a range of pipes with diameters up to two inches. A distinctive feature of the design is the location of the machine mechanism on a trolley equipped with a table, which allows it to be easily moved to the desired location. The machines are used in various workshops carrying out repair work and on construction sites, the intensity of the use of pipe threaded connections in the production of work is not significant. The machine can cut both right-handed and left-handed threads of inch or metric type. The set of threading machines includes knives made of special high-speed steel. The electrical power consumption of the machines does not exceed 1.5 kW, they are equipped with a safety system and fully comply with international quality standards applied to industrial equipment.

The next type of machines is produced for stationary installation on workbenches, workshops and utility companies. The main feature of this type of machines is that they are equipped with a special pipe fixing mechanism. The principle of operation of the mechanism is based on impact wedging of the pipe between three clamping jaws, which makes it possible to create a rigid fixation of the pipe for subsequent processing. In addition, the machine implements a mechanism for automatic lubrication of the thread cutting process by supplying oil from a special container directly to the threading head. The design of the threading head is made in an original way and is a self-expanding structure. Such machines are usually equipped with a separate deburring tool and pipe cutter. The equipment is equipped with a safety system implemented through a foot-operated emergency shutdown system. In addition to its main function of thread cutting, machines of this type can cut pipes, for which they are equipped with cutting rollers. The power consumption of such equipment does not exceed 1100 W and meets all the requirements set by international standards for this type of machines and tools.

There are a huge variety of models of threading machines produced, each of which differs from the previous one by an additional function or expansion of an existing one. But there are machines that are a collective image of all modifications and perform the most complete set of possible operations for making threads of both inch and metric types. These models are used in industrial production and the main distinguishing element of the design is the equipment of the machine with an automatic chuck. The machine adapts to production requirements by using different motors and die heads.

Thread cutting machines at ProfTehSnab

How to buy a thread cutting machine?

Purchasing professional equipment for thread cutting requires careful consideration of all parameters and production prospects, because the machine should not only decorate a workshop or workshop, but also justify itself economically. Before placing an order in the TBS online store, consult a company specialist about the optimal performance, dimensions, and brand of equipment. We offer both inexpensive machines for mass production and precision units that provide jewelry joining of pipes of any diameter and purpose.

TBS company terminals are located in Moscow, St. Petersburg and Novosibirsk. In the regions where the company operates, courier delivery of machines and consumables is available to customers. Condition – order in the amount of 10,000 rubles. Throughout Russia, the thread cutting machine will be delivered quickly and inexpensively by partner transport companies.

For any questions, please contact TBS 8 toll-free number or online chat on the website.

Threading technology

Special tools and devices are used to make carvings. Threads can be cut:

- Special cutters and combs. The tool is machined on lathes; both internal and external threads can be cut.

- With dies. Only external threads are cut; they are used both manually and mechanically.

- Taps. For internal threads only, universal use.

The maximum force acts on the cutter edge when entering and exiting the cutting mode, critical loads can cause displacement. Tan λ = P *ns π × d2 is the formula for determining the actual angle of inclination of the plane of the turns. The technical characteristics of the connection depend on the values of this parameter.

Determining a specific thread cutting method is done after analyzing the following factors:

Part parameters. The thread parameters, batch size, and steel grade of the workpiece are taken into account. Quality requirements are analyzed: external or internal, pitch, number of passes and tolerance ranges

For steel, the machinability, hardness, chip breaking and physical characteristics of the alloy are taken into account. Selection of tools and equipment. Cutters can be full profile, multi-toothed or V-profile

The machine is manual, semi-automatic or automatic. The machines have individual characteristics regarding the rigidity of fixing the elements, the type of spindle, the method of approaching the workpiece, tool overhang, power, etc. Cutting method. Optimal cutting conditions are calculated taking into account the above factors. The values depend on the quality of the thread, tool life, wear of the working plates, and chip control. The plunge can be one-sided lateral, radial or double-sided lateral. The direction and magnitude of the loads on the workpiece depends on the type.

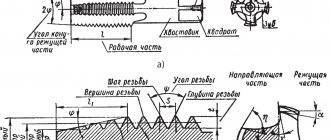

When choosing a tap and die, the rake and back angles, the angle and length of the cutting part, the spiral point angle, pitch, diameter, and chip ejection forces are taken into account. During thread cutting, the depth (t), cutting speed (V) and feed speed (S) must be controlled.

Design and parameters of knurling rollers

Knurling rollers are cylindrical disks made of alloy steel grades, on the surface of which there is a certain type of thread or ring-type turns. The dimensions of the knurling roller depend on the following factors:

- type of rolled thread (single or multi-start);

- rolling method (tangential, axial, radial);

- applied thread rolling equipment (semi-automatic, automatic, head).

The tangential rolling method is highly productive and is performed by feeding two rollers, each of them having its own peripheral speed, at the same speed or in special centers. There are cylindrical and backed knurling rollers. The latter, in addition to intake and calibrating elements, also have a discharging element, which speeds up the cutting process and makes it possible to process 2 workpieces simultaneously or apply it on both sides. The axial rolling method is used when it is necessary to roll threads onto a workpiece of large length. The most common knurling method is radial. In this case, cylindrical rollers are used for rolling external and internal threads. They must comply with the requirements of GOST 9539-72. Most often, products with mounting holes of 45, 54, 63 or 80 mm are used.

The material for the manufacture of rolling tools is steel, which contains chromium, vanadium, molybdenum and other refractory elements: Kh12M, Kh6VF, Kh12F1, 6Kh6V3MFS, R18, R6M5, R18. In this case, the surface hardness should be within 58÷61 HRC. The knurling roller can withstand pressure up to 1400 MPa, while the manufacturing accuracy is 0.1 mm.

The main parameters of the product are as follows:

- diameter of the external thread profile, indicated in mm;

- internal diameter along the depressions;

- profile angle in degrees;

- width;

- groove dimensions - width and depth;

- thread pitch and length.

Machine design

Cutting equipment can be industrial or portable for private workshops and home production. It consists of several main elements:

- Frame made of metal corners, channels. It must be stable so that the cuts are smooth and the machine does not move when the engine is turned on.

- Desktop. It may have clamps for workpieces, a tape measure, and a protractor.

- Electric motor. Transmits rotational force to the cutting disc.

- The drive that supplies the working part of the machine to the workpiece.

The electric motor transmits force to the equipment using gears. There are two types:

- Belt - installed on industrial equipment. Allows you to work with the machine for a long time without interruptions. Produces minimal noise during operation.

- Toothed - installed on compact models of cutting machines. Takes up little space, which is suitable for small workshops.

The equipment is used for cutting various materials. To ensure safe working with it, manufacturers install protective covers on cutting discs, which open the working part shortly before contact with the workpiece.

Device

The electrical part is designed for a regular consumer network of 230 V, 50 Hz. Three-core wire with a grounding terminal. The electric motor has protective double insulation, power up to 1.02 kW. Graphite commutator brushes wear out over time and need periodic replacement with new contacts.

Device

The force is transmitted to the cutting tool through a multi-axis gearbox. For example, the Gerat electric socket has 7 shafts in the gearbox with gears that have undergone microwave hardening. The transmission mechanism is located in a housing made of aluminum alloy; the closed type does not require additional lubrication. It operates stably under heavy loads in forward and reverse modes. The thread-cutting part is inserted into the seat using an external octagon. For internal Ø up to 1 1/4″, it is secured with an all-metal adapter; if the Ø is larger, it is secured with a retaining spring ring.

The body of the clamp is covered with durable fiberglass and silumin.

Description

High power, productivity and rugged construction are just some of the advantages of thread rolling equipment. Using cold rolling under pressure, it produces fine threads. A thread rolling machine works with various metals (steel, alloys, non-ferrous metals) and is common in the field of general mechanical engineering. The machine produces external thread cutting using rotating thread rolling rollers. The material can be deformed under cold rolling, thereby increasing the hardness and strength of the metal being processed.

Typically, each thread rolling machine consists of a power and rolling systems. The power one activates the mechanical drive, which is responsible for synchronizing the shafts, rollers and module for their counter movement. The knurling system consists of a spindle and movable heads located on the same axis. The knurling rollers have a support, and the thread entry on them is located the same.

Very often in industry a hydraulic thread rolling machine is used. It is suitable for processing profiles of round configurations, from which cylindrical, conical, shaped, threaded surfaces, as well as screws, etc. are made by knurling. In particular, a pipe thread rolling machine is used. Knurling, compared to cutting, uses metal economically, the manufacturing process proceeds in a waste-free mode, and the output is a precisely machined part with high performance qualities.

Thread rolling machines with the index “A” are designed for rolling threads on pipes

| JDY-30/JDY-50 |

|

|

|

Cylindrical cutters - their types and purpose

Cylindrical cutters are used to work with complex parts and workpieces. For the manufacture of equipment, such types of steel as alloy, carbon and high-speed steel are used. Equipment is available with straight and inclined (screw) cutting edges. The equipment effectively copes not only with complex and multi-layer surfaces, but also with such types of materials as cast iron, structural and heat-resistant steel, plexiglass, and fiberglass.

Particularly popular are devices that have a screw-shaped cutting part. They are more efficient, but most importantly, they allow you to get the job done efficiently.

To achieve high processing accuracy, it is important for the milling operator to take into account the load experienced by the structure (depending on the type of material being processed)

A cylindrical cutter with straight teeth has found its application in surface processing on workpieces that have direct access.

Finding this type of cutting equipment is quite difficult, since they are not popular and are not produced by all manufacturers.

A cylindrical cutter with helical teeth is used for processing workpiece surfaces with narrow areas or hard-to-reach places.

To reduce the axial load, equipment with different angles of inclination of the working part is used. They are also called double, as their teeth have different angles of inclination. Due to this design of the cutting edges, the load is balanced during the cutting process.

In the group of cylindrical cutters there are attachments, which are also called “corn”. They got their name due to their direct resemblance to vegetables. “Corn” is used for processing ledges, as well as for cutting grooves.

Electrical equipment

The electric pipe threading tool is ergonomic and productive. High quality electrical sockets are manufactured in the USA, China, Germany and our domestic manufacturers. This line of products has earned approval from professional craftsmen, and is distinguished by loyal prices and convenient purchasing options.

At a low level of consumption, these mechanisms demonstrate a high reduction rate. Manufacturers have made every effort to ensure that operations with this type of equipment are comfortable and provide high productivity.

Video

What is a klupp.

Watch this video on YouTube

Electric options are considered a compromise among manual machines and machines for similar work. Although professionals say that craftsmen are required to have both manual and electric units with them, because no one knows what “surprise” may await upon arrival at the site. This could be a lack of electricity, hard-to-reach places on the highway, and much more.

The operating technology of these tools is as follows.

- The main working body is the combs that perform the threading. They are made from high quality tool steel, which guarantees easy cutting on steel pipe materials. When starting the process, you need to secure the head with the cutters into a recess with eight corners on the power drive.

- The pipe is tightened by the holder and sent to the cutting head. At the same time, you should fix the stopper on the clamp.

- The area where the interaction between the dies and the pipe occurs is treated with a cooling lubricant.

- Start the machine using the switch.

- After which the unit is pressed against the finishing product. After completing several revolutions, the head will fit tightly into the material of the product.

- After this, the electrical clamp can operate without any effort on the part of the operator. A person will only need to stop the process at the right time.

Video

Tapered pipe thread cutting. ROTHENBERGER.

Watch this video on YouTube

Such units do not require special care; you only need to periodically change the dull cutters on the working heads.

Location of the main components of the UPW 12.5 thread rolling machine

Location of the main components of the UPW 12.5 x 70 thread rolling machine

- Scale for setting the slide to the diameter of the rolled thread

- Rotary knob for setting the stroke length of the slide

- Nut for fastening the support

- Support

- Self-locking spline nut

- Knurling spindle

- Knife support stand

- Support knife

- Clamping part

- Headstock

- Screws for fastening the headstock

- Mounting screw

- Eccentric for setting the parallelism of spindles

- Nut for fixing the axial position of the spindle

- Clutch for spindle coupling

- Rotary handle for radial movement of spindles

- Screw for setting the stroke length of the slide

- Screw for setting the slide to the diameter of the rolled thread

- General switch Нр3

- Button D4 to turn on the hydraulic and coolant pumps

- Button D3 to turn off the hydraulic and coolant pumps

- Button D6 to turn on the slide feed

- Button D5 to activate the retraction of the slide

- Multi-position switch WS 3 for setting the knurling time

- Multi-position switch WS 2 for automatic cycle setting

- Valve VD 2 for setting the knurling force

- Pressure gauge for checking knurling force

- Pressure gauge shut-off valve

- Push button D2 to turn on the knurling spindle motor

- Push button DI to turn off the spindle motor

- Multi-position switch WS I for setting the direction of rotation of the spindles

- Rotary knob for setting the spindle speed

- Foot button D 7 to turn on the feed of the sled

- Rotary knob Po I for setting the knurling time

- Rotary knob Po 2 for setting the time required to replace a part

- Lever for moving the slide / when adjusting threads /

- Button E5 for turning on the spindle motor / when adjusting threads /

- Button D8 for switching the direction of rotation of the spindles and reducing the knurling force

- Multi-position switch WS 4 for switching off the spindle and slide motor at the same time when the knurling force is reduced

- VW valve 2 for setting the slide feed rate

- Lever for switching the slide from high speed to working feed

- Throttle VDr to slow down the reverse motion of the skid

- Signal light

- Button D10 – emergency

- Counting device

- Sled

- Pointer showing spindle speed

- Generator to the pointer showing the speed of the spindles

- Knurling spindle motor

- Hydraulic pump motor

- Coolant pump

- Lubrication pump

- Chain transmission mechanism, stepless regulation

- Coolant shut-off valve

- Hydraulic tank

- Tank for cooling and lubricating oils

- Plug socket for connecting local machine lighting

- Socket for connecting a device for axial movement of a part

- Star-shaped handle for setting reduced knurling force

Main types

Depending on the design of the thread-cutting dies, the heads can be:

1. With flat radial combs. 2. With flat tangential combs. 3. With round radial combs.

Products with round radial combs are the most popular. This is due to the fact that they:

• have a long service life, as they can be sharpened; • are maximally resistant to aggressive influences; • economical to operate; • make it possible to obtain round combs by grinding.

Heads with round radial combs can be:

1. Non-rotating

. When the heads operate, the part rotates. The head itself moves along its axis. Opening of the heads at the end and closing at the beginning of the process is ensured using a special handle. 2. Rotating

.

Such heads are used on drilling machines, automatic lathes and semi-automatic machines. The head itself provides the working rotation and feed movement. The part, in turn, can rotate in the same direction. This allows the desired reduction in cutting speed to be achieved. Two stops open and close the head. 3. Special non-rotating

. Such heads are used to create threads of small diameter (4-10 mm). Thread-cutting products are installed on automatic lathes. The opening of the heads is ensured automatically, and the closing occurs when the turret is turned using a stop and a curved lever.

When cutting external threads, heads with round combs are usually used. These products differ:

• simple design; • capabilities for working with a large number of regrinds; • greater stability.

The thread is cut with a forced feed of the head. Internal threads are most often cut using threading heads with prismatic dies. The cutting edges of the tool are located on the same diameter and have a lead-in cone. The number of dies in the set depends on the size of the threading head. In the set, the combs are offset relative to each other in accordance with the angle of the helix.

Cutting threads on a pipe using a hand clamp.

When cutting long screws and worms, cutting heads are used. Such threading heads are installed on the machine support. The cutting head structurally consists of a housing that rotates from a separate drive. The incisors (from 1 to 4) are fixed in the body. Their profile matches the thread profile.

Requirements for using the device

A thread-cutting tool is an individual, portable, electric one, so the following requirements must be met:

Secure the clamp with a fixing clamp parallel to the section of the pipe on which the thread is being made. Ensure that the axes of the head coincide with the longitudinal axis of the workpiece

The distance between the clamp and the tool body must be sufficient to cut the specified length. Check the direction of rotation of the die. Apply thread cutting oil to the area, maintaining a sufficient amount at all times to reduce the friction load and heat the cutters. Pay special attention to the entry of the first two turns, then the threading die cuts automatically. The forward speed provided by the Rothenberger electric die is 15 - 20 rpm; in reverse, the head rotates 60 rpm. Considerable force is applied to the cutting edges, so when working with old pipes, you need to hold them with a gas wrench. The standard thread size is obtained by aligning the edge of the pipe with the exit edge of the cutting comb of the head. Before each subsequent operation, the combs should be cleaned of chips and old oil. You need to work with the Rothenberger clamp from a comfortable, stable position

The distance should not exceed that necessary to hold the power tool firmly and stationary.

https://youtube.com/watch?v=rYO7M-3fDp0

The European standard normalizes the duration of engine operation as S2 (short-term duty) with a period, depending on the load, of 15, 30, 45, 55 minutes. Between intervals, the electric motor is given time to cool completely.

Before starting cutting, it is necessary to prepare the end of the pipe for uniform entry of the cutter (flare it, chamfer it). The thread will not be cut correctly if the cut is not made at a right angle.

In difficult conditions, when the thread is located close to the walls (stops), there is a need to update the old thread, it is not possible to clamp the workpiece in a vice. In such a situation, to obtain the effect with a minimum forward stroke, it is possible to change the direction of the combs in the head to the opposite.

Roller thread rolling technologies

Let's start with a description of the equipment. Automatic and semi-automatic machines are used for rolling threads. They have 2 or 3 spindles and are equipped with drives that create the necessary forces to deform the workpieces.

Let us briefly describe the most important characteristics and features of the process.

- Rolling speed. It depends on the type of thread and the strength of the workpiece material. Speed varies from 15 to 90 m/min.

- Knurling force. Selected according to special nomograms or experimentally.

- Functionality. Modern machines are program controlled.

- Automation. To ensure this, the machines are equipped with loading and unloading devices, which we described above.

The most common equipment

Let's look at the machines that have become most widespread.

- SNSH-12. This is a machine from Komand. With its help, high-quality threaded rods are produced using rolling technology. The machine can be operated by one person. There are a large number of programs for obtaining high-precision products.

Photo No. 4: processing of the workpiece on the SNSh-12 machine from Komand

- ARM-40C. The purpose of this machine is to manufacture fittings. It can be used directly on objects. These units are used on construction sites all over the world.

- PROFIROLL. These are universal and high-performance thread rolling machines from a German manufacturer. They are distinguished by a convenient control system, long service life and ease of maintenance.

Photo No. 5: PROFIROLL thread rolling machine

- RH-65B. These thread rolling machines produce reliable, high-quality self-tapping screws. Equipment productivity is over 100 pieces/min.

- Pee-Wee. This is another German brand. The company manufactures high-quality machines designed for rolling threads on solid workpieces. The pressures exerted on the surface vary from 5 to 100 tons.

Photo #6: Pee-Wee thread rolling machine

Selection options

How to choose a thread cutting machine? In addition to the type and method of control, the following factors must be taken into account:

- equipment power. For domestic purposes, machines with a power of 750 – 1000 Watts are optimal. In industrial production, it is recommended to use machines with a power of 2,000 - 2,500 Watts;

- the rotation speed of the spindle through which the thread is applied. The parameter is directly proportional to the power of the equipment and can vary from 27 revolutions per minute to 515 revolutions over the same period of time.

Some models may be additionally equipped with a speed mode selection option, which allows you to select the most optimal rotation speed for a particular material;

- thread cutting range (processing workpieces of different sizes). In most cases, manual equipment is capable of processing workpieces with a diameter of 3–50 mm, and electric machines are intended for pipes with a diameter of 50–200 mm;

- weight. If you plan to use the machine when laying highways, then it is more advisable to select more mobile equipment that is lightweight;

- additional options. A threading kit can include several accessories at the same time: a pipe threading machine, a chamfering tool, a built-in oiler, and so on.

The more functions the equipment can perform, the more functionality and cost it has.

All technical parameters are indicated in the accompanying documentation.

Equipment technical parameters

Line of equipment for the production of self-tapping screws

Self-tapping screws are widely used for fastening certain objects to almost any surface. The cross-section of the thread, which resembles a triangle, allows the self-tapping screw to make holes in any materials, unlike most similar fastening materials.

This type of fastening is manufactured on special machines.

The equipment used to produce self-tapping screws consists of several separate machines that make up the production line. The main ones among them are the following:

- thread rolling machine;

- baths for applying anti-corrosion protection;

- packing machine.

- drying installation;

- hardening furnace;

- cold heading mill;

- drawing mill;

We recommend reading: Sample letter requesting approval of a project

Drawing Mill The first part of such equipment is the drawing mill, which produces thin rods from the metal that is used as raw material.

Types of threading machines

Thread cutting machines are divided into groups:

- manual - light weight, do not require special qualifications of a worker, but are used for cutting threaded connections on pipes with a diameter of no more than 50 cm;

- electric ones are bulky and heavy, of complex design, but reliable and neat in operation; they are common in production. Compact models with low functionality and a weight of 60 kg have been developed; more powerful units weigh under 250 kg;

- in the operation of automatic equipment, the operator is required to correctly set the thread parameters, turn on the machine and monitor the process on a software control device; such machines are used in the continuous production of a large number of pipes.

The following machines are used for cutting:

- thread rolling;

- thread milling;

- thread grinding.

Thread rolling

The principle of operation is plastic deformation of the surface without removing chips. The installed workpiece is rolled between flat or round tools and compressed. Metal under pressure fills the depressions between the strong turns of the working tool, and a thread is created.

Threaded segments, dies, and rollers are used as working tools for rolling. The rolling process is performed on semi-automatic and automatic pipe threading machines; sometimes turret and lathe units are used. They make inch and metric threads with round, triangular, tangential profiles.

Thread milling

The production method is widely used in industry; special machines with comb and disk cutters installed on them are used. Applies the principle of formative promotion. The workpiece rotates slowly (circular feed), and the longitudinally fed cutter moves in concert with it, which makes it possible to cut threads with large pitches over a fairly long area. Strict coordination of simultaneous submissions is required.

Comb cutters (presented in the form of a set of disk cutters) are used for cutting small threads along the entire length at once. The simultaneous formation of turns significantly speeds up the work of cutting internal and external threads in pipes, while the shortest length of the comb tool should be two to three steps longer than the predicted thread.

Thread grinding

Thread grinding is used in the manufacturing process of working tools for thread cutting, thread gauges, knurling rollers, hobs, lead screws for serial and small-scale production. The grinding process occurs using multi-thread and single-thread abrasives. The schemes for producing thread profiles are similar to thread milling, only instead of cutters, profiled grinding wheels are used (single-thread wheels are used as disc wheels, and multi-thread wheels are used as comb wheels).

The profile on the circles is applied in accordance with the profile of the groove of the thread being manufactured. During operation, the abrasive moves in a circular motion, and the workpiece moves longitudinally with a turn per step. The technology makes it possible to obtain high-precision threaded tools with various length and profile parameters.

Grinding of threads with multi-filament abrasives is carried out using longitudinal feed in combination with plunge-cut grinding. The axes of the workpiece and the circle are placed parallel; the method is used for the production of threaded tools with short threads and cutting of ring turns. As a result of multi-thread grinding, a working tool with low accuracy and a pitch of 4 mm or less is obtained. The parallel arrangement of the axes leads to a slight distortion of the thread profile.

How to choose the most suitable model?

The Ridgid thread-cutting machine or the VMC 2a thread-cutting machine are in demand in small and large-scale production. When choosing a specific model, you should pay attention to:

- Type of design: weight, compactness, location of the main elements, degree of protection of moving elements and cutting zones. There is a large selection on the market for the sale of such equipment. For example, you can purchase a vertical REMS version or with a horizontal layout. It all depends on the tasks assigned.

- Type of installed drive. The mechanical drive has been installed for many years because it is easy to use and compact. However, it is worth considering that there are quite a few types of mechanical drive, some are reliable and accurate, others fail quite quickly.

- When considering an electric motor, you should pay attention to what network it is powered from and whether there is protection against overheating. High power in this case will not mean good performance.

- Type of clamping device installed. During processing there is a possibility of quite a large load. To ensure high accuracy of thread cutting and safe operation of the structure, the clamping device must be reliable.

- Availability of supply of cooling and lubricating fluid. When processing carbide material, there is a possibility of significant heating of the cutting tool and the workpiece itself. When such a situation occurs, the tool quickly wears out, and the quality of the material changes.

Threading machine REMS Tornado

- Availability of an automation system. Recently, numerically controlled models have become increasingly popular, as they allow the production of precise parts with high productivity. Moreover, almost the entire process is performed without human intervention, that is, an operator with little experience in threading can operate a threading machine from Ridgid or another manufacturer.

When choosing, they also pay attention to which company is indicated by the manufacturer. For example, Rothenberger is a fairly well-known manufacturer, which determines the high quality of the resulting products. However, the cost of Rothenberger equipment will be significantly higher than products from domestic manufacturers.