The importance of calcining materials before performing welding work has been proven by many professionals. The lack of heat treatment affects the quality both during welding and after. Poor ignition and sticking of the rod, shedding of the coating, unreliability and defectiveness of the welded joint, unsatisfactory appearance of the finished product (in the photo on the right: bubbly slag from the wet coating) - and these are just the main problems.

When is drying done?

If the electrodes have been stored in a warehouse for more than 3 months, they must be dried, even if visual inspection does not reveal obvious signs of high humidity. The same applies to electrodes that have been stored for more than five days without sealed packaging. Their technical characteristics deteriorate, creating an uneven arc and improper heating of the metal, which results in a poor-quality weld. Therefore, there are clear storage rules for electrodes, as well as parameters for calcination and drying in a cabinet, oven or pencil case.

Damp electrodes lead to weld defects:

- pores form;

- fistulas may occur;

- cracks form;

- The electrode often sticks.

If the welding seam is of poor quality, or problems arise with the electrode sticking or arc ignition, then first of all it is necessary to dry the electrodes. This will not only give a high-quality seam, but also reduce the consumption of electrodes. It is not always possible to store electrodes in ideal conditions. At large construction sites or enterprises, they are purchased in large quantities and stored for quite a long time. At home, electrodes also deteriorate due to long-term storage in the garage, basement or country house.

Proper storage

To prevent the formation of excess moisture in the electrodes, they should be stored correctly. Factory-made shrink film cannot always protect products, especially during long-term storage.

The first thing you need to remember is the temperature in the room where the rods are located. The warehouse or utility room should not be colder than 15°C. Room temperature will be enough to prevent them from getting damp. Also avoid large temperature changes. This may cause condensation to form inside the packages.

Another important point is the humidity level. It should be minimal. Otherwise, the electrodes will pick up moisture very quickly. Drying may not help and you will have to spend a lot of time calcining.

Take special care to protect the electrodes from mechanical influences. Damage or chipping of the coating impairs welding properties.

Following these simple rules will extend the shelf life of the electrodes. They will retain their qualities, and you will be able to make high-quality and reliable connections.

How is drying done?

The temperature and holding time are different for different electrodes, so before you start drying, carefully study the packaging. Foreign manufacturers do not always indicate drying parameters on their boxes; to find them out, you need to go to the manufacturer’s website, where more detailed technical specifications are posted. Since cellulose electrodes must have the lowest moisture content in the coating during operation, they are packaged in metal cans and it is not recommended to calcinate this type of electrodes. In practice, they can be calcined at a temperature no higher than 70 degrees, otherwise the coating will collapse.

Special devices have been developed for this:

- bake;

- closet;

- pencil case.

In addition, there are “folk” methods - how to dry electrodes without the use of special equipment. It is recommended to carry out calcination and drying no more than 3 times. Practice has shown that with a greater number of calcinations, the coating crumbles and crumbles.

What is Calcination?

calcination

— CARINE, liu, only; linen (yon, ena); Sov., that. Subject to strong heat. Ozhegov's explanatory dictionary.

Interesting materials:

How do babies sit at 6 months? How does sugar affect a child? How to independently determine the gender of your unborn child? How is age calculated for premature babies? How to behave if your child is hysterical? How to form all fours for a child? How to change a child’s surname in Uzbekistan? How to change a child's last name? How to remove a child's lens? How to remove swelling from a bruise in a child?

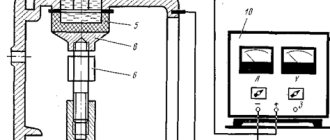

Stationary ovens for drying electrodes

In stationary conditions, an electric heating furnace is used. This is a metal cabinet with special trays for electrodes. To maintain a given temperature, all walls in it are lined with heat-insulating materials. It is equipped with a thermostat for medium temperatures ranging from 60 to 500 degrees in order to carry out drying in strict accordance with the manufacturer’s requirements. This ensures even heating and temperature retention throughout the entire process. Depending on the size and number of trays, the oven can be designed to simultaneously load batches weighing from 10 to 250 kg.

The drying process is very simple - the electrodes are placed inside the oven for the required time. The heating temperature is regulated and maintained automatically. New models have a timer that will turn off the oven after a strictly specified time. Due to thermal insulation, the cooling process occurs evenly. After this, the electrodes are ready for use.

Ready-made models

- Electric furnace for calcining electrodes EPSE 40 400. Manufactured in Russia by the thermal equipment plant Novel CJSC. It has an automation system that can maintain temperatures of 100 – 400 degrees Celsius. The maximum number of loaded electrodes is 40 kilograms. Power is supplied from a 220 volt network. Its cost is 10,000 rubles.

- Oven for electrode drying Russian PSPE 20-400 051-9015-1. It is a portable pencil-type stove. Its power is 1.4 kW, maximum operating temperature is 400 degrees Celsius. Power supply is supplied from a 220 volt network. The price of this model is 6600 rubles.

- Thermal pencil case PE-6/150 Russian 051-9047. This portable tank for storing and heating electrodes is powered by a welding transformer with a voltage of 36 - 50 volts. Its price is 2430 rubles.

- Electric furnace BAMZ EPSE-10/400 7370007. This is a portable pen-type device with a power of 1 kW. The maximum operating temperature is 400 degrees Celsius, it operates from a conventional electrical network of 220 volts. Cost – 4450 rubles.

- Electric oven with electronic display BAMZ PSPE-160/400. Powerful industrial installation of 8.4 kW. Operates on 380 volts. The operating temperature range is from 100 to 400 degrees Celsius. It is capable of processing up to 160 kilograms of electrode raw materials. The cost of this model is 75,400 rubles.

Cases thermoses and thermal cases

It often happens that welding work is carried out outdoors or in conditions of high humidity, so the electrodes can quickly become damp and become unusable again. Pencil cases are specially designed for such cases. They are sealed and thermally insulated, allowing the electrodes to remain dry for a long time. According to their design, thermos and thermal pencil cases are distinguished.

Thermos cases are small in size and have a heat-insulating inner coating. They are especially convenient for storing already dried electrodes at construction sites in any weather and time. The electrode drying case is equipped with heating elements, a thermostat and allows drying right on the spot. It is small in size and can dry about 10 kilograms of electrodes at a time. Thermal canisters have two types of connection - to a socket and to a welding transformer.

Drying equipment makes it possible to obtain different temperature conditions and precise time control, allowing you to calcinate electrodes of various brands and manufacturers. It restores the working properties of the electrodes, speeds up the work of the welder and saves money on the purchase of new electrodes. Drying the electrodes is much faster and easier than redoing a poor-quality weld later.

Bottom line

Proper preparation for welding is the key to its reliable and high-quality work. This also applies to electrodes that need to be dried and calcined, especially when welding critical metal structures or obtaining sealed seams.

At the same time, do not forget how many times you can heat treat them, because it is not recommended to anneal the electrodes more than twice. This is due to the fact that the electrode coating may deteriorate and the rods will become unusable.

Sources

- https://met-lit.ru/raboty-s-metallami/prokalivanie-elektrodov.html

- https://art-stal.ru/instrumenty/prokalka-svarochnyh-elektrodov.html

- https://instanko.ru/osnastka/sushilka-dlya-elektrodov.html

- https://spark-welding.ru/instrumenty-i-oborudovanie/kak-prokalit-svarochnye-elektrody.html

- https://titan-spec.ru/stanki-i-instrumenty/prokalivanie-elektrodov.html

- https://rezkamet.ru/prokalka-elektrodov-v-domashnih-usloviyah/

- https://cs-important.ru/tehnika/kak-prokalit-elektrody-v-domashnih-usloviyah-kak-sushit-v-duhovke-fenom-svoimi-rukami.html

- https://ometalledo.ru/prokalivanie-elektrodov-pered-svarkoj.html

- https://uniform-met.ru/articles/layfkhak-dlya-svarshchika-kak-prosushit-elektrody-v-domashnikh-usloviyakh/

- https://magelectrod.ru/article/prokalka-elektrodov-zachem-ona-nuzhna/

How to dry electrodes at home

The main purpose of calcination is to reduce the percentage of moisture in the coating of welding electrodes, while the structure does not change in any way. To dry the electrodes you do not need any special skills or knowledge. Just look at the packaging for the temperature and time of the process. On average, it is recommended to carry out the procedure at a temperature of 220 - 250 degrees for 1.5 - 2 hours.

To do this, you can use any heating device that you have at home. An electric oven or gas oven is perfect. An electric oven is more suitable for drying than a gas oven, since the gas contains a certain amount of water and in no case should it be heated over an open fire. The quality of this method cannot be compared with the result using a professional cabinet or pencil case.

In this situation, the worst decision would be not to calcinate the electrodes at all. This will lead to increased consumption of materials, poor-quality seams, and loss of time, and in the worst case scenario, redoing the entire job.

Features of the process implementation

All the secrets of preparing electrodes for welding lie in the correct calcination procedure. Typically the process is carried out in several stages:

- Consumables are placed inside the device or for special occasions. The machine or oven closes.

- The temperature rises. Usually the characteristic is written directly on the packaging, set by the manufacturer;

- Turn on the oven and wait for the desired interval. The consumable material must cool down, after which it can be removed for direct use.

The procedure obliges the specialist to comply with safety requirements. Actions must be performed in a special uniform and using other personal protective equipment.

Exploitation

The instructions for proper operation of the equipment recommend taking out the electrodes while hot after calcination is completed and placing them inside the thermal case. Inside the chamber they will be inaccessible to moisture. They can be moved long distances and stored for a long time.

Before drying the welding electrodes, the device is installed on a special leg. Select the method of connecting to power. The plug is plugged into a power outlet. The two wires are connected to the cables going to the holder and clamp on the part.

The thermal pen is turned on in advance so that the camera has time to warm up. After about 30 minutes, you can open the front cover, take the electrode and start working. The pencil case should be kept closed to dry remaining materials.

Manufacturers

The market for steel-making electric arc equipment is flooded with offers of counterfeit, homemade models at low prices. Therefore, when planning a purchase, find the website of manufacturers of similar equipment on the Internet and order stoves directly or through official dealers. By purchasing units from an unverified seller, you risk purchasing a low-quality and short-lived design, albeit for little money.

Here is a short list of companies producing electric arc furnaces:

- The group produces steel-smelting units of various designs and capacities for laboratory research and the metallurgical industry. High temperature furnaces can melt in a vacuum or at atmospheric pressure. In all cases, careful monitoring of the air condition in the chamber with the melt is carried out. The technique is used not only in the steelmaking industry, it works successfully in growing single crystals and for producing optical fiber.

- The Russian company produces electric steel-melting furnaces for industrial installations under the “DPPT” and “ESHP” labels. DPPT models are one of the most powerful industrial steel-smelting electric arc furnaces. They contain the entire supply of designers and operators when developing a project for melting devices operating on alternating electric current. Powerful DC converters work for servicing stoves, chipboard models.

- Arc steel furnace from Taiwan is a popular brand of manufacturers on the Russian market. Thyristor electric melting furnaces work not only with metals. The simplicity and reliability of the design allows the devices to be manufactured in 2 versions. They can be supplied with a hydraulic or gear version. Perfectly suited for small and medium-sized steelmaking enterprises with a 3-level productivity of over 2000 tons per year.

- Since 1989, a scientific and technical company has been successfully operating on the Russian market, specializing in the production of thermal industrial equipment. Scientific methods used in the development and design of furnaces allow the company to compete with foreign manufacturers, especially in terms of price and product quality. AC and DC arc furnaces can be used to produce aluminum alloys and other metals.

- Chinese furnaces provide fast melting at a reduced cost of operating the unit. Minimum dimensions with a large loading volume, excellent heat dissipation characteristics and a minimal level of environmental pollution when fully loaded and melting the charge - this is not a complete list of the advantages of this technology. Models “KGPS 200kW” are used for the production of stainless steel, cast iron, all types of alloy, heat-resistant and structural steels. Can be used to obtain non-ferrous and precious metals.

There is no point in indicating prices; they change very quickly. Therefore, we advise you to contact the manufacturers directly and find out the cost of the equipment you are interested in.

Heat or dry - what's the difference?

The calcination and drying procedures are similar in almost all respects. However, there are slight differences. Calcination is carried out strictly according to the instructions presented on the packaging (as in the photo above). The main purpose of drying is to remove moisture

Therefore, for this procedure it is not so important to carefully and seriously follow the recommendations

Therefore, in some cases, you can use “folk” remedies for heat treatment. But for this you need to have information on how to dry electrodes at home. Information should be obtained from reliable sources and rely only on expert opinion. Below are basic explanations on how to dry electrodes at home.

Calcination of welding rods

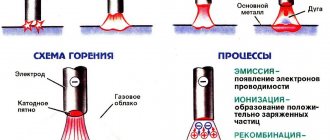

The drying process (calcination) is a treatment using a temperature that removes moisture from surfaces. Excessive presence of water in electrode deposits causes them to fall off the rod.

It is impossible to work with such an electrode, it is difficult to ignite, and the quality of work leaves much to be desired.

You will have to buy a new package, which is not cheap. Before welding, it is recommended to check the electrodes and, if necessary, prepare them. Novice welders are interested in: why use drying and liming when preparing?

There are several situations in which drying is necessary:

- Chopsticks haven't been vacuum packed in a long time.

- The storage location is characterized by high humidity.

- The electrodes are wet.

Remember! Drying welding rods before welding is an important process that, if not done, will affect the outcome of your job.

At the same time, remember that such work cannot be done more than twice, otherwise the spraying of the rod will completely fall apart.

An interesting fact is that annealing welding rods increases the thermal conditions of material consumption before work. Some raw materials, due to large temperature differences, distort the solder bath, which makes the solder weak.

To avoid defects, resort to pre-drying.

Calcination units

Drying welding rods at home is possible using special tools.

Recommended use:

- Electric oven with temperature controller. The device is small in size and can be easily transported from one place to another. The operation is based on heating elements, which are controlled automatically using regulators. Such a stove operates on a standard ten-twenty-volt network. The power of this type of mechanism varies from one to three kilowatts. The maximum load is fifty kilograms.

- Electric oven with dehumidifying function. Modern models have a built-in microprocessor with which you can configure the entire operation. Thermal insulation is a feature of this unit. Uniform heating of welding rods is achieved through the use of built-in heat shields. A regular network is not suitable; for such equipment it is necessary to have three phases of 380 W each. Maximum power 8.5 kW and capacity up to 160 kg.

- Thermal pen case. The so-called “dryer” for welding rods. Thermally insulated, sealed design that can be used as a storage container. The device is of optimal size, which allows welders to be stored at the workplace. The main skill of this technique is the ability to heat welding rods from a transformer or from a regular 220 network. The capacity of such boxes is 10 kg of rods.

Principle of dehydration

For different types of electrodes, it is necessary to correctly determine the temperature and drying time. To do this, before starting annealing, read the instructions on the packaging to correctly determine the drying parameters.

Please note that foreign manufacturers often do not provide the requested information. Therefore, we recommend that you visit their website, where you will definitely find the parameters you are interested in

Remember! Cellulose welding rods are not annealed. In addition, they must contain a minimum of water in the spray; for this they are sold in steel cans. Experience shows that such electrodes can be calcined as long as the temperature does not exceed 70 degrees, otherwise the coating will be damaged.

Do-it-yourself drying

As mentioned, the main purpose of calcination is to reduce the amount of moisture introduced when the metal rod is sprayed. The process is simple and does not require time.