When carrying out work on the installation of gas or water mains, it often becomes necessary to change the direction of the line, while the pipeline is cut and then welded at the desired angle. Most often, the direction changes by 90 degrees, and the question arises - how to cut the pipe at 45 degrees in order to accurately connect the joints when welding.

You can cope with the problem of cutting edge angles of 45 or 90 degrees if you have the appropriate knowledge and techniques that will help save not only time, but also materials during the work. At other rotation angles, it is impossible to solve the problem using a ruler and a sheet of paper; you will have to call computer technology for help.

Fig. 1 How to cut a pipe at an angle of 45 degrees

45 degree cutting

Typically, in order to rotate a pipe by 45 degrees, fittings and bends with a rotation angle of 45 degrees are used, made of the same material as the pipes themselves; if the pipes are steel, then the turns are welded from steel. For HDPE pipes, there are electric-welded or cast bends at 45 degrees (note that it is almost impossible to find compression fittings with this angle of rotation in Russia).

But, if you still need to cut a round pipe made of steel or various types of plastics, then for this you will need a pattern for cutting pipes at an angle, the shape of which is calculated manually or by machine. The task is greatly simplified if it is necessary to cut a square metal profile at an angle of forty-five degrees.

For quick cutting, you can use a regular sheet of paper folded diagonally to mark the surface for future cutting. When using folded paper, proceed as follows:

- carry out on a straight surface of the profile in the place where the cut is made, strictly perpendicular to the line;

- apply a sheet of paper folded diagonally to the side surface with the sharp end to the line so that the upper edge of the paper triangle is flush with the top side of the metal profile.

Rice. 2 Homemade template for cutting pipes at 45 degrees

- draw a line with a pencil along the side of the sheet at an angle of 45 degrees, after which the paper corner is applied to the other side and traced with a pencil (it is better to use a thin marker).

For sawing, you can use a grinder with a metal disc, first drawing a thin line along the marking, and then gradually deepening it until the edges are completely separated.

When working with an angle grinder, the following factor must be taken into account: if the edges are completely cut, the disk may be damaged by a sharp corner, which will lead to its failure, and in the absence of protection on the angle grinder, even to injury to the worker. Therefore, it is advisable not to cut the corner edges to the end, but to leave a narrow groove and then break them off, subsequently grinding the protrusion.

Making a template for cutting metal profiles

If you need to cut a large number of pipes, you can make a template from a metal profile of a larger diameter using a paper sheet using the above method. The angle of inclination is checked with a protractor or a construction square - in this case, the two edges of the cut parts of the template are connected.

When working, a template is placed on the part to be cut in the right place and pressed tightly, the markings are applied with a sharply sharpened scriber while tracing the template outline. The part is cut in several passes with a gradual deepening of the groove.

Rice. 3 Cutting a metal profile using a miter box

DIY miter box for cutting pipes

Using a template is not very convenient - you have to make a cut along the line, holding the grinder in weight, which leads to large errors. If you have a welding machine, you can make a simple miter box - guides for the grinder disk, preventing it from moving to the side.

To do this, use a previously made template, drill a hole in the side of which and weld a nut. When working, a homemade miter box is placed on the profile, a bolt is screwed into its nut and the device is pressed against the profile surface. A grinder with a metal disc is used to make a cut, lightly pressing the disc against the side surface of the device. It is clear that with prolonged use, the edges in the miter box are gradually ground down, and although the process occurs simultaneously on all edges, some errors will appear over time. Therefore, it is better to make the device from hard, wear-resistant metal in order to increase its service life and obtain a more accurate instrument.

Where to get sand for sandblasting

My version of sandblasting... or in other words, my personal experience and the use of sandblasting for myself in garage conditions. And so: My compressor is Werk ZBM 60-50

• Power: 2 kW • Receiver: 50 l • Capacity: 300 l/min • Pressure: 10 bar • Weight: 52 kg

I’ll answer the question right away: Is it enough? For small jobs - yes, it’s enough, but if you do it professionally or sand the whole car - the answer is NO! My experience began with this device:

I was not happy with the result... the fact is that there is a tube that captures sand of a very small diameter, so the gun is of no use. Then I bought this device:

For garage use it’s just super, but there are some disadvantages - high consumption of sand and air (which is not at all good for low-performance garage compressors), and you have to carry a bucket of sand with you. But the main thing is that it works, not so fast, but it works and cleans very well. Next I would like to thank one person - Vadyaha! He made this device for himself:

And he gladly agreed to do something similar for me. For which I thank him very much! And here is his work:

Scheme of operation of this device:

After I started using it, I had a couple of ideas for improvements: Well, first, it’s terribly inconvenient to open the taps on the device itself, I moved all the controls, thus making a pistol. And I added an additional air hose directly to the gun... Well, by the way, so as not to tell you too much, here is a diagram:

There are plans to add a pressure gauge and definitely a moisture separator because it’s hard to work without it! Well, a few words to process? Personally, I tried: quartz sand, corundum, soda. Soda is expensive and a big expense. Gentle handling. Corundum is expensive but can be used repeatedly (3-4 times more than quartz sand), plus it processes much faster and causes much less harm to the body than sand. Quartz sand - well, this is the cheapest and most widely used abrasive.

What kind of lamps are they and what is their cost? And what mesh do you sow through?

Probably UFO type lamps, which we have for 100-150 green? I dry it on a potbelly stove without a lid, in a saucepan, stirring slowly so as not to burn): Honestly, it’s a disgusting task!

the exhaust will be from a sealed chamber directly outside into the atmosphere.

tobol added 12/20/2009 at 04:29 pm What does silicosis have to do with it?

Dear raddan. Thank you for the advice. Of course, you can’t ensure 100 percent tightness, but I think the hood plays a major role in this matter, and it will draw all the dust into the atmosphere, that is, onto the street. And through the existing micro-slits, the air flow will flow into the chamber and not into room. Tell me why a filter is needed then if all this crap will fly into the atmosphere?

tobol added 12/20/2009 at 5:13 pm Yes, and I think the camera can be made airtight if desired.

So quit smoking!))). And as for the atmosphere, it’s unlikely that anyone will dispose of all the nasty stuff from the filter, they just throw it into the same atmosphere or pour it on the ground.

tobol added 12/20/2009 at 5:45 pm I agree about the mask. How much does one cost?

So quit smoking!))). And as for the atmosphere, it’s unlikely that anyone will dispose of all the nasty stuff from the filter, they just throw it into the same atmosphere or pour it on the ground.

tobol added 12/20/2009 at 5:45 pm I agree about the mask. How much does one cost? A half mask costs around 2500, but a full mask costs 6000 (I recommend taking a full one; it fits nicer and doesn’t interfere with your view. Spare filters are 800 rubles per set. This is not a cheap thing, but compared to it, our army gas mask is superior in all respects. Well, in terms of In my opinion, the best way to dispose of dust is to bury it.

A half mask costs around 2500, but a full mask costs 6000 (I recommend taking a full one; it fits nicer and doesn’t interfere with your view. Spare filters are 800 rubles per set. This is not a cheap thing, but compared to it, our army gas mask is superior in all respects. Well, in terms of In my opinion, the best way to dispose of dust is to bury it.

90 degree cutting

To cut a round pipeline or metal profile of rectangular cross-section evenly across, use a sheet of plain paper. They wrap the workpiece so that the edges of the paper sheet coincide, after which it is fixed to the part using tape or glue. Using a grinder, a thin line is drawn near the edge of the paper sheet, after which it is gradually deepened until it is completely cut out.

A metal profile or round pipe can be cut using a template by placing an evenly cut element with a large internal diameter on it.

Collar insert

To obtain branches of metal pipeline lines in the form of tees, a collar insert is used, for which it is necessary to cut the edge of a round pipe adjacent to the walls of another at a right angle. To implement the method proceed as follows:

- cut the edges of the workpiece at right angles using the previously described method.

- On the round end surface, a marker marks four equidistant points located at angles of 90 and 180 degrees to each other.

- The size of the circle is measured, the resulting diameter is divided by 3. The resulting distance is plotted from two diametrically located points, after which these points are connected to two others by a smooth arc, drawing a line with a marker.

Fig.5 Example of a collar section of a pipe

- According to the markings, a cut is made with a grinder and semicircular segments are separated, after which the part is ready for welding. If there are minor inaccuracies in the mating, it can be compacted with a sledgehammer, placing it against the round surface of another element.

Laser equipment

Laser cutting of a profile pipe will be one of the highest quality and less labor-intensive compared to mechanical processing options. This is professional equipment that gives an absolutely even cut, which no mechanical tool is capable of. Thanks to laser equipment, you can easily make cuts at an angle of 45 degrees, which is very difficult to achieve when using a cutter or grinder.

Pipe profile cutting to size:

- The maximum thickness of the metal layer is 6.5 mm;

- Maximum part radius – 80 mm;

- The maximum length of the material is 3-3.5 m.

The photo shows a laser machine that automatically cuts metal parts.

Techniques for cutting round pipes at an angle

Round pipes of different diameters are cut at an angle when changing the direction of the pipeline, but it should be taken into account that a straight cut at the desired angle, unlike a rectangular section, will not lead to a tight connection of the edges. Therefore, special patterns are used in which the marked edge has a curved shape, which makes it possible to obtain a high joint density.

Paper pattern for pipe

One of the common ways to make a pattern for pipes with a round surface is a method for which you will need a lined sheet of paper, a ruler and a pencil. To obtain a paper pattern proceed as follows:

- Draw a circle on a piece of paper with the diameter of the pipe being cut, divide the circle into 16 equal segments, each time dividing large segments into two equal ones.

Rice. 6 How to cut a pipe at 45 degrees - paper pattern

- Measure the length of the circle by multiplying its diameter by the number Pi equal to 3.14. Lay this dimension on both sides of the axis of the circle in equal segments, each of which is divided into 8 equal parts.

- Draw vertical lines upward from segments on a straight line and horizontal lines from points placed on the circle.

- The places where they intersect are connected by a smooth line and, as a result, a template is printed on paper, which is cut out and glued to the surface to be trimmed. For trimming, it is better to use a grinder with a disk of small diameter - the surface will be curved and when using a large disk, the error will increase.

Marking a corner with a piece of paper

Marking with a paper sheet is one of the simplest ways to complete the task. A square sheet is required. It folds exactly diagonally. The resulting template for cutting pipes must be wrapped around the product so that the long side runs parallel to its cross-section.

Then an angle of 45 degrees is formed on the smaller side. All that remains is to mark the cutting line using a construction pencil or marker on a sheet of paper.

It is recommended to wrap the marking area with narrow tape to prevent it from being accidentally erased. This method is excellent for long, large pipes with the cut location approximately in the middle of the product.

Tools used

There are several ways to cut a pipe; for this, construction and industrial tools for metal processing are used. Of all the types, only the grinder allows you to obtain curved surfaces without further processing with the closest arrangement of edges.

For individual use

The following tool is used for cutting steel pipes at home:

Manual pipe cutters. Allows you to cut round parts with an even, right angle of cut due to the cutting edges of the rollers. There are several varieties of products of this type, consisting of single rollers or a series of rollers attached to a chain. In everyday life, such devices are quite rare and are more suitable for professional work.

Characteristics of abrasive materials for a sandblasting machine

Bulk substances used as an abrasive for a sandblasting machine must have a certain set of characteristics:

- the hardness of a material shows the resistance of its particles to damage by another, more durable substance (estimated on a 10-point scale, where ten corresponds to the hardness of a diamond);

- geometric dimensions of the abrasive grain (fraction) - the documentation reflects several types of fractions, the percentage of their content (this characteristic directly affects the choice of tool nozzle and air pressure);

- a parameter that determines the number of workpieces (or surface area) processed over a specific period of time is called abrasive ability;

- resistance to mechanical damage;

- resistance to chemical attack;

- Possibility of reuse after use.

How to cut a cast iron pipe

The main difference between cast iron and ordinary steel is its high fragility and large wall thickness; its precise cutting must be performed in the following sequence:

- The marking angle is drawn according to the template using a scriber, for

supports under the part are placed on a wooden board or board.

- Use a grinder to make a shallow cut of the surface around the entire perimeter.

- Next, the groove is deepened in several passes until the two parts are completely separated.

All and a little more about gas tanks for motorboats

A continuous supply of fuel for the movement of a motor boat is provided by the gas tank for the outboard motor, which is an integral part of the fuel system.

They come in different types and configurations, and also vary in volume. This article will tell you more about this and whether it is possible to make a fuel tank with your own hands.

Some tips for cutting pipes

Sometimes households need to cut to connect a pipeline at different angles or along an axis. The main tool for performing these works is a universal grinder and metal discs.

Rice. 9 Pipeline slitting

Making a longitudinal cut

To make a high-quality, even longitudinal cut, you can use a simple device in the form of a metal corner. It is securely fixed to a flat wooden surface with screws and the pipe is pressed against it with a heavy weight. Using an angle grinder, make a longitudinal cut in the pipe top, lightly resting the disc on the surface of the angle.

The corner can be attached to the pipe with clamps and a slot can be made along the upper wall of the corner in a similar way.

Work order

Drilling holes has a general order that does not depend on the type of pipe and looks like this:

- Fixing the pipe at the location of the future hole.

- Marking.

- In the center of the marking, use a core and a hammer to make a notch (mark the drilling point). The notch will prevent the drill from shifting during operation.

When drilling, it is recommended to use a block to fix the position of the drill. Also, during the process, the drill must be vertical to the pipe, otherwise it may break under the influence of lateral loads.

Note! Before making a large-diameter hole on metal products, you must first make a hole with a small cross-section. There are special drill bits that allow you to make a hole with a diameter of up to 100 mm.

Oblique cut

When changing the direction of the pipeline at an angle greater than 90 degrees, manual methods for making templates become too complex. Using a special program for calculating and creating patterns on a computer for any angles can come to the rescue. The good thing about this method is that it has high accuracy in creating paper templates and is easy to implement if you have a printer.

To obtain a paper pattern, the necessary data on bending angles and pipe diameter is entered into the program, after which a template is obtained, which is printed on a printer in full size. All that remains is to cut it out, stick it on the element to be cut and mark its outline.

Further cutting is done using a grinder in the standard way. An important advantage of machine templates is the ability to cut them in unlimited quantities with the same accuracy.

Rice. 10 Example of a calculation program

For high-quality connection of cylindrical pipeline elements, their precise cutting at angles of 45 and 90 degrees is required. To perform these works, special patterns are used, the shape of the bends of which is calculated manually or constructed by computer. They are cut out on paper and glued to the pipe surface, then the element is cut along the paper contour with a grinder with a small disk. Thus, it is possible to obtain a high-precision corner connection with the edges as close as possible.

Application of thermal methods

HOW TO LEARN TO CUT A PROFILE PIPE STRAIGHT!

With the help of such machines, thick-walled metal pipes can be cut. However, it is extremely difficult to obtain a perfectly even, high-quality cut using electric welding or gas autogen.

Cutting technology using electric welding and autogen is widespread everywhere. The technique does not provide high cutting accuracy, but when installing pipes this factor is often not decisive

Typically, after thermal cutting, products undergo additional processing. The cutting line is aligned and the required angle values are adjusted. This approach is economically unprofitable, as it is accompanied by additional costs for mechanical processing.

As a rule, thermal cutting techniques are used in industrial production conditions. True, housing and communal services also often resort to this technique.

Any angle on a profile pipe without a protractor or protractor!

Thermal cutting is also used to work with plastic materials. There are devices - thermal guillotines. The sharp thin blade of such devices is heated to a high temperature, after which the cut is performed.

Thermal guillotines support cutting at an angle, and this is their advantage. However, these devices cannot be used to work with materials that are more rigid than polyvinyl chloride, wood, or chipboards.

To cut metal-plastic pipes, you need pipe cutters that can evenly divide products with a multilayer structure into parts. Our recommended article is devoted to their varieties and methods of application.

Method 3 Use a vice and a hacksaw

This method is suitable for small volumes of work, with small cross-sectional sizes of an iron pipe, angle, steel strip, helical stud, etc.

At a theoretical level, you can manually saw off a metal pin five to seven cm in diameter or a 50 by 50 corner half a centimeter wide. True, this will take more than one hour of time and will require a lot of strength and endurance.

If you don’t have a hacksaw for metal, then from time to time an ordinary ratfil will help, but rather not for cutting, but for cutting metal (for example, a thin rod for the next bending).

Hacksaw machine

This tool consists of a handle, a mobile frame, a cutter and an adjustment screw. Before cutting, the product is secured using a vice and then cut. A mechanical machine for cutting profile pipes is quite convenient to use, but has several disadvantages:

- The cutter may become very hot during operation;

- Mechanical cutting takes a lot of time;

- The edge of the cut pipe will have burrs that will have to be sanded down.

Structure and capabilities of the grinder

An electronic angle grinder is used for grinding, polishing and cleaning surfaces, welds and edges. The technique is effective in cutting various materials and making products from metals, stones, bricks and concrete. The development of artificial diamond technologies has made it possible to transform the grinder into a universal cutting machine. At the moment, the quality of their implementation is regulated by GOST R IEC60745-2-3-2011 and is tested in laboratories.

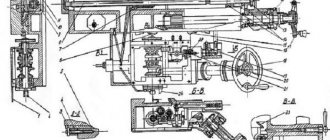

In general, the device in an angle grinder is as follows:

- The rotation of the motor rotor is ensured by an electric motor with a control unit and a current supply cable.

- A gear and a fan are installed on the shaft. The mechanism is engaged with a driven gear mounted on the drive spindle. The latter turns the working tool - a disk or a stone.

According to their design, one- and two-handed grinders are distinguished:

- One-handed tools. There is no main handle, they weigh up to 2.5 kg, the diameter of the circle is 100, 115 and 125 mm.

- Two-handed instruments. There are main and additional handles, the diameter of the circle ranges from 125 to 230 mm, the weight of the machines is 2.5-6 kg.